Allis-Chalmers HD-9 User manual

SERVICE

MANU

L

FOR

DEL

HD9

TRACT

R

1955

PROPERTY

OF

LITHO. !N U.S.A.

3

FOREWORD

"

TMis

manual

is

prepared

to provide the customer

and

the maintenance

personnel with complete information

and

instructions on

the

mainte-

nance of the Model "HD-9B" Tractor (standard model). Extreme care

has

been

exercised

in

the

designing, selection of materials,

and

the

building of the tractor. By

proper

maintenance

and

skillful operation

of the tractor, the utmost satisfaction

in

performance

and

service will

be

obtained.

In

order

to

become

familiar with the various parts of

the

tractor,

it

is

urged

that

the mechanic study

the

instructions

in

this manual

and

use

it

as

a reference

when

performing repair

or

maintenance operations.

All information

and

photographs shown throughout this manual are of

the

"Standard"

Model "HD-9B" Tractor, unless otherwise stated.

Sections I through

XIX

of this manual contain a

detailed

description

of the various assemblies of the tractor

and

instructions for

the

proper

adjustment

and

repair or rebuilding of these assemblies.

Section

XX

describes the Special Equipment available for

the

tractor

and

outlines the service of these parts.

General

Maintenance Instructions are given

in

Section XXI,

and

Fits

and

Tolerances

in

Section XXI/.

Trouble Shooting Information given

in

Section

XXIII

will

aid

in

deter-

mining

the

cause of

operating

irregularities

and

tells

what

may

be

done

to correct them.

General

information on

the

availability of

Special Tools is given

in

Se.ction XXIV.

To

assure

the

best

results

and

to maintain the original quality built

into

the

tractor,

it

is

important that

Genuine"

Allis-Chalmers" Parts

be

used

when

new

parts are required.

IMPORTANT:

ALWAYS

FURNISH

THE

DEALER

WITH BOTH

THE

TRACTOR

AND

ENGINE

SERIAL

NUMBERS WHEN ORDERING, pARTS.

Many owners of

"Allis-Cha/~Jii.s"

equipment

employ

the

Dealer's

Service Department for all work other than routine care

and

adjust-

ments.

This

practice

is

encouraged

as

our dealers are

kept

well informed

by

the

factory regarding

advanced

methods of servicing "Allis-

Chalmers" products

and

are

equipped

to render satisfactory service.

4

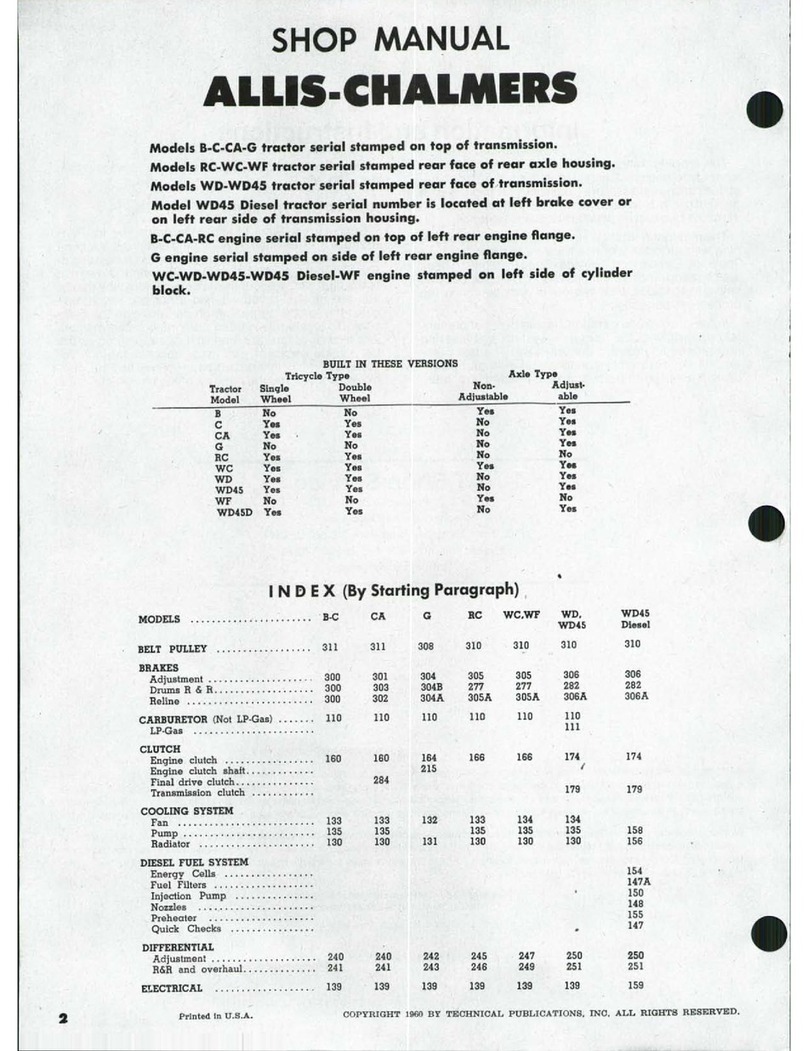

SUBJECT

INDEX

SUBJECT

PAGE SECTIOlli

Description

and

Specifications 1

Engine Fuel System

15

Engine Air Intake System

43

Engine Cooling System

68

Engine lubricating System

81

Engine Controls

and

Governor

94

Electrical System 104

Instruments

112

Engine 115

Engine Clutch

and

Clutch Brake 174

Transmission

and

Bevel

Gear

187

Steering Clutches

and

Controls 208

Steering Brakes 219

Final Drives 224

Truck Frames

241

Draw Bar 259

Tracks

261

Main Frame

and

Equalizer Spring 266

Fender

and

Seat

Group 270

Special Equipment 272

General

Maintenance Instructions 282

Fits

and

Tolerances 287

Trouble Shooting 295

Special Tools 313

.(~

5

SECTION

I-DESCRIPTION

AND SPECIFICATIONS

Topic Title Topic No.

General Description

...............

1

General Specifications

.............

2

Specifications of lubricants

..

. . . . . . . . 3

Specifications of

Fuel

..............

4

Fuel

Storage

.....................

5

Tractor

and

Engine Serial

Numbers.

. . 6

1.

GENERAL DESCRIPTION

The description given herein

and

the information

contained

in

this manual pertains to

~he

Model

"HD-98" Tractor (Standard Model), unless other-

wise stated.

The Model "HD-9B" Tractor

is

on 18,800 pound

track-type tractor powered with a 4-cylinder,

2-

cycle

"DIESEL"

Engine. Power from the engine

is

transmitted through a single plate, over-center type

engine clutch to the transmission through a drive

shaft universal joint assembly.

From

the trans-

mission, the power

is

transmitted to the bevel

gear,

and

from the bevel

gear

through two multiple disc

steering clutches (one on

each

side

of

the bevel

gear

shaft) to the final drives

and

the track drive

sprockets.

The

transmission provides 6 forward speeds rang-

ing from 1.4 M.P.H.

in

low

gear

to

5.7

M.P.H.

6

in

high

gear

and

3 reverse speeds ranging from

1.6

M.P.H.

in

low

reverse to 4.4

M.P.H.

in

high

reverse, under

full

governed engine

speed

of

1600

R.P.M.

Mechanical "Booster-Type" steering clutch

Con-

trols, mechanical self energizing brakes, adjustable

and

wide operator's seat,

and

unobstructed view

of the front of both tracks assure easy, positive

control of the

trador

at

all times.

The tractor

is

equipped with electric starting

and

lighting equipment, muffler,

full

width crankcase

guard,

front pull hook, bumper, hinged type

radi-

ator

grille, suction type fan,

and

16-inch integral

grouser shoes.

The

truck wheels, track idlers,

and

support rollers have positive type seals

and

are

protected by guards.

BACK

TRUCK

WHEEL

OUTER

TRACK

SUPPORT

EXHAUST

STACK

AIR

PRE-CLEANER

~

~

'RADIATOR

CAP

/

HEADLIGHTS

RAI)IArOR GRillE

HOOK

GUARD

L

______________

Fig.

I-Model

HD-9B Tracfor

______________

.....J

7

8

2.

GENERAl. SPECIFICATIONS

(STANDARD TRACTOR)

GENERAL SPECIFICATIONS:

Overall

length

,

.•

'

.•.

'

...

,

........

".,

..

,

.......•.

',."

..

"

....

,

...

,.,

........

,."

..

"

....

12

ft.

6 in.

Overall Height (without ,tacks)

.,

.•.........

"

....

,

•....

".,'

.....

,

•..

,.,

....

"

...........

," 6

ft.

11>

in.

Overall Width (standard

,hoe,)

...........................

"

.................

"

.........

7 ft.

11-1/16

in.

Turning Radius

..

,

....

,

....

,

............•.......

,

........

,

......•.....

,

....

,

.........

,

.....

8 ft. 7% in.

Ground Clearance

..•...•..........................

,.,

...

,

............

,

..

,

.................

13-5(16

in.

Drowbor Height (center line of jaw)

.,.'

..

"

.....

,",.,

....

,

.....

,'

...

,.'

........

'

....

,.,.',.

16-17/32

in.

Lateral Drawbar Movement

.•...

,

.•...............

,

.•.

"

.....•..

,

....••..•.............•...•.•..

26%

in.

Shipping

Weight

(approximate)

..•..

,

......

,

....

"

..

,.'.',

......

,.,."

..........

',

..

,

...

"

...

1

a,BOO

Ib,.

length

of Track on Ground "

•....•..

,"',

.....

,

...•

"

..

,

..

"

........

,.,.,

•....

,

.....

",

...

7 ft.

1%

in.

Width of

Standard

Track Shoes

.••....

""'

............

,

..

,

..

,.,

•.....

"

..

',

...

,

......

,'

........

,'

16 in,

Maximum Width Track Shoes Available

.. .,

, , , ,

........

.,

, , . , ,

....

, ,

.....

,.,

. , . ,

...........

,

.......

22

in.

Ground Contact Area

(standard

,hoe,)

...

"

..

".,

...

"

...

"

..

"

..............

"

........

.,

....

2744 sq. in.

Number of Track Shoes

per

Track

...

" ,

""

..

, ,

..

, , . , , , "

.,

...

, '

....

,

.......

.,

,

...

,

.........

, ,

..

,

..

, .3B

Ground Pressure

per

Sq.

In.

(standard

shoes)

....•

"',.,

..

"

•..

,.,

...

,

•....•....

,.,.,

....

,,

....•

' ,6.B5 Ibs,

Tread width

(center.to~center

of

tracks)

......

,

...•........

,

....

,',

.........

,

....•..............

,"

,74

in.

TRACTOR

SPEEDS

(at

Rated

Engine

Speed):

GEAR RANGE

SPEED

lst

Gear

..

,

....

,

...

,

.......

,.,"",

.......

,',.,

...

,

....

,

..............

,

..

,

..

"

•...

,

....

,

..

1.4

M.P,H.

2nd

Gear.,.,

, . , . ,

..

, ,

......•..

, ' . , , ,

.........

'

.....

,

....

,

..

, ,

..

,

.........

, .

,.

, . ,

.•.

, . ,

....

2.1

M,P,H.

3rd

Gear

•...•..

"."

...

,.,

......

,.,

.....

,

.....

,

...

,

......

,.""

...........

,

...

",

.........

2,9

M.P,H,

4th

Gear

••....

,

...

,.,"',

......

,.,."."

....

,.,.,"',

.........

,."

.........••.

,."

..

"

..•.

3.8

M.P.H.

5th

Gear

.............

,',.,

....

,."

...

,

..

,

..........

"

....

,.,

...

,.,

...

,",

...

,',.,",."

••.

4.4

M.P.H.

6th

Gear"

..........

,',."

.......

,.".,',

..

,

.......

,",

...........

,

...

,

..

,

....

,

......

,',

..

5.7

M.P.H.

1st

Reverse,.,.,

....

,

..

,.",

...

,

.......

"

...

""

......

,.,."

.....

,.,."

............

"""

..

1.6 M.P.H.

2nd Reverse

............

""

................

,

.................

",

.........

"

...........

,.,

..

3.5

M.P.H.

3rd

Reverse.,

...........

,

....

",

........

,

....

".,

.........

,

...

",.,

.......

"

.....

,

.....

"

..

4.4

M.P,H.

ENGINE:

Make

•.

,

.......•

,.,

..•.......•.....•..•.•••.•

,

.......•..

,

.•.........••...

',

•••

IIGeneral MotorsN Diesel

;:Y~;b~;~i

Cyii~d~~;

'.''-.'.'.'.'.'.'.'.'.':.'.'

.

.'.'.'.''.'''-'

'-:::.'

. .'.'

::.'.'.-.'.-.-::::.'.':.-:::.'.-.':

..

"

::.:.:::.'

.'.".r~aCy~l:

Bore

...•

,

...•.•.........

,

......••••.

,',.,.,

....

,

.••.•..•......•.

,.,

••...•...••••

,

•....•......

41;,1

in.

Stroke

.•••..•..

,

........••....

"."

..

,

...•••..

,

...

,',

.•.

"

..

""'

••...•......

"

..

,.,

••

,"'

.....

,,'

5 in.

Piston Displacement

...

,.,

.......

"

...

"

................

,

...

,

.•

"

...................

,',

.....

,

2B4

cu. in.

Engine

Speed

(governed

at

full lood)

.......

,'

...•

,',

.....

,

.......•

,

..

,',

....•

,"

..

,.",

....

,1600

R,P,M.

lubrication

.,

.......

,

......

".,

............

,.,

...

,.,.,

•....

,',

.......

,,'.,

...

,.,

......

,

...

Forced Feed

Foel

Used

..

,

.........

"

..

,

...

,

........

,.,

........

.",

.....

'

....

., ..

,.,

...

,.,

No. 1 or No. 2 Die,el

Fuel

Fuel Supptied by

..

"

...............•..•..

"

........

"

......

,.,

....•..•

,.,"'

...

55

cu.

mm.

Unit Injectors

CAPACITIES

(Approximate)

(U.

S.

Standard

Measure):

Cooling System

...

,',',

.....

,.,

...

'.,

..

,

.....

,'.'.,.,',

....

,"."

........

"

......

,',

.....•...

7Y.i

Gal"

Crankcase

and

Filter

.,

....•.........

,

..

,.,',.,

..

',

...........•.

,',

.......

, , , . ,

..

"

..........

,

..

,4

Gals.

Transmission

Case,

....

,

.'

...........

,

.................

,

..

, . , . ,

........

, , , , , ,

..•..

,

......

, , , .

,6JA

Gals.

Finol Drives (each)

..

,

....

,.,.,"

......

,.,',

..

"

....

,',

..

,

...

,

...........

,,',.,

..

,',

..

,'

..

,

,.3v..

Gals.

fuel Tank

.',

..

,.,

..

,

......

,.,

.....

,.,"'"

......•.....

'."

.....

,

"',

...

,

.....

,

..

".,',.,

...

55

Gols.

Track Release Housing (each)

•..

,.,.,.,

..........

,',

••.

,

.....•.

,.,.,

.•.......

"',

•..

,,.,

...

,

...

,2

Gals.

Air

Cleaner

...

,',

..........

',.,

.....

,.,.,

...

"

..

'"

...

',

....

,

.............

,.,

",

..

,."".,

..

1 Gol.

The Allis-Chalmers Manufacturing

Company

reserves the right to

make

changes

in

the

above specifications

or

to

add

improvements

at

any

time without notice

or

obligation.

9

3.

SPECIFICATIONS

OF

LUBRICANTS

A. Engine

Crankcase

Lubricant

USE

NON-CORROSIVE

"DIESEL"

ENGINE

WBRI-

CATING

OIL

CONTAINING

ADDITIVES

WHICH

WILL

PREVENT

SWDGE

OR

GUM

DEPOSITS_

UNDER

NO

CIRCUMSTANCES

SHOULD

A

COR-

ROSIVE

"DIESEL"

ENGINE

LUBRICATING

OIL

EVER

BE

USED.

Use

oils

of the following viscosities,

Atmospheric

Temperature

Viscosity

Above 32°

F.

Use

SAE

30

0°

F.

to

320

F.

Use

SAE

20W

0°

F.

and

below

Use

SAE

lOW

Manufacturers of lubricants recognize the impor-

tance of the qualities required for use

in

our equip-

ment

and

they

are

cooperating

fully

to assure the

use of only those oils which

fulfill

these require-

ments. The

oil

distributor

and

oil

manufacturer

are

to be held responsible for the results obtained from

their products.

The outstanding lubricating requirements for effi-

cient operation of the engine are, The maintaining

of piston rings

in

a clean, free condition; absence

of hard carbon

and

"varnish" deposits on or within

engine ports; the prevention of bearing corrosion;

and

the

promotion of general cleanliness within

the engine.

Proper operation

and

maintenance of the engine

are

necessary to obtain the desired results from

the lubricating oil.

B.

Transmission

and

Final Drive

Lubricant

Lubricate these assemblies with

any

good

grade

10

of engine lubricating

oil

purchased from a

reputa-

ble

oil

company.

Use

oils of the following viscosities:

Atmospheric

Temperature

Viscosity

Above 32°

F.

Use

SAE

50

320

F.

and

below

Use

SAE

30

C.

Track

Release

Housing

Lubricant

Lubricate these assemblies

with

SAE

50

engine

lubricating

oil

in

all seasons.

D.

Truck

Wheel,

Track

Idler,

and

Track

Support

Roller Lubricant

Lubricate these assemblies

with

a grease

that

has

been tested

and

found satisfactory for use by

the

Allis-Chalmers Manufacturing Company. A revised

list

of approved greases

is

issued every six months.

Ask

your nearest "Allis-Chalmers" authorized

Dealer for the latest

list.

E.

Pressure

Gun

Lubricant

Use

a ball

and

roller bearing lubricant with a

minimum melting point of 300°

F.

This

lubricant

should have a viscosity range

so

as to assure

easy

handling

in

the pressure gun

at

the prevailing

atmospheric temperature.

This

lubricant must

be

waterproof.

f.

Air

Cleaner

Use

the

same viscosity

oil

in

the air cleaner

as

used

in

the

engine.

CAUTION:

Do

not use on oil that

foams.

4.

SPECIFICATIONS

OF

FUEL

Use

a No. 1

"DIESEL"

Fuel

purchased from a

reputable

oil

company.

In

warm weather

No.2

"DIESEL"

Fuel

may be used.

This

fuel

must

be

within the classification limits as established

by

the

American Society for Testing Material, Tentative

"DIESEL"

Fuel

Oil Specifications

(ASTM

0975).

For

longer engine life

and

performance, fuel re-

quirements

mus~

comply with four basic qualifi-

cations:

I. Physical cleanliness.

2. Absence of chemical contamination.

3. Proper burning characteristics.

4. Cold starting ability.

Physical cleanliness means freedom from water,

dirt,

and

other incombustible ingredients. Since

all present

day

high speed

"DIESEL"

fuels

are

com-

pletely distilled, they leave the refinery

in

clean

condition.

The most objectionable chemical contaminants

are

free sulphur

and

gum, which, even

in

relatively

small quantities

are

largely responsible for harm-

ful

internal engine deposits. The fuel must also be

11

free from alkali

and

mineral acids.

Proper burning characteristics

are

dependent upon

ignition quality

and

volatility.

All

fuels meeting the requirements of the No.

1-0

and

also the lighter types of fuel

in

the No.

2-D

grade

of ASTM-D975

"DIESEL"

Fuel

Oil Specifica-

tions

are

satisfactory.

The

more volatile

grade

(ASTM No.

I-D)

is

recommended for all types of

service where frequent speed

and

load changes

occur, while fuels

in

the heavier

grade

(ASTM

No.

2-D) may be used with sustained high loads.

Prolonged use of fuels combining low ignition

quality (less than

45

Cetane Number) with high

boiling temperature (more than 6750

F.

end

paint)

should be avoided, particularly

in

cold weather.

CAUTION,

The

sulphur content of

"DIESEL"

fuel

should be

as

low

as

possible.

For

warm

weather

conditions, the fuel should contain not more than

V.

of

1% sulphur.

For

cold weather operation, fuel

with not more than

3/10

of 1% sulphur

is

preferable.

5.

FUEL

STORAGE

The importance of proper storage of fuel cannol

be

too strongly stressed. Storage tanks, drums, or

service tanks must

be

free from rust, scale, sedi-

ment, or

any

other foreign molter which

will

contaminate the fuel. Dirty fuel

will

clog the fuel

filters

and

eventuolly

damage

the fuel pump

and

injectors.

A portable storage tank provides the best method

for storing fuel on the job.

In

a storage tank, the

sediment

and

water can easily

be

drained

and

the

fuel can be pumped into the tractor fuel tank with

a

minimum

of handling. Consult your nearest"Allis-

Chalmers" Dealer for details

about

this type

of

storage tank. Since condensation

will

occur

in

the

storage tank,

it

is

very important

that

a sediment

sump be provided

50

that

water

and

se'ltlings

ccm

be drained daily.

Fuel

should be allowed to settle

at

least

48

hours

in

the storage container before

it

is

added

to the

fuel tank of the tractor.

It

is

advisable to use a

pump

and

draw the fuel from the container rather

than to drain

it

from the bollom of the container.

Where conditions

are

such that drums must

be

used

to supply fuel,

it

is

advisable

to

have enough drums

to allow sufficient time for the fuel to sellie. The

fuel should be used only to within about three

(3)

inches from the bottom of the drums.

The

fuel thus

left

in

a number of drums can be collected into

one drum

and

used after the usual time allowed

for settling.

In

this

manner, the sediment

and

for-

eign matter

will

be disposed of

and

no fuel

will

be

wasted. Whenever drums

are

used for fuel

storage,

they should

be

covered

or

placed under shelter

to

avoid contamination of

the

fuel

by

water, which

will

enter through the filler plugs when it rains,

even though the plugs

are

tight.

The fuel tank of the tractor should

be

filled

at

the

end

of

the day's run rather than

at

the start; this

will

reduce the water content,

as

a

full

lank

is

less

subject to condensation. The tractor fuel tank

is

provided with a drain elbow

and

drain cock, for

draining accumulated

waler

and

sediment.

L-

_______________

Fig. 3 Fuel Storage Tonk

--------

______

---J

12

6.

TRACTOR

AND

ENGINE

SERIAL

NUMBER.S

On all parts orders

and

in

all correspondence rela-

tive to the tractor, it

is

necessary that both the

tractor

and

engine serial numbers be given.

This

will

properly identify the particular machine

and

will

assure obtaining the correct replacement parts

for it.

The tractor serial number

is

stamped

in

the

rear

13

face of the steering clutch housing (near the upper

right corner)

and

is

also stamped on a serial

number plate

attached

to the cowl.

The engine serial number

is

stamped on the upper

right side of the cylinder block, below the governor

control housing.

14

SECTION

II-ENGINE

FUEL

SYSTEM

Topic Title

Description

of

System

............

. Topic No.

1

Checking

Fuel

Supply System

......

. 2

Fuel

Tank

and

Drain Elbow

........

. 3

Fuel

Filters . . . . . . . . . . . . . . . . . . . . . .

..

4

Fuel

Pump.

. . . . . . . . . . .

..

. . .

..

.

..

5

Fuel

Injectors

...................

6

Injector Copper

Tubes.

. . . . . . . . . . . . 7

Fuel

Manifolds . . . . . . . . . . . . . . . . . . . 8

1.

DESCRIPTION OF SYSTEM

The

engine fuel system consists of the fuel tank,

first stage fuel filter, fuel pump, second stage fuel

filter, injectors, fuel lines,

and

fuel pressure

gage.

The

fuel

is

drawn from

the

bottom of the fuel tank

and

through the first

stage

fuel filter by the fuel

pump.

The

pump then circulates the fuel under

pressure through

the

second'stage

fuel filter, fuel

inlet monifold

on

the right side of the cylinder

head,

and then through the injectors.

As

the fuel

enters each injector, it passes through a small

porous metal filter

in

the injector body. The amount

of fuel required by the engine

is

injected into the

cylinders by the injectors; surplus fuel, not required

for combustion, leaves eoch injector through an-

other porous metal filter, enters the return fuel

manifold and

is

returned to the fuel tank. A pres-

sure of

20

to 55 pounds

is

maintained within the

fuel system by a restricted fitting located

in

the

rear

of the return fuel manifold.

The

continuous

circulation of fuel helps to cool the injectors

and

eliminates the possibility

of

air pockets

in

the fuel

system.

INJECTOR

FUEl

LINES

RETURN

FUEL

MANIFOLD

FUEl

TANK

DRAIN

COCK

~~,

."

...

"

;:

"

"

"

"

"

"

"

"

.,

RETURN

TO

TANK

~::::==~=:9

FUEl

TANK

SHUT.OFF

VALVE

INJECTORS

O--o-O~o

2nd

STAGE

FUEL

FILTER

\ ( \

INLET

FUEL

MANIFOLD

u

ht

STAGE

FUEL

FILTER

'---

____________

fig.

I-Schematic

ruel

Flow

Diagram

____________

----'

15

2.

CHECKING

FUEL

SUPPI.Y SYSTEM

A.

General

Under normal conditions, with the

engine

running

at

full throttle,

20

to

55

pounds pressure will

be

indicated on

the

fuel pressure

gage.

Fuel pressure

below

normal, uneven running of

the

engine,

ex-

cessive vibration, stalling when idling,

and

a loss

of power

are

indications of insufficient fuel supply

to

the

injectors.

To

determine

the

cause

for

the

above

conditions, check for

the

following:

1. Air being

drawn

into fuel system on

the

suc-

tion side of

the

fuel pump.

2.

Clogged

fuel filter elements

and

fuel lines.

3.

Clogged

injector fuel filters.

4. Inoperative fuel pump.

B.

Check

for

Full Flow

of

Fuel

Through

System

To check

the

flow of fuel through

the

system, dis-

connect

the

fuel return line

at

the

fuel

tank.

With

the

engine

operating

at

high idle,

the

system

will

be

functioning

properly

when a full stream of fuel

with considerable pressure can

be

observed re-

turning to

the

fuel

tank

through the return fuel

line.

If

only a small stream

is

observed returning

to the tank, all causes listed

above

must

be

checked

and

eliminated

in

turn.

C.

Check

for

Admission

of

Air

into

System,

Clogged

Fuel

Filter

Elements,

and

Clogged

Fuel Lines

To check for

air

being

admitted

into

the

system,

follow

the

same

procedure

as

used

in

checking

for

flow of fuel.

If

air

is

entering into fuel system,

foam

or bubbles will

be

observed

in

the fuel

that

emerges

from the loosened connection. Correct

this condition

by

tightening

any

loose fuel lines

and

filter connections

between

the

fuel

tank

and

the

fuel pump.

Start

the

engine

and

test for smooth

operation

and

full flow of fuel.

If

the fuel lines or filters

are

clogged,

clean

the

first

stage

or second

stage

fuel filter, or both, in-

stall new elements,

and

blowout

the

lines while

they

are

disconnected.

This

should eliminate

the

difficulty. Check for

full

flow of fuel

after

engine

is

again

started.

16

D.

Check

for

Clogged

Fuel

Iniector

Filters

If

the

engine still runs

"ragged"

with suitable fuel

return,

the

injector filters for one or more of

the

cylinders may

be

partially clogged. Locate

the

faulty injector

as

follows:

Run

the

engine

at

low idle speed

and

cut

out

each

injector

in

turn

by

holding the injector follower

down with a screwdriver or small block of

wood.

CAUTION:

Do

not allow the screwdriver to slip

off the iniector follower

as

damage

to the valve

assemblies can easily result. A

decrease

in

engine

speed

with

the

injector follower held down

will

indicate

that

the

injector for

that

cylinder

is

func-

tioning properly.

If

engine

speed

does

not de-

crease, the injector

is

inoperative

and

should

be

removed for further inspection.

To

determine

whether or not

the

faulty injector

is

obtaining suf-

ficient fuel, stop

the

engine

and

remove

the

fuel

line

that

connects

the

injector to the return fuel

manifold. Hold a finger over the injector fuel out-

let

and

crank

the

engine

with the starter.

If

fuel

gushes from

the

injector fuel outlet while

the

starter

is

cranking

the

engine,

an

ample

fuel supply

is

indicated.

illlliilllliilllliilllli'" INJECTOR FOlLOWER

'-

__

-'I

Fig. 2 -

Locating

Faulty

Injector

___

-'

E.

Check

for

inoperative

Fuel

Pump

Assuming

that

there

is

a sufficient supply of fuel

in

the fuel tonk,

and

that fuel

is

reaching the fuel

pump, loosen the vent screw located

in

the top of

the second stage fuel fliter.

The

fuel should gush

from the vent screw opening

in

the filter with the

engine running

at

low

idle.

If

fuel does not gush

from this opening, the fuel pump

will

be

consid-

ered inoperative and must be repaired or replaced.

F.

Excessively

High Fuel

Pressure

A relief valve

is

installed

in

the fuel pump to pre-

vent high fuel pressure.

If

the relief valve sticks,

high pressure

will

develop

and

will

be indicated

on

the fuel pressure

gage.

When this occurs, the

valve

in

the fuel pump should be inspected and

the couse determined for

its

sticking.

The

second

stage fuel filter, the restricted fitting installed

in

the rear of the return fuel manifold,

and

all the

fuel lines should

be

inspected for clogged

passages.

Continued operation with excessively high pressure

(over 55 pounds) may result

in

damage

to the fuel

system.

3.

FUEL

TANK

AND

DRAIN ELBOW

A.

Description

The

fuel tonk, located

at

the

rear

of the tractor,

has a capacity of approximately

55

gallons.

The

drain elbow

at

the bottom of the fuel tonk provides

a means for draining the tonk when flushing and

also acts

as

a sediment sump.

Open

the drain cock

in

this elbow before the engine

is

storied

at

the

beginning of the day's operation

in

worm weather

or shortly after the end of the day's operation

in

freezing weather; close the drain cock when clean

fuel runs out. Drain

and

flush the fuel tonk

if

a

large accumulation of rust

and

scale

is

evident.

B.

Maintenance

If

a large accumulation of rust or scale

in

the fuel

tank becomes apparent, remove the drain plug

from the fuel tank drain elbow, disconnect the fuel

lines from the fuel tank,

and

flush

the tank with

17

clean fuel or clean the tank with live steam.

This

will

prevent frequent clogging

of

the fuel filters

and

will

eliminate possible trouble

in

the fuel

system.

C.

Removal

1.

Remove the seat cushion. Remove the side

cushion from the top of each battery box.

Remove

the bolt attaching each battery box

to the front of the fuel tank (one bolt on

each side).

2. Remove the capscrew ollaching the battery

cable supporting clip to the fuel tank.

3. Close the fuel tank shut-off valve located

at

the lower front side of the fuel tank.

Discon-

nect the fuel supply line from the fuel tank

shut-off valve

and

disconnect the fuel re-

turn line from the fuel tank.

4. Remove the bolts attaching each side of the

fuel tank to the

rear

fenders.

5. Place a suitable chain or rope around the

fuel tank

and

remove the tonk from the trac-

tor. Protect all openings of the fuel tonk and

the disconnected fuel lines against entrance

of foreign material.

D.

Installation

Install the fuel tonk by a direct reversal of the re-

moval procedure (refer to

C.

above).

4.

FUEL

FILTERS

A.

Description

The engine

is

equipped with two

(2)

fuel filters,

each containing a replaceable filter element. The

first stage fuel filter

is

mounted

at

the left rear side

of the engine

and

the second stage fuel filter

is

mounted on the right side of the engine. A drain

cock

is

provided

in

the bottom of each filter for

draining of water

and

sediment.

'--_

fig.

4 -

first

Stage

Fuel Filter Location .

18

B.

Service

The service of each fuel filter

is

the same.

To

serv-

ice

the fuel filters proceed

as

follows:

Open the mter drain cock daily, before

the

engine

is

started

at

the beginning of the day's operation

in

warm weather or shortly after the end

of

the

day's operation

in

freezing weather,

and

allow

the water or sediment

to

drain. Close the drain

cock

as

soon as clean fuel runs out. Remove

and

discard the old element

and

install a new element

after every

300

to

500

hours of operation (more

often

if

conditions warrant) or when the filter ele-

ment becomes clogged. A clogged filter element

is

usually indicated by irregular engine performance.

c.

Replacement

of

First

Stage

Fuel

Filter

Element

1. Close the fuel tank shut-off valve.

2. Thoroughly clean the filter cover

and

the

surrounding

area.

Loosen

the drain cock, lo-

cated

in

the bottom of the filter shell,

and

allow the filter to

drain.

3. Loosen the cover screw

and

remove the cover

screwl cover screw gasket, cover, cover

gasket,

and

spring as a unit. Remove

the

cover gasket from the cover

and

discard the

gasket.

4. Remove

and

discard the element washer,

element gasket,

and

the filter element.

5. Reaching inside the filter shell, remove the

element gasket

and

elemen! washer from

the shell centerbolt

and

discard.

6. Thoroughly wash

and

dry the interior of

the

filter shell. Close

and

tighten the drain cock

located

in

the bottom of the filter shell.

7. Install a new element washer

in

position on

the shell centerbolt, then install a new filter

gasket

and

press the gasket down firmly onto

the element washer.

8. Install a new elemen!

in

position

in

the filter

shell. Place a new element gasket

and

an

element washer

in

position

on

the shell cen-

terbolt

and

press the gasket down firmly

onto the top of the

fi

Iter element.

9. Install a new cover gasket

in

position

in

the

cover.

10. Open the fuel tonk shut-off valve

and

allow

the filter to

fill

with fuel, then install the cover

in

position on the filter shell

and

tighten

the cover screw securely.

/"'"

COVER

SCREW

~i

COVER

SCREW

"'O."....--GASKET

~

__

-SPRING

COVER

GASKET?

"""'''';~:''_EI.EMENT

WASHER

ELEMENT

GASKET~

FilTER

ELEMENT

---

ElEMENT

GASKET

_-ELEMENT

WASHER

COCK

FilTER

'--

__

Fig.

6 - First

Slage

Fuel filrer Oelalls

D.

Replacement

of

Second

Stage

Fuel Filter

Element

1. Thoroughly clean the fuel filter

head

and

the surrounding

area.

loosen the drain cock,

located

in

the bottom of the filter shell,

and

allow the Alter to drain.

2. Remove the Alter shell (with

its

components)

from the fuel Alter

head

by loosening the

shell retaining nut. 19

______

:;....-SCREW

GASKET

VENT

SCREW

n

/.iJ

RETAINING

NUT

GASKET

SHEIL

RETAINING

0---

NUT

FUEL

FilTER

FILTER

ELEMENT

~

-

ELEMENT

SEATING

SEATING

PLATE

~

....

~

PLATE

GASKET~

ELEMENT

s~

~METAL

WASHER

~GASKET

'--

__

Fig. 7 Second Stage Fuel

filter

Details

3. Remove

and

discard the

Alter

element.

Re-

move the centering guide, element seating

plate, seating plate gasket, metal washer,

and

element spring from the shell centerbolt.

Discard the seating plate gasket, metal

washer,

and

shell gasket.

4. Thoroughly wash

and

dry the interior of the

Alter shell. Close

and

tighten the drain cock

located

in

the bottom of the filter shell.

5. Place the element spring (large end down-

ward)

in

position

On

the shell centerbolt

and

install a new metal washer over the shell

center

bolt

and

down against the element

spring.

6. Install a new seating plate gasket

in

position

in

the element seating plate, then install the

gasket

and

element seating plate

in

pasition

on

the shell centerbolt.

7. Install the centering guide

in

position on the

shell centerbolt and install a

neW

filter ele-

ment

in

position

in

the filter shell. Install a

new shell gasket

in

position

in

the filter shell.

8. Hold the filter shell

in

position under the fuel

filter

head

and

tighten the shell retaining

nut. Remove the vent screw

and

screw gasket

from the shell retaining nut.

9. With the engine shut-off knob pulled back

(stop position), crank the engine momentari-

ly

with the starter until fuel emerges from

the vent screw opening

in

the shell retaining

nut. Install the vent screw

and

screw gasket

and

tighten the vent screw securely.

10. Start the engine

and

observe for fuel leaks;

correct any leaks found.

L

__

Fig.

8-Heavy-Duty

E.

Heavy-Duty

Fuel Filter

(Special Equipment)

On

tractors equipped

with

a Heavy-Duty Fuel

Fil-

ter, service as·follows:

Loosen the drain plug located

in

the bottom

of

the

fuel fllter housing, before the engine

is

started

at

the beginning of the day's operation

in

warm

weather or shortly after the

end

of the day's op-

eration

in

freezing weather

and

allow the water

or sediment to drain. Tighten the drain plug when

clean fuel runs out. Remove

and

discard the old

fllter element

and

install a new

one

after every

300

20

to 500 hours of operation or when the fuel pressure

drops below 20 pounds per square inch.

A=,~~~VENT

PLUG

,

I

I

I

,

I

GASKET

REINFORONG

I

PLATE

:

~

FUEL

FILTER

HOUSING

,

=r;:qy

GASKETS

L

'

HOLLOW

iLDRAIN

PLUG

Fig. 9 -

Heavy-Duty

Fuel

Filter Details

F.

Replacement

of

Heavy-Duty

Fuel Filter

Element

1. Close the fuel

tank

shut-off valve.

2. Remove the drain plug from bottom of the

fuel filter housing

and

then allow the fuel to

drain from the filter. Remove the cover cap-

screws

ond

lift the cover from the housing.

3. Unscrew the T-handle hold-down assembly

from the center tube

ond

remove the T-han-

dle hold-down assembly

and

the element

centering plate. Remove the fllter element

from the housing by lifting

with

the pull-out

bail.

DisC<'lrd

the fllter element and the cover

gasket.

4. Clean the interior of the fuel filter housing

thoroughly

and

install the drain plug.

5.

To

assure leak-proof sealing, examine the

center-tube seal

at

each

end

of the new

fll-

ter element to see

that

the seals

are

in

good

condition

and

clean. Insert the new fllter

element into position

in

the fllter housing

and

press the fllter element down firmly.

6.

Place the element centering plate

in

posi-

tion on the top of the fllter element

and

in-

stall the T-handle hold-down assembly

and

tighten securely.

7. Install a new cover gasket

in

position

in

the

cover

and

place the cover

in

position on the

filter housing. Install the cover capscrews

and

tighten evenly

and

securely.

8.

Fill

the fuel tank so that there

will

be

suffi-

cient fuel

in

the tank

to

fill

the fuel fllter

by

gravity.

Open

the fuel tank shut-off valve.

9. Remove the vent plug from the fliter cover

and

allow the fllter

to

flll

with fuel by grav-

ity. Install

and

tighten the vent plug when

fuel emerges from the vent

pll!l;J

opening.

CAUTION,

Use

only a

"DIESELPAK"

filter

element

in

the Heavy-Duty Filter.

5.

FUEl.

PUMP

A.

Description

The fuel pump

is

a constant flow

gear

type pump,

having a delivery capacity of approximately

35

gallons

per

hour

at

1000 engine

R.P.M.

with a

pump discharge pressure of

40

pounds

per

square

inch. The pump

is

bolted to the

rear

end

of the

blower end plate cover,

and

is

driven

by

the lower

blower rotor shaft through a self-aligning,

U-shaped, steel coupling.

Two

steel

gears

revolve

inside the pump housing to

create

a vacuum

in

the

intake chamber, thus drawing the fuel from the

fuel tank. The fuel

is

carried

around

the

gears

in

the

spaces between the teeth

and

is

forced out of

the pump under pressure. The pump driving

gear

is

mounted on a free-floating

type

driving

gear

shaft

and

is

attached to the shaft by a

shear

pin.

The pump driven

gear

is

supported

in

the

bore

of

the pump housing by

its

supporting journal, which

is

an

integral

part

of the driven

gear.

Two pump shaft

oil

seals

are

used inside the stator

at

the

coupling end. The sealing

edge

of one

oil

seal faces the pump housing

and

retains the fuel

within the pump, the sealing

edge

of the other

oil

seal faces the coupling end of

the

stator

and

pre-

vents engine lubrication oil from entering the

pump.

Two

(2) drain holes, located between the

two seals, vent to the atmosphere.

A spring loaded relief valve, located on the inlet

side of the pump (left side of pump viewed from

pump housing end),

is

provided to by-pass fuel

back

to the inlet side when

the

outlet pressure ex-

21

ceeds

47

to

60

P.S.1.

This

valve normally does not

open since

its

purpose

is

to relleve excessive pres-

sure

in

case clogging occurs

in

the fuel lines or

filters.

B.

Service

If

the fuel pump

is

to

be reconditioned, the pump

assembly must be removed from the engine.

C.

Removal

of

Fuel

Pump

1. Close the fuel tank shut-off valve.

2.

Disconnect the two fuel lines from the pump.

3. Remove the three (3) capscrews attaching

the fuel pump to the blower end plate cover.

(Use

the special fuel pump wrench to remove

the capscrew nearest the cylinder block.)

Remove the fuel pump

and

the drive cou-

pling as a unit, withdrawing the pump

straight from the blower end plate cover.

4. Rotate Ihe pump driving

gear

shaft by hand

10 see

if

the internal parts of Ihe pump rotale

freely.

If

binding or sticking

is

evident,

disassembly

and

inspection of the pump

will

be necessary.

D.

Disassembly

of

Fuel

Pump

When repairing the pump,

if

an

oil

seal expanding

1001

is

not available there

is

considerable

danger

in

damaging the

oil

seals when Ihe pump driving

gear

shaft

is

again installed. When installing the

shaft,

il

is

very essential 10 install

it

withoul

damage

to the 0

iI

sea

Is.

The relief valve assembly may be removed from

the pump slalor wilhout disassembly of the olher

paris of the pump,

by

removing the pressure relief

valve plug

and

jarring the valve parIs from the

pump slalor.

1. Remove the eight screws attaching the

pump

housing to the stator. Install four

(4)

cap-

screws

v..

x

20

NC

x 3

in

four of the

cap-

screw holes

so

that the heads of the screws

can

be

tapped

with a hammer to

separate

the pump stator

and

the pump housing.

2. Holding the pump assembly

in

the

hand,

tap

the heads of the capscrews with a soft

hammer, separating the pump stotor

and

the

pump housing.

CAUTION:

DO

NOT

PRY

PUMP

STATOR

AND

PUMP

HOUSING

APART.

3. Remove the driven

gear

from the pump

housing.

4. Remove the pump driving

gear

shaft

and

driving

gear

from the pump stator carefully,

to prevent

damage

to the

oil

seals.

5. Remove the dowel pins

if

necessary.

6.

If

it

is

necessary to remove the

oil

seals from

the pump stator, a tool of the proper design

should be used to prevent

damoge

to the

seals.

When removing Ihe relief valve assembly, note the

position of each

part

so thaI the parts may

be

reassembled

in

their same relative position.

E.

Inspection

of

Fuel

Pump

Parts

If

only Ihe pressure relief valve assembly

is

to

be

inspected, no further disassembly of the pump

is

necessary. If the pump

is

to be dismantled, proceed

as

follows:

1. Wash the fuel pump paris

in

clean fuel or

solvent

and

inspect carefully. The

oil

seals,

once removed from the pump, should

be

re-

placed

with

new seols. If the sealing

edges

of the

oil

seals

are

domaged

in

any

way, so

DR1V!NG

GEAR

PUMP

STATOR

~._

I

DRIVING GEAR SHAFT

~

~

INNE'

OIL

SEAL

~

~

\

/'

\ HOUSING

:I

",

SHEAR

PIN

;)RIVEN

GEAR

~~

OUTER

Oil

SEAL

)~

SPRING

PRESSURE

RELIEF/'x.,

I

jGASKEl

VAtVE

PLuNGER

,

PLUG

GUIDE

PIN

,

SCREW

o j;,

LOCKWASHER

'--

________

Fig.

11

-Fuel Pump Detail.

_________

...J

22

This manual suits for next models

1

Table of contents

Other Allis-Chalmers Tractor manuals

Allis-Chalmers

Allis-Chalmers ac130 series User manual

Allis-Chalmers

Allis-Chalmers HD-14 User manual

Allis-Chalmers

Allis-Chalmers HD-5 User manual

Allis-Chalmers

Allis-Chalmers 10 hp User manual

Allis-Chalmers

Allis-Chalmers 910-6 Speed User manual

Allis-Chalmers

Allis-Chalmers HD 6B User manual

Allis-Chalmers

Allis-Chalmers regent hydro 14 User manual

Allis-Chalmers

Allis-Chalmers H 4 Specifications

Allis-Chalmers

Allis-Chalmers HD-4 Specifications

Allis-Chalmers

Allis-Chalmers G User manual