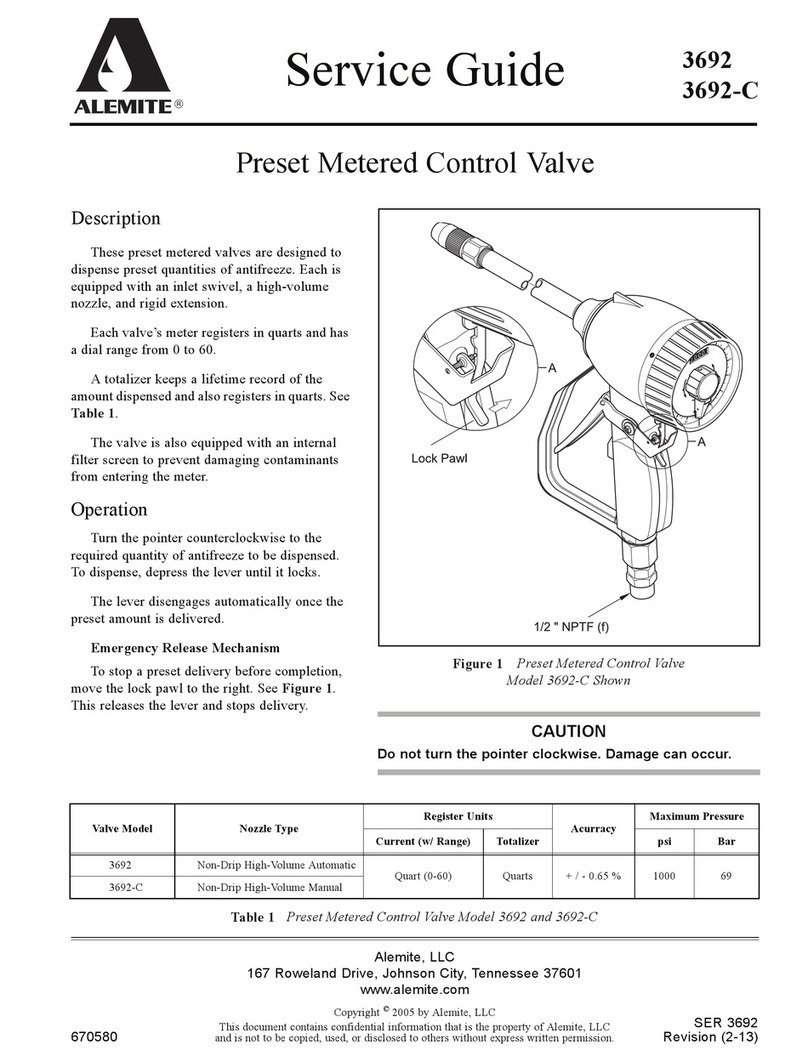

High-Pressure Measuring Control Valve

SER 7716-D1

Alemite Corporation 3 Revision (11-95)

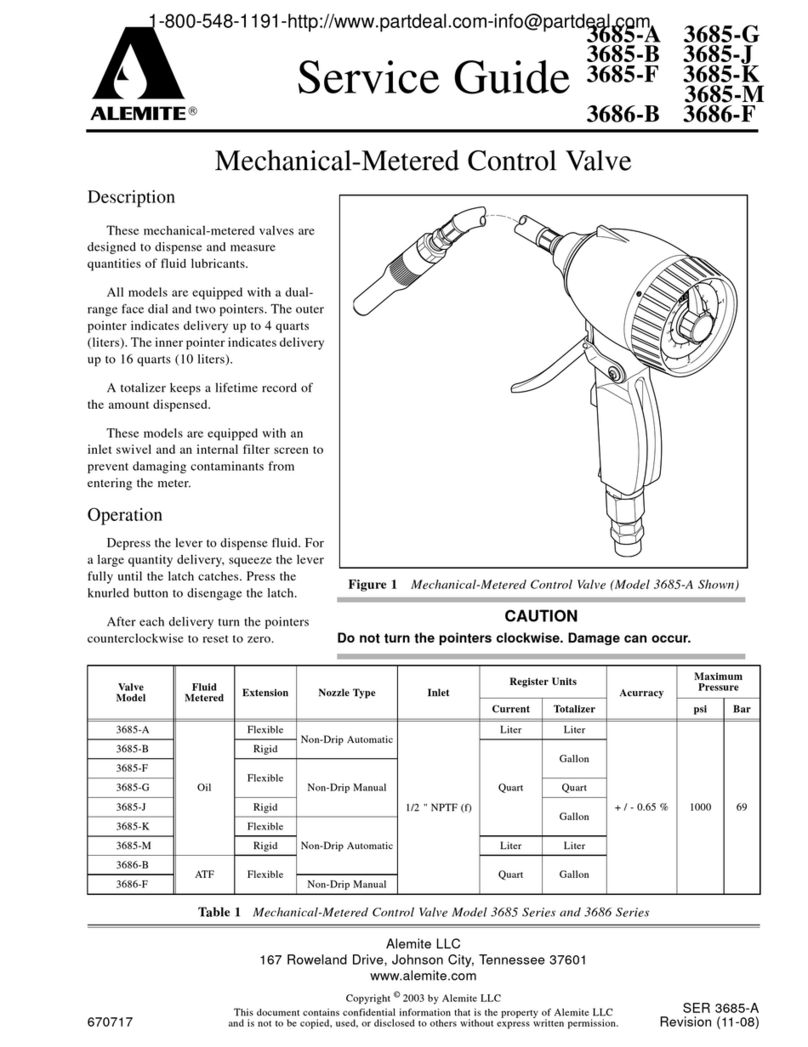

Item

No. Part No. Description Qty Notes Numeric Order

Part # (Item #)

1Plug, 1-5/16 " -20 16304-B (41)

2171001-20 O-Ring, 1-5/16 " OD x 1-1/16 " ID 245569 (36)

3171009-9 O-Ring, 1-1/16 " OD x 15/16 " ID 249136 (40)

4337044 Packing, V-Block, 1.20 " OD 2

53952

(9)

5338971 Ring, Split, Backup (Teflon) 2

76839

(25)

6326355 Piston, Measuring 1

77795

(20)

7328499 Body, Valve 1

77863

(26)

8319211 Screw, Packing, 1-5/16 " -20 x 13/16 " -20 1131132 (32)

9V-Packing 1131133 (33)

10 Nut, 13/16 " -20 1

131135

(34)

11 328224 Plug, 1/4 " -28 1

131137

(31)

12 305413 Screw, Adjusting, 1/2 " -20 1170779 (19)

13 Seal, 3/4 " OD x 3/8 " ID 2171001-20 (2)

14 Washer, 0.372 " (Brass) 2171009-9 (3)

15 Retainer, 15/16 " -20 x 7/8 " -20 1171013-17 (27)

16 302678 Washer, 0.265 " 1

172190-32

(13)

17 305784 Spring, 2 " Long 1302678 (16)

18 Cap, 15/16 " -20 x 1/4 " -20 1

305412

(10)

19 170779 Setscrew, Hexagon Head Socket, 1/4 “ -20 x 5/8 " 1305413 (12)

20 Nut, 1/4 " -20 1

305414

(37)

21 Gasket, Valve Seat 1305415 (24)

22 305780 Valve and Seat Assembly, Slide 1

305416

(38)

23 305426 Guide, Valve 1

305418

(35)

24 305415 Lever 1

305419

(21)

25 Washer, Lock, 6 2305426 (23)

26 Screw, 6 -32 x 3/8 " 2

305431

(30)

27 171013-17 O-Ring, 1.00 " OD x 13/16 " ID 1

305432

(29)

28 Handle, Inlet 1305780 (22)

29 Bushing, 13/16 " -20 1305783 (39)

30 Gasket (Aluminum) 1305784 (17)

31 Stud, 8 -32 1

305785

(18)

32 131132 Strainer, 1.00 " Long (Compressed) 1

305786

(15)

33 131133 Washer, Retaining, 0.172 " 1

310107

(14)

34 Nut, Knurled 8 -32 1319211 (8)

35 Screw, Packing, 7/8 " -20 1

319212

(1)

36 45569 Nut, 10 -32 1326355 (6)

37 Setscrew, 10 -32 x 1.00 " 1328224 (11)

38 Pin, 1-15/16 " Long 1

328498

(28)

39 305783 Stem, Valve Actuation 1328499 (7)

40 49136 Extension, Rigid 1337044 (4)

41 6304-B Coupler, Hydraulic 1338971 (5)

Optional Equipment

1a 6778 Extension, Rigid/Flexible

Legend

:

Part numbers left blank (or in

italics

) are not available separately

designates a repair kit item

Repair Kits

Part No. Kit Symbol Description

398971-2

Kit, Major Repair

393530-32

Kit, Minor Repair [includes five (5) of item number

13

]