Visit our website at www.alemlube.com.au or www.alemlube.co.nz

NSW/ACT

TEL: (02) 9677 1555

FAX: (02) 9675 1155

QLD/PNG

TEL: (07) 3204 9166

FAX: (07) 3204 1224

VIC/TAS

TEL: (03) 8787 8288

FAX: (03) 8787 8266

WA

TEL: (08) 9302 4199

FAX: (08) 9303 2095

SA/NT

TEL: (08) 8241 7111

FAX: (08) 8241 7011

NZ

TEL: (09) 447 1007

FAX: (09) 447 1008

2

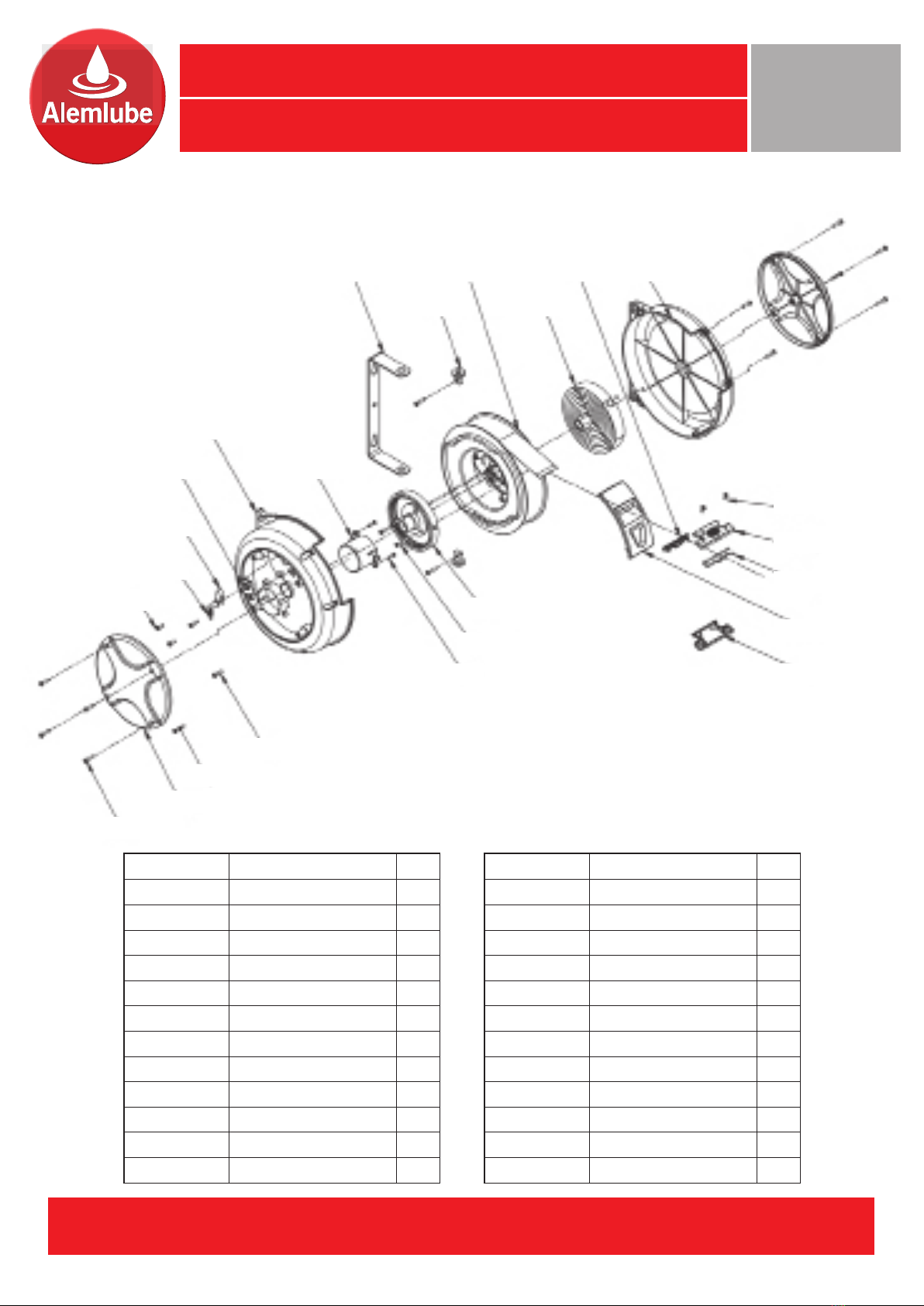

Danger Safety Barrier Reel

OWNER’S TECHNICAL MANUAL

BR50010D

GENERAL SAFETY REGULATIONS

WARNING: The warnings, cautions, and instructions discussed in this instruction manual cannot

cover all possible conditions or situations that could occur. It must be understood by the operator

that common sense and caution are factors that cannot be built into this product, but must

be supplied by the operator.

1. Keep the work area clean and dry. Damp or wet work areas can result in injury.

2. Keep children away from work area. Do not allow children to handle this product.

3. Use the right tool for the job. Do not attempt to force small equipment to do the work of larger industrial

equipment. There are certain applications for which this equipment was designed. It will do the job better

and more safely at the capacity for which it was intended. Do not modify this equipment, and do not use this

equipment for a purpose for which it Was not intended.

4. Check for damaged parts. Before using this product, carefully check that it will operate properly and perform

its intended function. Check for damaged parts and any other conditions that may aect the operation of this

product. Replace damaged or worn parts immediately.

5. Do not overreach. Keep proper footing and balance at all times to prevent tripping, falling, back injury, etc.

6. Do not use the equipment when tired or under the inuence of drugs, alcohol, or medication.

A moment of inattention while operating this equipment may result in serious personal injury.

7. Use proper goggles when assembling and using the warning tape reel.

8. Personal injury and/or equipment damage may result if proper safety precautions are not observed.

9. Make sure the spring force is fully released before maintenance.

10. Don’t jerk the warning tape.

INSTALLATION

Unpack and inspect reel for damage. Turn by hand to check for smooth operation.

Check for completeness.

1. It can be installed on the optional column: The height of the column is 1.2m,

the base and the ground need to be connected with appropriate bolts,

and ensure that they are rmly tightened

2. You will need to purchase appropriate hardware for mounting your new reel.

3. The reel base has three 8.5mm drilled holes for mounting on a suitable

at surface.

4. Using the three holes in the base, mount the reel in the desired location.

Be sure to use appropriate hardware and tighten securely.

5. Double adjustment function, see below the picture. Adjust the latch spring

to left position, could lock the warning tape at any desired length.

Adjust the latch spring to opposite position, have non-lock function,

then warning tape can be freely moved.