4

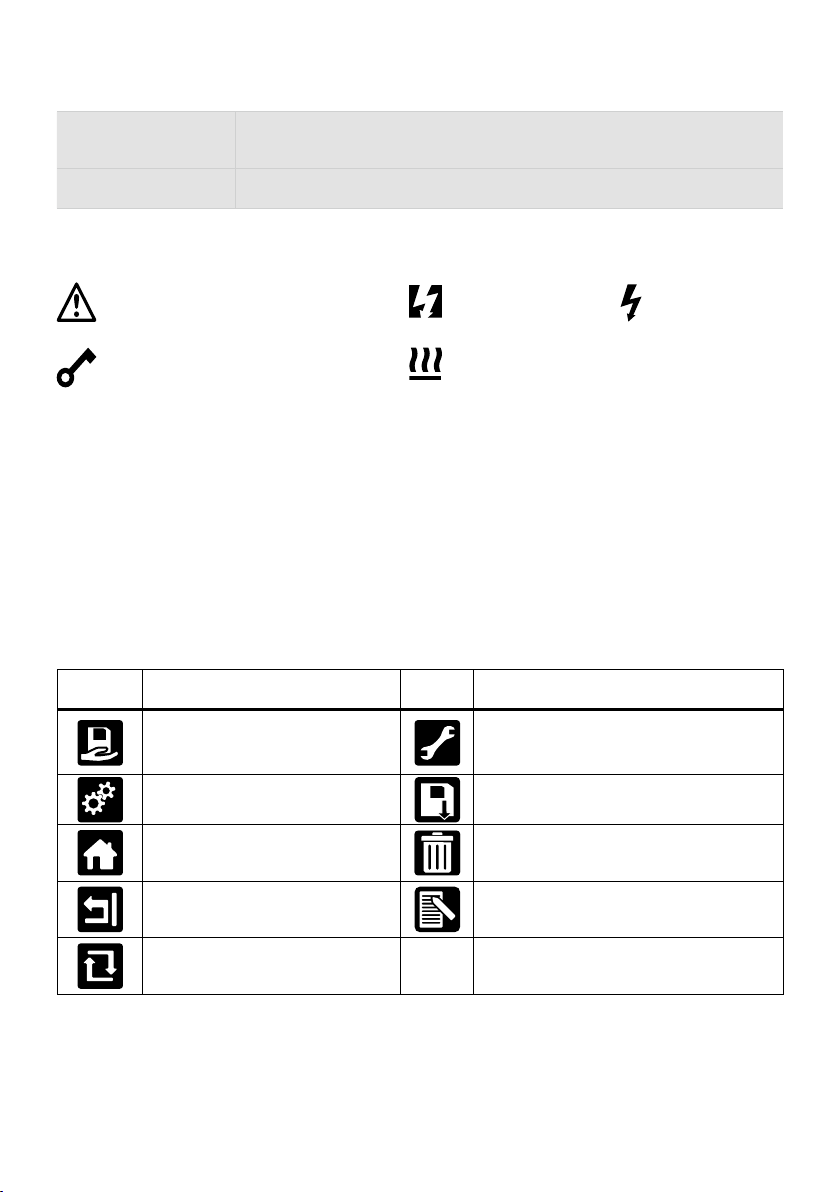

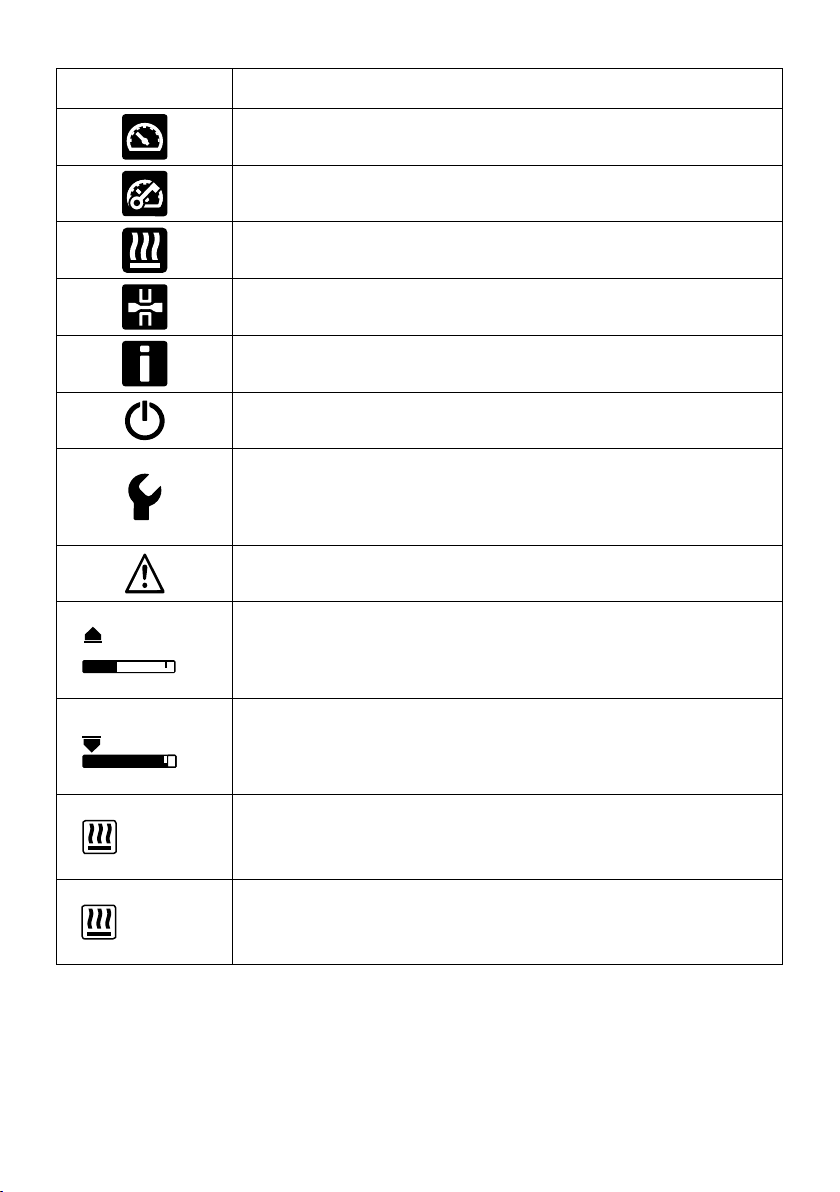

Danger to life

There is a danger to life from electric shock due to electrical voltage. The hot

wedge welding machine must therefore only be connected to sockets and

extension cables with a protective earth conductor. Protect the hot wedge welding

machine from moisture and wet conditions. Before switching on, check the power

cord, the plug, and the extension cable for electrical and mechanical damage.

The hot wedge welding machine may only be opened by instructed, qualified

personnel.

Danger of fire and explosion

The hot wedge welding machine can become an ignition source for fire and

explosion. It must therefore not be used near explosive gases or flammable

materials To avoid burning of the material to be welded, please read the material

safety data sheet from the material manufacturer. The hot wedge welding machi-

ne must only be used in the open or in a well-ventilated area.

2. Important safety instructions

Risk of burning

Do not touch the hot wedge when hot. The device should always first be allowed

to cool down.

Do not touch moving parts

There is a risk of inadvertently becoming caught and being pulled in. Do not wear

loose articles of clothing such as scarves or shawls. Tie up long hair or protect it

by wearing headgear.

If the device is being used on construction sites, a fault current circuit breaker

must be used to protect site personnel.

When welding, be aware of hazards in the surrounding area, e.g., risk of tripping,

risk of slipping, strong sunlight, unattended equipment, etc.

The device may only be operated under supervision as waste heat can reach

flammable materials.

The device should only be operated by trained specialists or under their super-

vision. Children are not permitted to operate the device.

The local supply voltage must match the line voltage specified on the device. If

the line voltage fails, switch o the main switch and place the welding machine

in the park position.

Warning

Caution