Allfett ALL-5 DC Reference manual

This manual suits for next models

12

Other Allfett Water Pump manuals

Allfett

Allfett ALL-600 Reference manual

Allfett

Allfett Multi Line ALL-25 Series Reference manual

Allfett

Allfett ALL-6 Instruction Manual

Allfett

Allfett ALL-5 AC Reference manual

Allfett

Allfett ALL-5 Two Line Reference manual

Allfett

Allfett ALL-5 Two Line Reference manual

Allfett

Allfett ALL-1 PS User manual

Allfett

Allfett Multi Line ALL-10 Series Reference manual

Allfett

Allfett LUBMATIC MINI Series Reference manual

Allfett

Allfett ALL-1 Reference manual

Popular Water Pump manuals by other brands

Ingersoll-Rand

Ingersoll-Rand NM2304B-X-X Operator's manual

Stairs

Stairs HBI Service manual

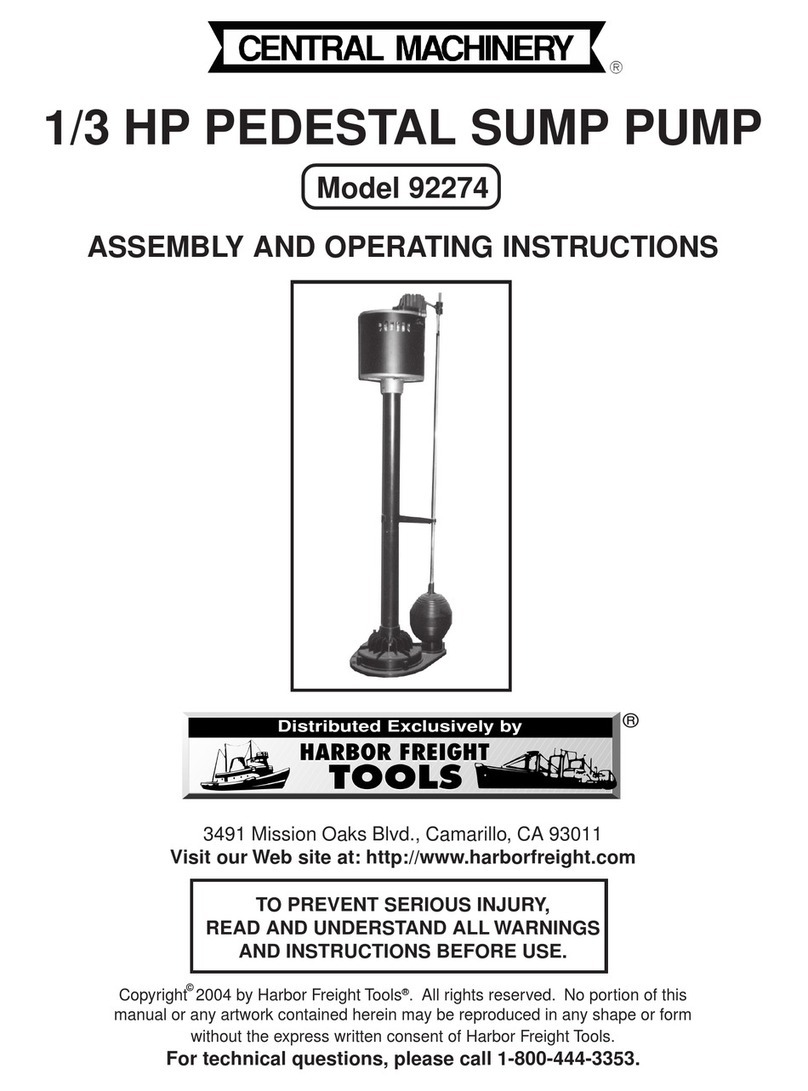

Central Machinery

Central Machinery CENTRAL MACHINERY 92274 Assembly and operating instructions

ARO

ARO ARO PH10A Series Operator's manual

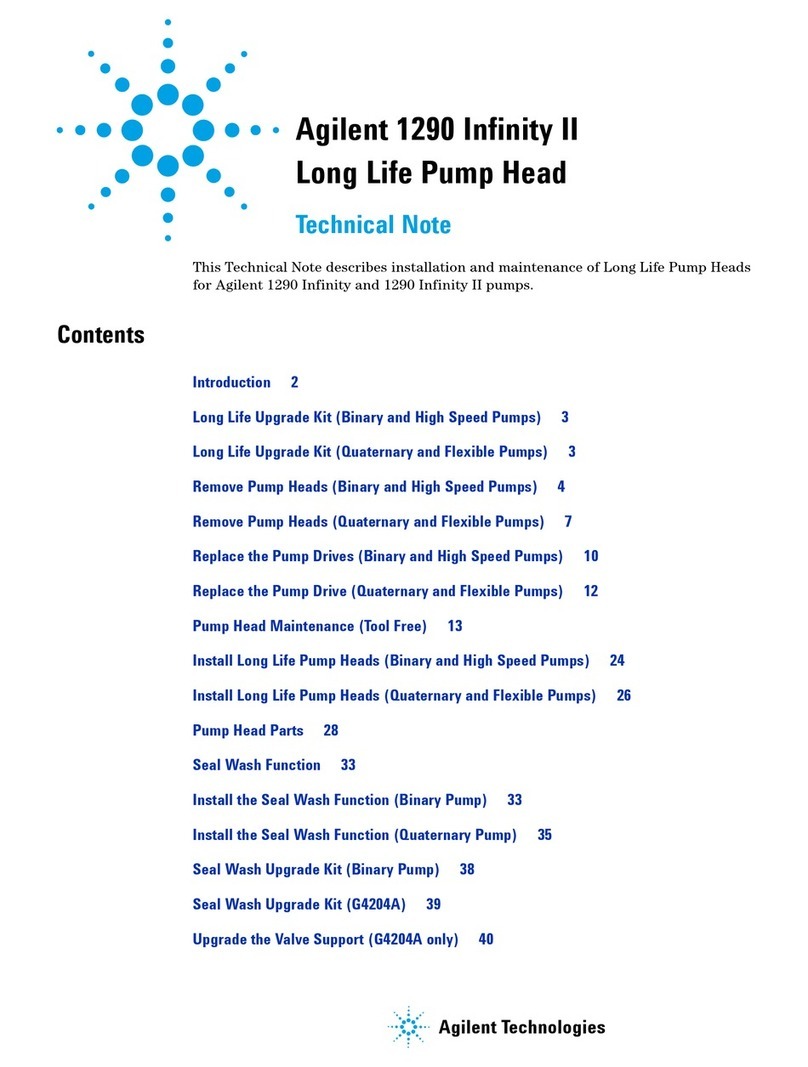

Agilent Technologies

Agilent Technologies 1290 Infinity II Technical note

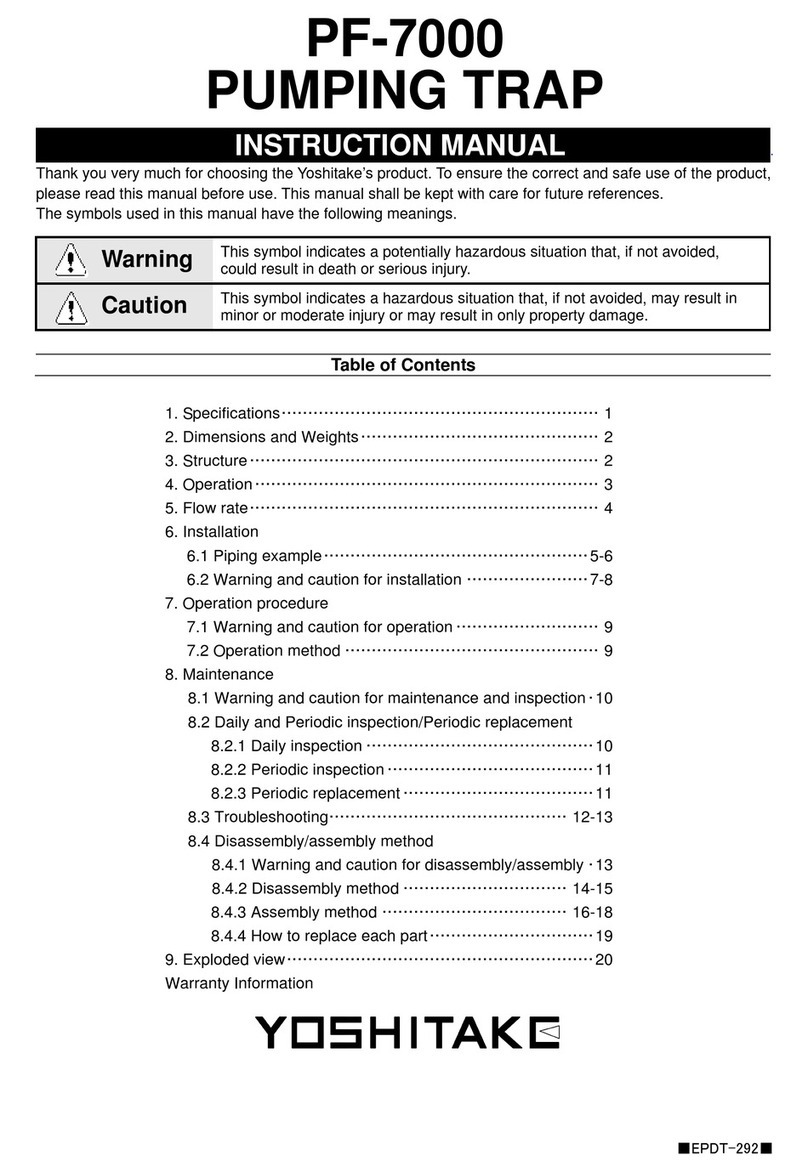

Yoshitake

Yoshitake PF-7000 instruction manual

Oase

Oase Neptun 1600 Warranty, safety and operating instructions

Speck

Speck P30 quick start guide

Hyundai power products

Hyundai power products HY50-A-1 Original instructions

Oase

Oase ProMax Garden Automatic 3500 operating instructions

MYERS

MYERS HJ Installation & service manual

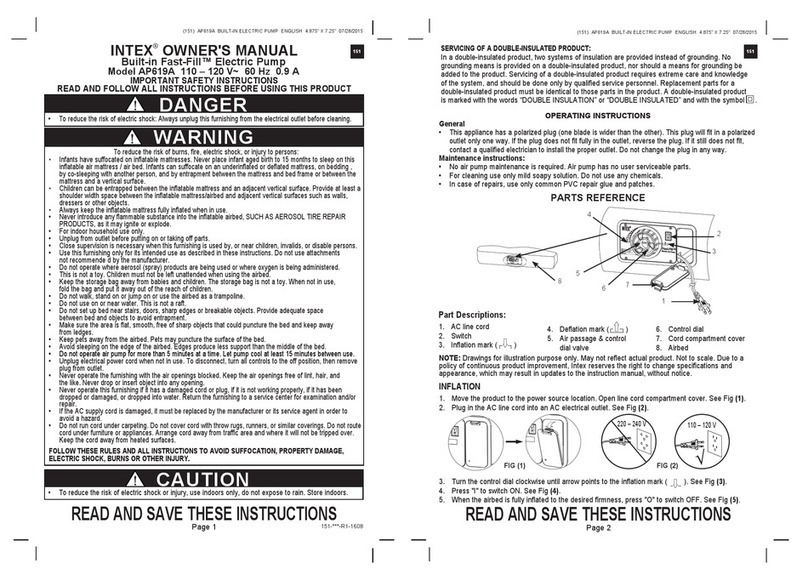

Intex

Intex AP619A owner's manual

Pfeiffer Vacuum

Pfeiffer Vacuum OKTA 1000 ATEX operating instructions

Acqua Brevetti

Acqua Brevetti MiniDUE FILTRO USE AND MAINTENANCE INSTRUCTION MANUAL ASSEMBLY AND INSTALLATION MANUAL

vacuubrand

vacuubrand RE 9 Instructions for repair

SATA

SATA HKU 60 operating instructions

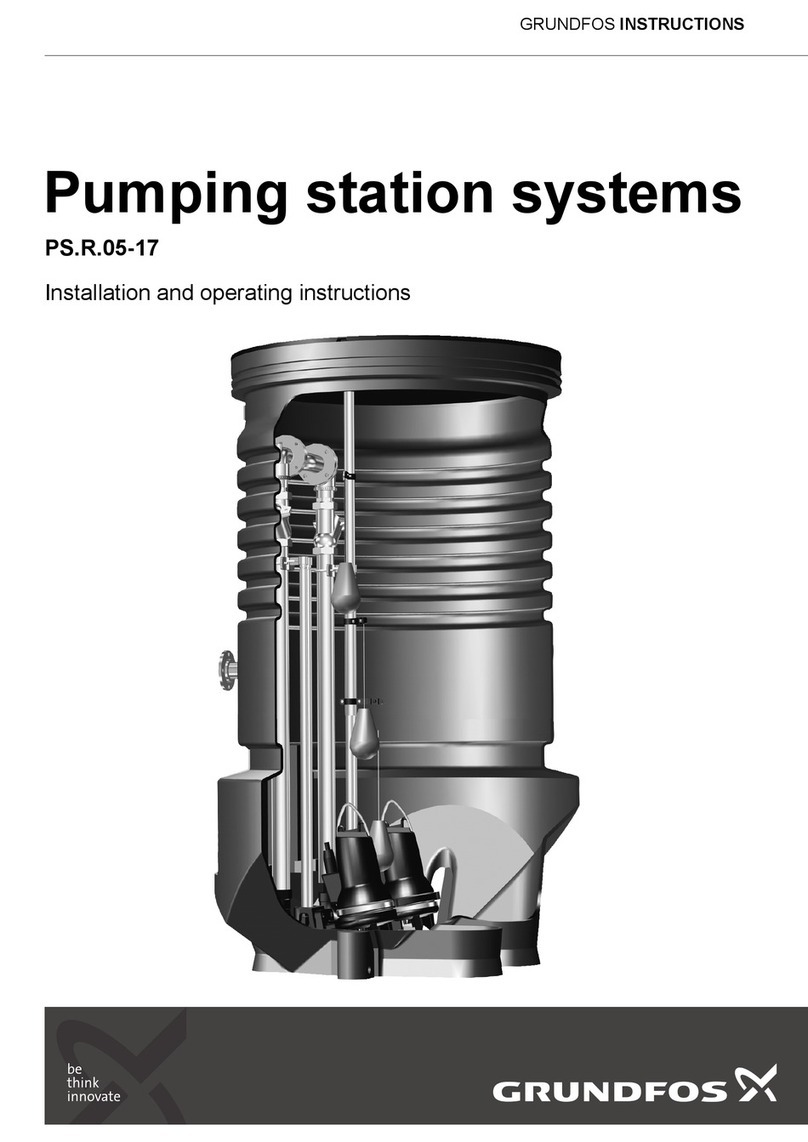

Grundfos

Grundfos PS.R.05-17 Installation and operating instructions

Dover

Dover PSG MOUVEX A65 Installation operation & maintenance