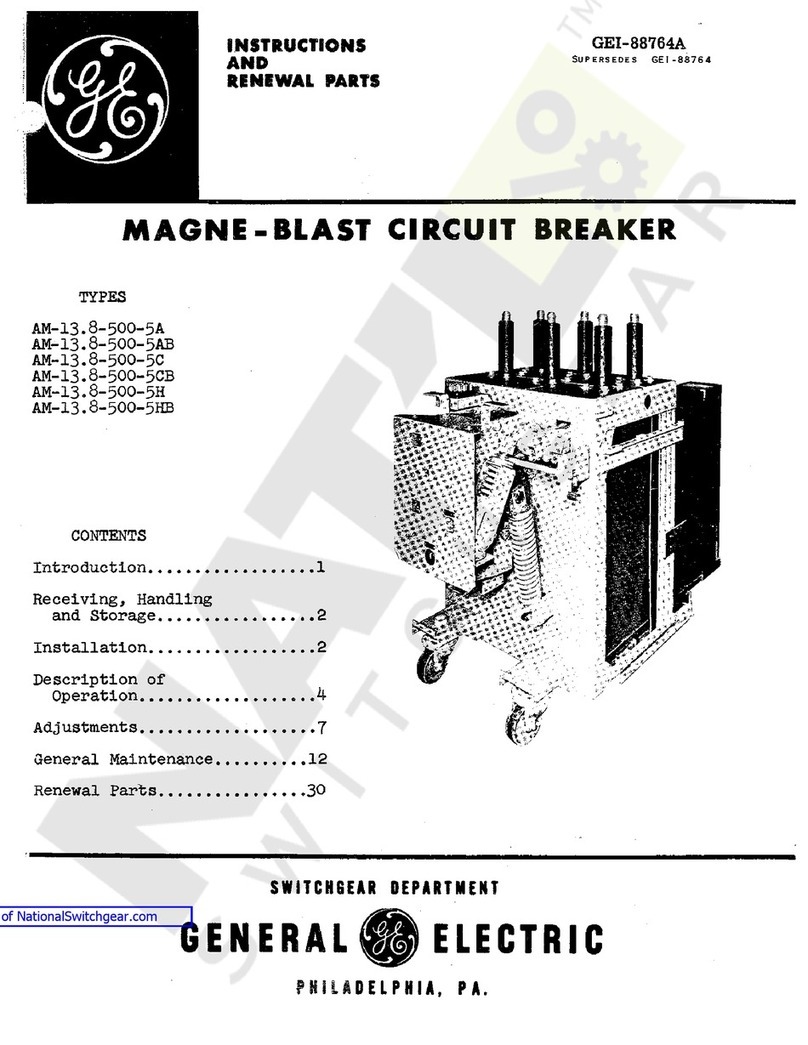

Power

Circuit

Breakers

CONTENTS

Description

P~ge

".........,.

•

.......,,,..,_,_~-··----·...,.-~,

..

~~

........

~··---~·~~~=""-"'•r.•·•"'"~~,.-""",,_,,_...,._,,,~

-.-..~.,~-~-

..._

~-._

...

,

..

•»k·=•~»

.•,,,

...

·'

--~="~·=··~-

SE

CT~Ot~

·1

~

....

,

Reciii~h1~~1g~

and Storage

,, ,,

..

,.

.

..

. .

.:J

SECTION 2

~

lnstalhi·Uon

................

3

Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

........

3

Stationary Breakers (God9

S)

......................

3

Draw Out Breakers (Code

D)

.......................

3

Breaker Insertion

...........................

.4

Breaker Removal

...........................

.4

SECTION 3 -

Operation

.................

5

Electrical Operation

.............................

5

Manual Operation

...............................

6

Connections

...................................

6

Control Connections

.........................

6

SECTION 4 -

Maintenance

..............

8

Inspection

.....................................

8

Separation

of

Front and Back Frame

................

8

Lubrication

....................................

8

Troubleshooting

................................

9

SECTION 5 -

Basic

Breaker

Components

.............

10

Disconnects

..................................

10

Primary Disconnects

........................

1O

Secondary Disconnects

......................

1O

Replacement of Movable Secondary

Disconnects

...........................

10

Arc Quencher

.................................

11

Replacement

..............................

11

BreakerContactStructure

.......................

11

Contact Adjustments

............................

11

Contact Replacement

...........................

12

General Preparation

........................

12

Removal

of

Movable Contacts

.................

12

Removal of StationaryContacts

...............

12

Replacement of StationaryContacts

............

12

Replacement

of

Movable Contacts

.............

14

Contact Springs

............................

14

Mechanism

...................................

14

Adjustment

................................

15

Latch Adjustment

...........................

16

Mechanism Replacement

....................

16

Removal of Front Escutcheon of

Manual Breakers

.......................

16

Auxiliary Switch

................................

16

Replacement

..............................

17

2 ©

1984

General Electric Company

.i?!!S~~-iJ~ti?!!_.

___

~--,,·--···-·

--

..

-~·

--

..

···-----·-~~ge

SECT;ON 6

~-

Electrica.1

Replacernent

Ccm·troi

Components

..

1?

Glo5ing Solenoid

...............................

11

Coil Fl:aplacement . . . . . . . . . . . . . .

..

. . . .i 7

"K"Reiay

....................................

17

"E"

Relay

....................................

i 7

Reµiacernerri

..............................

·1

7

Cut-off Switch

.................................

17

Replacement -

..............................

18

Closing Switch

................................

18

Replacement

..............................

18

ShuntTrip Device

..............................

19

Replacement

..............................

20

Adjustment

................................

20

SECTION 7 -

Protective

Devices

.....

21

Undervoltage Device

...........................

21

Adjustment

................................

21

Static Time-Delay Undervoltage

...................

22

Electric Lockout Device

.........................

22

Bell Alarm Switch and/or Lockout Attachments

.......

23

Operation

.................................

23

Open Fuse Lockout Device (OFLO)

................

24

Operation

.................................

24

Adjustments

...............................

24

Replacement

..............................

24

Draw

Out

Interlocks

............................

25

SECTION 8 - MicroVersaTrip®

Trip

Device

...............

26

Programmer Unit

..............................

26

Fault Trip Indicators

.............................

27

Remote Fault Indication

.........................

27

MicroVersaTrip Installation

.......................

28

Current Sensors

...............................

28

Replacement

..............................

28

Flux Shift Trip Device

...........................

28

Troubleshooting

...............................

29

Resistance Values

..........................

29

False Tripping -Breakers Equipped with

Ground Fault

...........................

30

SECTION 9 -

Electrical

Characteristics

..........

35

SECTION 10-

Renewal

Parts

.........

38

JI·

I

i

!

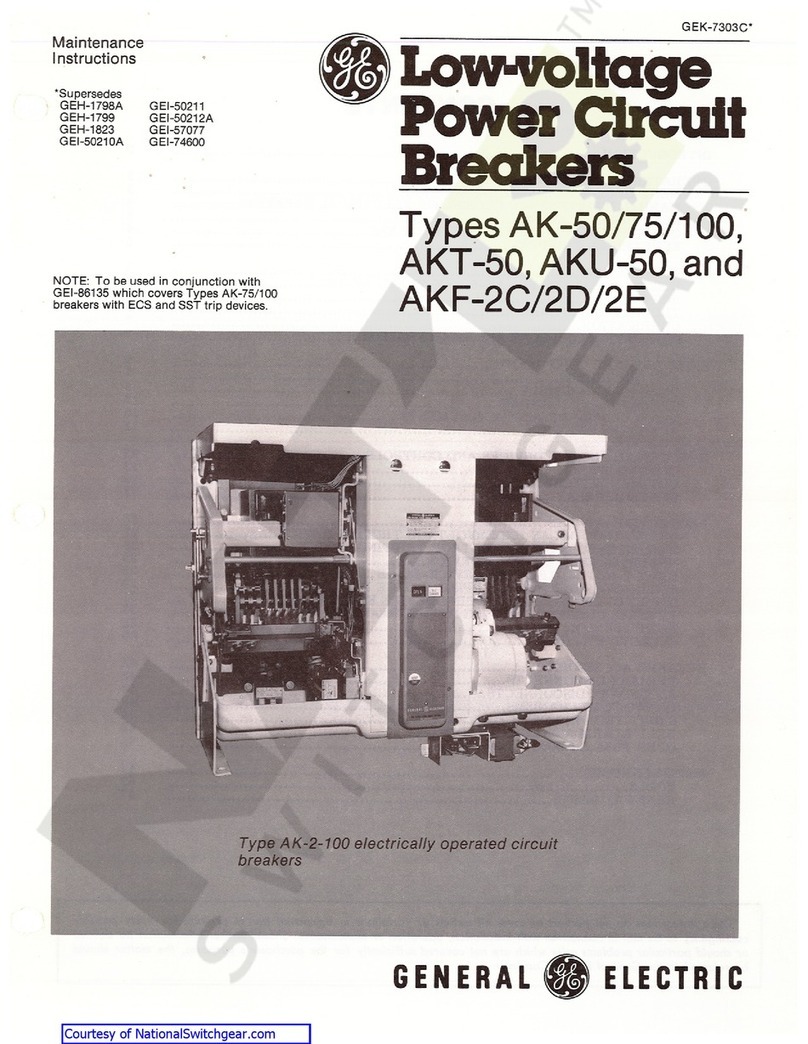

NOTE: Before installing

or

operating these circuit

breakers, carefullyread Sections

1,

2,

and

3.

SECT~ON

1 -

Receh1ing~

Handling~

and

Storage

Upon

H:-Geipt

uf

a circuit brei:iker, immediatelyexamine for

any

dwnage

01·

loss susiained

in

shipment. Hinjury, loss, or

rough handling is evident,

rne

n damage claim at once with the

transportation company and notity tho nearest General Electric

Sales Office.

Unpack

the circuit breaker as soon as possible after it has

been received. Exercise care in unpacking to avoid

damage

to

the breaker parts. Be sure that no loose

pa~t_s

are missing

or

left

SECTION

2 -

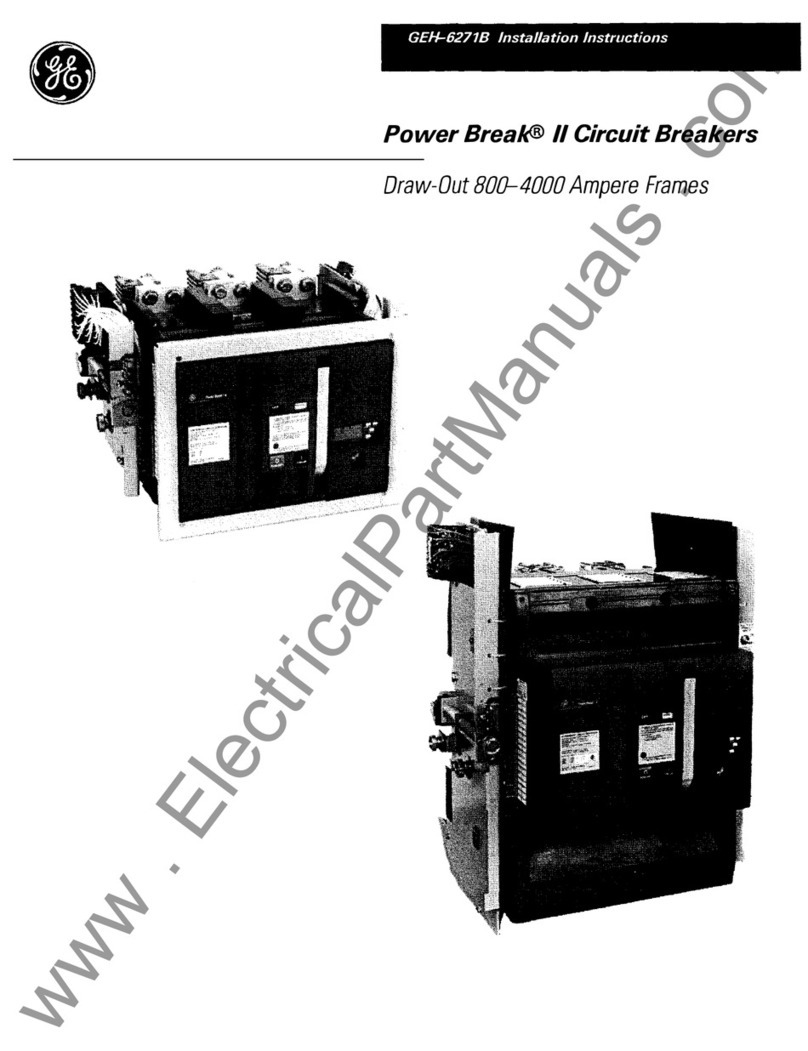

Installation

Location

In choosing a location forthe installation

of

these breakers

there are two factors to be considered. The first isthe location's

environmental impact on the breaker. Betterperformance and

longer life can be expected if the area is clean, dry, dust-free,

and well ventilated.

The

second is convenience for operation

and maintenance. The breaker should be easily accessible to

the operator and there should besufficient space available for

maintenance work.

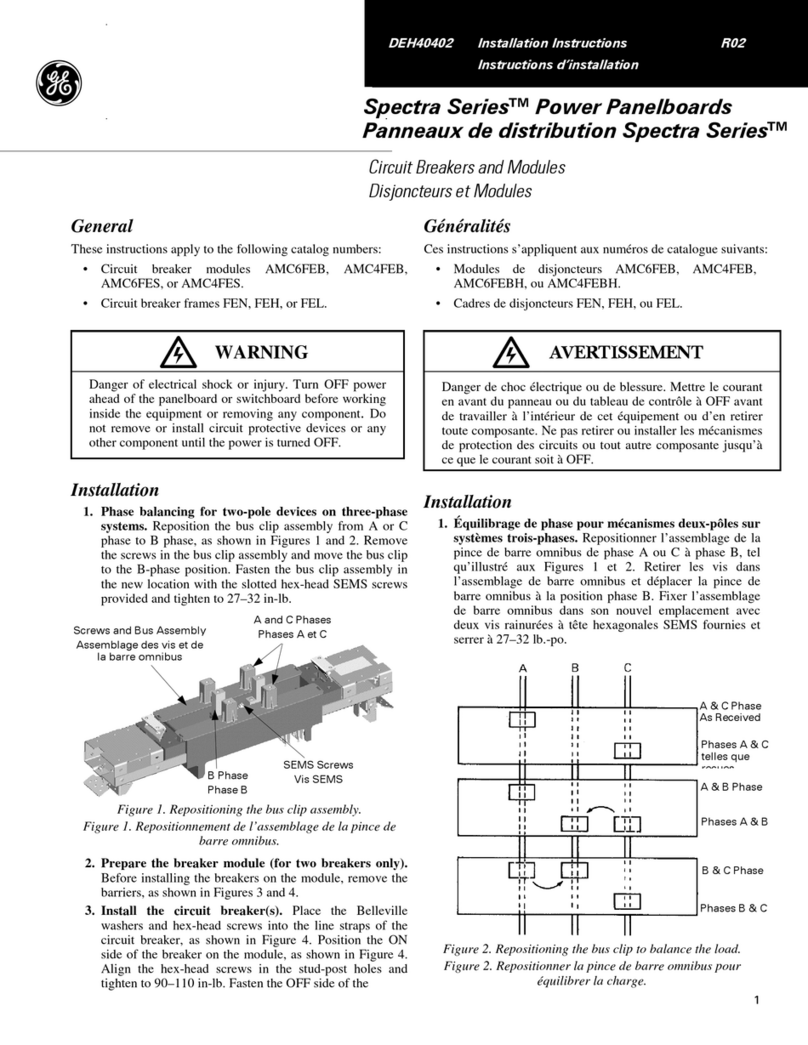

Stationary

Breaker$

(Code

S)

These breakers are designed for mounting in a switchboard

or

enclosure designed and constructed byothers. Mounting

consists

of

bolting the breaker frame to a supporting structure

within the switchboard

or

enclosure, connecting the power

buses

or

cables, and making any necessarycontrol

connections. The front cover of the breaker enclosure may be a

hinged dooror a plate bolted to the panel, including a cutout

opening through which

the

front escutcheon

of

the breaker can

protrude.

The surface on which the breaker is mounted must be flat to

avoid internal distortion

of

the breaker. The supporting structure

must be rigid enough to avoid any possibility

of

the breaker

studs supporting the weight

of

the breaker. Minimum cutout

dimensions as given by the appropriate outline drawing must be

maintained to provide adequate electrical clearance.

Connecting bus and cables

must

be rigidly supported to prevent

unduestress on the breaker terminals.

ir1

!he

µ<:1c~.i:l.ying

material. Biow

cut

any

din

or

ioosa

particies

of

packaging materiai remaininq on or in

Hm

breakec

ii

Hie ci1cui!

breaker

is nut to be placed in service at once,

store it in a clean,

dry

location in an upright position.

Support

it

to prevent bendiny of the studs or damage to any

of

the breaker

parts. Do not coverthe-breaker with packing

or

other material

which absorbs moisture that maycause corrosion

of

breaker

parts. A covering of kraft or othernon-absorbent paper will

prevent dustfrom settling on the breaker.

The outline drawings in Table 1 provide basic dimensional

information for designing the panel or enclosure mounting.

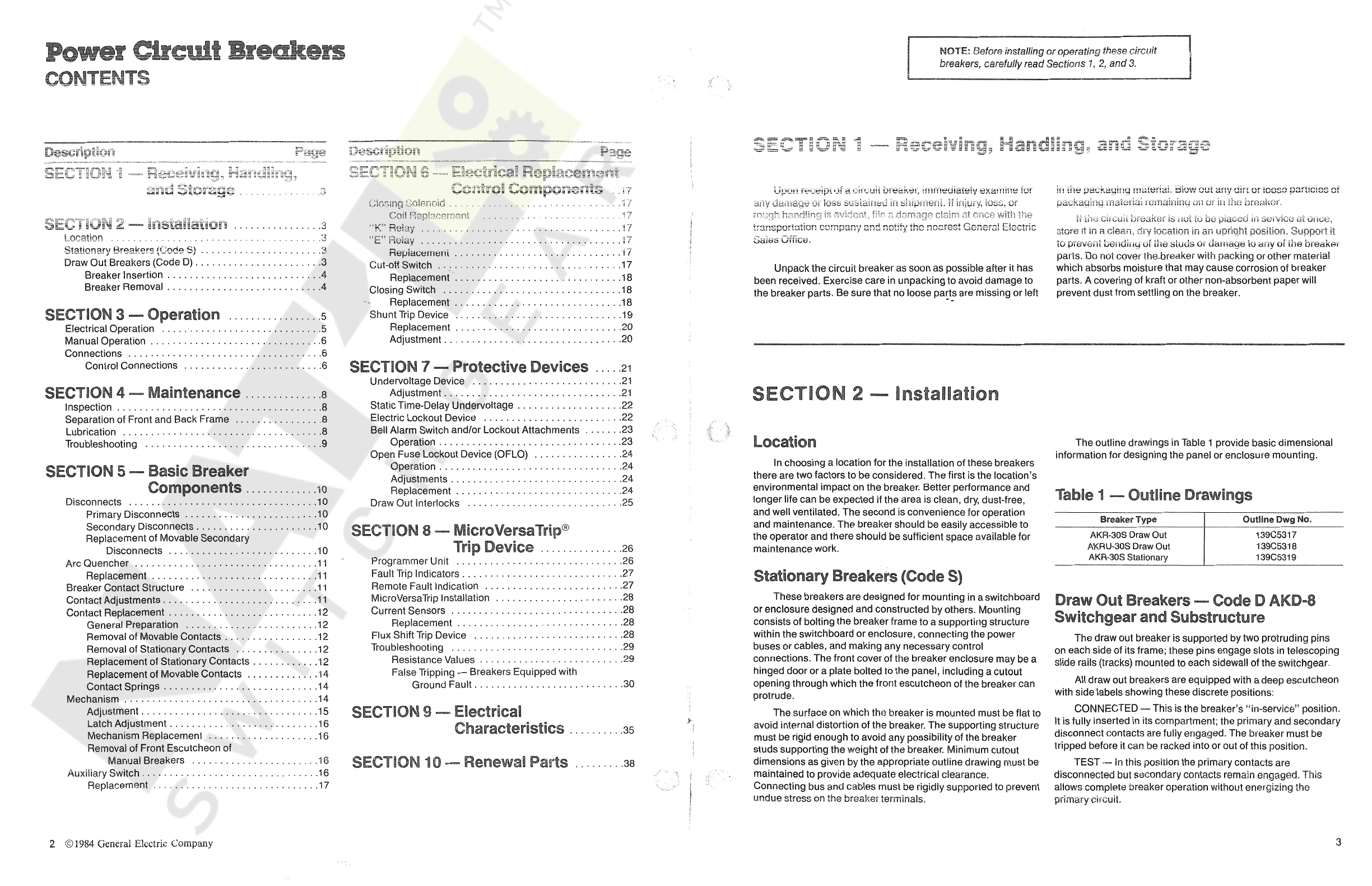

Table 1 -

Outline

Drawings

Breaker Type

AKR-30S Draw Out

AKRU-30S Draw Out

AKR-30S Stationary

Outline

Dwg

No.

139C5317

139C5318

139C5319

Draw

Out

Breakers

-

Code

D

AKD-8

Switchgear

and

Substructure

The

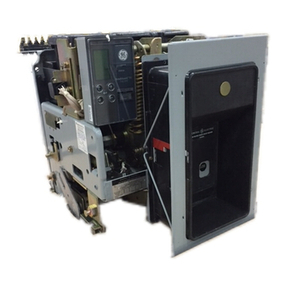

draw

out breaker is supported bytwo protruding pins

on each side of its frame; these pins engage slots in telescoping

slide rails (tracks) mounted to each sidewall

of

the switchgear.

All

draw

out breakers are equipped with a deep escutcheon

with side labels showing these discrete positions:

CONNECTED-This is the breaker's

"in-service"

position.

It is fully inserted in its compartment; the primaryand secondary

disconnectcontacts are fully engaged. The breaker

must

be

tripped before it can be racked intoor out of this position.

TEST -In this position the primary contacts are

disconnected but secondary contacts remain engaged. This

allows complete breaker operation without energizing

the

primary circuit.

3

Courtesy of NationalSwitchgear.com