Revision (10-04) 8 Alemite Corporation

SER 3640 Electronic Preset Metered Control Valve

Recalibration

It may become necessary to recalibrate the meter.

Variables that cause a meter to require recalibration are:

• fluid viscosity

• fluid temperature

• flow rate

NOTE: The original scale factor is recorded

by the factory on the back of the lever. See

Figure 2-B.

Scale Factor Calculation

IMPORTANT: Dispense the fluid at the nor-

mal flow rate in the Manual mode of opera-

tion.

1. Dispense any amount of fluid greater than 1 gallon

(3.8 liters) into an appropriate-sized graduated beaker.

2. Record the amount dispensed and the value displayed

on the meter.

3. Insert a blunt tool (5/32 "allen wrench) into the access

hole in the back of the meter.

•See

Figure 4.

4. Press and hold the tool for 2 seconds.

• The screen begins to flash and then displays the

current scale factor and unit of measure.

• The current unit of measure flashes.

5. Record the current scale factor.

6. Divide the value of the amount dispensed by the value

displayed on the meter. Multiply this product by the

existing scale factor. The product is the new scale

factor.

EXAMPLE: Exactly 4 quarts were dis-

pensed into the beaker and the meter regis-

tered 4.16 quarts. If the existing scale factor

is 0.957, a new scale factor of 0.920 must be

entered.

(4 ÷ 4.16) x 0.957 = 0.920

Change the Scale Factor

7. Press the RESET button.

• The first digit of the scale factor flashes.

8. Press the TOTAL button until the required value

appears.

NOTE: The first digit can be set to 0 or 1.

All remaining digits to the right of the deci-

mal point (comma) have a full range from

0 to 9.

9. Press the RESET button.

• The next digit of the scale factor flashes.

10. Repeat steps 8 and 9 for all digits.

11. Once the last digit is set, press the RESET button.

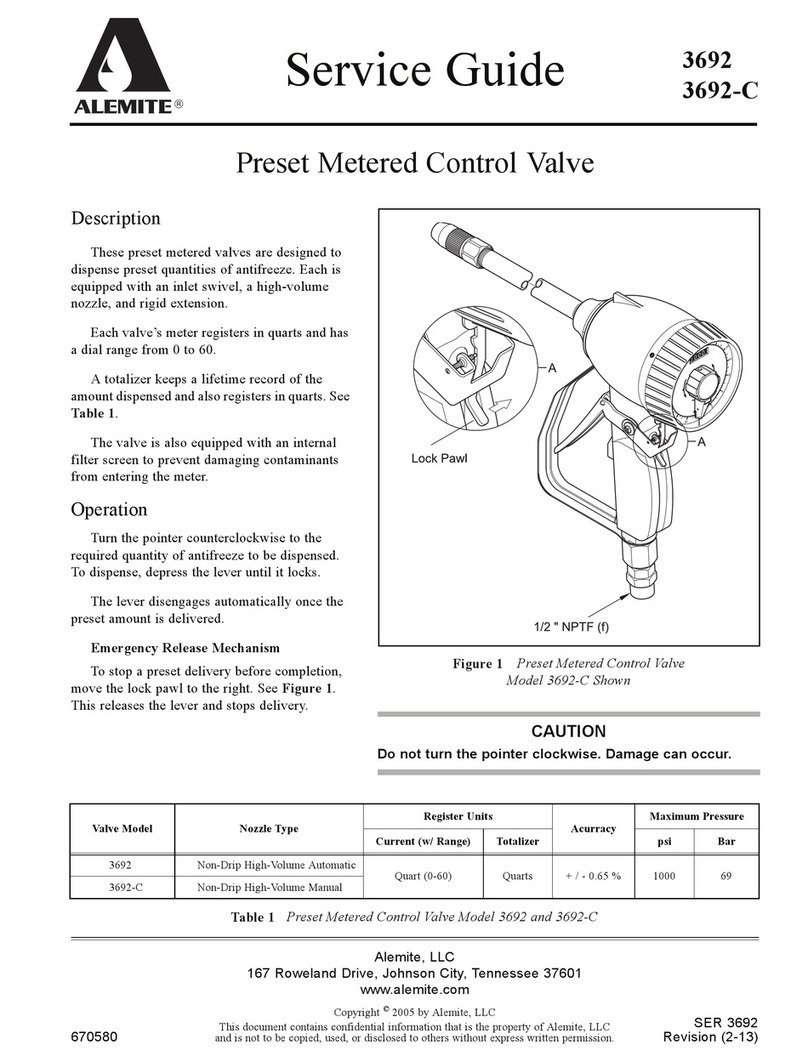

• The pulse delay factor (PS) screen appears.

• See Figure 6.

IMPORTANT: The pulse delay factor should

always be set to zero. No pulse delay is

required on these control valve models.

12. Insert the tool into the access hole in the back of the

meter once again.

13. Press and hold the tool.

• The screen flashes three (3) times and then goes

blank.

14. Press the RESET button.

• The normal delivery screen appears.

Figure 6 Pulse Delay Factor Screen