PAGE 11

www.allfett.net

RULES TO COMPLY WHILE USING AND WARRANTY CONDITIONS

Any foreign materials, dirt or small particules lead to system units failing and possibly property damage

to equipments. Damages or faults occur from this reason DISQUALIFIES THE WARANTY.

13.

Lubricant will be used in the system must certainly be clean and any foreign materials must not enter

while changing grease bucket or barrel.

12.

Rubber based lubricant types must not be used in the system. Damages or faults occur from this reason

DISQUALIFIES THE WARANTY.

11.

Only LITHIUM based and EP additive lubricants must be used with in system.10.

Only proper NLGI class lubricants must be used with in system. NLGI class must be changed according

to weather conditions. Use NLGI 0 for cold weather, increase the NLGI class up to 3 towards hot weathers.

9.

8. Transformer is necessary if there is no 24 V DC electrical source. Use minimum 30A current transformer.

Keeping an uncovered cable(s) during system assembly may cause fatal damages where high voltage

is transformed to low voltage. Lines must be connected properly to prevent personal injury and damage

to property.

7.

Damages coming from voltage fluctuation, wrong electricity installation, connecting wrong voltage to

product DISQUALIFIES THE WARANTY.

6.

All electrical connections and lines must be checked regularly for damage and to ensure that they are

firmly in place.

5.

Pumps have an electric driven motor. Electrical lines must be connected properly by qualified and instructed

personel.

4.

3. Washing of the pump with pressured water causes damage. Any damage occur from this reason

DISQUALIFIES THE WARANTY.

2. Pumps are produced to lubrication purpose only and are not convenient to work more than 2 hours

continuously. Working under maximum pressure more than 2 hours will harm the system. Damages occur

from this reason DISQUALIFIES THE WARANTY.

1. Damages occur while additional transports after delivering the goods from ALLFETT to the customer

DISQUALIFIES THE WARANTY.

ALLFETT Mekanik ve Elektronik Sistemler SAN. TIC. LTD. STI and ALLFETT Pazarlama ve Dis Ticaret LTD.

STI. does not accept responsibility for damages described in items above on equipments which ALLFETT

systems are installed.

17.

Unouthorized modifications to the units and the use of unouthorized spare parts and aids prohobited

and DISQUALIFIES THE WARANTY. Only maintenance may apply descibed in PAGE 14 - 15. ALLFETT

Technical Service must be informed to any other possible troubles and necessary procedures must be

performed.

16.

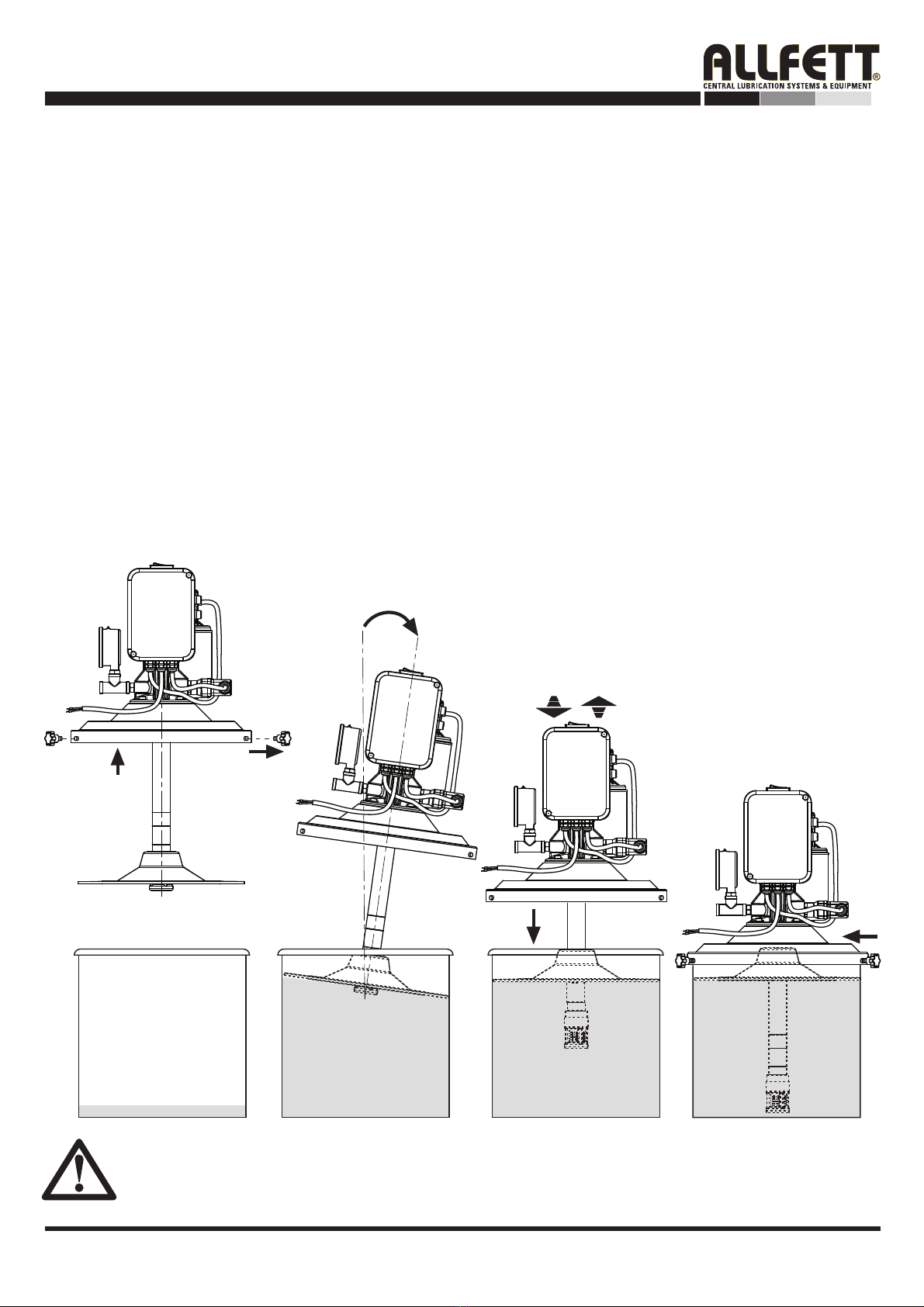

Another goal of Centralized Lubrication Systems is to protect environment. So it is adviced to fill grease

to the systems by mobile or hand pumps.

15.

Disassembling or loosing any part while pump working is prohibited. Any damage coming from this

reason DISQUALIFIES THE WARANTY. Also any personal injury occur from this reason ALLFETT does

not accept responsibility.

14.