ALLEN FACE & COMPANY D-Meter User manual

INSTRUCTION MANUAL

For

D-Meter®

ALLEN FACE & COMPANY, L.L.C.

338 Arrowhead Dr.

Gilberts, IL 60136

Tel: (224) 699-9000

Fax: (847) 844-0325

Web: www.allenface.com

© 2022 Allen Face & Company, L.L.C. –All rights reserved.

TABLE OF CONTENTS

Section I: BATTERY CHARGING, RE-CALIBRATION, & MAINTENANCE

Charging the internal Lithium-ion battery I-1

Re-Calibration Requirements I-1

Routine Maintenance I-1

Returning Your Unit for Service I-2

Notice to Overseas Customers I-3

Section II: SETTING-UP & OPERATING the DOWNLOAD SOFTWARE

Loading the D-Meter® Download Software onto Your PC’s Hard Drive II-1

Section III: GENERAL OPERATION

Recommended Run Pattern III-1

Unit Power-Up & Memory Clearance III-1

“Start New Session ?” Query III-1

The “<OFF>” Screen III-2

Starting and Completing a Run III-2

Displaying Run Results III-2

Check Codes III-3

Automatic Retention of All Run Records III-3

Automatic Downloading of All Run Records to Excel® III-3/4

Section IV: DETAILED KEY & LED LIGHT DESCRIPTIONS IV-1

Section V: DETAILED SCREEN DESCRIPTIONS

Status / Information Screens V-1

Query Screens V-2

Instruction Screens V-2

Results Screens V-2/3

Battery Status Screens V-4

Error Message Screens V-4/5

Error Codes V-5

Section VI: D-METER PROJECT MANAGEMENT VI-1

I. BATTERY CHARGING, RE-CALIBRATION, & MAINTENANCE

A. Charging Internal Lithium-ion Battery (International Customers see Page I-3)

To charge / recharge the D-Meter’s internal power pack, plug the charger into a 115 volt

grounded outlet and plug the charger lead into the socket on the left hand side of the unit.

B. Re-Calibration Requirements

The D-Meter’s calibration is set at the factory and cannot be changed by the operator.

Unless the unit is dropped or otherwise obviously damaged, the factory calibration should

remain constant well beyond the re-calibration period.

Every D-Meter must be returned to the factory annually (for domestic customers) or biennial

(for international customers) for re-calibration and refurbishment. (There is a nominal

charge for this service.) The re-calibration date is displayed on the D-Meter’s screen every

time the unit is turned on. Normal turn around time for all factory services is one week

(excluding transit time).

D-Meters in current calibration are fully warranted indefinitely for both parts and labor

(absent obvious abuse).

C. Routine Maintenance

1. Use a commercial glass cleaner (e.g. Windex®) and a soft cloth to clean all exterior

surfaces. NEVER use any type of organic solvent to clean the unit.

2. For the D-Meter software to work properly, the bottoms of the black rubber “shoes”

mounted on the swivel feet must remain clean and properly positioned.

3. If the unit “hangs-up” and the display cannot be returned to the <OFF> screen by

pressing the <STOP/ESC> key, reset the entire system by pressing the POWER

<OFF> and POWER<ON> keys. Only the readings in the run being recorded when

the unit is reset will be lost.

***************************************************************************************

Warning! The D-meter is a sealed unit. NEVER attempt to remove either of the end plates.

!!! IRREPARABLE ELECTRONIC DAMAGE WILL OCCUR!!!

***************************************************************************************

(I –1)

***************************************************************************************

Warning! NEVER immerse the unit.

NEVER run the unit through standing water.

NEVER expose the unit to steady rain.

!!! IRREPARABLE ELECTRONIC DAMAGE WILL OCCUR!!!

***************************************************************************************

Warning! All liabilities attendant to the use of any D-Meter shall reside entirely with the

user. AF&Co does not warrant the accuracy or adequacy of any of the

information provided by the D-Meter and will not be liable for any damages

suffered as a consequence of any use thereof or reliance thereupon by any party.

***************************************************************************************

4. Questionable or troublesome units should be returned immediately to the factory for

inspection and repair along with a note describing the problems in detail.

5. When returning a unit for service or calibration, please remove the manual and

accessories from the case.

ALLEN FACE & COMPANY, L.L.C.

338 Arrowhead Dr.

Gilberts, IL 60136

Tel: (224) 699-9000

Fax: (847) 844-0325

Web: www.allenface.com

***************************************************************************************

Note: Please include your business card (or other identifying note) inside the case along with

specific instructions regarding billing and return shipment. Unless arranged otherwise,

return shipment will be ground via a carrier of our choice

***************************************************************************************

(I –2)

NOTICE TO INTERNATIONAL

CUSTOMERS

BATTERY CHARGER REQUIREMENTS

The battery charger supplied with your D-Meter is designed to operate on 60 cycle,

115 volt, AC electricity. If your electricity is different, you will have to acquire an

appropriate battery charger from your local electronics supplier.

The replacement battery charger should have the following operating characteristics:

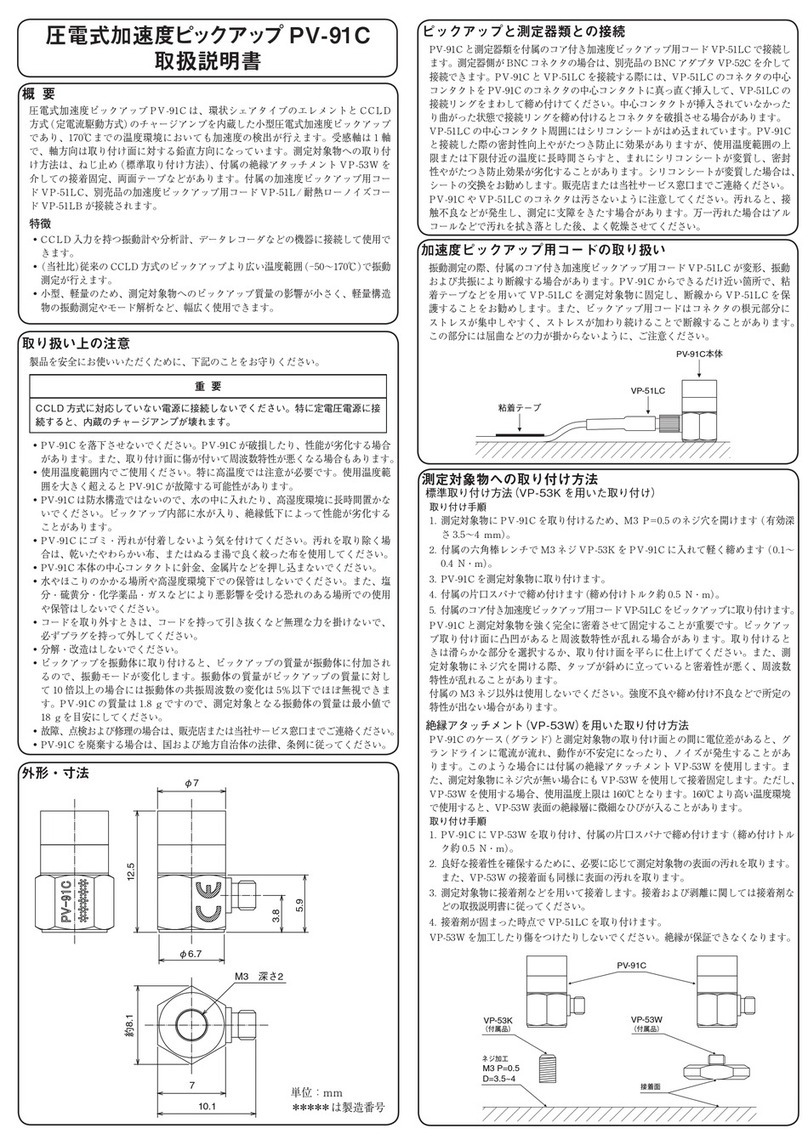

Output Voltage : 8.4 volts DC

Output Current : 1.2 amps

Polarity : Center pole positive ( + )

WARNING ! DO NOT USE A CHARGER OF OPPOSITE POLARITY ! USING A

CENTER POLE NEGATIVE ( - ) CHARGER WILL DESTROY THE

UNIT’S CIRCUIT BOARD !

BARREL ( - )

NEGATIVE

CENTER HOLE ( + )

POSITIVE

(I –3)

II. SETTING-UP & OPERATING the DOWNLOAD SOFTWARE

A. Loading the D-Meter®Download Software onto Your PC’s Hard Drive

NOTE: For the D-Meter Download software to run correctly, you must already have

Microsoft Excel® installed on your computer.

1. Uninstall any existing version of the Allen Face download programs.

At our web site https://allenface.com/projectmgmt/updates/software-updates/

page, click on the “Allen Face Download Manager”icon and proceed to download

the zip folder. Locate the downloaded zip folder, open the folder, and double click on

the “Allen Face and Companies LLC Download Manager”

Microsoft defender blue window will appear, click on “More info”, and then proceed

to install the program by clicking on the “Run anyway”tab.

Follow the setup instructions. Accepting the defaults will work for most installations.

Once the program is installed, a shortcut will appear on your desktop. Double click to

launch the manager.

2. Install the Driver for the USB to Serial adapter that was supplied with the meter (if

this is a meter that was recently purchased)

At our web site https://allenface.com/projectmgmt/updates/software-updates/

page, click on the “Driver for the USB to Serial adapter”icon and proceed to

download the zip folder. Locate the downloaded zip folder (PL2303_prolific_driver),

open the folder, and double click on the PL2303_Prolific_DriverInstaller_v1.8.19

file and proceed to install the driver.

B. System Requirements

1. Intel x86 or x64 processor, 512 MB RAM, Intel Duo Core Processor or above.

2. Operating Systems

a. Windows XP sp3

b. Windows Vista

c. Windows 7

d. Windows 10

(II –1)

III. GENERAL OPERATION

A. Recommended Run Pattern

Select the run pattern to be measured. ASTM E-1155 (see Appendix) requires that

measurement lines conform to one of the following two schemes:

1. Runs parallel and perpendicular to the longest slab boundary, where the aggregate

run length in each direction is approximately equal, or

2. Runs of any length all oriented at 45o to the longest slab boundary.

It is strongly recommended that all tests always be performed using an “X” the bays

approach –even if the N/S and E/W column spacing are net exactly equal. Standardizing the

run pattern on the bay diagonals offers a number of practical advantages:

1. The minimum qand zsampling requirement will always be well satisfied.

2. Uniform coverage is automatically obtained.

3. No run location decisions are required of the operator.

4. No measurement line diagrams ever have to be produced or archived.

5. Straight line runs without the aid of a taught string reference is facilitated.

6. Tests can always be easily duplicated in the future.

7. Results from different projects can always be reasonably compared.

B. Unit power-up & Memory Clearance

Press the <ON> button to turn the unit ON. Observe the various system status

screens during power up. Respond to all memory status inquiries as prompted:

At the “VOID Clears Memory” prompt, pressing the <VOID PREV RUN> button initiates

the MEMORY CLEARANCE routine. At the “Are You Sure ?” query, pressing the

<GO/OK> button will then permanently delete all resident run records from memory. Be

careful when clearing the memory! Erased (and voided) runs are unrecoverable.

Pressing <STOP/ESC> exits the MEMORY CLEARANCE routine at any prompt.

C. “Start New Session ?” Query

If the operation mode is kept at the same as that used for the previous power up, the

“Start New Session?” query will appear. Answering “NO” (by pressing the <STOP/ESC>

key) to this query will cause the runs collected during this power up to be added to those of

the previous session. Answering “YES” (by pressing the <GO/OK> key) will cause the runs

collected during this power up to be assembled under their own new session number.

(III –1)

D. The “<OFF>” Screen

After the session number has been selected, the <OFF> (i.e. “not recording”) screen will be

displayed. This is the unit’s “Home Screen”

E. Starting and Completing a Run

Place the unit on the floor at the desired run start point. Make sure that the “START” arrow

on the faceplate is pointing in the direction of the run. Make sure the screen on the D-meter

is displaying the <OFF> mode.

Hold the D-Meter upright (i.e. vertical not LEANING to either side) and still, and press the

<GO/OK> key. The screen will momentarily be “BLANK”, then reverts to the <ON>

screen.

**************************************************************************

NOTE: Not holding the meter handle vertically when collecting the readings will introduce

a slight uphill or downhill slope to the graph.

**************************************************************************

Using the handle, tilt the unit forward slightly raising the rear foot off of the floor. Keep the

front foot in contact with the floor, use a twisting motion with the handle and rotate the unit

1800 or end for end. Set the rear foot back on the floor and wait for the display and lights to

come back on. During the rotating step, the screen on the unit will go blank and the lights

will go off, this is normal for this operation. DO NOT proceed with moving the D-Meter to

continue the run until the display screen and red and green lights come back on.

Repeat the process described above until the end of the run has been reached.

The minimum run length is 12 feet 0 inches. Terminating a run that is shorter than this

distance will automatically cancel the run, unit returns to <OFF> mode.

The maximum run length is 600 feet 0 inches. Running the unit beyond this distance will

automatically cancel the run, and return the unit to <OFF> mode.

At the end of the run press the <STOP/ESC> key, the unit will display “Computing run

##”. (do not move the unit) After completing the calculation, the unit automatically returns

to the <OFF> mode and a new run can be started.

F. Displaying Run Results

Individual and combined F-Number results and run profile elevations are

displayed (or deleted) using the <PREV RUN>, <ALL RUNS>, <VOID PREV RUN>,

<GO/OK>, and <STOP/ESC> keys. See section IV for a detailed explanation of the key press

sequences used to manage and display the individual and aggregate session run records.

(III –2)

G. Check Codes

Immediately following each display of <PREV RUN> or <ALL RUNS> results, a nine (9)

character “Check Code” will now appear. This check code encrypts the pertinent FF/FL and

run date information to permit independent confirmation of all reported values.

A contractor self-testing his FF/FL numbers, for example, can submit his results (along with

the associated check codes) to an owner. The owner can then independently confirm the

veracity of the contractor’s report simply by accessing the Check Code screen on our

website: allenface.com. A match between these deciphered results and those presented in the

contractor’s original report is absolute confirmation of the reporter’s veracity.

H. Automatic Retention of All Run Records

The unit may be turned off at any time by pressing the <OFF> key. If the unit is

running “d #.##” software, all resident run data will be saved automatically, even

if the battery looses charge. Pressing the <GO/OK> key after power up at the “Are You

Sure ?” prompt is the only way that run records can be cleared from non-volatile memory.

When the memory has been cleared in this manner, the total run capacity is reset to 99

runs, and the session number (see below) is reset to 1.

The run records in all non-volatile memory units are organized under “session numbers”, and

the run numbers shown on the <OFF> and <ON> screens now consist of two parts: the

associated session number and the sequential run number. Run number “3, 14”, for example,

was recorded during the third session and was the fourteenth run in memory.

Every time the unit is turned ON, a new session begins. Turning the unit OFF terminates

the current session. This protocol allows runs taken on different projects (or slabs) to be

collected under different session numbers and thus be kept separate from one another. The

<ALL RUNS> routine reports the aggregate FF/FL results for all the runs collected during

each individual session as well as the aggregate FF/FL results for all the sessions combined

(i.e. all the runs in memory).

I. Automatic Downloading of All Run Records to Excel®

Section II describes how to install the Allen Face Download Manager on your PC or laptop.

All D-Meters have been fitted with serial communication ports and are fully capable

(with the requisite cabling and PC software) of downloading all retained data directly

into MicroSoft Excel. Utilizing the cables provided with your meter, connect the unit to a

USB port on your computer, open the Allen Face Download Manager program and

proceed to download all resident run data to the host computer as follows:

An icon with your meter’s serial number will be displayed on the top left corner, click on the

icon once and then click on “YES”to download its data. Once the download is ready, click

on the “Export To Excel”tab and then save the file to your computer.

(III –3)

The D-Meter Download Program puts the run data directly into Excel, and

immediately displays the individual run statistics, graphs, and data lists as soon as all the

files have transferred. Each download becomes a new Excel Workbook; each downloaded

session becomes a separate Worksheet in that Workbook; and each run becomes a separate

Chart on its session’s Worksheet. With just a rudimentary knowledge of Excel, these

downloaded data may be manipulated quickly to produce any type of formal report desired.

(III –4)

IV. DETAILED KEY & LED LIGHT DESCRIPTIONS

A. Key Functions

1. POWER Section

a. <ON> : Turns power “On”

b. <OFF> : Turns power “Off”

2. RECORD Section

a. <GO/OK> : Doubles as a “YES”command

b. <STOP/ESC> : Doubles as a “NO”command

3. RESULTS Section

a. <PREV RUN>

Selects the particular run results to be displayed beginning with the last

run recorded. Sequentially pushing the <PREV RUN> key scrolls the

selected run number. When the desired run number appears in the “<OK>

Shows Run ss,ss” screen, pressing the <GO/OK> key displays the results for that run.

b. <ALL RUNS>

Displays composite results for all recorded (unvoided) runs. Aggregate

results are displayed for all runs in memory and for all runs contained in

each section.

c. <VOID PREV RUNS>

Selects particular run to be deleted beginning with the last run

recorded. Sequentially pushing <VOID PREV RUNS> scrolls

the selected run number. When the desired run number appears in

“<OK> Voids Run ss.rr” screen, press the <GO/OK> key to void that run.

***************************************************************************************

Warning! Once voided, run records cannot be recovered.

***************************************************************************************

B. LED Lights Descriptions

1. POWER led (green) When steady, indicates unit power is ON

When flashing, indicates low battery condition

2. RECORD led (red) When steady, indicates unit is in “<ON>” mode.

When flashing indicates that recording has been stopped

automatically by a “soft-fail” or “run length error” event

(IV –1)

V. DETAILED SCREEN DESCRIPTIONS

A. STATUS / INFORMATION SCREENS

1. “D-Meter [d #.##]” : Software version identification

2. “c 2004: Allen Face” : Software copyright notice

3. “c 2004: Allen Face” : Software copyright notice

4. “S/N: #### ” : The unit’s serial number

5. “Re-calibrate by:” : The date by which the unit must be returned to factory

“mmm dd yyyy” for re-calibration

Note. D-meter warranty terms require that each unit be returned annually (every two years for

international units) to the factory for re-calibration. Please consult our website www.allenface.com

and click on D-Meter Walking Profiler for the current fee charged for this service. In-shop time for

routine re-calibrations averages less than 3 days.

6. “Battery: xxxx ” : Displays the current charge status of the battery

7. “No Runs Stored ” : The run memory is empty

8. “rr Runs Stored ” : There are currently “rr” run records stored in memory

9. “Deleting All Records ” : The desire to clear memory has been confirmed

“Re-starting unit” for re-calibration

10. “rr Runs Left ” : “rr” runs can still be recorded before the memory is full

11. “Max Run Length = 600’: Reminder that the maximum length allowable for any run is

600 feet.

12. “<OFF> ss, rr ff’ ” : The “<OFF>” screen. The unit is not recording. “ss” is

the current session number. “rr” is the last run number

recorded. “ff’ ” are the total feet traveled in all of the

recorded runs of session “ss”.

13. “<ON> rr: ff’ +/- i.iii <”: The “<ON>” screen. The unit is recording a run. “rr” is

the run number being recorded. “ff’ ” are the total feet and

traveled in run “rr”. +/- i.iii in inches, the instantaneous

unzeroed elevation difference between the front and rear

swivel feet. The sign (+ or -) indicates whether the reported

elevation is above (+) or below (-) the mean profile

elevation.

Note: These displayed front-to-rear elevation differences may or may not be perfectly

zeroed. Thus, a value of “ 0.000” “ will not necessarily indicate perfect level. Their relative

magnitudes will be correct to within +/- 0.002” however.

14. “Computing Run rr” : The run just recorded (sequential run number “rr” ) is now

being calculated.

15. “Serial I/O Active” : This message scrolls across the screen whenever the D-Meter

is communicating with another computer through the cable.

(V –1)

B. QUERY SCREENS

1. “<Void> Clears Runs” : Pressing the <VOID PREV RUN> key at this start-up

prompt will initiate memory clearance & unit reset.

Pressing the <STOP/ESC> key at this prompt will skip the

memory clearance routine and retain all current run records

2. “Are You Sure ?” : The memory clearance routine has been entered by pressing

the <VOID PREV RUN> key at the “<Void> Clears Runs”

query. Pressing the <GO/OK> key at this query will

permanently delete all run records and cause the unit to

perform a full reset. Pressing the <STOP/ESC> key at this

query will exit the memory clearance routine and retain all

current run records.

3. .“<OK> Shows Run rr” : Pressing the <GO/OK> key at this prompt causes the results

for run “rr” to be displayed.

Pressing the <PREV RUN> key at this prompt scrolls

“rr” to the previous recorded run number.

Pressing the <STOP?ESC> key at this prompt exits the run

results selection routine and returns to the “<OFF>” screen

4. .“Run: n Show H’s ?” : Pressing the <GO/OK> key at this query causes the point

elevations (on 1 foot centers) down run number “rr” to be

displayed sequentially.

5. .“<OK> Voids Run nn” : Pressing the <GO/OK> key at this prompt causes the results

for run “rr” to be deleted permanently from memory.

Pressing the <VOID PREV RUN> key at this prompt scrolls

“rr” to the next recorded run number.

Pressing the <STOP/ESC> key at this prompt exits the void

run results selection routine and returns to the “<OFF>”

screen.

6. .“Start New Session ?” : Pressing <GO/OK> key at this query begins a new

sequentially numbered session.

Pressing the <STOP/ESC> key at this query exits the start

new session routine and returns to the “<OFF>” screen.

C. INSTRUCTION SCREENS

1. “Don’t Move” : The unit is automatically recording a static reading. Do not

move the unit until prompted to do so.

2. “Go”: The unit is ready to proceed with dynamic run recording.

D. RESULTS SCREENS

1. “Run Date: mm/dd/yy” : Depending upon context, in month / day/ /year format, either:

The GMT date the run being reported was recorded, or

The GMT run date of the last run recorded in the particular

session being reported.

(V –2)

2. “Run Time: hh:mm GMT” : Depending upon context, in military Greenwich Mean Time

either:

The time the run being reported was recorded, or

The run time of the last run recorded in the particular

session being reported.

3. “NO Runs Saved” : The memory is empty. There are no run records to display.

4.“Run rr Voided” : Run number “rr” has previously been deleted from memory

and can no longer be displayed.

5.“ss,rr: L=###.0 ft” : The length of run number “rr” in session number “ss” is

“###.0” feet.

6.“ss,rr: FF=###.#” : The FF number calculated for run number “rr” in session

number “ss” is “###.#”

7.“ss,rr: FL=###.#” : The FL number calculated for run number “rr” in session

number “ss” is “###.#”

8.“90% CI = <aaa.a,- zzz.z>”: The 90% confidence interval (see ASTM E1155) for the FF

or FL value being reported ranges between the lower limit

“aaa.a” and the upper limit “zzz.z”.

9.“Chk Code: $$$$$$$$$” : The check code for the current run or session being reported

is “$$$$$$$$$”.

10.“ff: H = iiii +” : The profile elevation “ff” feet from the start point of the run

currently being reported is “iiii” / 1000 inches. The sign

(+ or -) indicates whether the reported elevation is above (+)

or below (-) the mean profile elevation.

Note. For consistency of reporting and graphing, every run profile is arbitrarily referenced

to its mean elevation. Thus, elevation “000.0” (i.e. the x-axis) simply corresponds to

the average profile elevation (i.e. the area under the run profile above the x-axis will

always equal the area above the run profile under the x-axis.)

11.“All ss Sessions” : The results which follow are the aggregation of all the runs

contained in all “ss” sessions in memory.

12.“Session ss” : The results which follow are the aggregation of all the runs

contained in session number “ss”.

(V –3)

13.“rr Runs fffff.0 ft” : The aggregate length of all “rr” runs in the current session

being reported is “fffff.0” feet.

14.”rr Runs FF=###.#” : The aggregate FF number for all “rr” runs in the current

session being reported is “###.#”

15.”rr Runs FL=###.#” : The aggregate FF number for all “rr” runs in the current

session being reported is “###.#”

E. BATTERY STATUS SCREENS

1.“Bat Life = #### min”: Current charge status of the battery in minutes.

F. ERROR MESSAGE SCREENS

1.“Run Structure Error” : The subject run record has been corrupted. Clearing the

memory of all runs at unit start-up will usually correct this

problem. If this problem occurs repeatedly, however, the

unit will have to be returned to the factory for service.

2.“Memory Error” : The current run pointer has been corrupted. Clearing the

memory of all runs at unit start-up will usually correct this

problem. If this problem occurs repeatedly, however, the

unit will have to be returned to the factory for service.

3.“Operator Error” : The operator has violated the required operational protocol.

4.“Unit Has Moved” : The unit has moved with the “<Don’t Move>” screen

displayed. Press the <STOP/ESC> key to cancel the run and

return to the “<OFF>” screen.

5.“Run rr Too Short” : Run “rr” has been terminated before 12’ – 0” have been

measured.

6.“Softfail @ fff’ ii” ” : A reading outside the permitted range has been taken in

“<ON>” mode. Press the <STOP/ESC> key to cancel the

run and return to the “<OFF>” screen.

7.“Run Length > 240’ Max” : The length of the run being recorded has exceeded the

maximum 240’ – 0” allowable.

8.“Run ss, rr Cancelled” : The run being recorded has suffered a fatal recording error

and has been cancelled. Press the <STOP/ESC> key to

return to the “<OFF>” screen.

(V –4)

9.“<OK>=Yes <ESC>=NO”: A key other than the <GO/OK> or <STOP/ESC> key has

been pressed in response to a query screen requiring a “Yes”

or “No” answer. Press the <GO/OK> key for “Yes”, or the

<STOP/ESC> key for “No”.

F. ERROR CODES

0 : Fatal RAM test failure during unit start up.

1 : NVRAM Memory Corrupted (invalid next run number).

2 : Very low battery (recharge immediately).

3 : Low battery (recharge as soon as possible).

4 : NVRAM Memory Corrupted (invalid control character).

5 : Calculated FF not a number.

6 : Calculated FF = positive infinity.

7 : Calculated FF = negative infinity.

8 : Calculated 90% Confidence Interval for FF not a number.

9 : Calculated 90% Confidence Interval for FF = positive infinity.

10 : Calculated 90% Confidence Interval for FF = negative infinity.

11 : Calculated FL not a number.

12 : Calculated FL = positive infinity.

13 : Calculated FL = negative infinity.

14 : Calculated 90% Confidence Interval for FL not a number.

15 : Calculated 90% Confidence Interval for FL = positive infinity.

16 : Calculated 90% Confidence Interval for FL = negative infinity.

17 : Slope sensor reading outside allowable range.

18 : Invalid key press (recording).

(V –5)

VI. D-METER PROJECT MANAGEMENT

Proper reporting of daily FF and FL results are made easy with the AF&CO’s new Excel sheet

report generator.

Go to https://allenface.com/projectmgmt/, and download the “Daily FF/FL Report”.

Open the “Daily Report”Excel file and customize the blue font fields as desired to create your own

standard report template.

Each line of the Daily Report corresponds to a separate slab placement. After testing the first floor

slab placement on any new project, se sure to record the following:

Specified OAFF

Specified OAFL

Specified MLFF

Specified MLFL

Test Date

Slab Designation

Slab Area

Measured FF

Measured FL

Now to report the results for that first floor slab, open your Daily Report & Chart template,

customize the project identification fields, and type the various specified FF and FL values into the

header. Save this modified template in a new folder for the project.

Re-open the template you just created and type the test date, slab name, slab area, and measured

FF/FL numbers into the top line. Print both pages, save the file using today's date as the file name,

and distribute the 2-page report.

That's it. After collecting the test results for each new slab, simply open the previous report file, add

the new data to the next line, print both pages, save this latest amended report as a new file using

today's date as the file name, and distribute the 2 new modified pages.

The 2-page Daily Report & Chart contains all of the information necessary to manage the flatness

and levelness of any new floor installation. In doing so, it avoids all of the unnecessary

complications that are created by the extraneous and voluminous distribution of the individual run

results.

(VI –1)

D-Meter® ALLEN FACE & COMPANY, LLC

ACI / ASTM “Acceptance” of F-Number Test Instruments

The question occasionally arises as to ACI’s and/or ASTM’s “acceptance” of the D-Meter for floor

tolerance testing. Unfortunately, such questions fundamentally misunderstand the roles that both

these organizations play in promulgating the F-Number System. In fact, neither ACI or ASTM are

involved in any way in the approval of any particular proprietary instrument for the testing of

F-Numbers. The status of the D-Meter relative to ACI’s or ASTM’s “acceptance” is, therefore, no

different from that of the Profileograph, or the Dipstick, or the FloorPro, or the F-Meter, or any

other instrument intended for the measurement of floor profiles.

In its committee 117 (Tolerances) and 302 (Floor Construction) documents, ACI only provides

information regarding specification format, the particular F-Number values to be specified for

various floor categories, the testing time limits, and the exact testing procedure (i.e. ASTM E-

1155) to be used. However, nowhere in ACI will be found any list of “approved” floor profile

testing devices.

Likewise, Paragraph 6 (“Apparatus”) of ASTM E-1155 establishes only minimal requirements for

the test device to be used. Indeed, it was the specific intention of the task group that developed E-

1155 (strongly encouraged by key members of ACI-117) that the user be given wide latitude in

selecting his test apparatus, so that neither ACI nor ASTM could ever be accused of collusion in

promoting sales of the Dipstick, which was, at that time, by far the most practical device available

for measuring F-Numbers. This ambition to allow a wide variety of test devices was (and still

remains) entirely consistent with ASTM’s long-standing policy mandating the use of any particular

proprietary product. Note 3 still clearly reflects that ambition:

Since the basis of the results to be obtained with this test method will vary directly with the accuracy

of the particular measurement device employed, all project participants should agree on the exact

test apparatus to be used prior to the application of this test method for contract specification

enforcement.

Though often misunderstood to be otherwise, ASTM’s mission has never involved the direct

acceptance and/or rejection of proprietary test equipment, and consequently, nowhere in ASTM will

be found any list of “approved” floor profile testing devices.

The D-Meter fully conforms to the Type II Apparatus requirements set forth in Paragraph 6.1.2 of

ASTM E-1155. As far as ASTM is concerned, this fact alone is sufficient to categorize the

D-Meter as an “acceptable device” for the measurement of FF and FL numbers in accordance

with that test procedure.

I hope this information helps to dispel any concerns regarding the D-Meter’s utility vis-a-vis ASTM

E- 1155. Of course, if any questions persist regarding this or any other issue, please do not hesitate

to call us at 224-699-9000. Thank you for your interest in the D-meter

Table of contents