Installation Data

System Power Supply

Cat. No. 1771P1

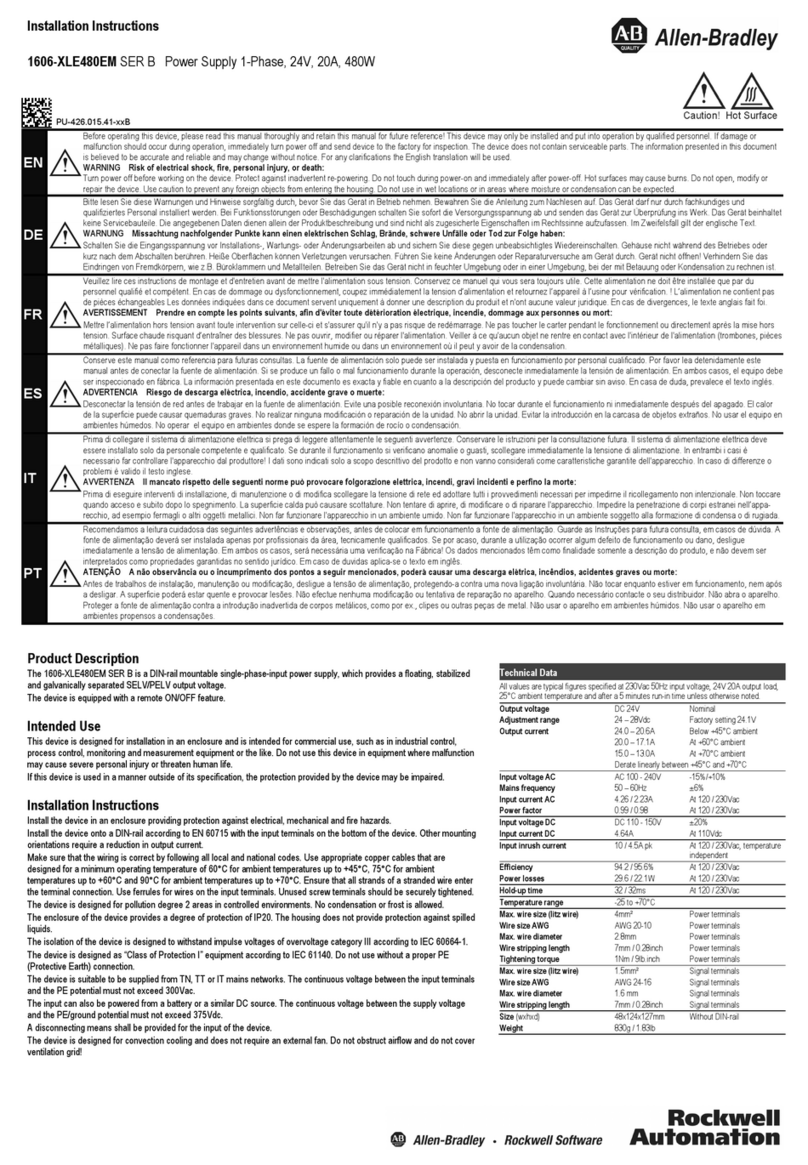

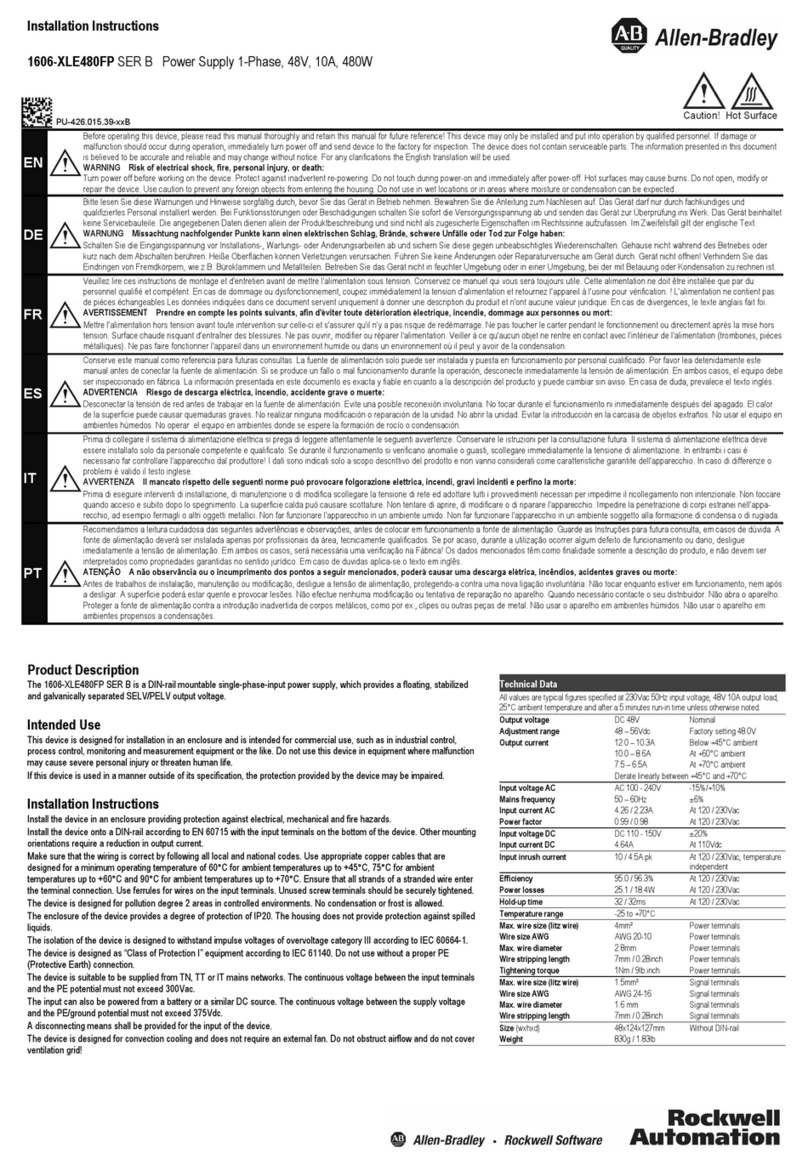

10

Nominal Input Voltage/Current 120V ac @ .75A

220/240V ac @ .38A

Input Voltage for 120V operation

Range for 220/240V operation

98132V ac

196250V ac

Input Power real

apparent

65W @ full load

90VA @ full load

External Transformer 160VA @ full load

Frequency Range 60/50Hz

Isolation Voltage 2500V dc for 1 sec

1800V rms for 1 sec input power to equipment/chassis ground

Output logic circuitry

Voltage memory

5V dc ±5%

5V dc ±5%

Output Current 6.5A maximum @ 5V dc

Power Loss Time Delay

Input Power Loss to Processor Disable

13.5 ±2.5msec

Battery Type 2 alkaline Dsize 1.5V or

1 lithium Dsize 3.4V

Replacement for 120V operation

Fuses for 220/240V operation

1A, 3AG (slow blow) Bussmann MDL 1 Littelfuse 313001

0.5A, 3AG (slow blow) Bussmann MDL 0.5 Littelfuse 313.500

Weight 5.89 kg (13 lbs)

Dimensions (W x H x D) 116mm x 285mm x 182mm

(4.56" x 11.25" x 7.16")

Environmental Operating Temperature

Conditions: Storage Temperature

Relative Humidity

0 to 60°C (32 to 140°F)

40 to 85°C (40 to 185°F)

5 to 95%, noncondensing

Location side plate of bulletin 1771 I/O chassis or

5 cablefeet from I/O chassis

Cables 1771CM

1771CL

1.52m (5 ft ) connects I/O chassis to panel mounted 1771P1

.30m (1 ft.) - connects I/O chassis to chassis mounted 1771P1

PLC-2 and PLC-2/15 are registered trademarks of Allen-Bradley Company, Inc.

RayOVac is a registered trademark of RayOVac Corporation.

Specifications

With offices in major cities worldwide

WORLD

HEADQUARTERS

Allen-Bradley

1201 South Second Street

Milwaukee, WI 53204 USA

Tel: (1) 414 382-2000

Telex: 43 11 016

FAX: (1) 414 382-4444

EUROPE/MIDDLE

EAST/AFRICA

HEADQUARTERS

Allen-Bradley Europe B.V.

Amsterdamseweg 15

1422 AC Uithoorn

The Netherlands

Tel: (31) 2975/43500

Telex: (844) 18042

FAX: (31) 2975/60222

ASIA/PACIFIC

HEADQUARTERS

Allen-Bradley (Hong Kong)

Limited

Room 1006, Block B, Sea

View Estate

28 Watson Road

Hong Kong

Tel: (852) 887-4788

Telex: (780) 64347

FAX: (852) 510-9436

CANADA

HEADQUARTERS

Allen-Bradley Canada

Limited

135 Dundas Street

Cambridge, Ontario N1R

5X1

Canada

Tel: (1) 519 623-1810

FAX: (1) 519 623-8930

LATIN AMERICA

HEADQUARTERS

Allen-Bradley

1201 South Second Street

Milwaukee, WI 53204 USA

Tel: (1) 414 382-2000

Telex: 43 11 016

FAX: (1) 414 382-2400

As a subsidiary of Rockwell International, one of the world’s largest technology

companies — Allen-Bradley meets today’s challenges of industrial automation with over

85 years of practical plant-floor experience. More than 11,000 employees throughout the

world design, manufacture and apply a wide range of control and automation products

and supporting services to help our customers continuously improve quality, productivity

and time to market. These products and services not only control individual machines but

integrate the manufacturing process, while providing access to vital plant floor data that

can be used to support decision-making throughout the enterprise.

Publication 1771-2.6 — November 1992

Supersedes 1771-2.6 — July 1984 PN 955113-23

Copyright 1992 Allen-Bradley Company, Inc. Printed in USA