allen HP205 Application guide

Other allen Trowel manuals

allen

allen HDX780 Guide

allen

allen Hydra-Drive Extreme Series Guide

allen

allen PRO WALK-BEHIND User manual

allen

allen MSP455 Guide

allen

allen HDX605 Guide

allen

allen PRO WALK-BEHIND Application guide

allen

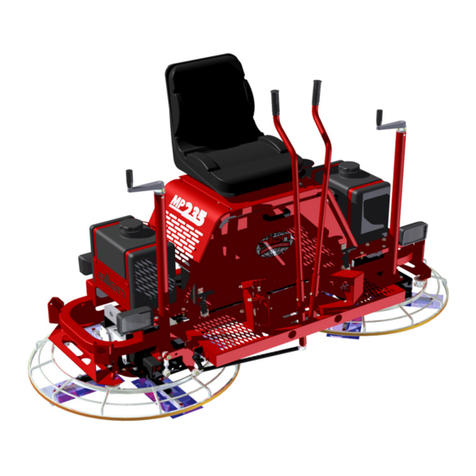

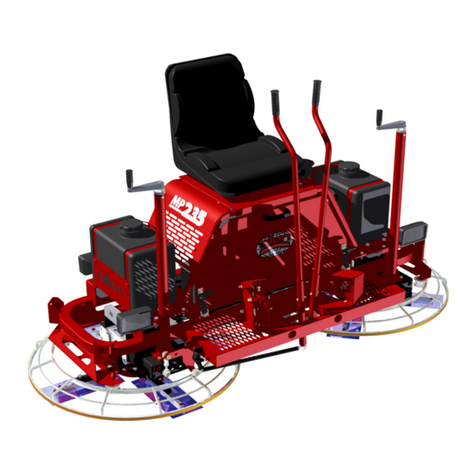

allen MP245 Guide

allen

allen HDX Series Application guide

allen

allen HDX750 Application guide

allen

allen PRO 430 Application guide

Popular Trowel manuals by other brands

Wacker Neuson

Wacker Neuson CT 36-400E Operator's manual

MULTIQUIP

MULTIQUIP BH11C Supplemental operating instructions

Atlas Copco

Atlas Copco BG 240 E Safety and operating instructions

MULTIQUIP

MULTIQUIP Whiteman STXD6i Operation manual

MQ Multiquip

MQ Multiquip JS36/30H55DE Series Operation and parts manual

swepac

swepac TR 600P user manual

MULTIQUIP

MULTIQUIP Whiteman HHNG5 parts manual

Wacker Neuson

Wacker Neuson CT 36 Operator's manual

Marshalltown

Marshalltown Speed Striker STRIKE45-L instructions

MULTIQUIP

MULTIQUIP CA4HM Operation manual

MULTIQUIP

MULTIQUIP Whiteman HTXD6i parts manual

Wacker Neuson

Wacker Neuson CRT 48-31V Operator's manual