2

K-Line™ G-Set™ irrigation

G-Set is a solid set fixed system that minimises “labour” for

the day to day operation of irrigation.

It is suitable for all land areas, and is not restricted by the

shape, terrain, size or topography.

Due to this flexibility, there are numerous configurations

of valves, pressure regulation and sprinkler selection to

accommodate the various design requirements.

These installation instructions apply to all of these options.

RX Plastics has developed two “control” options to operate

the system.

The first is a wireless radio mesh system (IPC) of control

which allows the operator to communicate with the units

remotely from any point from which a single unit is visible.

With this system we do not require direct line of sight to

all of the units.

The second is an individual, battery operated control

(C1013). These units need to be synchronised and

programmed prior to installation and any future adjustment

must be done individually or on a group basis.

This installation manual is a guide to the best practice of

installing G-Set. Failure to follow these instructions can

lead to instability and poor performance.

G-Set installation 3

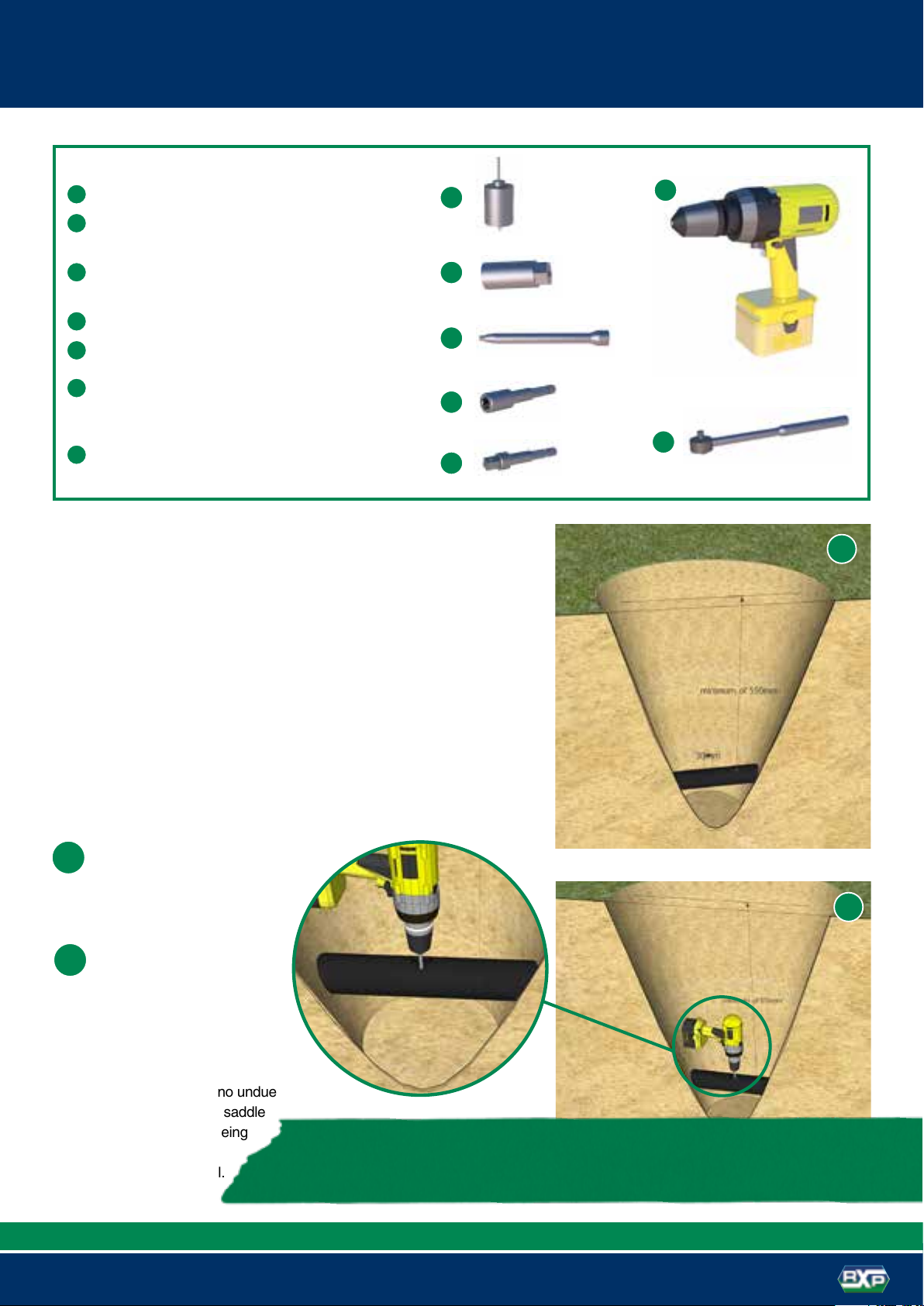

Pipe exposure and saddle installation.

Standard G-Set installation 4

Side Entry G-Set installation 5

Completing the G-Set installation 6

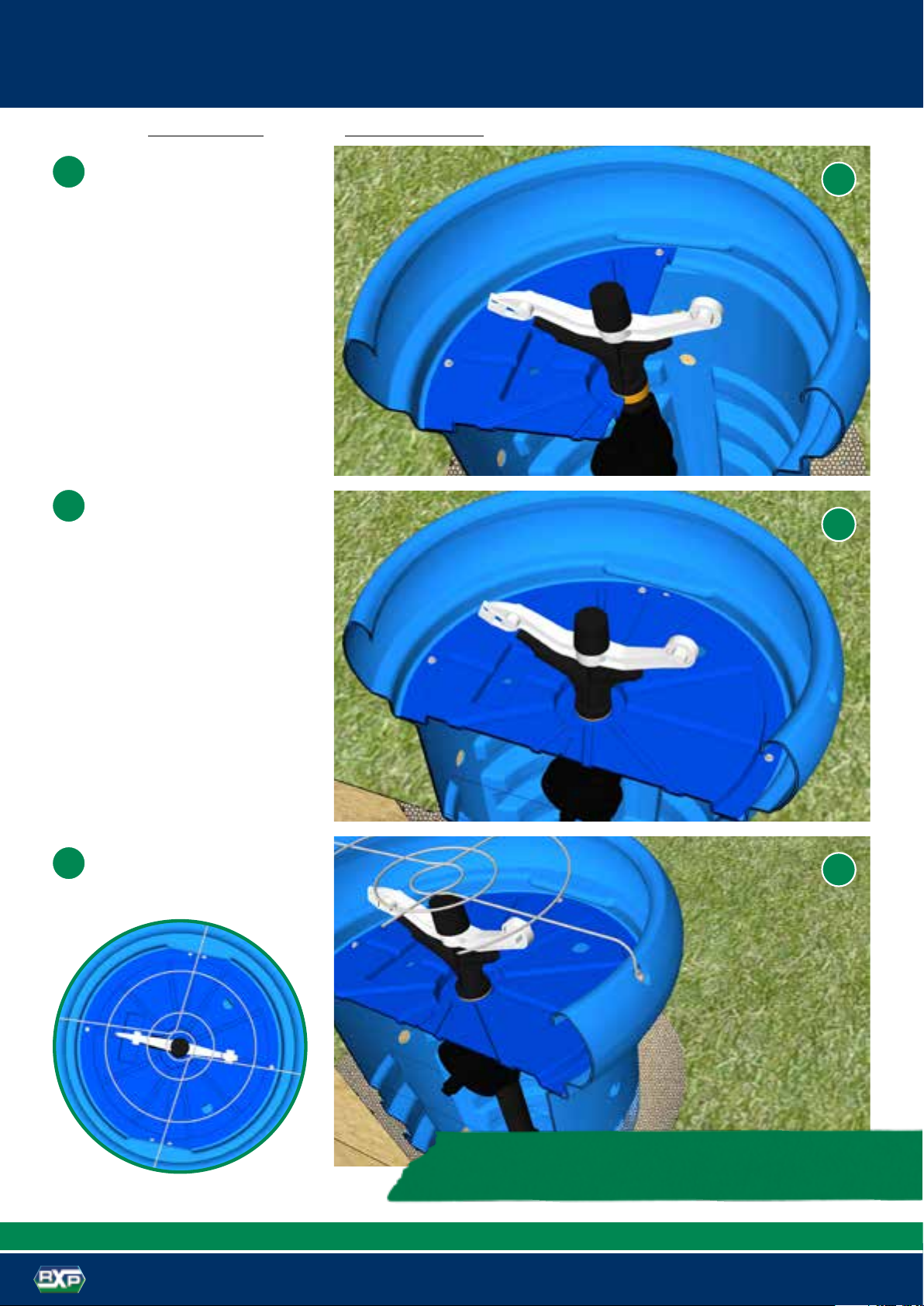

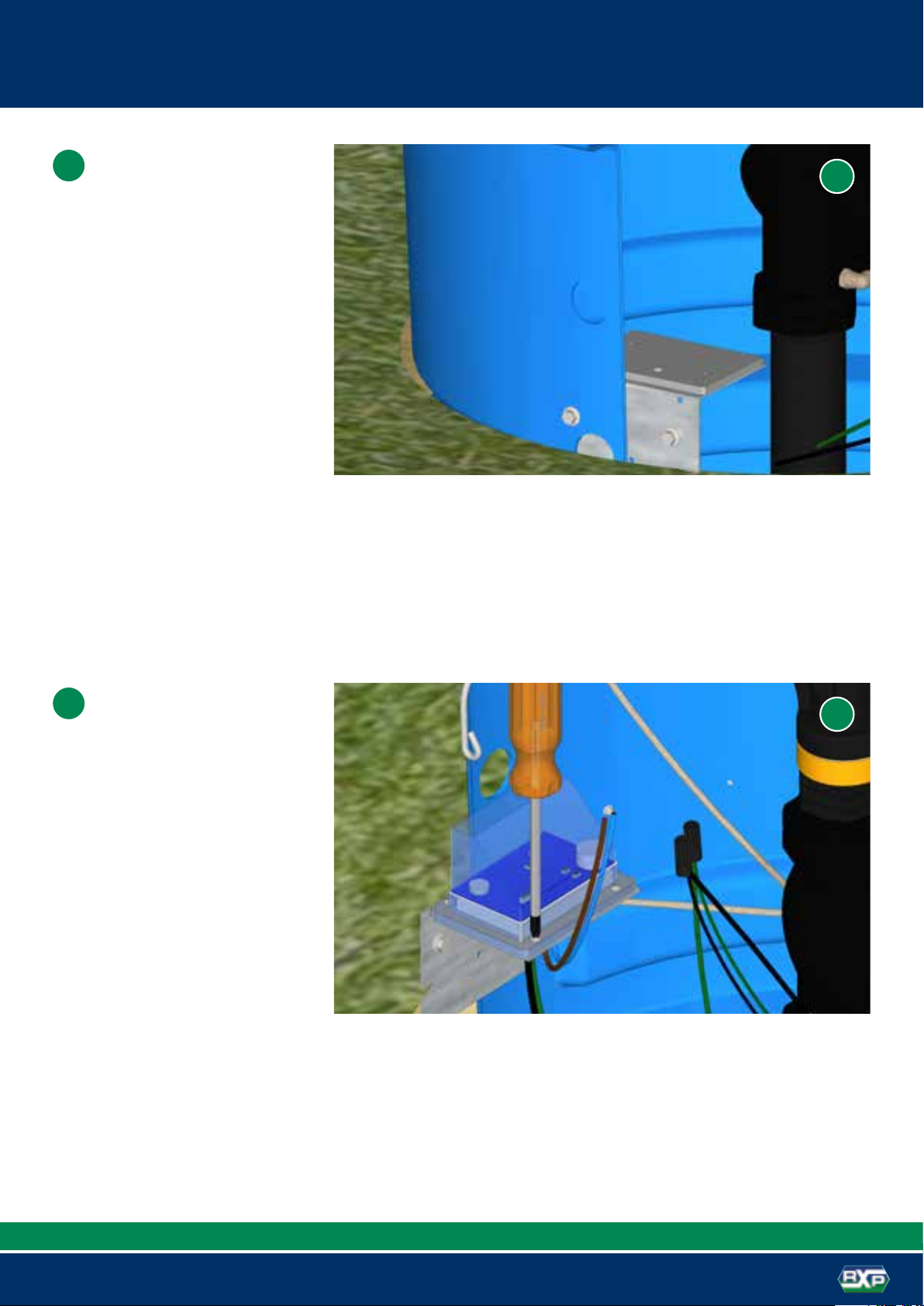

Wireless Controller (IPC)

mounting instructions 7 – 12

Guides to ensure you get the optimum

performance from your IPC.

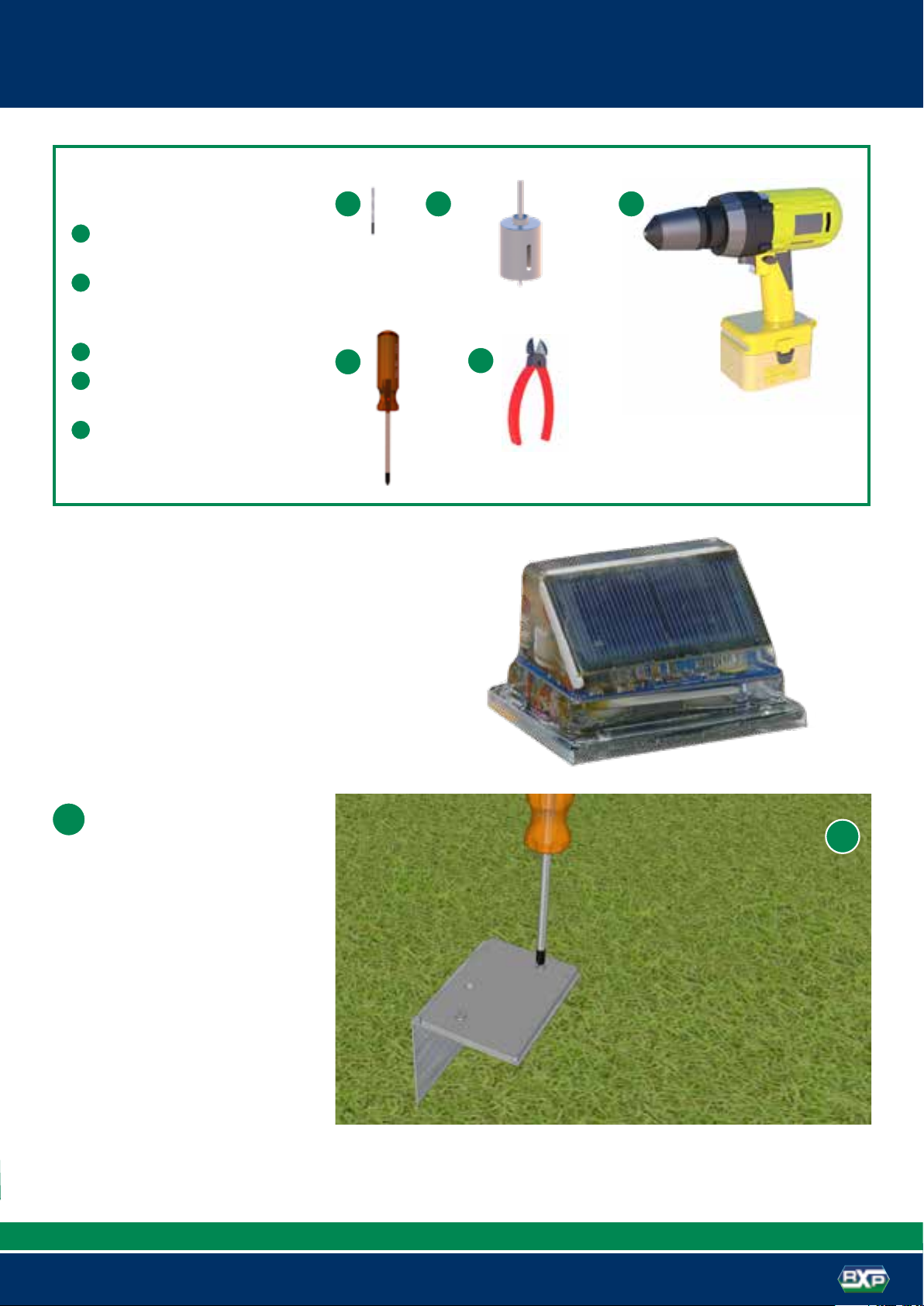

Battery Controller (C1013) 13 – 15

A guide to ensure you get the optimum

performance from your K-LineTM G-Set

C-1013 control.

KLGS.RX2000

KLGS.C1013

G-Set is an irrigation ‘system’, and to

achieve the desired outcome, must be

approached and treated as such, and

not an accumulation of components.

Contents