8

EN

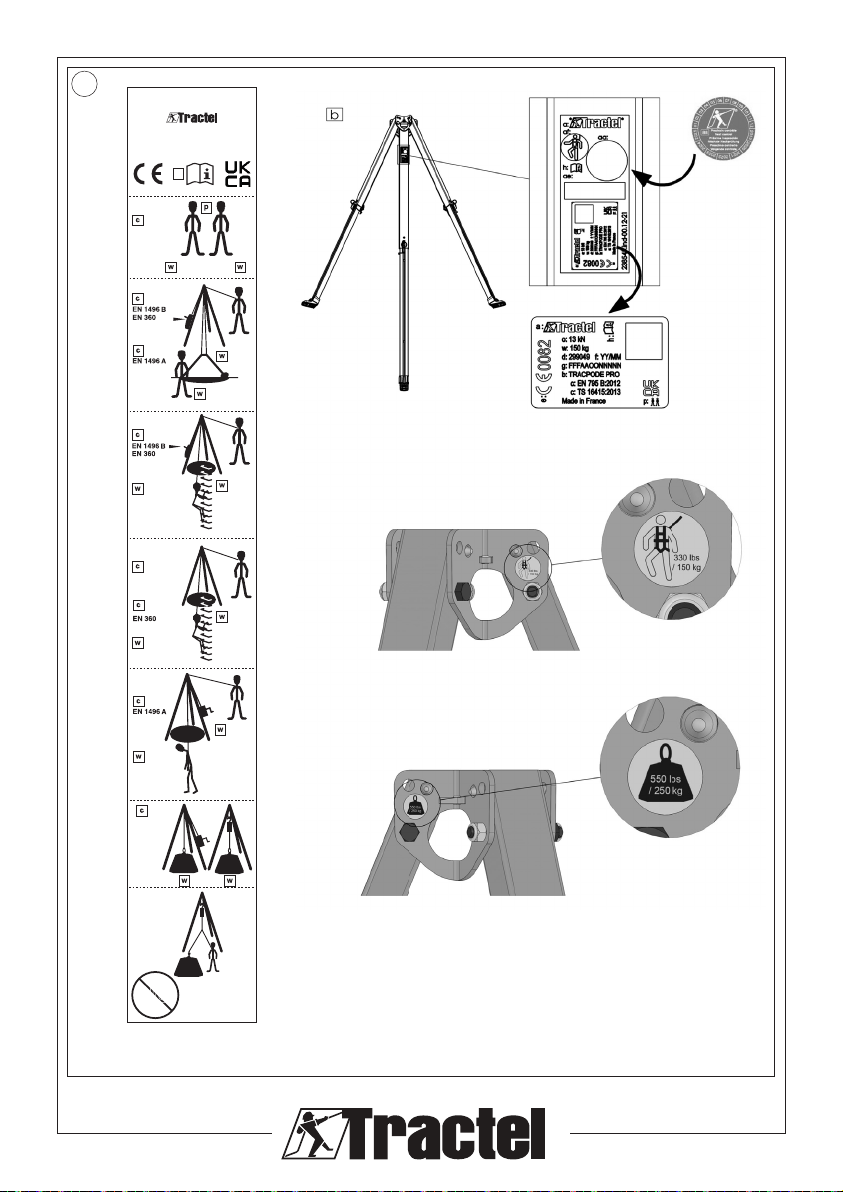

Technical specications

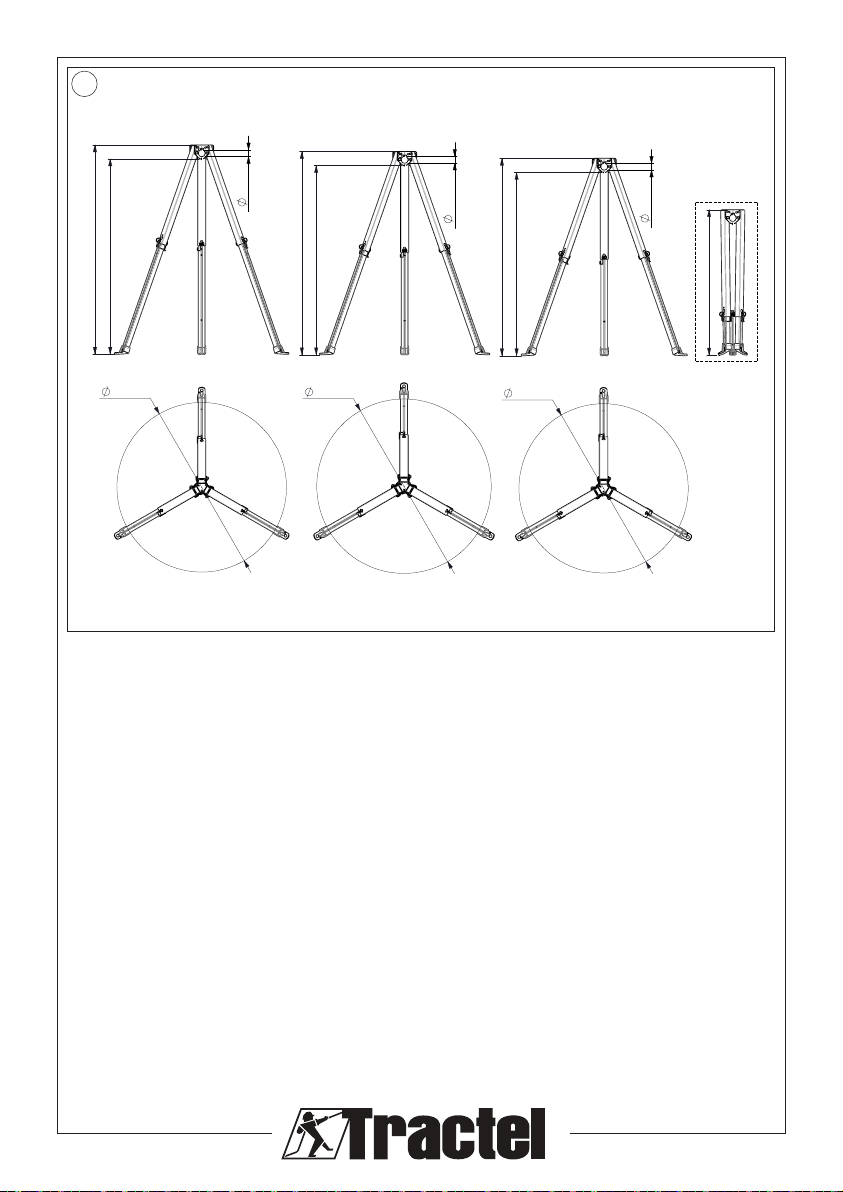

The dimensional specications are shown in gure 7 in

the rst part of this manual and in the table below.

Position (g. 2.c) Overall height (g. 7, HO) Height under head (g. 7, H) External diameter, feet (g. 7, DE)

2.3 1,62 m 1,51 m 1,31 m

2.2 1,57 m 1,46 m 1,27 m

2.1 1,52 m 1,41 m 1,23 m

Weight of the Tracpode PRO: 11.9 kg

Length of the Tracpode PRO when folded: 1.12 m

IMPORTANT: The Tracpode PRO may be used as

a temporary anchor point (EN 795-B: 2012), which can

be tted with fall-arrest systems conforming with

EN 363:2002), rescue lifting devices (conforming with

EN 1496:2017 type A or B outside CE), and devices

which allow working while suspended from a rope in

accordance with Directive 2001/45/EC.

If the Tracpode PRO is used as a system for lifting

loads, in accordance with EU Machinery Regulation

2006/42/EC, it must not be used simultaneously as a

temporary anchor point.

The Tracpode PRO is a CE-marked anchor point

covered by the European Regulation UE. The certicate

of conformity issued by the laboratory QUINTIN

CERTIFICATIONS (QC) covers its use in accordance

with the requirements stated in standard EN 795:2012

and TS 16415:2013.

The EU examination certicate of conformity issued

by QC exclude applications associated with other

directives. These other products require, depending on

what they are used for, a declaration of conformity with:

• Standard EN 1496:2017, rescue lifting devices.

• Directive 2001/45/EC, rope-suspended working

devices.

• EU Machinery Regulation 2006/42/EC, CE-marked

lifting application.

1. General warning

1. Before using a Tracpode PRO, it is essential that

the user reviews and understands the information

in the manual provided by Tractel SAS, in order to

ensure safe and eective use of the equipment.

These instructions should be made available to all

users. Further copies can be supplied on request.

2. Before using this safety equipment, it is essential to

have been trained to use it. Check the condition of

associated equipment and ensure there is enough

vertical clearance.

3. The Tracpode PRO may only be used by a single

trained and competent operator or by an operator

while overseen by a trained and competent

supervisor.

4. If a Tracpode PRO is not in good visual condition

or if it has arrested a fall, all the equipment must

be inspected by Tractel SAS or by a qualied

and competent technician, from whom written

authorisation must be given to reuse the equipment.

A visual inspection is recommended before each

use.

5. No modication or addition may be made to the

equipment without prior written approval from

TRACTEL SAS. The equipment must be transported

and stored in its original packaging.

6. Any Tracpode PRO that has not been periodically

inspected within the last twelve months, or that has

arrested a fall, must not be used. It may only be

used again following a periodic re-inspection carried

out by a qualied and competent technician who will

authorise its use in writing. If these inspections and

authorisations are not carried out, the Tracpode

PRO must be decommissioned and destroyed.

User safety is protected if the equipment is always

kept in a well-maintained state.

7. The Tracpode PRO is a fall-arrest anchor point

capable of arresting the fall of two people weighing

up to 150 kg each. The maximum operating load for

the Tracpode PRO is 150 kg.

8. If the weight of the operator, including the weight

of their equipment and tools, is between 100 kg

and 150 kg, you must ensure that the total weight

(operator, equipment + tools) does not exceed the

maximum load of each of the components of the

fall-arrest system.

9. This equipment is suitable for use on an open-air

work site and a temperature range between -40 °C

and 60 °C. Avoid contact with sharp edges, abrasive

surfaces and chemical products.

10. If the equipment will be assigned to an employee

or similar person, ensure compliance with the

applicable labour regulations.

11. The operator must be physically and mentally t

when using this equipment. If in doubt, check with

your doctor or your occupational doctor. Pregnant

women may not use this product.

12. This equipment should not be used beyond its limits

or in any situation other than that for which it is

specied: see “4. Functions and description”.