Table of contents

3

Table of contents

Package contents.............................................................................................2

General information ....................................................................................... 4

Reading and storing the user manual ..................................................................4

Proper use..................................................................................................................4

Residual risks.............................................................................................................5

Explanation of symbols .................................................................................. 5

Safety............................................................................................................... 6

Explanation of notes ................................................................................................6

General power tool safety instructions .................................................................6

Safety instructions for reciprocating saws ...........................................................9

Supplementary safety instructions ..................................................................... 10

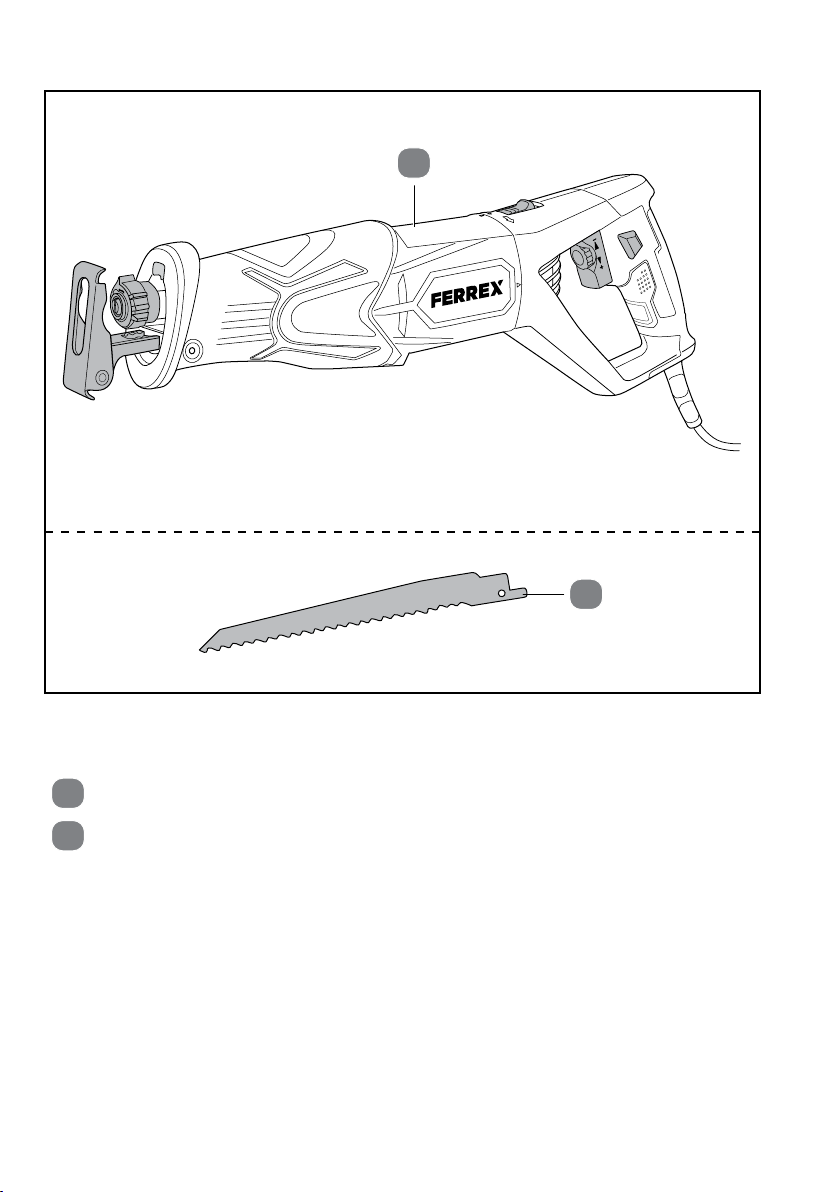

Product description .......................................................................................13

First use ..........................................................................................................14

Checking the product and package contents.................................................... 14

Use ..................................................................................................................14

Inserting/changing the saw blade...................................................................... 15

Adjusting the saw shoe.......................................................................................... 15

Adjusting the saw alignment.................................................................................17

Adjusting the stroke rate limit ...............................................................................17

Connecting............................................................................................................... 18

Sawing...................................................................................................................... 18

LED work light...........................................................................................................21

Troubleshooting ............................................................................................21

Cleaning and maintenance ...........................................................................22

Cleaning ...................................................................................................................23

Inspecting the product ..........................................................................................23

Maintenance ............................................................................................................23

Storage .....................................................................................................................23

Transport..................................................................................................................24

Technical data ............................................................................................... 24

Noise/vibration information ........................................................................ 24

Disposal ......................................................................................................... 26

Disposing of the packaging ..................................................................................26

Disposing of the product .......................................................................................26

Declaration of Conformity .............................................................................27