Tempsens CALsys 1700 User manual

CALsys 1700

USER MANUAL

Temperature Calibrator

TEMPSENS INSTRUMENTS (l) PVT. LTD. U#ll

Thermal & Cable Solutions

1. General Instruction............................................................................................... 2

1.1 Information on operating instruction

1.2 Liability & warranty

1.3 Unpacking & initial inspection

2 Before you start.................................................................................................... 3

2.1 Safety information

2.2 Warning

2.3 Caution

3 Technical Data....................................................................................................... 4

3.1 Technical specification

3.2 Circuit diagram

4 Overview................................................................................................................ 5

4.1 Introduction

4.2 Outline description

5 Operating Instruction........................................................................................... 9

5.1 Power

5.2 Setting the temperature

5.3 Operating Instruction

6. Operation of Controller........................................................................................ 10

6.1 The Temperature Controller

6.2 Altering the set point

6.3 Monitoring the Controlling Status

6.4 Units

7 Maintenance & Trouble shooting........................................................................ 11

7.1 Maintenance

7.2 Troubleshooting

8 Software Installation........................................................................................... 12

8.1 Installation

8.2 Parameter in main screen

9 Safety Instruction................................................................................................ 14

Content

1.1 Information on operating instruction

Congratulations on your purchase of high-quality and efficient CALsys 1700 temperature calibrator.Read this

manual carefully to all instructions on safety, operation and maintenance. It serves as an important source of

information and reference for installation and operation of the device. The general safety requirements must be

strictly adhered to when operating the device. The fact contained especially safety are observed. If you experience

any further questions, please contact our technical support by phone or mail to

1.2 Liability and warranty

This instrument has been manufactured to exacting standards and is warranted for twelve months against electrical

breakdown or mechanical failure caused through defective material or workmanship, provided the failure is not the

result of misuse. In the event of failure covered by this warranty, the instrument must be returned, carriage paid, to

the supplier for examination and will be replaced or repaired at our option.

INTERFERENCE WITH OR FAILURE TO PROPERLY MAINTAIN THIS INSTRUMENT MAY INVALID THIS

WARRANTY.

1.3 Unpacking & Initial Inspection

Our packing department uses custom designed packaging to send out your unit, but as accidents can still happen in

transit, you are advised, after unpacking the unit, to inspect it for any sign of damage, and confirm that your delivery

is in accordance with the packing note. If you find any damage or find any part missing during delivery notify us and

the carrier immediately. If the unit is damaged you should keep the packing for possible insurance assessment.

After unpacking you will find following items.

Phone No.

0294-3052959

2

1. General Instruction

Calsys 1700 Heaters 4 Nos Software CD

Rs-232

B Type T/C Ceramic Block for Dry Block Ceramic Cavity for Black Body

3

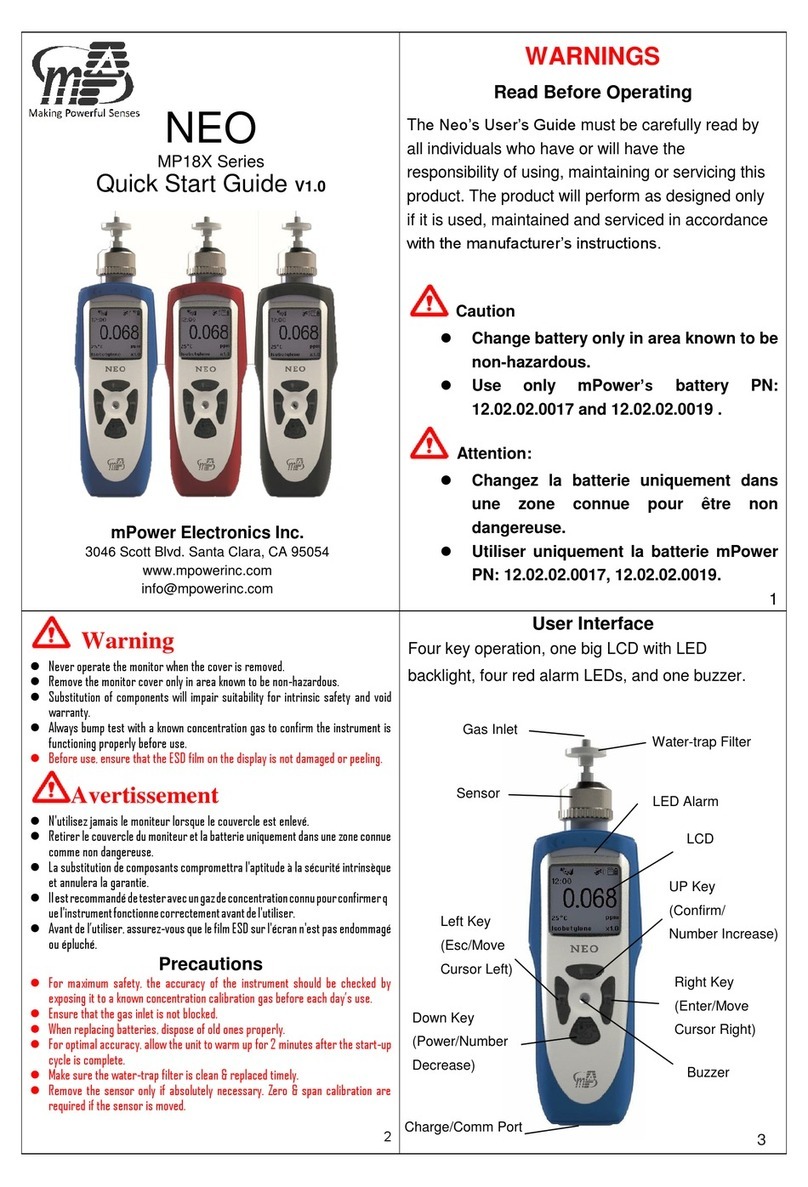

2.1 Safety Information

Use the instrument only as specified in this manual. Otherwise, the protection provided by the instrument may be

impaired. Refer to the safety information below and throughout the manual.

The following definitions apply to the terms “Warning” and “Caution”.

Ÿ“Warning” identifies conditions and actions that may pose hazards to the user.

Ÿ“Caution” identifies conditions and actions that may damage the instrument being used.

2.2 Warning

To avoid possible electric shock or personal injury, follow these guidelines.

ŸThis equipment must be correctly earthed.

ŸA protective earth is used to ensure the conductive parts can not become live in the event of a failure of the

insulation.

ŸThe protective conductor of the flexible mains cable which is colored green/yellow MUST be connected to a

suitable earth.

ŸWarning: Internal mains voltage hazard. Do not remove the panels.

ŸThere are no user serviceable parts inside. Contact us for repair.

ŸDo not use the apparatus outside its recommended range i.e., + 500 to 1700° C.

ŸEnsure inflammable materials, are kept away from hot parts of the apparatus, to prevent fire risk.

ŸBefore connecting to the electricity supply, please familiarize yourself with the parts of the calibrator with the

help of operating manual.

ŸBurn Hazard – Do not touch the target surface of the unit.

ŸAlways replace the fuse with one of the same rating, voltage and type.

ŸOverhead clearance is required. Do not place unit under a cabinet or other structure.

ŸDo not use this unit for any application other than calibration work.

ŸCompletely unattended high temperature operation is not recommended for safety reasons.

ŸCalibration Equipment should only be used by Trained Personnel.

ŸWear appropriate protective clothing.

2.3 Caution

To avoid possible damage to the instrument, follow these guidelines.

ŸComponents and heater lifetime can be shortened by continuous high temperature operation.

ŸDo not change the values of the calibration constants from the factory set values. The correct setting of these

parameters is important to the safety and proper operation of the calibrator.

[!] Warning :

DANGER !

The blackbody is only to be used as described in this manual. It is recommended that you only

use accessories provided by the manufacturer.

Power is present even if the front panel circuit breaker is in the OFF (0) position.

2. Before You Start

3.1 Technical Specification

Voltage : 230 V AC

Power : 3kw

Supply Frequency : 50/60 Hz

Temperature Range : 500 to 1700°C

Resolution : 0.1 °C

Stability : ± 2.0 °C

Controlling Sensor : B type T/C Duplex

Time to reach Max. Temperature : 3 hours

Operating Temperature : 20 to 45 °C

Controller Specifications : Eurotherm P104 series

Over temperature Protection : Autonics safety controller with B Type T/C

Stabilization Time : 15 to 20 Min.

Dimensions : 640(H) x 500(W) x 550(D) mm

Block/Cavity Aperture : 2X6.5, 2x8.5 mm with 140mm depth/Ceremic 29MM dia end

closed tube

Weight : Approx 80 kg

4

3. Technical Data

3.2 Circuit Diagram

N

P

E

R

F

Fan 230V AC

Transformer

Heater

B Type T/C

P: PHASE= RED WIRE

N: NEUTRAL = BLACK WIRE

E: EARTH =BLUE WIRE

N

P

MCB

ROCKER

SWITCH

Controller

Thyristor

1

2

3

4

56

P N

V+

V-

+

-

1A

1B

Communication Cable

RS-485

Convertor

Contector

N

P

Fuse

SF

RS-232

5

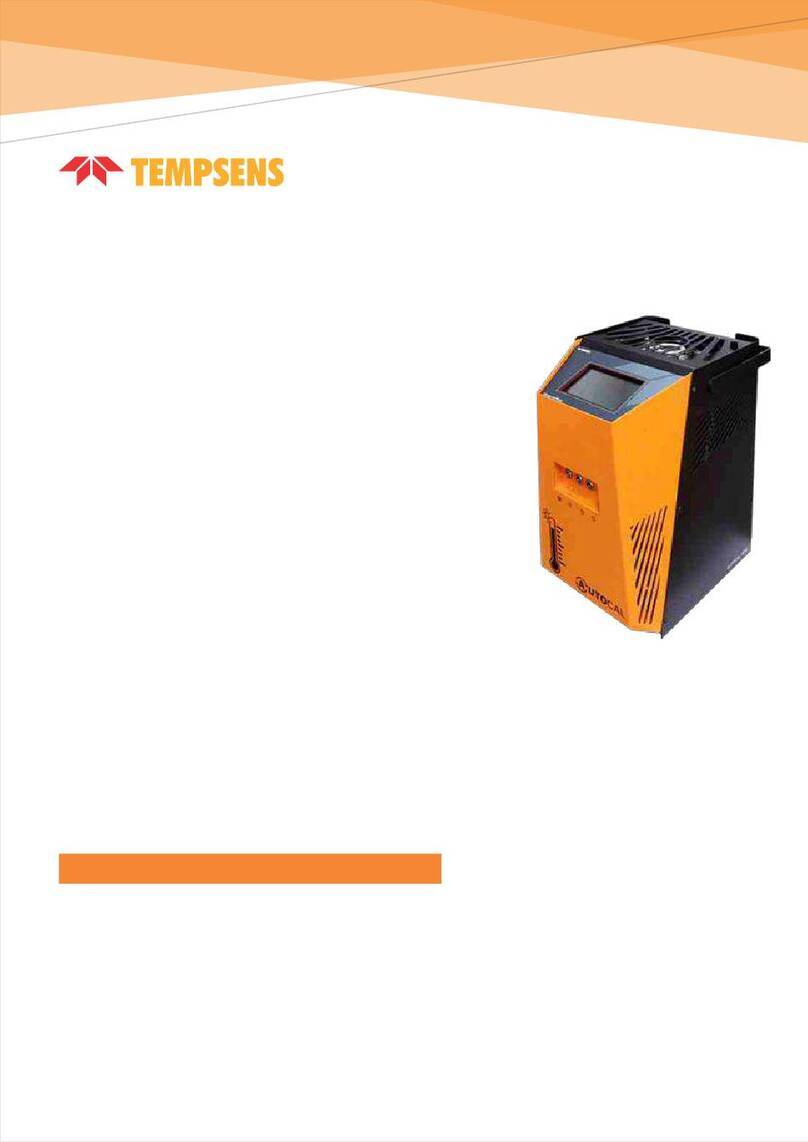

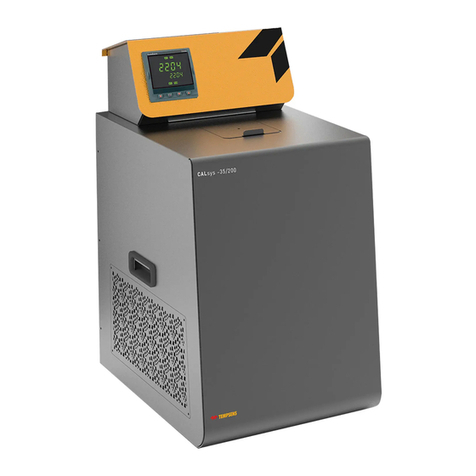

4.1 Introduction

The CALsys 1700 used as Dry block calibrator for thermocouple calibration and it can be used also as a pyrometer

calibration with ceramic cavity.

The 'CALsys 1700' has been designed to provide stable and accurate temperature to enable professionals to

calibrate Temperature Sensing Devices (Thermocouple & pyrometer) by comparison method up to a temperature

range of 1700°C. The 'CALsys 1700L' model has been designed to be rugged and easily maintained. This model

provides an isothermal enclosure (Ceramic block) in which the thermocouple can be calibrated against the

temperature of the calibrator.

The 'CALsys 1700BB' model has been designed in single part. This model provides an isothermal enclosure in

which the Non contact pyrometers can be checked against the temperature of the black body. For traceable

calibration a master pyrometer should be used. The units' features emissivity of 0.99, thus offering the closest

approximation of a target surface that is a perfect emitter of infrared energy.

4.2 Outline Description

'Calsys 1700 is a transportable unit designed for use on any reasonable flat surface. The target is a ridged Ceramic

Tube Cavity which is painted by a high emissive paint .The target is heated by MoSiO2 heaters which allows the

source to heat up to 1700°C in about 3Hrs and hold it stable at temperature within ±2.0°C. The heater blockhouses

consists a heater & the controller sensor. The temperature controller to sense the block temperature uses this

sensor. To obtain the maintain a required temperature the controller varies the power to the heaters via a power

control device.

[!] Warning : Do not insert impure materials, metal objects or probes etc. into the cavity.

4. Overview

Ceramic Block for 1700L Ceramic

Cavity for 1700BB

NOTE:

1. Ceramic block and ceramic cavity should be

removing at ambient temperature.

2. Use at a time block or ceramic cavity ( Not use both at

a time)

3. Fumes will appear initially for 3-4 times of CALsys

1700 operation.

4. Insertion of Ceramic cavity and ceramic block should

be such that it matches face to Face of inner SS

chamber for proper calibration.

4.3 Parts Details

(3) Strips of heating

element : This are aluminum

braided strips which are used

for making Series

connection.

(1) CALsys 1700 Housing :

This is the powder coated box

of CRCA

(2) Heating Chamber : This is

a SS chamber having ceramic

fiber board Insulation.

(4) Molybdenum di-silicate

heating element : The Moly-

D element is dense cermets

material consisting of

molybdenum di-silicate

(MoSi2) and glassy phase

silicon dioxide (SiO2).

6

(5) Element Mounting Metallic Holder : The Moly-D elements are hung vertically

and must be supported by the cold ends. This Metallic holder is used for same

purpose.

(6) All Accessories

RS-232 Cable

Cavity

Block

Sensor

Blots

Heating

Element

Wool

Hording Clamp Strips

(7) RS-232 cable : It is used for connect the controller to the PC. I tools (Download

from Eurotherm website) software is used for communicate the controller to PC and

CAL soft for graphical view and data logging of the CALsys 1700.

(8) Controlling Sensor Connection : Connect thermocouple wire to the controller terminal according to polarity.

(There is difference between main controller and safety controller reading, is not configured by others.)

Main Controller T/C Connection (1A+)

Connect at V+ & (1B-) Connect at V-

Safety Controller T/C Connection

(2A+) connect at 5 & (2B-) connect at 6

7

4.4 Installation of Calsys 1700

1) Unpack the furnace carefully

and inspect it for any damage

that may have occurred during

shipment. If there is shipping

damage, notify the carrier

immediately.

2) Open the front plate and back

sheet of CALsys 1700 and

remove all packing sheets from

inside.

3) Heating chamber of CALsys

1700.

4) heaters are inserted in holding clamp and then

heaters with clamp are inserted in heating

chamber.

holding clamp inserting in heaters holding clamp with heaters tight

with screw

Insert heaters in insulation board

as shown in figure (ceremic board)

Note : Heaters are very

fragile so please

assemble very - very

carefully and do not

apply more force on

heater and other

element but connection

should not be loosed.

5) Insertion of heating element in ceremic board.

Measure the height should be around 40mm from

insulation board.

Insertion of heating element 40 mm height after inserting

heating element

After insertion of heaters

Note : Heaters are very

fragile so please

assemble very- very

carefully and do not

apply more force on

heater and other

element but connection

should not be loosed.

6) After fixed all heaters connects the connection strips

(through nut and bolt with spanner). All four heaters

connected in series connection.

Connection strips connect

with heater

Connection strips connect in pair

of 3 heaters

remaining 2 heaters connect

individual strip

Note : The inner

chamber include open

connection strip placed

back side of main outer

body of furnace for

proper connection.

8

7) After connecting strips cover

ceramic board with insulation

wool for prevention heat loses.

8) Insert the Controlling Sensor in chamber till it

doesn't touch the ceramic tube. Controlling Sensor is

very fragile please insert it very carefully.Sensor

sholud be touch the ceramic tube otherwise deviation

will occur.

Insert controlling sensor here Insert sensor in the hole carefully

tight bolt with screw driver

Note : remember that

after inserting B type

sensor screw should

not be very tight and

sensor not insert before

insertion of heating

element otherwise

sensor will be damage.

9) After above all steps complete. The inner chamber

is Ready for installation in outer cabinate.

The inner chamber insert carefully from front side and

after this all four nut bolt tight shown as below.

fix the ss chamber into

outer cabinate

nut bolt tight

12) After this the transformer lead connect (through

nut and bolt with the help of spanner) in the open strip

from back side as per shown in Figure.

cable connect

with right open

strip in back side

cable connect

with left open

strip in back

side

13) Screw tight the cable with the strips . As shown in

figure.

10) Check the ss chamber proper fit in the outer

chamber.

14) After all Connection (Not Loose also not too much

given force to terminals ) the Back View of furnace is

Look As below.

Note : Once you heated 3-4 times then recheck all

heater connection of CALsys 1700 (there are no any

loose connection) to avoid any drops of voltage.

Re-fix the front panel and back with help of bolts

11) Connect B type sensor M & S terminal with safety

controller as shown in the Figure.

Sensor M Terminal

Sensor S Terminal

9

5. Operating Instruction

1

2

3 4 5 6

(6.1)"B" type duplex thermocouple

for controlling & over temperature

protection.

5.1 Power

Plug the black body power cord into a mains outlet of the proper voltage, frequency and current capability. Typically

this will be (230 VAC±10%, 50-60 Hz). Turn on the black body using "Mains" switch loacated at rear side. The black

body will turn on and begin to heat for previously programmed set point.

Note:

ŸAll other controller parameters are company set and locked. It is recommended not to change them.

ŸWhen the source is operated at any temperature above ambient, the front face and plate become hot.

5.2 Setting the Temperature

Press “UP” or “DOWN” buttons to change the change the temperature set-point value. When the set-point

temperature is changed the controller will switch the CALsys 1700 ON or OFF to raise or lower the temperature. The

displayed temperature will gradually change until it reaches the setpoint temperature. The temperature bath

requires 15 to 20 minutes to reach the set-point depending on the span. Another 10 to 15 minutes is required to

stabilize the temperature bath within ± 2.0ºC of the set-point.

[!] Warning : Do not connect or disconnect while power is on. Do not disconnect power when blackbody is

hot and fans are running.

5.3 Operating Instruction

ŸAfter the completely installation.

ŸConnect the 'CALsys 1700' to a suitable power supply. ON the Mains switch located at back side with power

entry.

ŸSet the desire temperature value in PID by using UP & Down key.

ŸAim the reference (Master) standard infrared temperature sensor to the target area.

ŸPV (Present value) display in controller will gradually rise until it reaches the set point temperature. The

controller takes some times to reach the set-point depending on the span. Furnace is stable when PV is equal to

SV (Set Value).

ŸMaster sensor take some times to reach the set point temperature and stable at temperature near about

controller set temperature.

ŸWhen temperature of the master and UUC (Unit under calibration) are stable record the readings of master

sensor.

ŸCompare the UUC reading with the master's reading & find out the error by comparison method.

ŸReset the controller and / or repeat the calibration for another calibration point or for another sensor.

ŸWhen the calibration is complete, reset the controller to 0°C & wait until the unit has cooled to below 100°C,

before moving the 'CALsys 1700 to new location the 'CALsys 1700' must be cooled below 100°C before it can

be put back into its carrying case.

ŸNOTE : Always use a reference IR thermometer for comparison calibration method.3

[!] Warning : Do not exceed the maximum temperature above 1700°C.

3. RS-232

4. Power Cable

5. MCB (for Heater)

6. FAN (Safety controller for over heating temperature.)

1. ON/OFF Switch

2. PID Controller

10

6. Operation of Controller

6.1 The Temperature Controller

The controller has a dual display, the upper display indicates the measured temperature, and the lower display

indicates the desired temperature or set point.

6.2 Altering the Set point

To change the set point of the controller use the UP and DOWN keys to raise and lower the set point to the required

value. The lower display changes to indicate the new set point.

6.3 Monitoring the Controller Status

A row indicate the controllers status as follows

OP1 Heat Output

REM This beacon indicates activity on the PC interface

ALM this indicates when PV (Present value) is more than 1700°C.

6.4 Units

Momentary pressing of the Scroll key will show the controller units °C or °F by using SCROLL key & UP & DOWN key

unit can be change.

IMPORTANT NOTICE

The controller's function settings are preset and will not require adjustment. Use only up & down key.

Front Panel Layout

Page Down UP Enter

Preset value of temperature

Set value of temperature

11

7. Maintenance & Trouble shooting

7.1 Maintenance

ŸThe calibration instrument has been designed with the utmost care. Ease of operation and simplicity of

maintenance have been a central theme in the product development. Therefore, with proper care the

instrument should require very little maintenance. Avoid operating the instrument in an oily, wet, dirty, or dusty

environment.

ŸIf the outside of the instrument becomes soiled, it may be wiped clean with a damp cloth and mild detergent. Do

not use harsh chemicals on the surface which may damage the paint.

ŸAvoid knocking or dropping the calibrator.

ŸIf the mains supply cord becomes damaged, replace it with a cord with the appropriate gauge wire for the

current of the instrument.

ŸDepending on the environment in which it is used, periodic cleaning is recommended. Cleaning may be

accomplished by the use of a small dry paint brush.

7.2 Trouble Shooting

1. Unit Fails to Operate

Check fuse if it is tripped switch is ON. If not power ON of calsys 1700 consult us.

2. Unit Unstable

Controller parameter has been interfered, consult us.

3. If the temperature of the calibrator is not rising

(a) The heating element may be open.

(b) The thermocouple may be open.

(c) The Thyristor may be not giving open.

(d) Transformer not giving open.

(e) The controller may not be giving output.

(f) The ambient temperature inside the chamber is raised and safety controller switched OFF the power.

Cautionary Note

Tempsens Products Are Intended For Use By Technically Trained And Competent Personnel Familiar With Good

Measurement Practices.

It Is Expected That Personnel Using This Equipment Will Be Competent With The Management Of Apparatus Which

May Be Powered Or Under Extremes Of Temperature, And Are Able To Appreciate The Hazards Which May Be

Associated With, And The Precautions To Be Taken With, Such Equipment.

12

8. Software Installation

The provided Tempsens software offers possibilities to connect furnace temperature bath and change set

point,maximum time span, view real time graph and evaluate measuring data.

8.1 Installation

Install the calibration software using the installation guide file on CD ROM. After installation of the software; Double

click the application. It willopen the screen of software.

8.2 Parameter in Main Screen

8.2.1 Communication

Communication between the furnace and the software is implemented via a RS-232 cable connected between the

furnace and the PC serial port. This enables the acquisition and recording of data, as well as the transfer of

commands from the software application to the tempsens furnace. Communication can be done by clicking on

connect and select correct COM port address (fig. 1) where furnace is connected. Also user has to select type of

controller version3216 (fig. 2). Then click on CONNECT button. Shown com2 connected successfully. Select 3216

version for P104.

13

8.2.2 Scale Trend

in scale trend you have to change the Y-Axis Min value 0 and Y-AxisMax value 1700.MaximumTime Span, Minutes

have to save data the data logging up to 120 minutes, than clickon start graph button. After complete the task clickon

save to file button.

Set Point (°C) : in which you can set temperature of furnace as your requirement.

PVI Value : Read the current PVvalue (present value of furnace temperature).

File will be stored in .xls formatto save previous recordopen the file by clicking on menu file open.

Safety Instructions:

Do's and don'ts -

Install the calibration software using the installation guide file on CD ROM. After installation of the software; Double

click the application. It willopen the screen of software.

ŸKeep swich off the power supply after swich off the furnace MCB.

ŸDon't touch surface chamber during furnace is ON causes over heating injury.

ŸDon't remove power plug during furnace is ON.

ŸKeep swich off red button at front of furnace after use.

ŸKeep down the furnace temperature at ambient after use then switch off the furnace.

ŸAfter open the furnace keep place cavity and furnace parts safely.

ŸDon't open the furnace chamber during furnace is ON.

ŸIn case of any trouble please contact our contact person.

Information

Packing Instruction

To transport or store the instrument, please use the original box or a box padded with sufficient shock absorbing

material. For storage in humid areas or shipment overseas, the device should be placed in welded foil ( ideally along

with silicon gel) to protect it from humidity.

Warranty

TEMPSENS CALsys 1700 instrument have a warranty of one year from the invoice date. This warranty covers

manufacturing defects. User induced faults are not covered under this warranty.

Limit of Liability

TEMPSENS not liable for any damages that arise from the use of any examples or processes mentioned in this

Specifications are subject to change without notice

Copyright@ 2009, TEMPSENS all right

This document may contain proprietary information and shall be respected as a proprietary document to

TEMPSENS with permission for review and usage given only to the rightful owner of the equipment with which this

document is associated.

TEMPSENS reserves the right to make changes, without further notice, to any product herein to improve

reliability, function, or design . TEMPSENS does not assume any liability arising out of the application or use of any

product described herein, neither does it convey any license under its patent right nor the right of others.

Copyright@2009

14

www.tempsens.com

ABOUT US

Tempsens Instruments (l) Pvt. Ltd.

Tempsens Instruments (I) Pvt. Ltd. is a part of Pyrotech Group which was established by four technocrats in 1976 at

Udaipur, with their first product as Thermocouples and RTDs. Today ‘Tempsens’ is one of the largest manufacturers of

Temperature Sensors in India.

Tempsens Instruments (I) Pvt. Ltd. U # II was started in 2009 to produce cables with high standard of manufacturing

process conforming to national & international specifications. We manufacturer wide range of cables for Temperature

sensors and Instrumentation in various insulations as PTFE, FEP/PFA, Kapton, Silicon, Fiber Glass, Ceramic Fiber,

Refrasil/Nextel, PVC etc. in variety of configurations. These cables are available in temperature range -60°C to 1200°C.

All our products are manufactured under strict ISO-9001 quality management system. We also provide Calibration

Certificates with all cables. We stock most types of cables which enable us for fast delivery of goods. Our engineering staff

are capable to custom design solutions for all applications for customers.

We are dedicated to provide the highest quality products that meet our customer's specifications for various

applications.

We continuously focus on improving our manufacturing processes and competitiveness in the industry

TEMPSENS INSTRUMENTS (l) PVT. LTD. U#ll

Other manuals for CALsys 1700

1

Table of contents

Other Tempsens Measuring Instrument manuals

Tempsens

Tempsens CALsys 1500 User manual

Tempsens

Tempsens CALsys-15/110 Autocal User manual

Tempsens

Tempsens CALsys -35/200 User manual

Tempsens

Tempsens CALsys 250 User manual

Tempsens

Tempsens CALsys 1200 User manual

Tempsens

Tempsens CALsys 1500 L User manual

Tempsens

Tempsens CALSYS 650 User manual

Tempsens

Tempsens CALsys 1500 BB User manual