5

en

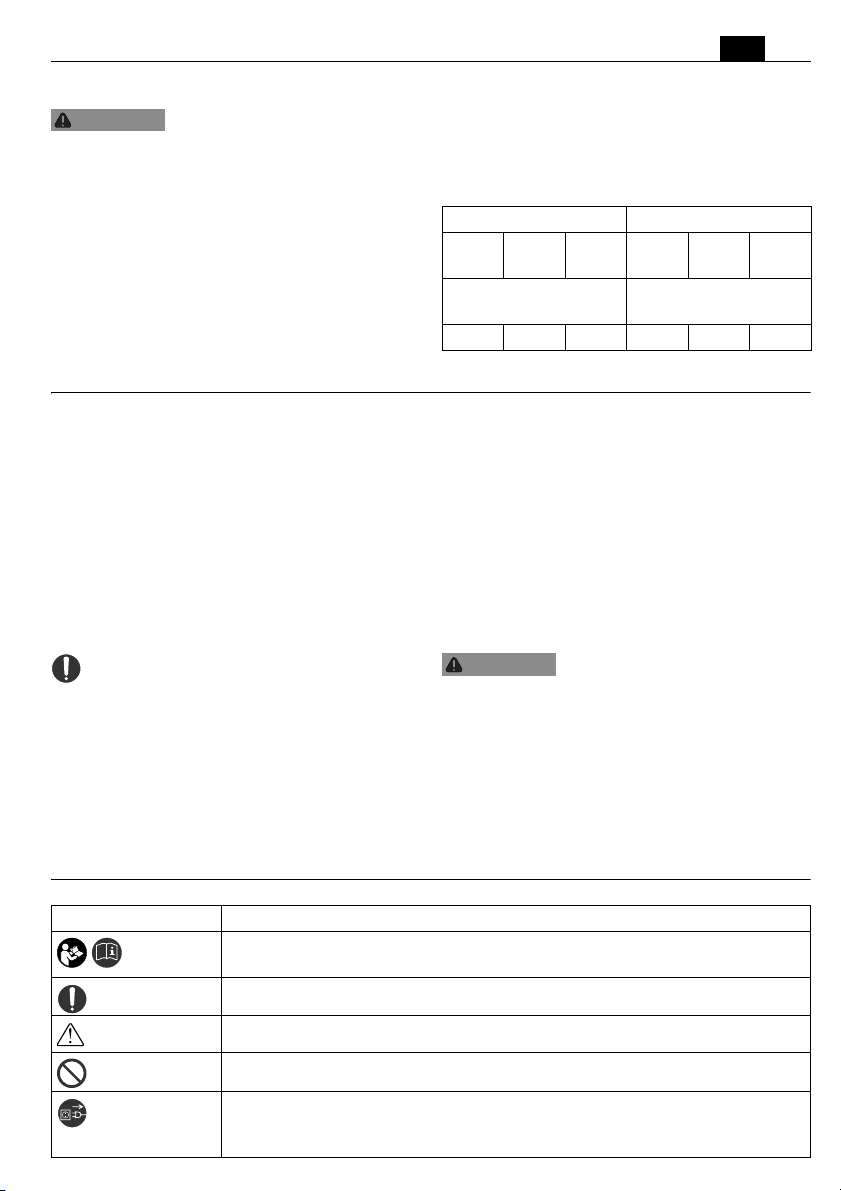

Safety instructions.

Bevel milling tool Safety Warnings

Hold power tool by insulated gripping sur-

faces only, because the cutting tool could cut

into the machine's power cord. Contact with

a “live” wire make exposed metal parts of

tool “live” and shock the operator.

Use clamps or another practical way to

secure and support the workpiece on a stable

platform. Holding the work by hand or

against your body leaves it unstable and may

lead to loss of control.

Special safety instructions.

Do not use accessories which are not specifi-

cally designed and recommended by the tool

manufacturer. Just because the accessory can

be attached to your power tool, it does not

assure safe operation.

Do not use a damaged accessory. Before each

use, check the indexable inserts for chipping

and cracks, wear or heavy use. If the machine

or application tool is dropped, inspect for

damage or install an undamaged application

tool.

Wear personal protective equipment. Depend-

ing on application, use a face shield, safety

goggles or safety glasses. As appropriate,

wear dust mask, hearing protectors, gloves

and workshop apron capable of stopping

small abrasive or work piece fragments. The

eye protection must be capable of stopping

flying debris generated by various operations.

The dust mask or respirator must be capable

of filtrating particles generated by your oper-

ation. Prolonged exposure to high intensity

noise may cause hearing loss.

Keep bystanders a safe distance away from

work area. Anyone entering the work area

must wear personal protective equipment.

Fragments of workpiece or of a broken acces-

sory may fly away and cause injury beyond

immediate area of operation.

Always hold the power tool firmly when start-

ing it. The reaction torque of the motor, as it

accelerates to full speed, can cause the power

tool to twist.

If possible, use clamps to fasten or affix the

workpiece. Never hold a workpiece in one

hand and the power tool in the other hand

while in use. Clamping workpieces allows

you to use both hands for better control the

power tool.

Never lay the power tool down until the acces-

sory has come to a complete stop. The spin-

ning accessory may grab the surface and pull

the power tool out of your control.

Do not run the power tool while carrying it at

your side. Accidental contact with the spin-

ning accessory could snag your clothing, pull-

ing the accessory into your body.

Regularly clean the power tool’s air vents.

The motor’s fan will draw the dust inside the

housing and excessive accumulation of pow-

dered metal may cause electrical hazards.

Do not operate the power tool near flammable

materials. Sparks could ignite these materials.

Do not use accessories that require liquid

coolants. Using water or other liquid coolants

may result in electrocution or shock.

Secure the work piece firmly. A work piece

that is gripped tightly in a clamping device or

vice, is more secure than if held by hand.

Before putting into operation, check the

power connection and the power plug for

damage.

Recommendation: The tool should always be

supplied with power via a ground fault circuit

interrupter (GFCI) with a rated current of

30 mA or less.

Kickback and related warnings

Kickback is the sudden reaction to a pinched

or snagged rotating application tool. Pinching

or snagging causes the rotating application

tool to rapidly stop. This can cause a power

tool to be forced in the opposite direction to

the rotating application tool at the point of

binding.

For example, if the indexable insert is snagged

or pinched in the workpiece, the edge of the

indexable insert entering into the workpiece

can get caught, causing the indexable insert to

break out or cause kickback. The indexable-

insert holder may either jump toward or