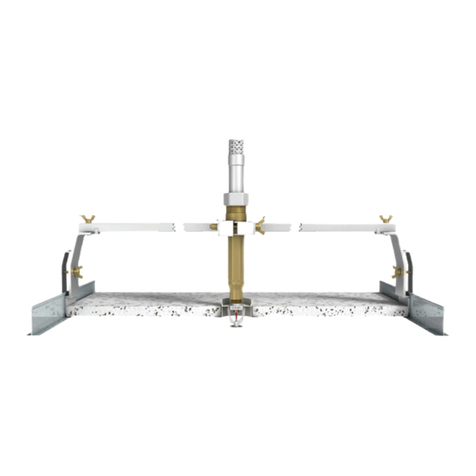

K. As depicted in Figure 3E, use the In-

stitutional Escutcheon Installation

Wrench to screw on the escutcheon

plate clockwise. The face of the es-

cutcheon plate is equipped with four

indentations to complement the de-

sign of the Institutional Escutcheon

Installation Wrench and facilitate in-

stallation of the escutcheon plate.

As the escutcheon plate is threaded

ontothesprinklerbody,thefourarms

of the lockring must fully engage with

theradialgroovesontheinsideofthe

escutcheon plate. Continue to thread

the escutcheon plate onto the sprin-

kler body until the plate’s flange fits

tightly againstthesurfaceoftheceil-

ing. Then, proceed to turn the es-

cutcheon plate another 1/2 turn

clockwise to ensure that it is secured

to the ceiling.

The arms of the lockring are angled

and designed to wedge into the

coined radial grooves on the inside

face of the escutcheon plate to keep

the escutcheon plate from being un-

screwed. Thus, anattempttoremove

theescutcheonplateafterinstallation

is prevented. DONOT MODIFY THE

UNIT.

L. The retaining flange, located behind

the finished ceiling, must fit snug

against the inner surface of the ceil-

ing to prevent vertical movement of

theassembly.Use a 1/8" hex wrench

to tighten the retaining flange screw

and secure the assembly into place

to prevent it from being pulled

through the ceiling.

M. DISASSEMBLY: Refer to section 9.

MAINTENANCE, paragraph D. and

follow all warnings and instructions.

9. MAINTENANCE

(Refer to Figures 1, 2, and 3.)

NOTICE: The owner is responsible for

maintaining the fire protection system

and devices in proper operating condi-

tion. For minimum maintenance and in-

spection requirements, refer to the ap-

propriate National Fire Protection Asso-

ciation’s pamphlet that describes care

and maintenance of sprinkler systems.

In addition, the Authority Having Juris-

diction may have additional mainte-

nance requirements that must be fol-

lowed.

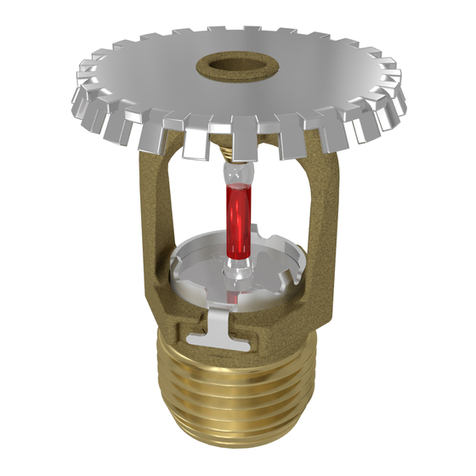

A. The sprinklers must be inspected on

a regular basis for corrosion, me-

chanical damage, obstructions,

paint, etc. The frequency of the in-

spections may vary due to corrosive

atmospheres, water supplies, and

activity around the device.

B. Sprinklers that have been painted or

mechanically damaged must be re-

placed immediately. Sprinklers

showing signs of corrosion shall be

tested and/or replaced immediately

as required. Quick response sprin-

klers that are 20 years old shall be

tested and/or replaced as required.

Sprinklers that have operated cannot

be reassembled or reused, but must

be replaced. When replacing sprin-

klers, use only new sprinklers.

C. The sprinkler discharge pattern is

critical for proper fire protection.

Nothing should be hung from the

sprinkler, attached to it, or other-

wise obstruct the discharge pat-

tern. All obstructions must be imme-

diately removed or, if necessary, ad-

ditional sprinklers installed.

D. When replacing existing sprinklers,

the system must be removed from

service. Refer to the appropriate sys-

tem description and/or valve instruc-

tions. Prior to removing the system

from service, notify all Authorities

Having Jurisdiction. Consideration

should be given to employment of a

fire patrol in the affected area.

There are two methods of sprinkler

disassembly. In Method 1, the es-

cutcheon plate and lockring are re-

moved first, and then the remaining

sprinkler components can be re-

moved without being destroyed.

Note, however, that this first method

of disassembly results in damage to

the escutcheon plate and lockring,

and so they cannot be reused.

Using Disassembly Method 1:

1. Remove the system from service,

drain all water, and relieve all

pressure on the piping.

2. Use a 1/4" drill (not available from

Viking)to maketwoholesthrough

two opposite indentations on the

face of the escutcheon plate.

3.Useanadjustablespannerwrench

(not available from Viking) to un-

thread the escutcheon plate by

turning it counterclockwise. Make

sure that the sprinkler body does

not turn or loosen.

4. Remove the lockring from the

sprinkler body.

5. Place a protective sprinkler shell

(from the spare sprinkler cabinet)

over the sprinkler to be removed.

6. With the protective shell over the

sprinkler, place the special Flush/

Concealed Sprinkler Wrench over

the unit and turn it counterclock-

wise to carefully unthread the

sprinkler body from the reducing

coupling.

7. Installthe new unit using the Flush /

Concealed Sprinkler Wrench.

Caremustbe takentoensurethat

the replacement sprinkler is the

proper model and style, with the

appropriate orifice size, tempera-

ture rating, and response charac-

teristics. A fully stocked spare

sprinkler cabinet should be pro-

vided for this purpose. (Stock of

spare lockrings and escutcheon

plates should be available in the

spare sprinkler cabinet in addition

to the spare sprinkler heads.)

8. Place the system back in service

and secure all valves. Check the

replaced sprinklers and repair all

leaks.

Using Disassembly Method 2:

The second method of removing the

Model HQR-2 Institutional Quick Re-

sponse Flush Pendent Sprinkler re-

sults in complete destruction of the

unit. Therefore, none of the sprinkler

components may be reused:

1. Remove the system from service,

drain all water, and relieve all

pressure on the piping.

2. Disassemble and remove the fus-

ible element, andbend thedeflec-

tor and sealing assembly to ex-

pose the waterway of the sprin-

kler.

3. Insert an easy-out screw extractor

(Trade No. 6) into the waterway.

Turn the easy-out counterclock-

wise with a wrench to remove the

sprinkler assembly from the re-

ducing coupling.

5. Install the new unit usingtheFlush/

ConcealedSprinklerWrench.Care

must be taken to ensure that the

replacement sprinkler is the

proper model and style, with the

appropriate orifice size, tempera-

ture rating, and response charac-

teristics. A fully stocked spare

sprinkler cabinet should be pro-

vided for this purpose. (Stock of

spare lockrings and escutcheon

plates should be available in the

spare sprinkler cabinet in addition

to the spare sprinkler heads.)

6. Place the system back in service

and secure all valves. Check the

replaced sprinklers and repair all

leaks.

E. Sprinkler systems that have been

subject to a fire must be returned to

service as soon as possible. The en-

tire system must be inspected for

damage and repaired or replaced as

necessary.Sprinklersthathavebeen

exposed to corrosive products of

combustionorhighambienttempera-

tures, but have not operated, should

be replaced. Refer to the Authority

Having Jurisdiction for minimum re-

placement requirements.

TECHNICAL DATA

March 18, 1999

Sprinkler 60 d

MODEL HQR-2 INSTITUTIONAL

QUICK RESPONSE FLUSH

PENDENT SPRINKLER

Form No. F_100998

Replaces page 60 a-d, dated February 25, 1999

(added disclaimer and installation tip).