08-19-05 Z08-02643

SPECIFICATIONS

MAXIMUM FLOW....................................................... 7.8 GPM / 30 LPM

MAX UNLOADING PRESSURE.............................. 3650 PSI / 251 BAR

MAXIMUM TEMPERATURE ................................... UP TO 190°F / 88°C

WEIGHT....................................................................... 2.1 LBS / 0.91 KG

BYPASS..................................................................................... 1/4 FNPT

INLET & DISCHARGE............................................................... 3/8 FNPT

REPAIR PARTS PACKAGE

*C07-03700K - Includes 1 of item #1, 1 of item #2, 1 of item #3,

3 of item #4, 2 of item #7, 2 of item #13,

1 of item# 14, 1 of item# 27

UNLOADING ADJUSTMENT

1. Install an appropriate pressure gauge in pump head outlet.

The gauge should have a range twice the operating pressure.

2. Loosen nut (Item 19) and turn the knob (Item 20) counter

clockwiseuntil minimum spring tension.

3. Open the trigger gun, start the pump, and observe

pressure gauge reading.Slowly tighten the knobclockwise

until the desired pressure.

4. Close and open the trigger gun to check unloading

pressure and bypass function of the unloader valve.

The unloading pressure should not exceed operating

pressure more than 400 PSI.

5. Lock the setting by tightening the nut (item 19).

NOTE: Once the operating pressure is reached,

turning the knob clockwise will increase the

unloading pressure only.

ACCESSORIES

Y02-00009............................................... 0 TO 1500 PSI / 103 BAR GAUGE

Y02-00002............................................... 0 TO 2000 PSI / 138 BAR GAUGE

Y02-00010............................................... 0 TO 5000 PSI / 345 BAR GAUGE

Supersedes 04-29-03 Z08-02634

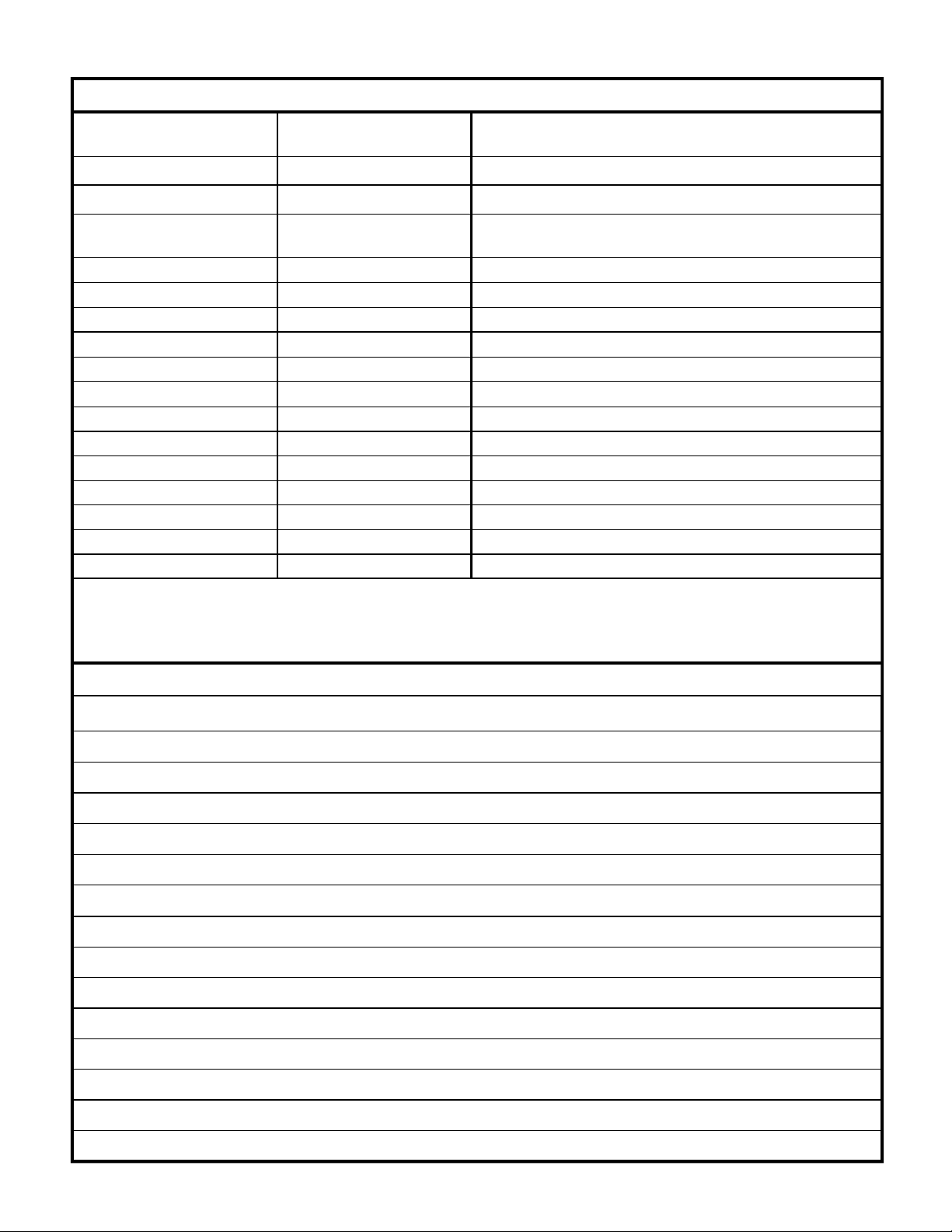

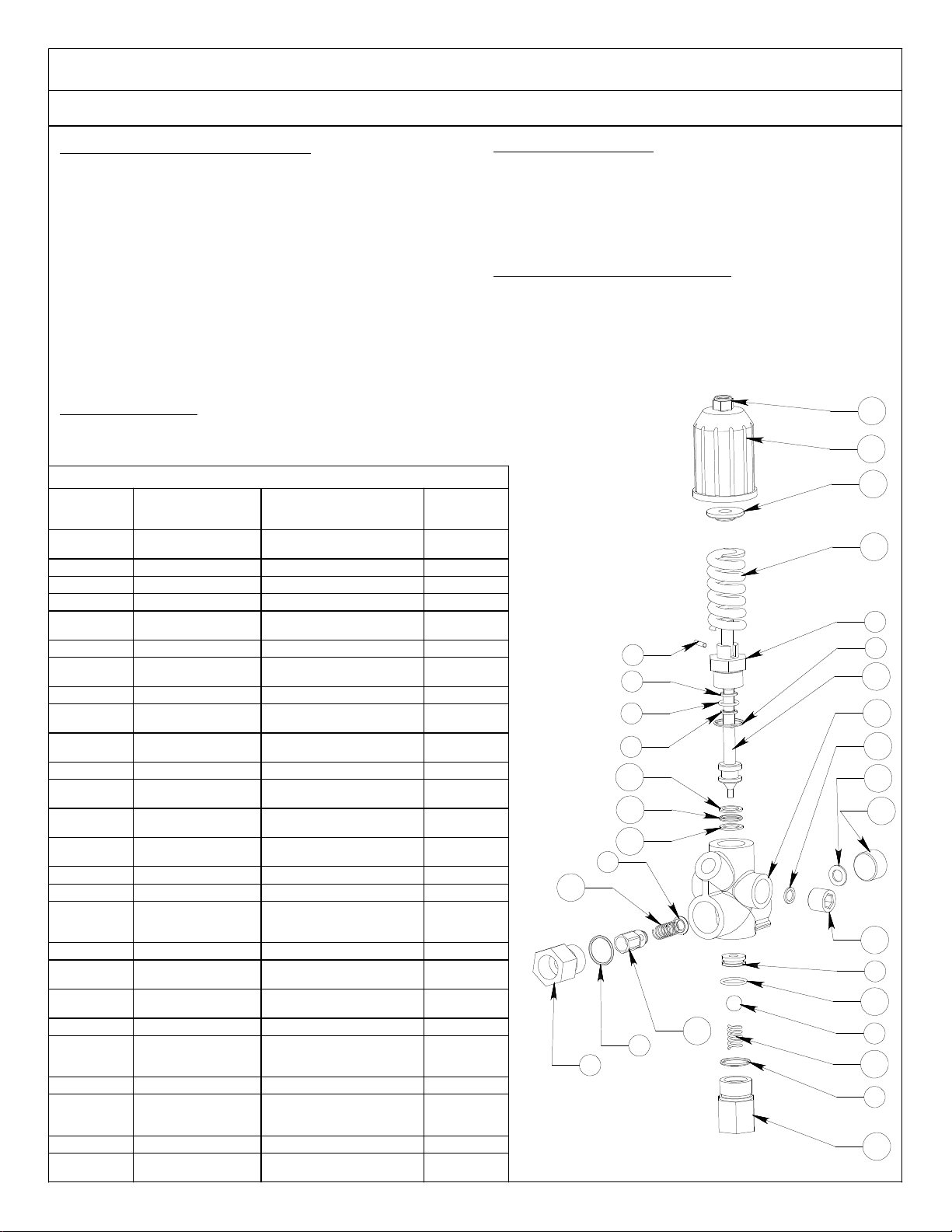

PART LISTS

ITEM PART

NUMBER PART DESCRIPTION QTY.

18RS6-000SV01 O-RING - 1/16CS X

1/2ID 1

2C07-02000-18 BALL, SS 11/32 1

3C07-02000-20 O-RING 1

4C07-02300-08 O-RING - 11/16 ID 3

5C07-03700-1 FITTING, OUTLET - 3/8 1

6C07-03700-11 GUIDE PISTON 1

7C07-03700-12 RING,

ANTI-EXTRUSION 2

8C07-03700-15 PIN, ROLL 1

9C07-03700-21 GUIDE, PISTON - SS 1

10 C07-03700-23 SPRING,

COMPRESSION 1

12 C07-03700-26 PISTON 1

13 C07-03700-28 RING,

ANTI-EXTRUSION 2

14 C07-03700-29 O-RING - 3/32 X 7/16ID

X 3043 1

15 C07-03700-3 SPRING,

COMPRESSION 1

16 C07-03700-4 ORIFICE, SHUTTER 1

17 C07-03700-6A PLUG,, 3/8NPT 2

18 C07-03700-6B GASKET, WASHER -

1/16CS X 5/16 X

7/16OD 2

19 C07-03700-7 NUT, NY-LOCK 1

20 C07-03700-8 KNOB, ADJUSTMENT 1

21 C07-03700-9 FOLLOWER, SPRING 1

22 C07-0370010C SPRING, BLUE 1

23 C07-0370018B HOUSING, UNLOADER

- 3/8FNPT 1

24 C07-0370019A PLUG 1

25 C07-0370019B GASKET, WASHER -

1/16CS X 5/16ID X

9/16OD 1

26 C07-03800-24 GUIDE, BALL 1

27 N07-20028 O-RING - 1/16CS X

7/16ID 1

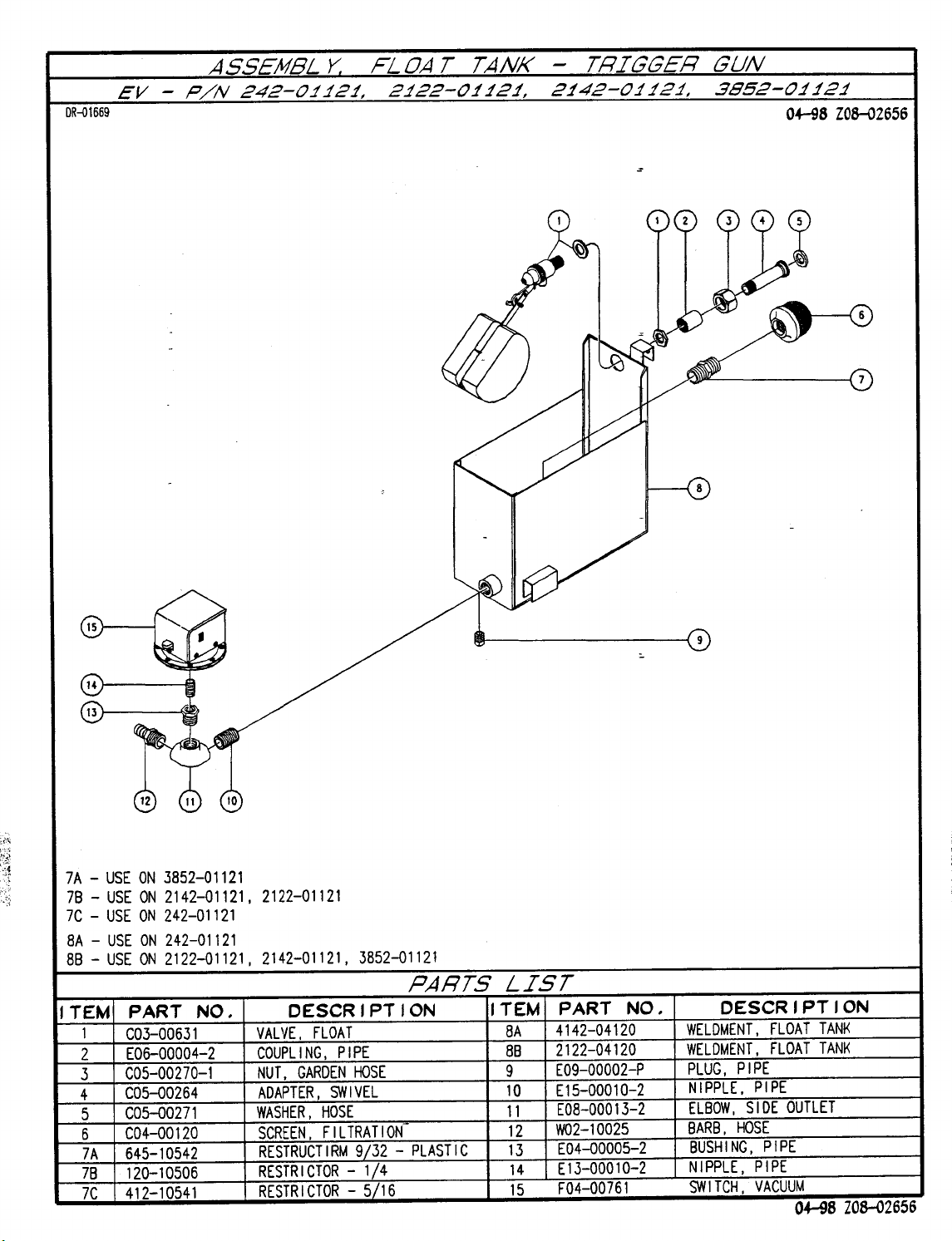

20

21

22

6

4

12

13

14

13

23

18

17

9

27

2

10

4

26

3

15

16

4

5

8

19

7

1

7

25

24

*

*

*

*

*

*

*

**

*

**

*

*

AL606

VALVE, UNLOADER - BLUE SPRING 3650 PSI

BREAKDOWN - P/N C07-03700