Allis-Chalmers HD-4 Specifications

OPERATORS

INSTRUCTIONS

MODEL

HD4

CRAWLER

TRACTOR

ALLIS-CHALMERS

BOX 521,TOPEKA, KANSAS 66601

LITHO.

IN

U.

S.

A.

FORMTM482A

(4·69)

1"'"

o

o

ff')

.~

Q

:r:

•

o

z

"..,.I

cC

....

DC

!WI

'"

DEALERS

PRE-DELIVERY

SERVICE

IN DUSTRIA L HD-4 CRA W

LER

TRA

CTO R

YOUR

EQUIPMENT

HAS

BEEN

SET

UP,

LUBRICATED

AND

ALL

THE

PRE-DELIVERY

SERVICE

HAS

BEEN

COMPLETED,

BY

YOUR

DEALER.

DEALER

________________

__

TRACTOR

SERIAL

It'--

___

_

ADDRESS,

___________________

_

ENGINE

SERIAL

/I

PHONE

_____

_

BACKHOE

SERIAL

It

____________

_

DA

TE

DELIVERED'

______________

__

LOA

D

ER

SER

IA

L

It,

__________________

_

DO

Z

ER

SERIAL

#

_________________

_

OTHER

SERIAL

It

____________________

_

"-

LUBRICATED

13.

VALVE

TAPPET

CLEARANCE

CHECKED

2.

OIL

LEVEL

IN

GEAR

HOUSINGS

CHECKED

14.

ENGINE

SPEEDS

CHECKED

3.

ENGINE

OIL

LEVEL

CHECKED

15.

STEERING

CLUTCH

ADJUSTMENT

CHECKED

4.

AIR

CLEANER

CHECKED

16.

STEERING

BRAKE

ADJUSTMENT

CHECKED

5.

FUEL

FILTERS

CHECKED

17.

HYDRAULIC

SYSTEM

CHECKED

6.

BATTERY

CHECKED

18.

ALL

BOLTS"

NUTS

TIGHTENED

7.

COOLING

SOLUTION

IN

RADIATOR

CHECKED

19.

LIGHTS

CHECKED

8.

AL

TENATOR

CHARGE

RATE

CHECKED

20.

TRACK

ADJUSTMENT

9.

INJECTION

PUMP

TIMING

CHECKED

21,

APPEARANCE

OF

TRACTOR

10.

FAN

BELT

ADJUSTMENT

CHECKED

22.

ALL

PLUGS

AND

CONNECTIONS

IN

INTAKE

11.

CYLINDER

HEAD

TORQUE

CHECKED

MANIFOLD

ARE

TIGHT

12.

TORQUE

CONVERTOR"

SHUTTLE

CLUTCH

23.

LUBRICATED

FRONT

IDLERS,

TRACK

ROLLERS

OIL

LEVEL

CHECKED

AND

TOP

SUPPORT

ROLLERS

THIS

UNIT

HAS

SEEN

ADJUSTED

AND

SERVICED

SY

DEALER

PRIOR

TO

ITS

DELIVERy

TO

ME

AND

J

HAVE

BEEN

REQUESTED

TO

ADVISE

THE

DEALER

WHEN

THIS

UNIT

HAS

OPERATED

(30

DAYS

OR

100

HOURS)

SO

DEALER

REPRESENTATIVE

CAN

CHECK

ITS

ADJUSTMENTS

AND

PERFORMANCE.

OWNER

___________________________

__

Signature

DELIVERY RECORD

INDUSTRIAL

EQUIPMENT

THIS

FORM

MUST

BE

FILLED

OUT,

IN

TRIPliCATE,

BY

THE DEALER

AND

SIGNED

BY

THE

CUSTOMER

AT TIME UNIT

IS

DEliVERED.

DEliVERED

TO_______________

DEALER

R.

R.

'1~

...

____

BOX

,,__________

TOWN

__________________

_

TDWN__________________

TRACTOR SERIAL

It

____________

_

STATE__________________

TRACTOR ENGINE

'1

_____________

_

PHONE__________________

PRE-DEliVERED

BY

_____________

_

Use InslroctJon Book furnished with

each

unit when

explaining

$ervicins,

Malntenonce end

Adiustments

to

the Operator

cnd/or

Mechanic

in

charge.

All

applicable

items

listed

below must

be

serviced

before

unit

is

delivered

to

th.e

Purchaser,

IT

IS

THE

DEALERS RESPONSIBILITY

TO

EXPLAIN CARE, SAFE OPERATION

AND

ADJUSTMENTS

Of

ITEMS LISTED

BE

LOW,

o SPECIFICATION

OF

LUBRICANTS

o SPECIFICATION

OF

FUEL

o LUBRICATION INTERVALS & SERVICES

o BREAK-IN PERIOD

o RADIATOR DRAIN

COCKS

o RADIATOR

PRESSURE

CAP

o FAN

BELT

o ENGINE LUBRICATION

SYSTEM

o FUEL

FIL

TERS

o STARTING

MOTOR

o

GEAR

SHIFT

o STEERING CLUTCHES

o ENGINE CONTROLS

o OPERATING CONTROLS & INSTRUMENTS

o FUEL

STORAGE

o LUBRICATION

OF

FRONT IDLERS,

TRACK ROLLERS, &

TOP

SUPPORT

ROLLERS

REMARKS:

________

~

o

TORQUE

CONVERTOR & SHUTTLE CLUTCH

OIL &

FILTER-CHECK

o STEERING 8RAKES

n SHUTTLE CLUTCH

o

HYDRAUliC

SYSTEMS

& OIL FILTERS

o

DRAWBAR

o

FINAL

DRIVE

o

TRANS,'.-IISSION

o BATTERY CARE

o AIR CLEANERS

o LIGHTS

o

ST

ARTING & STOPPING

o STORING TRACTOR

o TRACK ADJUSTMENT

:J

WINCH

DRIVE

o OPERATORS SAFETY PRECAUTIONS

WARRANTY

TO

BE

COMPLETED

BACKHOE:

MAKE

M8DEL

_____

_

SERIAL No.

____

_

LOADER,

MAKE

_____

_

MODEL

SERIAL

No.

____

_

DOZERS:

MAKE

_____

_

MODEL

SERIAL

No.

____

_

OTHER

EQUIPMENT,

NAME

_____

_

MAKE

~.

_____

_

MODEL

SERIAL No.

____

_

!t

is understood

that

the

AI

tis-Chalmers mochinery

is

sold

by

the Dealer with

the

standard

warranty

of

the

Manufach.:rert

set

forth in the

Operotors

Manual,

This

warranty is the

only

warranty either express" implied, ar statutory, upon which soid machinery is

sold.

DELIVERY

AND

STARTING

OF

THE ABOVE DESCRIBED EQUIPMENT

HAS

BEEN

MADE

ON

THE DATE SPECIFIED

AND

THE

ABDVE

IS

A

CORRECT REPORT

DF

THIS

DEliVERY.

THE

RECIPIENT

OF

THE MACHINERY

ACKNOWLEDGES

THAT COMPLETE INSTRUCTIONS

ON

THE OPERATION, MAINTENANCE, CARE, ADJUSTMENTS

AND

SAFE OPERATING PRACTICES

OF

THIS EQUIPMENT

HAS

BEEN FURNISHED

TO

HIS

ORGANIZATION

TO

HIS

SATISFACTION,

USING

THE

OPERATOR'S INSTRUCTION

BOOK

AS

A GUIDE.

I

HAVE

BEEN

REQUESTED

TD

ADVISE

THE

DEALER

WHEN

THIS

TRACTOR

HAS

OPERATED

300AYS

[OR

100

HOURSl

SO

DEALER

REPRESENTATIVE

CAN

CHECK

ITS

ADJUSTMENTS

AND

PERFORMANCE,

DELIVER

ED

8Y:

Dealer

OWNER

_____

~~;;~---

__

-----

BY:

____________

--;:-

___

_

Dote OPERATOR:

____

~~------------

Signature

AlIT

BE

CAREFUL

1.

KEEP

ALL

SHIELDS

IN

PLACE.

..

2.

STOP

MACHINE

TO

ADJUST AND

OIL.

"

3.

WHEN

MECHANISM BECOMES CLOGG,ED'

~

DISENGAGE

POWER

BEFORE CLEANING,

KEEP HANDS,

FEET

AND CLOTHING

AWAY

FROM

POWER·DRIVEN PARTS.

KEEP OFF IMPLEMENT UNLESS SEAT

OR

PLATFORM

IS

PROVIDED.

KEEP OTHERS

OFF.

BE

A

SAfE

OPERATOR

AVOID

AOCIDENTS

Most

occidents

l

whether

they

occur in industrYI

on

the

form,

at

home,

or

on

the

highwoy,

are

caused

by

the

failure

of

some

in-

dividual

to

follow simple

and

fundomental

sofety

rules

or

pre-

cautions,

For

this

reason

most

occidents

con

be

prevented

by

recognizing

the

reol

couse

and

doing

something

about

it

before

the

occident

occurs,

Regardless

of

the

care

'used

in

the

design

and

construction

of

any

type

of

equipment,

there

are

many

conditions

that

Can

not

be

completely

safe

guarded

against

without

interfering

with reason-

able

accessibility

and

efficient

operation,

A CAREFUL OPERATOR

15

THE

BEST

INSURANCE

AGAINST

AN

ACCIDENT,

THE COMPLETE OBSERVANCE

OF

ON[

SIMPLE RULE

WOULD

PREVENT

MANY

THOUSAND

SERIOUS

INJURIES EACH

YEAR

THAT

RULE

IS:

NEVER

ATTEMPT

TO CLEAN, OIL,

OR

ADJUST A

MACHINE

WHILE

IT

IS

IN

MOTION!

""1-'

,

I

,

,

I

I

i

,

I

i

,

I

,

,

,

,

"

,

!

,

,

I

!

I

,

!

,

,

,

,

!

I

I

I

!

,

,

,

,

,

I

I

I

I

,

I

I

,

,

,

,

I

I

,

I

,

I

,

,

,

,

I

I

,

I

!

1

,

,

,

,

,

,

,

,

I

I

,

I

i

1

I

I

1

1

I

,

,

I

I

I

1

,

i

I

I

I

I

,

,

I

I

I

I

,

1

i

I

1

i

I

,

I

I

,

,

I

I

I

,

,

I

I

I

,

I

",1_"

i

,

I

I

I

I

I

I

I

I

I

,

I

I

I

I

I

I

I

I

I

I

I

,

I

I

I

,

I

I

I

I

I

I

,

I

I

I

,

,

I

I

I

,

I

,

,

I

I

,

,

I

I

,

I

I

,

,

I

j

,

,

,

,

,

I

I

I

,

,

I

I

I

I

I

I

I

I

I

I

I

I

I

DELIVERY RECORD

INDUSTRIAL

EQUIPMENT

THIS

FORM

MUST

BE

FILLED

OUT,

IN

TRIPLICATE, BY THE DEALER AND SIGNED BY THE

CUSTOMER

AT

TIME UNIT

IS

DELIVERED,

DELIVEREDTO____________________________

DEALER

_______________________________

__

R,R,#

__________

BOX#__________________

TDWN

__________________________________

__

TOWN~

....

______________________________

TRACTOR SERIAL

11

_______________________

_

STATE_________________________

TRACTOR ENGINE

11

_________________________

_

PHONE_____________________________

PR

E-DELIVER

ED

BY

___________________________

_

Use Instruction Book furnished with each

unit

when explaining Servicing, Mointenonce

and

Adjustr.1ents

ta

the

Operator

ond/or Mechonic

in

chorge,

All

applicabfe items

lisfed

beraw must

be

serviced before unit is delivered to the Purchoser.

IT

IS

THE DEALERS RESPONSIBILITY

TO

EXPLAIN CARE,

SAFE

OPERATION

AND

ADJUSTMENTS

OF

ITEMS LISTED

BELOW,

o SPECIFICATION OF LUBRICANTS

o SPECIFICATION

OF

FUEL

o LUBRICATION INTERVALS & SERVICES

o BREAK-IN PERIOD

o RADIATOR DRAIN

COCKS

o RADIATOR

PRESSURE

CAP

o FAN

BELT

o ENGINE LUBRICATION

SYSTEM

o FUEL FILTERS

o STARTING

MOTOR

o

GEAR

SHIFT

o STEERING CLUTCHES

o

ENGINE

CONTROLS

o OPERATING CONTROLS & INSTRUMENTS

o FUEL

STORAGE

o LUBRICATION

OF

FRONT IDLERS,

TRACK ROLLERS, &

TOP

SUPPORT

ROLLERS

o

TORQUE

CONVERTOR & SHUTTLE CLUTCH

OIL &

FILTER-CHECK

o STEERING BRAKES

o SHUTTLE CLUTCH

o HYDRAULIC

SYSTEMS

& OIL FILTERS

o

DRAWBAR

o

FINAL

DRIVE

o

TRANSMISSION

o BATTERY CARE

o

AIR

CLEANERS

o LIGHTS

o STARTING & STOPPING

o

STORING

TRACTOR

o TRACK ADJUSTMENT

o

WINCH

DRIVE

o OPERATORS SAFETY PRECAUTIONS

REMARKS:

________________________

~

WARRANTY

TO

BE

COMPLETED

BACKHOE:

MAKE

__________

_

MODEL

__________

_

SERIAL

No,

______

_

LOADER:

MAKE

__________

__

MODEL

SERIAL

No,

________

_

DOZERS:

MAKE

_________

__

MODEL

SERIAL

No.

_______

__

OTHER EQUIPMENT:

NAME

MAKE

MODEL

SERIAL

No.

______

_

It

[5 understood that the Allis-Chalmers. mochinery

is

sold

by

the Dealer with the standard

warranty

of

the Manufacturer,

set

forth

in

the Operators Manual.

This

worroniy

is

the

only

worranty eifher

express,

impliedr

ar

statutory, upon which sold maChinery is saId,

DELIVERY

AND

STARTING OF THE ABOVE DESCRIBED EQUIPMENT

HAS

BEEN MADE

ON

THE DATE SPECIFIED

AND

THE ABOVE

IS

A

CORRECT REPORT

OF

THIS DELIVERY.

THE

RECIPIENT

OF

THE MACHINERY ACKNOI'ILEDGES THAT COMPLETE INSTRUCTIONS

ON

THE OPERATION, MAINTENANCE, CARE, ADJUSTMENTS AND SAFE OPERATING PRACTICES

OF

THIS EQUIPMENT

HAS

BEEN FURNISHED

TO

HIS

ORGANIZATION

TO

HIS

SATISFACTION,

USING

THE

OPERATOR'S INSTRUCTION

BOOK

AS

A GUIDE.

[

HAVE

BEEN

REQUESTED

TO

ADVISE

THE

DEALER

WHEN

THIS

TRACTOR

HAS

OPERATED

30

DAYS

(OR

100

HOURS}

SO

DEALER

REPRESENTATIVE

CAN

CHECK

ITS

ADJUSTMENTS

AND

PERFORMANCE,

DELIVERED

OWNER

___________

~-------------------

Signature

BY:

________________________

~--------

Dote OPERATOR:

_______

ST.;;,~~----------------

2nd

Copy-

FOR

DEAlER'S

FILE

",~L"~~~,""~

BE

CAREFUL

1.

KEEP

ALL

SHIELDS IN PLACE.

..

2.

STOP

MACHINE

TO

ADJUST AND

OIL.

"

3.

WHEN

MECHANISM

BECOMES

CLOGGED,

~

DISENGAGE

POWER

BEFORE CLEANING.

KEEP HANDS,

FEET

AND CLOTHING

AWAY

FROM

POWER·DRIVEN PARTS.

KEEP OFF IMPLEMENT UNLESS SEAT

OR

PLATFORM

IS

PROVIDED.

KEEP OTHERS OFF.

BE

A SAFE OPERATOR

ACCIDENTS

Most

occidents,

whether

they

occur

in

industry,

on

the

form,

at

home, or on

the

highway,

are

caused

by

the

failure

of

some in-

dividual

to

follow

simple

and

fundamental

safety

rules or pre-

cautions.

For this reason most

accidents

can

be

prevented

by

recognizing

the

real

cause

and

doing

something

about

it

before

the occident

occurs.

Regardless

of

the

core

used in

the

design

ond

construction

of

any

type

of

equipment,

there

are

many

conditions

that

can

not

be

completely

safe

guarded

against

without

interfering

with reason-'

able

accessibility

and

efficient

operation.

A CAREFUL OPERATOR

IS

THE

BEST

INSURANCE

AGAINST

AN

ACCIDENT.

THE COMPLETE OBSERVANCE

OF

ONE SIMPLE RULE

WOULD

,

PREVENT

MANY

THOUSAND

SERIOUS

INJURIES EACH YEAR.

THAT

RULE

IS:

NEVER

ATTEMPT

TO

CLEAN, OIL,

OR

ADJUST A

MACHINE

WHILE

IT

IS

IN

MOTION!

DELIVERY

RECORD

INDUSTRIAL

EQUIPMENT

THIS

FORM

MUST

BE

FILLED

OUT,

IN

TRIPLICATE,

BY

THE

DEALER

AND

SIGNED

BY

THE

CUSTOMER

AT

TIME

UNIT

IS

DELIVERED.

DELIVERED

TO

______________

_ DEALER

R.

R.It

______

BOX

It

_________

_

TOWN

__________________________________

__

TOWN

_________________

__

TRACTOR

SERIAL

It

______________

_

STATE

__________________

_

TRACTOR

ENGINE

'Ii

___________________________

_

PRE-DELIVERED

BY

___________________

_

PHONE

_______

~-----------------------

Use

Instruction Book furnished with

each

unit when

explaining

Servicing,

Maintenance and Adjustments

fo

the

Operator ond/or Mechonic in

charge. All applicable items listeci below

must

be

serviced

before

unit is delivered to the Purchaser,

IT

IS

THE

DEALERS

RESPONSIBILITY

TO

EXPLAIN

CARE,

SAFE

OPERATION

AND

ADJUSTMENTS

OF

ITEMS

LISTED

BELOW:

D SPECIFICATION

OF

LUBRICANTS

o SPECIFICATION

OF

FUEL

o LUBRICATION INTERVALS

8.

SERVICES

o BREAK-IN

PERIOD

o

RADIATOR

DRAIN

COCKS

o

RADIATOR

PRESSURE

CAP

o

FAN

BELT

o

ENGINE

LUBRICATION

SYSTEM

D FUEL FILTERS

D

STARTING

MOTOR

D

GEAR

SHIFT

D

STEERING

CLUTCHES

o

ENGINE

CONTROLS

o

OPERATING

CONTROLS

&

INSTRUMENTS

D FUEL

STORAG

E

o LUBRICATION

OF

FRONT

IDLERS,

TRACK

ROLLERS,

&

TOP

SUPPORT

ROLLERS

o

TORQUE

CONVERTOR

8.

SHUTTLE

CLUTCH

OIL

8.

FILTER-CHECK

o

STEERING

BRAKES

o

SHUTTLE

CLUTCH

o HYDRAULIC

SYSTEMS

& OIL FILTERS

o

DRAWBAR

o FINAL

DRIVE

o

TRANSMISSION

D BATTERY

CARE

o

AIR

CLEANERS

o

LIGHTS

o

STARTING

&

STOPPING

o

STORING

TRACTOR

o

TRACK

ADJUSTMENT

o

WINCH

DR

IVE

o

OPERATORS

SAFETY

PRECAUTIONS

REMARKS'

_____________________________________________

___

WARRANTY

TO

BE

COMPLETED

BACKHOE,

MAKE

_________

_

MODEL

__________

_

SERIAL

No.

__

_

LOADER,

MAKE

__________

__

MODEL

SERIAL

flo.

_________

_

DOZERS:

MAKE

_______

__

MODEL

SERIAL

No,

____

_

OTHER

EQUIPMENT:

NAME

_

__

____

__

MAKE

MODEL

SERIAL

No.

_

...

_______

__

It

is

understood that

the

Allis-Chalmers

machinery

is

sold

by

the

Dealer with the stondord

warranty

of the Manufacturer,

set

forth

10

the

Operators Manual. This warranty is

the

only

warranty either

express,

implied,

or

statuforYI upon

which

soid

machinery is

sold.

DELIVERY

AND

STARTING

OF

THE

ABOVE

DESCRIBED

EQUIPMENT

HAS

BEEN

MADE

ON

THE

DATE

SPECIFIED

AND

THE

ABOVE

IS

A

CORRECT

REPORT

OF

THIS

DELIVERY.

THE

RECIPIENT

OF

THE

MACHINERY

ACKNOWLEDGES

THAT

COMPLETE

INSTRUCTIONS

ON

THE

OPERATION,

MAINTENANCE,

CARE,

AD:JUSTMENTS

AND

SAFE

OPERATING

PRACTICES

OF

THIS

EQUIPMENT

HAS

BEEN

FURNISHED

TO

HIS

ORGANIZATION

TO

HIS

SATISFACTION,

USING

THE

OP

ERATOR'S

INSTRUCTION

BOOK

AS

A

GUIDE.

I

HAVE

BEEN

REQUESTED

TO

ADVISE

THE

DEALER

WHEN

THIS

TRACTOR

HAS

OPERATED

30

DAYS

(OR

100

HOURSI

SO

DEALER

REPRESENTATIVE

CAN

CHECK

ITS

ADJUSTMENTS

AND

PERFORMANCE,

DELIVER

ED

BY:

____

-:::-;-

________________

_

Dealer

OWNER

____________

~----------------------

Signature

BY:

_________________________

-,:-

______

_

Dote

OP

ERA

TOR:

________

-::~-------------------

Signature

3rd

Copy-FOR

CUSTOMER

BE

CAREFui"

1.

KEEP

ALL

SHIELDS IN PLACE.

.dI

2.

STOP

MACHINE TO ADJUST AND

OIL.

"

3.

WHEN

MECHANISM

BECOMES

CLOGGED,

~

DISENGAGE

POWER

BEFORE CLEANING.

KEEP HANDS,

FEET

AND CLOTHING

AWAY

FROM

POWER-DRIVEN PARTS.

KEEP

OFF

IMPLEMENT UNLESS SEAT

OR

PLATFORM

IS

PROVIDED.

KEEP OTHERS

0....

~

IE

A SAFE OPERATOR

AVOID

ACI'IDENTS

Most

accidents,

whether

they

occur

in

industry,

on

the

form,

at

home,

or on

the

highway,

are

caused

by

the

failure

of

some

in-

dividual

to

fallow

simple

and

fundamental

safety

rules

or

pre-

cautions.

For this reoson

most

accidents

can

be

prevented

by

recognizing

the

real

couse

ond

doi. 'g

something

about

it

before

the

acddent

occurs.

Regardless

of

the

care

used

in

the

design

ond

construction

of

any

type

of

equipment,

there

are

mony

conditions

that

can

not

be

completely

safe

guarded

against

without

interfering

with reason-

able

accessibility

and

efficient

operation.

A CAREFUL OPERATOR

IS

THE

BEST

INSURANCE

AGAINST

AN

ACCIDENT.

THE COMPLETE OBSERVANCE

OF

ONE SIMPLE RULE

WOULD

PREVENT

MANY

THOUSAND

SERIOUS INJURIES EACH YEAR.

THAT

RULE

IS:

NEVER

ATTEMPT

TO

CLEAN, OIL,

OR

ADJUST A

MACHINE

WHILE

IT

IS

IN

MOTiON!

TO

OUR

CUSTOMER

The

following

pages

and

illustrations

are

printed

to

help

supply

you

with

the

knowledge

to

better

operate

and

service

your

new

Allis-Chalmers

equipment.

We

are

proud

to

have

you

as

a

customer

and

feel

you

will

be

proud

to

be

an

Allis-Chalmers

owner.

Any

piece

of

equipment

needs

and

must

have

a

certain

amount

0':

service

and

maintenance

to

keep

it

in

top

running

condition.

"'"vVe

have

attempted

to

cover

all

the

adjustments

required

to

fit

most

conditions;

however,

there

may

be

times

when

special

care

must

be

taken

to

fit

a

condition.

Study

your

manual

carefully

and

become

acquainted

with

all

the

adjustments

and

operating

procedures

before

attempting

to

operate

your

new

equipment,

Remember,

it

is

a

machine

and

has

been

designed

and

tested

to

do

an

efficient

job

in

most

operating

conditions

and

will

perform

in

relation

to

the

service

it

receives.

If

special

attention

is

required

for

som€:

conditions,

ask

your

Allis-Chal-

mers

dealer;

his

Parts

and

Service

Organization

will

be

glad

to

help

and

answer

any

questions

on

operation

and

service

of

your

new

machine.

This

!!SAFETY

DOT!!

is

used

in

the

book

to

emphasize

safety

precautions

that

should

be

followed

by

the

operator

to

avoid

acci-

dent

and

possible

injury~

When

you

see

this

emblem

heed

its

warn-

ing.

WARRANTY

ALLIS-CHALMERS MANUFACTURING COMPANY

(the

Company)

warronts

Its

new

machinery

covered by this

order

or

contract

(ex.cluding tires

and

B-Series

engines

and

engine

accessories which

are

worJ'onted

by

the

respective

manufacturers

only) to be free

of

defects

in

workmanship

and

moterio!

at

the

time

af

shIpment fram

the

Company's

factory.

This worranty

IS

the

anly

warranty upon which

the

Compony1s new

machinery

is

sold. NO OTHER

WARRANTY SHALL

BE

IMPLIED

AND

ALL STATUTORY WARRANTIES SHALL

BE

DEEMED WAIVED.

No

warranty

of

ony kind,

statutory,

implied, or otherwise, is

made

with

respect

to

second-hand

machinery

or

with respect to

new

machineJ'Y which, ofteJ'

shipment

from

the

Company's

factory, hos

been

altered,

repaired

or

treated

in

any

manner

whatsoever.

The

Company

will

repair

or

replace f,Q,b. its factory

any

port

in

its new mochinery which under

normal use foils

within

twelve

manths

(except six

months

insteod of twelve

months

in

the

case

of

products

of

the

Springfield

and

Deerfield

Works

of

the Company

and

engines sold

as

power units) from

date

of

delivery

of

such

machinery

to

the

fiJ'st user, pJ'ovided

that

the

Company

is

promptly notified

thereof

and

that

the

pOJ't

is

returned

to

the

Compony or to

on

authorized

dealer

properly identified! choJ'ges prepaid,

and

is

found

to

the

satisfaction

of

the

Company to have

been

defective

in

workmanship or materior

ot

the

time

of

shipment

of

the

machinery

from

the

factory

as

aforesaid.

The

Company's

liability

whether

in

controct

or

in

tort

ariSing

out

of warranties, representations,

instructions,

or

defects

fJ'om

any

couse

sholl

be

limited exc!usively

to

repoiJ'ing

or

replocing under

the

conditions

os

aforesoid,

No

representative

of

the

Company

has

authority

to

chonge

this

warranty

and

no

attempt

to

repair

or

promise to J'epoir

or

impJ'ove

the

machinery

by

any

representative

of

the

Company sholl

change

OJ'

extend

this warranty.

1

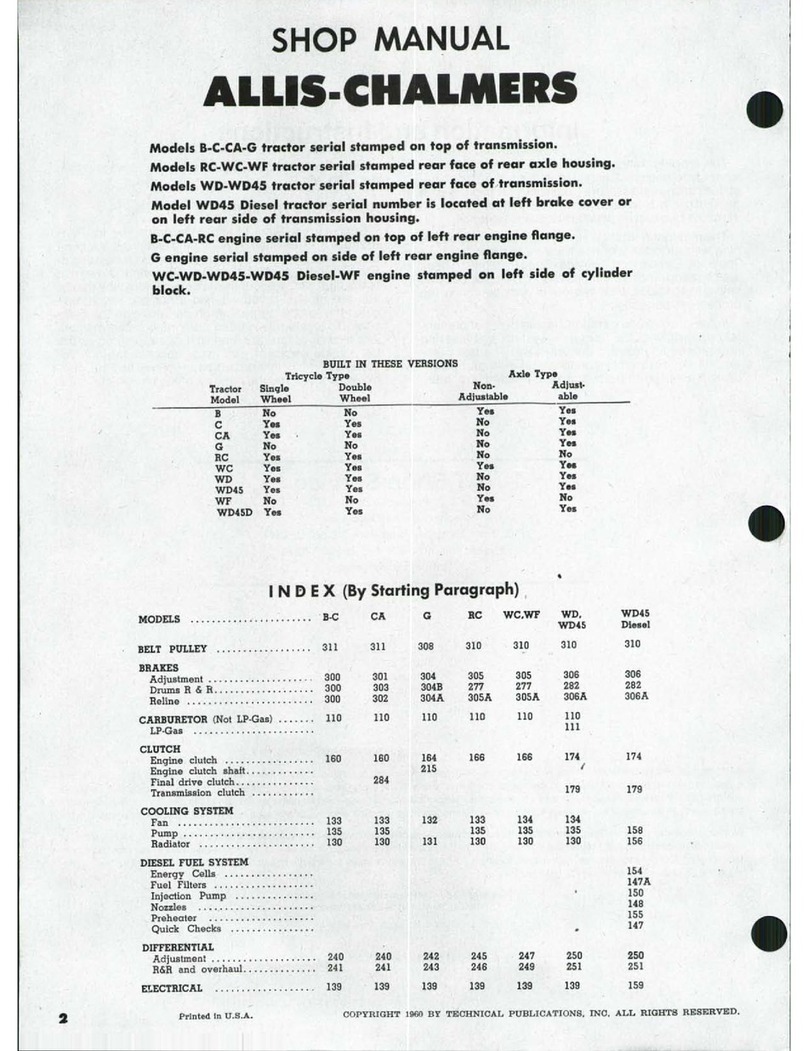

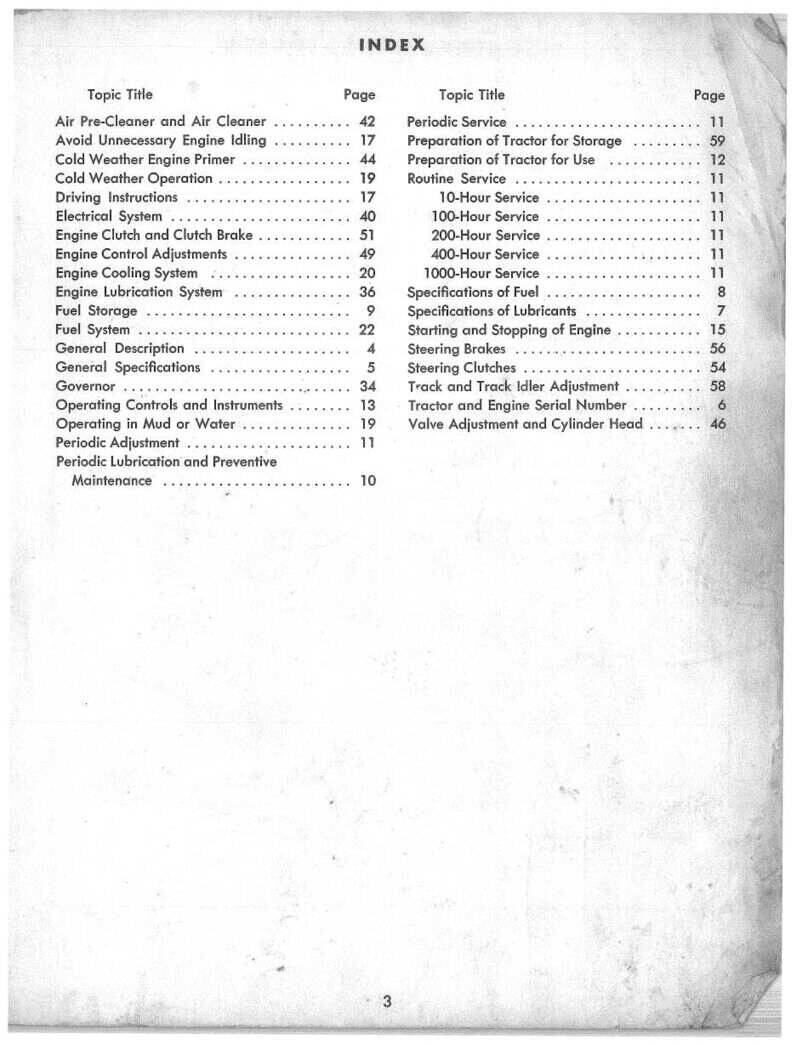

INDEX

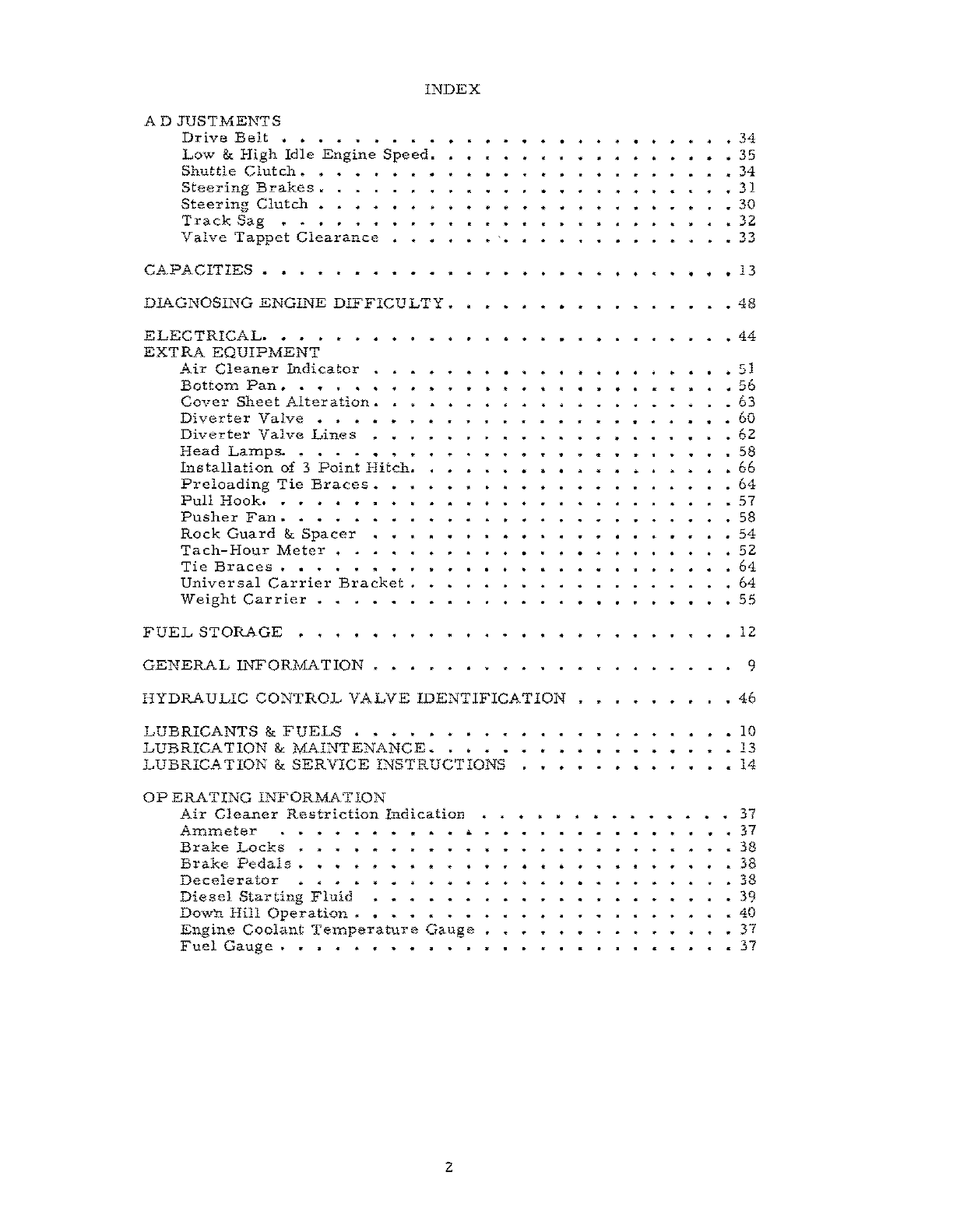

AD

JUSTMEl\TTS

Drive

Belt

• . .

..

.

..

. .

..

Low'"

High

Idle

Engine

Speed.

Shuttle

Clutch.

•

Steering

Brakes.

. . .

Steering

Clutch

..

..

.

..

Track

Sag

• • • • • •

Valve

Tappet

Clearance

CAPACITIES

• • • • • • •

DIAGNOSING

ENGINE

DIFFICULTY.

ELECTRICAL.

• • • • •

EXTRA

EQUIPMENT

Air

Cleaner

Indicator

Bottom

Pan..

..

• .

..

Cover

Sheet

Alter

a.tion

..

Diverter

Valve

. .

..

Divertel'

Valve

Lines

..

Head

LalTIps.

. • . . •

Installation

of

3

Point

Hitch.

Preloading

Tie

Braces

..

Pull

Hook.

. • • • •

Pusher

Fan..

..

..

.. ..

Rock

Guard'"

Spacer

Tach-Hour

Meter

.. ..

Tie

Braces..

..

. .

..

Universal

Carrier

Bracket.

Weight

Carrier

FUEL

STORAGE

•

GENERAL

ll'IFORMA

TION

.

•

HYDRAULIC

CONTROL

VALVE

IDE::;[TIFICATION

LUBRICANTS'"

FUELS

• • • • • • • • •

LUBRICATION'"

MAI::;[TE::;[ANCE

•••••

LUBRICATION'"

SERVICE

I::;[STRUCTIONS

OPERATI::;[G

r::;[FORMATIO::;[

Air

Cleaner

Restriction

Indication

Ammeter

....

Brake

Locks

•

Brake

Pedals.

Decelerator

Diesel

Starting

Fluid

Down

Hill

Operation.

Engine

Coolant

Temperature

Gauge

Fuel

Gauge.

• .

.. ..

.

.. ..

..

..

.

2

34

35

34

31

30

32

33

13

•

48

•

44

5J

56

63

60

62

58

66

64

57

58

54

52

64

64

55

12

9

46

10

13

14

37

37

38

38

38

39

40

37

37

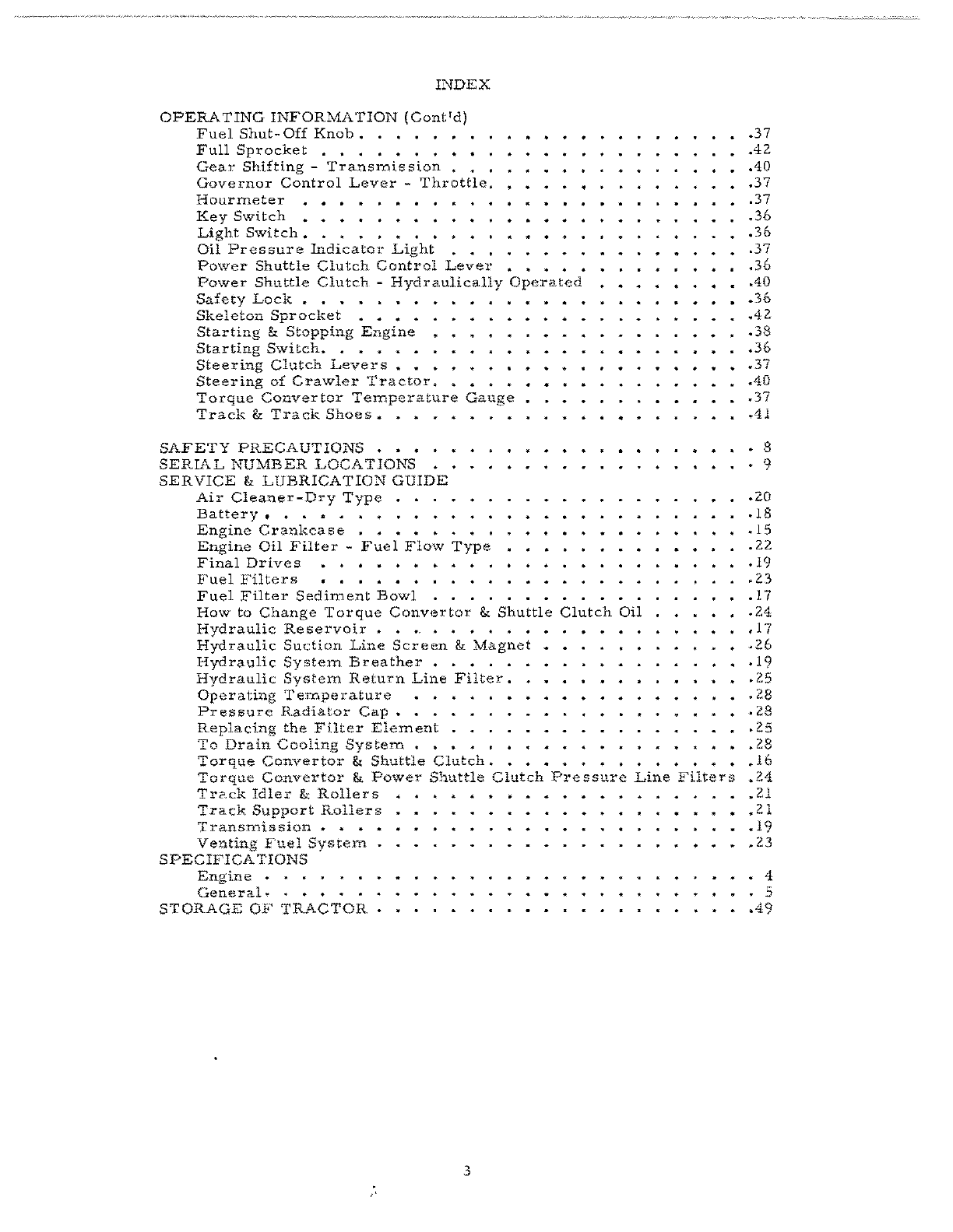

INDEX

OPERATING

INFORMATION

(Cont'd)

Fuel

Shut-

Off

Knob.

. • • •

Full

Sprocket

• • • • • • • • •

Gear

Shifting

-

Transluission

•

~

Governor

Control

Lever

-

Throttle.

Hourmeter

Key

Switch

• • • • • • • •

Light

Switch..

..

,.

• • • •

..

Oil

Pressure

Indicator

Light

Power

Shuttle

Clutch

Control

Lever

Power

Shuttle

Clutch

-

Hydraulically

Operated

Safety

Lock

• • • • . • •

Skeleton

Sprocket

• • • •

Starting

&.

Stopping

Engine

Starting

Switch.

• • • • •

Steering

Clutch

Levers..

..

Steering

of

Crawler

Tractor

*

Torque

Convertor

Temperature

Gauge

Track

&

Track

Shoes.

•

.37

.42

.40

.37

.37

.36

.36

.37

.36

.40

.36

.42

.38

.36

.37

.40

.37

.41

SAFETY

PRECAUTIONS

• 8

SERIAL

NUMBER

LOCATIOI\TS

9

SERVICE

&

LUBRICATIO::"l

GUIDE

Air

Cleaner-Dry

Type

.20

Battery

••••••

~

•

..

•

..

.18

Engine

Crankcase

• *

.. .. ..

•

~

15

Engine

Oil

Filter

-

Fuel

Flow

Type

.22

Final

Drives

..

• •

..

• •

.19

Fuel

Filters

.............

.23

Fuel

Filter

Sediment

Bowl

. . . .

.17

How

to

Change

Torque

Convertor

&

Shuttle

Clutch

Oil

.24

Hydraulic

Reservoir

• •

".

.. ..

•

.. ..

•

,17

Hydraulic

Suction

Line

Screen

&

Magnet

•

.26

Hydraulic

System

Breather

• • • . •

.19

Hydraulic

System

Return

Line

Filter.

.25

Operating

Temperature

.28

Pressure

Radiator

Cap.

• •

.28

Replacing

the

Filter

Element

.25

To

Drain

Cooling

System.

•

.28

Torque

Convertor

&

Shuttle

Clutch.

.16

Torque

Convertor

&

Power

Shuttle

Clutch

Pressure

Line

Filters

.24

Tr2<ck

Idler

&

Rollers

.21

Track

Support

Rollers

.21

Transmission

.. .. ..

,,19

Venting

Fuel

System

.23

SPECIFICA

TIONS

Engine

• • • • • • . 4

General..

. • •

~ ~

• 5

STORAGE

OF

TRACTOR

.49

3

"

ENGINE

SPECIFICATIONS

Model

Make

Type.

Number

of

Cylinders

Bore

Stroke

No.

of

Main

Bearings

•

Piston

Displacement

COn1pression

Ratio

Cornpres

sian.

Firing

Order

Low

Idle

..

Governed

@

Full

Load

High

Idle.

• • • • •

* • • •

D2200

ALLIS-CHALMERS

.4

cycle

naturally

aspirated

• • 4

•

3.88

• 5

.200

cu.

in.

16.25:

1

500

PSI

@600

RPM

•

..

1-3-4-2

650-700

RPM

•.

2100

RPM

2250-2310

RPM

Fuel

Injection

Pump

~ ~

.

.,

. • . . .

~

.

Roosa

Master

Model

DBGFC

437-7AF

Timed

@

26°

BTDC

Fuel

Nozzles.

Opening

Pressure.

VALVE

LASH

Intake

Clearance

.

Exhaust

Clearance

4

ALLIS-

CHALMERS

•

••

2750

P.S.I.

.015"

HOT

.015"HOT

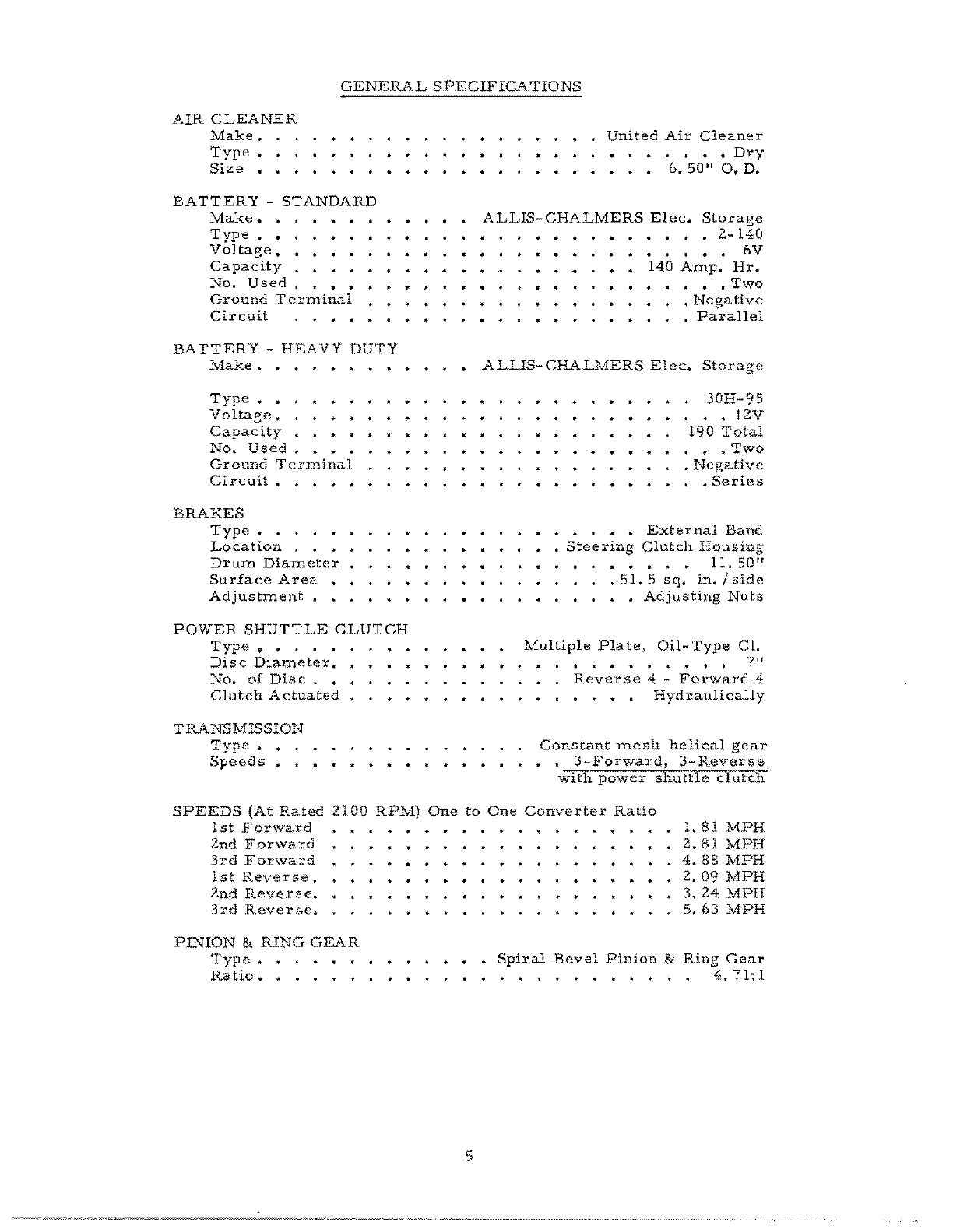

GENERAL

SPECIFICATIONS

AIR

CLEANER

Make.

Type.

Size

•

BATTERY

-

STANDARD

Make

....

Type

.•

Voltage.

Capacity

No.

Used

......

Ground

Terminal

Circuit

BA

TTER

Y -

HEAVY

DUTY

Make.

Type.

Voltage.

Capacity

No.

Used

Ground

Terminal

Circuit..

~

"

'*

..

BRAKES

Type

.......

Location

.••

Drum

Diameter

Surface

Area

Adjustment

••

POWER

SHUTTLE

CLUTCH

Type,

..

. •

..

Disc

Diameter.

No.

of

Disc

••

Clutch

Actuated

TRANSMISSION

Type.

Speeds

• •

United

Air

Cleaner

•

Dry

6.50"

O.D

..

ALLIS-CHALMERS

Elec.

Storage

.. .. ..

•

2-140

..

..

• " •

bV

140

Amp.

Hr.

•

••

Two

•

Negative

·

Parallel

ALLIS-CHALMERS

Elec.

Storage

30H-95

• •

12V

190

Total

"

~ ~

Two

..

Negative

.. ..

Series

• • • • •

External

Band

•

Steering

Clutch

Housing

•••••

11.50"

.51.5

sq.

in.

I

side

• •

Adjusting

Nuts

Multiple

Plate,

Oil-Type

Cl.

• • •

..

..

•

..

" • 7J J

Reverse

4 -

Forward

4

• • • •

Hydraulically

Constant

ITlesh

helical

gear

..

3-Forward,

3-Reverse

with

power

shuttle

clutch

SPEEDS

(At

Rated

2100

RPM)

One

to

One

Converter

Ratio

1st

Forward

1.

81

MPH

2.81

MPH

4.88

MPH

2.09

MPH

3.

24

2\,1PH

5.63

MPH

2nd

Forward

3rd

Forward

1st

Reverse.

2nd

Rever

s

e.

3rd

Reverse.

Pli'UON

&

RING

GEAR

Type.

Ratio..

_ . .

..

•

Spiral

Bevel

Pinion

&

Ring

Gear

••••••••••

4.71:1

5

GENERAL

SPECIFICA

TIONS

ELECTRICAL

SYSTEM

Al

terna

tor

....

Del

cotron

Make

..

Model.

• • • •

Output..

..

•

~

•

Voltage

Regulator

Make,.

•

,.

Model

•••

Starting

Motor

Make.

Model.

Ratio

..

Fuse

Size.

FAN

Type,.

"

..

• • •

..

•

Diameter.

.

..

•

~

..

Ratio-Fan

to

Engine

..

FINAL

DRIVES

Type

••

Ratio.

.

HYDRA

U

LIC

PUMP

Make

••

Type

t • " " •

Rotation

..

• "

Available

in

two

sizes

for

Doz.er

or

Backhoe

Applications

Loader

or

Backhoe

Applications

Torgue

Convert

OJ;

and

Power

Shuttle

hydraulic

pump

CAPACITIES

Coolbg

System

Engine

Cranl:::case

Oil

Change.

• "

Oil

and

Filter

Change.

•

Hydraulic

System

(Tractor

Only)

Transmission~

......

"

...

"

Power

Shuttle

Clutch

&:

Convert

or

.

Final

Drives

Each

..

Fuel

Tank

"

....

"'

•

Truck

Roller

(Each)

•

Idler

(Each).

• • • •

Support

Roller

(Each)

STEERING

Method.

Type

••

Disc

Diameter

GENERAL

DIMENSIONS

AND

WEIGHT

Delco-Remy

1100735

• •

32

Amps

Delco-

Rerny

• •

1119513

Delco-Rerny

1107589

•

14.2:

1

20

AMP

5

Blade-Spider

•

17"

. • • •

1.

4: 1

Single

Reduction

Spur

Gear

•••••••••

11.70:1

..

Webster

•

.2-Gear

Clockwise

15

GPM

@

2100

Engine

RPM

ZS

GPM

@

2100

Engine

RPM

8.5

GPM

@

2100

Engbe

RPM

.16

qte.

8

qt.

9

qt.

•

..

36

qt.

12-1/4

qt.

• •

33

qt.

.6-3/4

qt.

.18

gal.

4

oz.

4

oz.

4

oz.

Multiple

disc

clutch

• •

Dry

• • , • ,

,9-7/8"

Overall

Heights

with

Exhaust

Pipe(

Full

Grouser).

Overall

Heights

Less

Exhaust

Pipe

81-3/4"

71-5/8"

•

63"

Overall

Width

(12"

Grousers)

•

Weight

(Appro",)

••••

,

•••

· •

8800

6

GENERAL

SPECIFICATIONS

TRACKS

Type.

• • •

..

• . • . • . • .

..

•

..

Tread

Width

(Center

to

Center

of

Track)

Length

of

Track

on

Ground

(Center

of

sprocket

to

center

of

idler).

Interlocking

track

..

•

5111

•

69-3/4"

Width

of

Shoes

(Optional).

• • • • • • •

No.

of

Shoes

(Each

track).

. • • • • • •

...

10

11

-

1411

-

1211

36"

Track

Pitch

(Center

of

pin

to

center

of

next

pin).

No.

of

Track

Rollers

(Each

track)

•

No.

of

Support

Rollers

(Each

track)

• • • • • •

TORQUE

CONVERT

OR

Type

••••

Torque

Ratio

• • •

6"

5

• 1

Single

stage

2.

15

to

1

ALLIS-CHALMERS

reserves

the

right

to

make

changes

in

the

above

specifications

Or

to

add

improvements

at

any

time

without

notice

or

obligation.

7

SAFETY

PRECAUTIONS

Many

hours

of

lost

tirne

much

suffering

is

caused

by

the

failure

to

practice

simple

safety

rules.

IT

IS

TOO

L.';':TE

TO

REM&YfBER WHAT

SHOULD

HAVE

BEEN

DONE

AFTER

THE

ACCIDENT

HAS

HAPPENED.

1.

Do

not

fill

fuel

tanks

when

engine

is

hot

Or

while

using

a

lantern

or

when

smoking.

2.

Do

not

attempt

to

oil

or

grease

a

machine

or

tractor

while

it

is

in

operation.

3.

Do

not

weal'

loose

fitting

clothing

that

may

be

blown

into

moving

parts.

4.

Keep

all

shields

and

guards

in

place.

5.

Place

gear

shift

lever

in

neutral

position

when

starting

engine

or

dismounting

from

crawler

tractor.

6.

Machinery

should

be

only

operated

by

those

who

are

responsible

and

delegated

to

do

so.

7.

Only

one

person

-

the

operator

should

be

permitted

on

crawler

tractor

when

it

is

in

motion.

8.

The

rate

of

trave]

on

hillsides

Or

turns

should

be

regulated

so

there

is

no

danger

of

tipping.

9.

Do

not

remove

radiator

cap

when

engine

temperature

is

above

2IZoF.

10.

Brakes

and

steering

clutches

should

be

properly

adjusted.

11.

Do

not

dr

ive

too

close

to

t.~e

edge

or

a

ditch

or

creek.

12.

Never

operate

your

crawler

tractor

in

a

closed

garage

or

shed~

13.

'¥ben

crawler

tractor

is

hitched

to

a

stump

or

other

heavy

loads,

alv..-ays

hitch

to

drawbar

and

never

take

up

slack

in

chain

with

a

jerk~

14

..

Always

keep

tractor

in

gear

when

going

down

steep

grades.

15.

Do

not

leave

the

engine

running

unattend

ed

when

anyone

is

adjusting

or

repairing

a

driven

machine.

16.

Do

not

attempt

to

operate

crawler

tractor

unless

you

are

in

the

driver's

seat.

17~

Provide

a

first

aid

kit.

Treat

all

scratches]

cuts,

etc.

with

proper

antiseptic

immediately.

l8~

Never

stand

between

crawler

tractor

and

drawn

i:mpleTIlent

when

hitching.

Use

an

iron

hook

to

::andle

drawbar.

19.

Do

not

dismount

from

crawler

tractor

while

it

is

in

motion.

20.

Keep

a

fire

extinguisher

handy

at

all

times.

Z

1..

Lock

shuttle

clutch

lever

in

neutral

position

when

dismounting

tractor.

22.

Never

attempt

to

tow

or

coast

crawler

trac-

tor

with

transmission

in

gear.

UNDER

NO

CIRCUMSTANCES

SHOULD

ANYTHING

BE

PULLED

FROM,

OR

BE

HOOKED

TO

ANY

PART

OF

THE

TRACTOR

EXCEPT

THE

DRA

WEAR.

8

GENERAL

INFORMA

TION

The

Model

HD-4

Crawler

Tractor

is

powered

by

a

4

cylinder,

4

cycle,

oper..

cOll1bustion

chamber,

direct

injection

ALLIS-CHALMERS

Model

2200

Diesel

Engine.

Engirue

power

is

transmitted

through

a

torque

con-

vertor.

Torque

is

multiplied

to

a 2. 15

to

1

ratio,

by

the

convertor

and

transrnitted

to

the

power

shuttle

clutch

and

to

a

constant

mesh

helical

gear

trans::.nission.

Frolll

the

transmission,

the

power

is

transmitted

to

the

spiral

bevel

gear

and

from

the

spiral

bevel

gear

through

the

multiple

disc

steering

clutches,

to

the

final

drives

and

the

track

sprockets.

Forward

and

reverse

direction,

in

any

speed

range,

is

obtained

through

the

power

shuttle

clutch.

The

transmission

provides

3

forward

speeds

and

3

reverse

speeds.

In

f01--wardt

ranging

froID

1.

81

MPH

in

I

st

gear

to

4.88

MPH

in

3rd

gear.

In

reverse,

ranging

froD}

2.

09

in

1st

gear

to

5.63

MPH

in

3rd

gear,

at

rated

engine

speed

of

2100

RPM's

and

1: 1

convertor

ratio.

The

HD-4

Crawler

tractor

is

equipped

with

alternator

l

12

volt

electric

starting,

center

mounted

radiator

with

suction

t)"Pe

fan,

torque

convertoT

J

muffler,

panel

lighting

equipment,

necessary

gauges

and

sending

units.

For

a

complete

listing

of

all

available

equipment

consult

your

local

ALLIS-CHALMERS

dealer.

SERIAL

NlJMBER

LOCATIONS

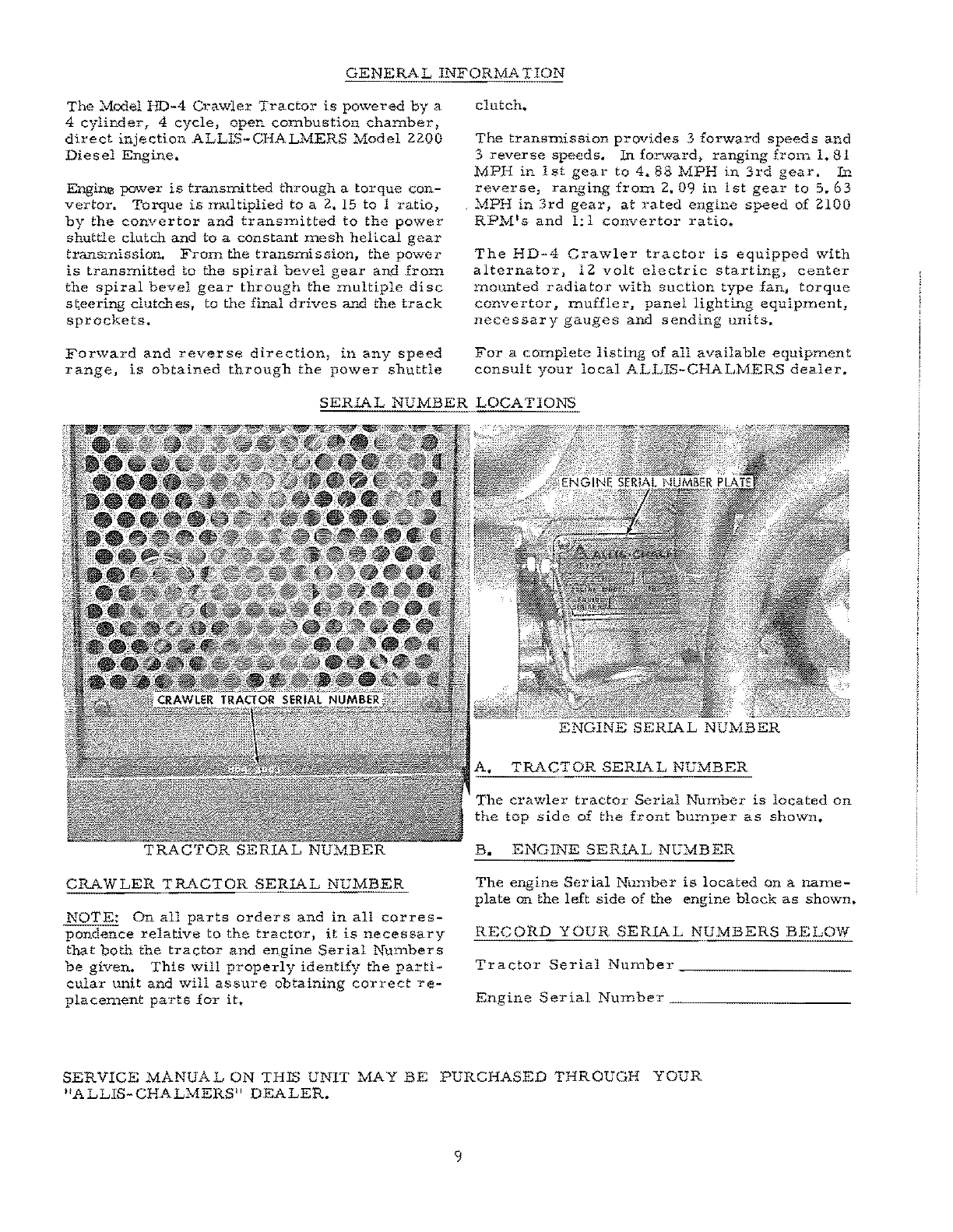

CRAWLER

TRACTOR

SERIAL

NUMBER

NOTE:

On

all

parts

orders

and

in

all

corres-

pondence

relative

to

the

tractor,

it

is

necessary

that

both

the

tractor

and

engine

Serial

Numbers

be

given.

This

will

properly

identify

the

pa::-ti-

cular

tmit

and

will

assure

obtaining

correct

re-

placelTI€nt

parts

for

it~

TR..'\CTOR

SERIAL

NUMBER

The

crawler

tractor

Serial

Number

is

located

On

the

top

side

of

the

front

bu:::nper

as

shown.

ENGINE

SERIAL

NUMBER

The

engine

Serial

Nu.."'TIber

is

located

on

a

narne-

plate

on

the

left

side

of

the

engine

block

as

shown.

RECORD

YOUR

SERIAL

NUMBERS

BELOW

Tractor

Serial

Number

_________

_

Engine

Serial

Nmnber

__________

_

SERVICE

MANUAL

ON

THIS

UNIT

MAY

BE

PURCHASED

THROUGH

YOUR

"ALLIS-CHALMERS"

DEALER.

9

LUBRICANTS

AND

FUELS

MOTOR

OIL

Motor

oils

are

designated

by

code

letters

as

follows:

DG

-

DM

-

DS.

The

letters

denote

the

type

of

service

for

which

the

unit

is

used.

DG

-

Diesel

General

Service

DM

-

Diesel

Medium

Service

DB

-

Diesel

Servere

Service

OIL

USED

IN

THE

ENGINE

CRANKCASE

SHOULD

MEET

THE

AMERICAL

PETROLEU1v1

INSTITUTE

(API)

DIESEL

CLASSIFICATION

OF

DS

SERIES

3

DIESEL

OIL.

Heavy

duty

oil

of

the

DS

classification

provides

the

most

satisfactory

lubrication

for

ALLIS-

CHALMERS

Diesel

engines.

These

oils

use

ad-

ditives

to

lower

the

pour

point

and

to

protect

the

engine

from

corrosion~

They

help

to

keep

the

engine

free

from

varnish

J

sludge

and

deposits

..

Unless

the

oil

has

the

proper

additives,

fuels

with

a

high

sulphur

content

cause

excessive

piston

ring

and

cylinder

liner

wear,

excessive

oil

consumption

and

piston

ring

sticking.

If

a

fuel

with

more

than.

50/0

sulphur

content

must

be

used

t

the

oil

change

interval

should

be

shortened.

Oil

designated

DS

SERIES

3

contains

certain

ad-

ditives

to

increase

film

strength,

to

be

COr-

rosion

resistant

l

to

carry

contamination

in

sus-

pension

and

as

pour

point

depressants,

etc.

The

fact

that

the

oil

has

the

ability

to

carry

contaminants

in

suspension

rather

than

deposit

them

in

the

engine,

causes

the

oil

to

discolor

rapidly.

Thus,

the

color

of

the

oil

cannot

be

used

to

determine

when

to

change.

(Follow

the

interval

given

in

the

Lubrication

and

Service

Guide).

FUEL

SPECIFICATIONS

FOR

ECONOMY

AND

PERFORMANCE

USE

FUELS

SPECIFIED

FOR

YOUR

ENGINE.

Fuel

used

in

the

ALLIS-CHALMERS

Diesel

en-

gine

:must

have

certain

qualities

in

order

to

ignite

and

burn

at

the

propel'

temperature

and

the

propel'

rate.

Experience

has

shown

that

the

fuel

best

suited:

closely

follows

these

specifications.

Gravity

(API)

30-35

Viscosity

Saybolt

Universal

at

IOOoF.

35-40

Flash

FO

minimum

ISOoF.

Diesel

Index

48.

5 -

65.5

Cetane

number

46

-

60

10

Pour

Point

OOF.

980/0

Recovery

700

o

F.

Sediment

and

Water

Trace

Ash

Maximum.

02

of

1%

max.

Gonradson

carbon

maximum.

03

of

1%

max.

Sulphur

maximum

1/2

of

1%

max.

NUMBER

2

HIGH

SPEED

DIESEL

FUELS

GEN-

ERALLY

MEET

THE

ABOVE

SPECIFICATIONS.

Some

of

the

more

desirable

high

speed

diesel

fuels

do

not

have

a

low

enough

pour

point

for

be-

low

zero

operation

and

cause

filter

plugging,

which

in

turn

causes

hard

starting.

In

this

event1

a

winter

grade

fuel

of

the

same

type

should

be

obtained

4

Pour

point

of

fuel

must

be

at

least

lOaF.

below

prevailing

atmospheric

temperature

for

satis-

factory

fuel

flow

through

lines

and

filters.

API

gravity

of

fuel

varies

with

its

specific

grav-

ity*

Low

API

fuels

are

desirable

because

they

have

high

specific

gravity

and

more

heat

units

per

gallon.. HOVlever,

the

higher

the

API

gravity,

the

better

ignition

quality

of

fuel

will

be.

Ignition

quality

of

fuel

is

expressed

as

a

Hcetane

numberll.

Higher

cetane

number:

higher

quality

of

fuel.

Higher

cetane

fuel

shortens

ignition

dela

y

period

to

facilitate

starting

and

improve

com-

bustion~

Diesel

index

number,

which

is

a

close

approximation

of

the

cetane

number,

is

a

field

nu"!thod

to

represent

ignition

quality.

Distillation

90%

point

and

end

point

are

impor-

tant.

High

volitility

is

required

to

enable

com-

plete

vaporization

of

fuel,

clean

combustion

and

low

residue

fonnation.

Flash

point

of

fuel

has

no

quality

significance,

but

is

important

with

respect

to

safety

in

fuel

storage

and

handling.

It

is

important

fuel

be

within

specified

limits

for

ash,

carbon,

water

and

sediment

content,

etc.

to

prevent

excessive

wear

and

darnage

to

engine

par

ts.

It

is

also

important

fuel

has

lubricating

properties

so

fuel

injection

pump

and

fuel

injection

nozzles

are

adequately

lubricated.

NOTE:

Sulphur

content

of

diesel

fuel

should

be

as

lOW'

as

possible;

fuel

should

not

contain

sulphur

content

of

more

than

1/2

of

10/0.

HANDLING

OF

FUEL

No

fuel

is

satisfactory

for

use

if

it

is

dirty.

A

few

small

pieces

of

dirt

can

cause

costly

damage

to

the

fuel

injection

pump,

which

is

built

of

closely

fitted

precision

parts.

The

following

rules

should

cover

the

handling

of

fuel

before

it

reaches

the

fuel

injection

pump~

1.

Do

not

handle

fuel

in

open

containers

where

dust

is

blowing

around.

2. Do

not

use

waste

or

Hnty

rags

around

fuet

containers

or

injection

equipment.

3.

Clean

all

st,,"zlge

tanks

at

regular

intervals.

4.

If

pumps

are

used

to

bring

fuel

from

storage

tank

to

tractor,

keep

covered

with

dust

proof

covers

when

not

in

use.

5~

vVhen

clnptying

a d

rum

or

storage

tank,

agitate

as

little

as

possible

and

leave

appI·ax.i-

II

matelyone

inch

of

fuel

in

bottom

of

tank

or

drum.

6.

Keep

all

fuel

handling

equipment

such

as

measure,

ftUmele,

containers.

etc.

scrupulously

clean

and

keep

thell1.

covered

when

not

in

USe.

Cleanliness

prevents

difficultYa

IMPORTANT:

The

lubricant

distributors

and/or

suppliers

are

to

be

held

responsible

for

the

re-

sults

obtained

from.

their

prOducts.

Procure

lubricants

from.

distributors

and/or

suppliers

of

unquestioned

integrity,

supplying

knowr..

and

tested

products.

Do

not

jeopardize

your

equipment

with

inferior

lubricants.

No

specific

brands

of

oil

are

recorlli--nended.

Use

only

products

quali-

fied

under

the

following

oil

viscosity

specifica-

tions

and

classifications

and

recolnmended

by

reputable

oil

com.panies.

FUEL

STORAGE

The

importance

of

proper

fuel

storage

cannot

be

too

strongly

stressed.

Storage

tanks,

dl'UlnS

or

portable

service

tanks

must

be

free

from

rust

scale,

sedimen.t,

or

any

other

foreign

ITlattel:'

which

will

contaminate

the

fuel.

COEtaminated

fuel

will

clog

the

fuel

filters

and

eventually

damage

the

fuel

injection

pump

and

fuel

nozzles.

The

most

practical

fuel

storage

seems

to

be

an

elevated

tank.

wit'h

an

open

sided

roof:

high

enough

for

air

to

circulate

tank.

This

protects

the

fuel

tank

from

rain

or

snow

and

hot

sun

rays.

The

fuel

storage

tank

should

be

installed

so

that

one

end

of

tank

is

slightly

lower

and

equipped

with

a

drab:

valve

at

the

lower

end

for

draining

off

the

sediment

and

water.

The

tank

should

also

be

provided

with

a

hose:

equipped

with

a

self

closing

nozzle

to

pr

event

the

entrance

of

dirt6

A

portable

storage

tank

provides

the

best

method

of

storing

fuel

on

the

job.

Since

all

storage

tanks

are

subject

to

condensation,

it

is

very

iITlportant

that

sediment

sump

be

provided

in

the

bottom

of

the

tank

so

that

water

and

sediment

can

be

drained

daily.

A

portable

storage

tank

should

be

provided

with

a

pump,

so

the

fuel

can

be

pwnped

into

the

tractor

fuel

tank

witi1 a

minimum

of

handling.

Draining

fuel

fror::1

supply

tank

into

bu.ckets

or

other

con-

tainers,

then

pouring

it

into

the

crawler

tractor

fuel

tank

is

not

considered

a

good

method

of

handling

fuel.

Fuel

should

be

allowed

to

settle

as

long

as

pos-

sible

i1:

a

storage

container,

before

it

is

used

in

the

fuel

ta..'Ll.:

of

the

crawler

tractor.

This

will

allow

the

sediment

and

water

to

settle

to

the

bottom

of

the

storage

container

and

permitting

cleaner

fuel

to

be

used

in

the

crawler

tractor

fuel

tank.

Where

conditions

are

such

that

drums

must

be

used

to

supply

fuel,

it

is

advisable

to

have

enough

d rUITlS

to

allow

sufficient

time

for

the

fuel

to

settle

before

being

used.

It

is

also

advisable

to

use

a

pwnp

and

pltlnp

the

fuel

from

the

drunl

or

co:r:.tainer,

rather

than

drain

it

from

the

bottom

of

the

fuel

container.

The

fuel

thus

left

in

a

number

of

drwns

can

be

collected

into

one

drwn

and

used

after

the

usual

time

allowed

for

settling.

In

this

manner

the

sedime:ct

and

foreign

matter

will

be

disposed

of

and

no

fuel

will

be

wasted.

¥lbenever

drums

are

used

for

fuel

storage.

they

should

be

covered,

or

placed

under

shelter

so

that

the

fuel

will

not

become

contaminated

by

water,

which

will

enter

through

the

filler

plug

when

it

rains,

even

though

the

plugs

are

tigbt.

The

fuel

tank

of

the

crawler

tractor

should

be

filled

at

the

end

of

the

day(s

run.

rat..."0er

t:'1.an

at

the

start

of

the

dayls

rur...

This

will

reduce

the

water

content

of

the

fuel

,

as

a

full

tank

is

less

subject

to

condensation.

FUEL

STORAGE

TANK

IZ

Table of contents

Other Allis-Chalmers Tractor manuals

Allis-Chalmers

Allis-Chalmers G User manual

Allis-Chalmers

Allis-Chalmers B Install guide

Allis-Chalmers

Allis-Chalmers regent hydro 14 User manual

Allis-Chalmers

Allis-Chalmers WD Use and care manual

Allis-Chalmers

Allis-Chalmers H 4 Specifications

Allis-Chalmers

Allis-Chalmers HD-14 User manual

Allis-Chalmers

Allis-Chalmers U Installation and user guide

Allis-Chalmers

Allis-Chalmers HD 6B User manual

Allis-Chalmers

Allis-Chalmers HD-5 User manual

Allis-Chalmers

Allis-Chalmers 910-6 Speed User manual