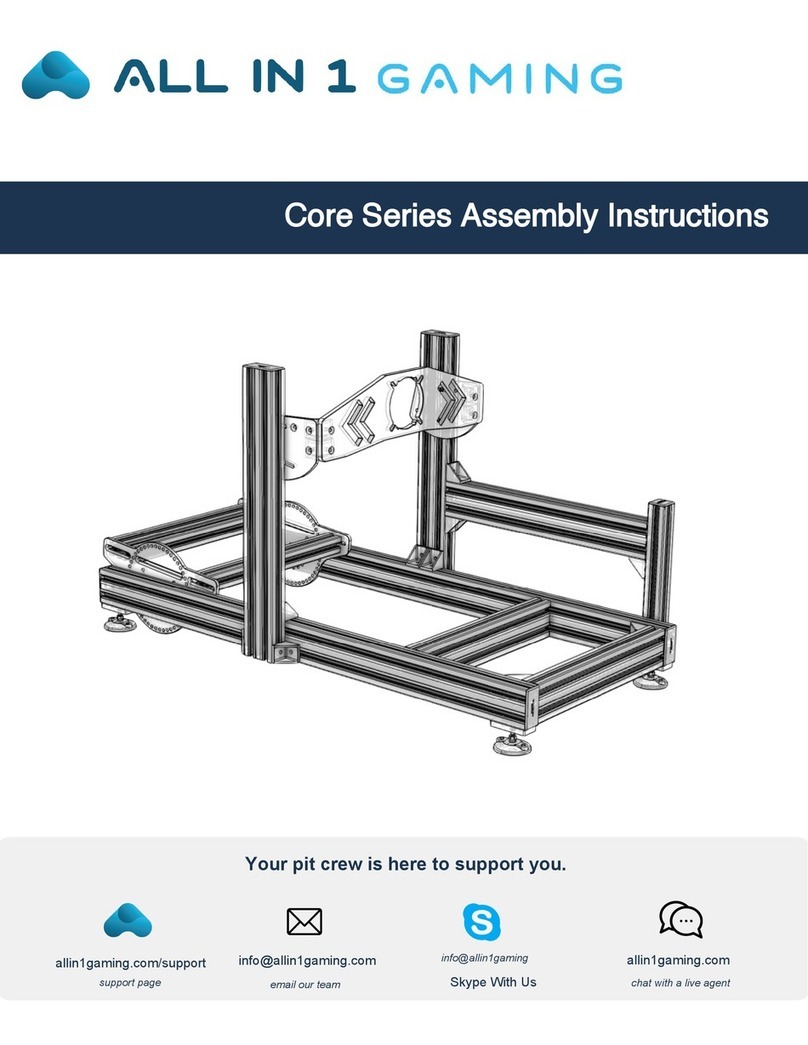

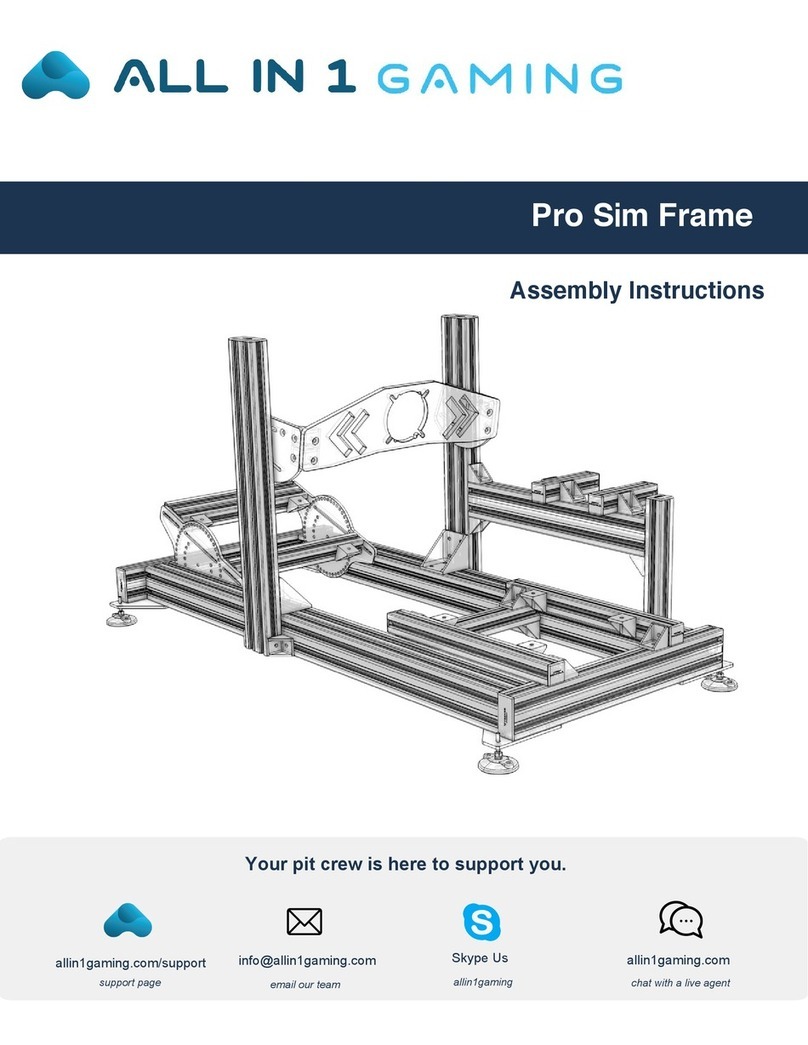

Unboxing

■Open every box first. Each group or section of the whole of a whole was seperatley packed.

■Consider placing the flattened cardboard boxes on the floor under your components to prevent them from

getting scratched during assembly.

■As you discard the packaging, be careful to not accidentally throw a part away. Please recycle as much as

possible.

Tips

■

You can slide T-nuts in from the end of an extrusion or insert them anywhere along the length of the

extrusion–no need to dismantle to insert a T-nut.

■

T-nuts work similarly regardless of their orientation. No need to orient them in the same direction inside

the T-slot.

■

Tighten fasteners with your fingers first and leave them slight ly loose until you've finished assembling a

sub-section. Once you've completely assembled your machine (or a sub-assembly), tighten it all up.

The Anodization process that makes such beautiful profiles also makes them more vulnerable to scratches. Please be

extra careful during assembly and place the profiles carefully without bumping them into anything.

Each aluminum profile that we receive is carefully inspected, cleaned and individually wrapped to ensure that your

frame will look beautiful. We reject any piece that does not live up to our standards. That being said, it would

be impossible to send back every profile that has a small imperfection and that will not even show in the final

assembly. If we notice a small scratch on a profile that has an “underside” that will not be visible in the final cockpit,

we do mark that side with a t-nut.

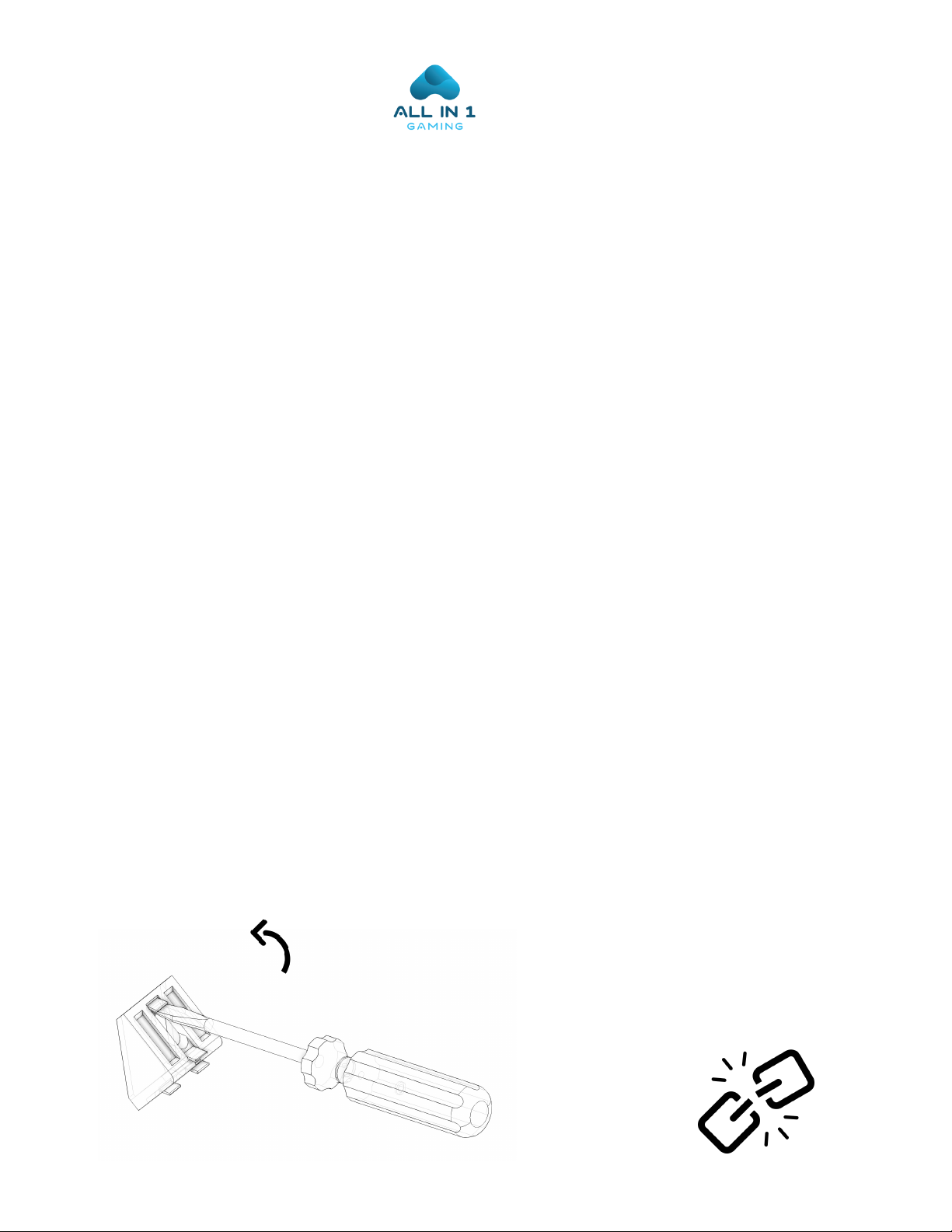

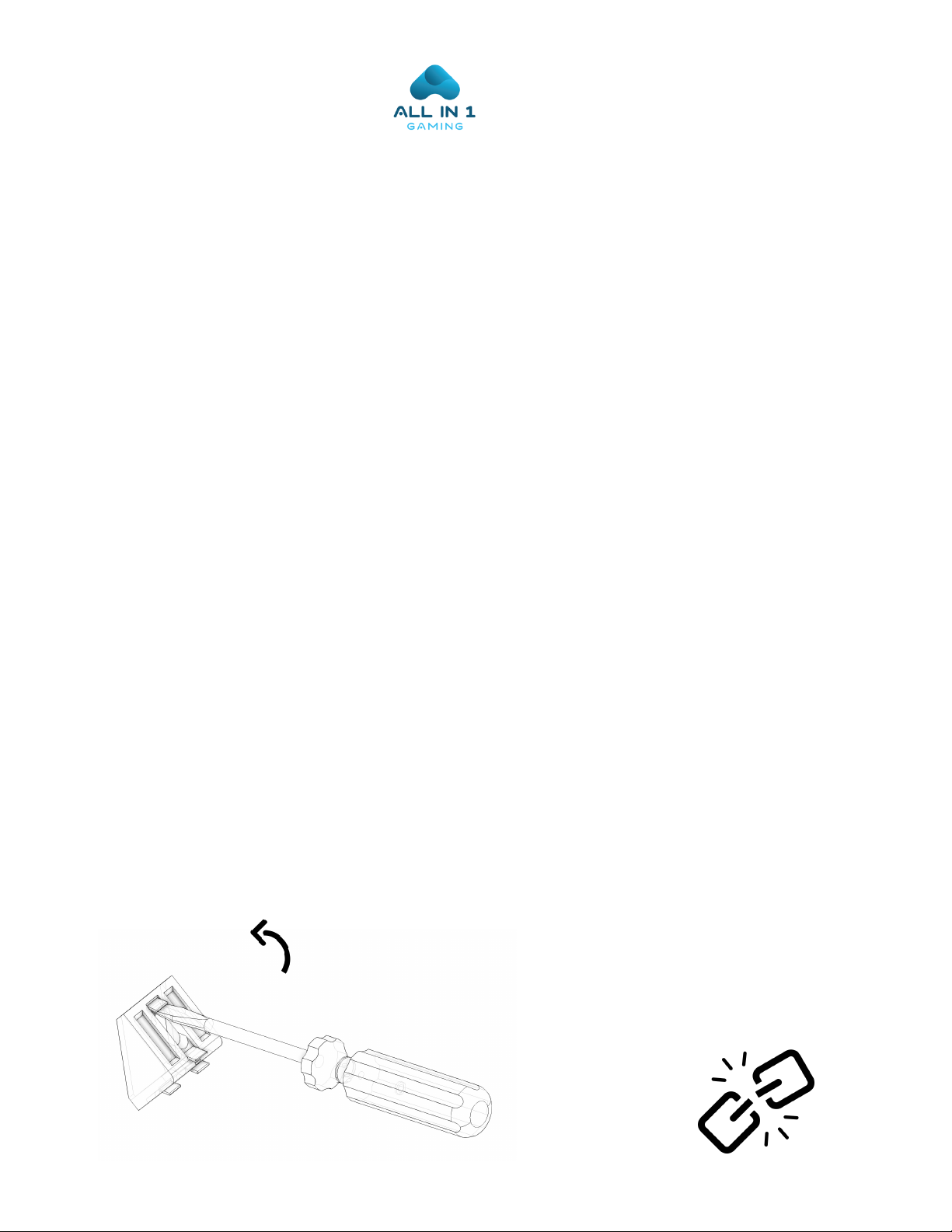

Corner Brackets

Tabs on the corner brackets may need to be removed if they are perpendicular to the extrusion they are

placed on. In this case they won't lie flatly on the extrusion. This can be done by placing a flathead

screwdriver behind the tab and tilt upwards away from your body.

The assembly instructions will show the

bottom break tab symbol on the

appropriate steps where tabs need ot

be broken off.