Allis-Chalmers H 4 Specifications

OPERATORS

INSTRUCTIONS

FOR

MODEL H 4

&.

HD4

TRACTORS

ALLIS-CHALMERS

BOX

512 • MILWAUKEE, WISCONSIN 53201

LITHO.

IN

U.

S. A.

FORM

TM-387 A

.-----=:~~

DEALERS PRE-DELIVERY SERVICE

===~--,

MODEL H 4 & HD 4 TRACTORS

FIRM

NAME

____________

_

DATE

DELIVERED

____________

_

ADDRESS

_____________

_

SERIAL

#

PHONE

ENGINE #

_____________

_

THE

FOLLOWING

PRE·DEUVERY

SERVICE

HAS

BEEN

COMPLETED:

1.

LUBRICATED

2.

OIL

LEVEL

IN

GEAR

HOUSINGS

CHECKED

3.

ENGINE

OIL

LEVEl

CHECKED

4.

AIR

CLEANER

CHECKED

5.

FUEL

FIlTERS

CHECKED

6.

BATTERY

CHECKED

7.

COOLING

SOLUTION

IN

RADIATOR

CHECKED

s.

GENERATOR

CHARGE

RATE

CHECKED

9.

IGNITION

TIMING

CHECKED

10.

INJECTION

PUMP

TIMING

CHECKED

11.

CARBURETOR

CHECKED

12.

FAN

BELT

ADJUSTMENT

CHECKED

13.

CYLINDER

HEAD

TORQUE

CHECKED

14.

VALVE

TAPPET

ClEARANCE

CHECKED

15.

SPARK

PLUG

GAP

CHECKED

16.

ENGINE

SPEEDS

CHECKED

17.

STEERING

CLUTCH

ADJUST~ENT

CHECKED

18.

STEERING

BRAKE

ADJUSTMENT

CHECKED

19.

HYDRAULIC

SYSTEM

CHECKED

20.

ALL

BOlTS

&

NUTS

TIGHTENED

21.

LIGHTS

CHECKED

22.

TRACK

ADJUSTMENT

23.

APPEARANCE

OF

TRACTOR

* * *

YOLIR

TRACTOR HAS

BEEN

ADJlISTED

AND

SERVICED

BY

DEALER

PRIOR

TO

ITS

DELIVERY

TO YOLI.

YOLI

ARE

REQUESTED

TO ADVISE

WHEN

TRACTOR HAS OPERATED 30 DAYS (OR

100

HOURS)

SO

DEALER

REPRESENTATIVE

CAN

CHECK

ITS

ADJUSTMENTS

AND

PERFORMANCE.

DELIVERY

RECORD

FOR

FARM

OR

INDUSTRIAL

TRACTORS

THIS

FORM

MUST

se

FILtED OUT,

!N

TRIPLICATE, Sy

THE

DEALER

AND

SIGNED

BY

THE

CUSTOMER

AT

TIME UN!T

15

DELIVERED,

DELIVERED TO

_______________________

_

DEALER

R. R.

#

__________

_

BOX

#

______

_

TOWN

TOWN

___________________

___

SERIAL

#

STATE

_________________________

__ ENGINE #

PHONE

_________________________

_ SERVICED

BY

CHECK

ONE

fARM

USE

0

INDUSTRIAL

USE

0

EXPLAIN

CARE,

SAFE

OPERATION

AND

ADJUSTMENTS

OF

tTEMS

LISTED

BELOW:

TO

BE

COMPLETED:

o

LUBRICATION

o

BREAK-IN

PERIOD

o

STEERING

BRAKES

o

SHUTTLE

CLUTCH

BACKHOE;

o

ENGINE

TEMPERATURE

o

HYDRAULIC

SYSTEMS

MAKE

______

_

o

RADIATOR

DRAIN

COCKS

o

DRAWBAR

MODEl

______

_

o

RADIATOR

PRESSURE

CAP

o

fiNAL

DRIVE

SERIAL

No.

_____

_

o

fAN

BELT

o

TRANSMISSION

o

MOTOR

011

o

BATTERY

CARE

LOADER:

o

PROPER

fUEL

o

OIL

FILTERS

o

fUEL

filTERS

o

STARTING

MOTOR

o

AIR

ClEANER

o

LIGHTS

o

STARTING

8.

STOPPING

o

STORING

TRACTOR

MAKE

______

_

MODEl

_.

_____

_

SERIAL

No.

_____

_

o

GEAR

SHIFT

o

STEERING

CLUTCHES

o

TRACK

ADJUSTMENT

o

WINCH

DRIVE

o

OPERATORS

SAFETY

PRECAUTIONS

DOZERS;

MAKE

_______

_

MODEL

-:-:-:-

____

_

SERIAL

NO.

_____

_

REMARKS,

___________________________________________

___

OTHER

EQUIPMENT~

NAME

_____

_

MAKE

______

_

MODEL

______

_

SERIAL

No.

______

_

WARRANTY

.7

It

it

understood thai the AWs-Chalmers machinery

i~

$old

by

the Deoler with

the:

!otondord

warranty

of

the Manufacturer, set

forth

in full

on

page

one

of Ihe

Operators

Manual. This war-

ranty

is

the only warranty either express, implied.

or

statutory, upon which

laid

mQcbinery

is

told.

THIS

MACHINE

HAS

BEEN

DElIVERED

TO

ME

IN

GOOD

CONDITION

AND

I

HAVE

BEEN

INSTRUCTED

IN

ITS

CARE,

ADJUSTMENT

AND

SAFE

OPERATING

PRACTICES.

DELIVERED BY: Deoier

OWNER

BY:

Dole

OPERATOR:

-----------S~~~----------------------

Original

Copy

-fOR ALLIS-CHALMERS BRANCH

BE

CAREFUL

~

1.

KEEP

ALL

SHIELDS IN PLACE.

2.

STOP

MACHINE

TO

ADJUST AND OIL.

3.

WHEN

MECHANISM

BECOMES

CLOGGED,

~

DISENGAGE

POWER

BEFORE CLEANING.

KEEP HANDS, FEET AND CLOTHING

AWAY

FROM

POWER·

DRIVEN PARTS.

KEEP

OFF

IMPLEMENT UNLESS SEAT

OR

PLATFORM

IS

PROVIDED.

KEEP OTHERS OFF.

BE

A SAFE OPERATOR

AVOID

ACCIDENTS

Mast

accidents,

whether

they

occur

in

industry, on

the

farm,

at

harne,

or

an

the

highway,

are

caused

by

the

failure

of

Some in-

dividual

to

follow simple

and

fundamental

safety

rules or pre-

cQutions. For

this

reason

most

occidents

con

be

prevented

by

recognizing

the

real

couse

and

doing

something

about

it

before

the

occident

occurs,

Regardless

of

the

core used in

the

design

and

construction

of

any

type

of

equipment,

there

are

many

conditions

that

can

nat

be

completely

safe

guarded

against

without

interfering

with reason-

able

accessibility

and

efficient

operation.

A CAREFUL OPERATOR

IS

THE

BEST

INSURANCE

AGAINST

AN

ACCIDENT.

THE COMPLETE OBSERVANCE

OF

ONE SIMPLE RULE

WOULD

PREVENT

MANY

THOUSAND

SERIOUS

INJURIES EACH YEAR.

THAT

RULE

IS:

NEVER

ATTEMPT

TO CLEAN, OIL,

OR

ADJUST A

MACHINE

WHILE

IT

IS

IN

MOTION'

"NATIONAL

SAFETY

COUNCIL"

,

:

I

;

,

I

;

;

,

I

;

,

I

,

I

i

•

I

I

I

I

I

I

,

i

I

I

I

I

I

I

I

i

•

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

,

,

I

\

,

I

I

I

I

I

I

I

I

i

I

,

I

I

I

I

I

I

I

I

I

I

I

i

DELIVERY

RECORD

FOR

FARM

OR

INDUSTRIAL

TRACTORS

THIS

FORM

MUST

Sf

FlllED OUT, IN

TRIPLICATE,

BY

THE

DEALER

AND SIGNED

BY

THE

CUSTOMER

AT

TIME

UNIT

IS

DeLIVERED.

DELIVERED

TO

___________________

_

•.•.

#

_________

sox #

____

_

TOWN

__________________

_

TOWN

____________________

_

SERIAL

#

~

________________

_

STATE

____________________

__

ENGINE

#

___________________

_

PHONE

____________________

_ SERVICED

BY

______________________

_

CHECK

ONE

FARM

USE

D

INDUSTRIAL

USE

o

EXPLAIN

CARE,

SAFE

OPERATION

AND

ADJUSTMENTS

OF

ITEMS

LISTED

BELOW:

TO

BE

COMPLETED,

o

LUBRICATION

o

BREAK·IN

PERIOD

o

STEERING

BRAKES

o

SHUTTlE

ClUTCH

BACKHOE~

o

ENGINE

TEMPERATURE

o

HYDRAULIC

SYSTEMS

MAKE

______

___

o

RADIATOR

DRAIN

COCKS

o

DRAWBAR

MODEl

______

_

o

RADIATOR

PRESSURE

CAP

o

FINAL

DRIVE

SERIAL

No.

_____

_

o

fAN

BELT

o

TRANSMISSION

o

MOTOR

OIL

o

BATTERY

CARE

LOADER:

o

PROPER

FUel

o

OlL

FILTERS

o

FUEL

filTERS

o

STARTING

MOTOR

o

AIR

ClEANER

o

LIGHTS

D

STARTING

&

STOPPING

o

STORING

TRACTOR

MAKE

______

_

MODEl

______

_

SERIAL

No.

_____

_

o

GEAR

SHIfT

o

STEERING

ClUTCHES

o

TRACK

ADJUSTMENT

o

WINCH

DRIVE

o

OPERATORS

SAFETY

PRECAUTIONS

DOZERSJ

MAKE

_______

_

MODEl

______

_

SERIAL

NO.

____

_

REMARKS,

____________________________

_ OTHER EQUiPMENT:

NAME

______

_

MAKE

______

_

MODEL

_____

___

SERIAL

No.

____

_

WARRANTY

If

is

lJoclenfoQd

that

the Allis-Chalmers machinery

is

sold by

the

Dealer witn }he

standard

warrQnly

of

tn.

MOllvfocturer, Jet

fadh

in fvll

Of'!

page

one

of

the

Operators

Manual.

This

war-

fOnty

11

the

only

wortonly

elthu

eXprei$# implied,

or

dotutory,

upon which said machinery

is

sold.

THIS

MACHINE

HAS

BEEN

DELIVERED

TO

ME

IN

GOOD

CONDITION

AND

I

HAVE

BEEN

INSTRUCTED

IN

ITS

CARE,

ADJUSTMENT

AND

SAFE

OPERATING

PRACTICES.

DEUVERED

BY:

OWNER

BY:

OPERATOft:

__________

~~--------------------------

Srgnafure

2nd

Copy-FOR

DEALER'S

FlU

BE

"CAREFui"

1.

KEEP

ALL

SHIELDS IN PLACE.

~

2.

STOP

MACHINE

TO

ADJUST

AND

OIL.

".

3.

WHEN

MECHANISM

BECOMES

CLOGGED,

~

DISENGAGE

POWER

BEFORE CLEANING.

KEEP

HANDS,

FEET AND CLOTHING

AWAY

FROM

POWER·DRIVEN PARTS.

KEEP OFF IMPLEMENT UNLESS SEAT

OR

PLATFORM

IS

PROVIDED.

KEE,OFF.

~

~

BE

A SAFE OPERATOR

AVOID

ACCIDENTS

Most

accidents,

whether

they

OCCur

in industry, on

the

farm,

at

home,

or

on

the

highway,

are

caused

by

the

failure

of some in-

dividual

to

follow

simple

and

fundamental

safety

rules or pre-

cautions.

For this

reason

most

accidents

can

be

prevented

by

recognizing

the

real

cause

and

doing

something

about

it

before

the

accident

occurs.

Regardless

of

the

care

used

in

the

design

and

construction

of

any

type

of

equipment,

there

are

many

conditions

thot

can

not

be

completely

safe

guarded

against

without

interfering

with reOson-

able

accessibility

and

efficient

aperation.

A CAREFUL

OPERATOR

IS

THE

BEST

INSURANCE AGAINST

AN

ACCIDENT.

THE COMPLETE OBSERVANCE

OF

ONE SIMPLE

RULE

WOULD

PREVENT

MANY

THOUSAND

SERIOUS

INJURIES EACH YEAR.

THAT

RULE

IS:

NEVER

ATTEMPT TO CLEAN, OIL,

OR

ADJUST A

MACHINE

WHILE

IT

IS

IN

MOTION!

"NATIONAL

SAFETY COUNCIL"

DELIVERY

RECORD

FOR

FARM

OR

INDUSTRIAL

TRACTORS

THIS

FORM

MUST

BE

FILLED

OUT,

IN

TRIPLJCA1f~

BY

THE

DEALER

AND

SIGNED

BY

THE

CUSTOMER

AT

TIME

UNIT

IS

DElIVERED.

DELIVERED

TO

_________________

_

DEALER

R.

R.

#

__________

BOX

#

____

_

TOWN

TOWN

____________________

_

SERIAL

#

STATE

____________________

_

ENGINE

#

PHONE

____________________

_ SERVICED

BY

CHECK

ONE

FARM

USE

0

INDUSTRIAL

USE

EXPLAIN

CARE,

SAFE

OPERATION

AND

ADJUSTMENTS

OF

ITEMS

LISTED

BelOW:

o

LUBRICATION

o

STEERING

BRAKES

o

BREAK-IN

PERIOD

o

SHUTTLE

CLUTCH

o

ENGINE

TEMPERATURE

o

HYDRAUliC

SYSTEMS

o

RADIATOR

DRAIN

COCKS

o

DRAWBAR

o

RADIATOR

PRESSURE

CAP

o

FINAL

DRIVE

o

FAN

BELT

o

TRANSMISSION

o

MOTOR

OIL

o

BATTERY

CARE

o

PROPER

FUEL

o

AIR

CLEANER

o

OIL

FILTERS

o

LIGHTS

o

FUEl

FILTERS

o

STARTING

&

STOPPING

o

STARTING

MOTOR

o

STORING

TRACTOR

o

GEAR

SHIFT

o

TRACK

ADJUSTMENT

o

STEERING

CLUTCHES

o

WINCH

DRIVE

o

OPERATORS

SAFETY

PRECAUTIONS

REMARKS:

___________________________

_

WARRANTY

0

TO

BE

COMPLETED:

BACKHOE:

MAKE

_______

_

MDDEL

______

_

SERIAL

No.

_____

_

LOADER:

MAKE

______

___

MODEL

______

_

SERIAL

No.

_____

_

DOZERS:

MAKE

MODEL-------

SERIAL

NO.

____

_

OTHER EQUIPMENT:

NAME

______

_

MAKE

______

_

MODEl

____

-------

SERIAL

No.

____

_

It

is

IJrtderstood

that

the

AIIi$-Cholmers machinery

is

sofd by

the

Dealer

wHh

tn

....

standord

warronty

of

the

Mortufoctufil't,

set forth in full on

page

one

of

the

Operators

Manual.

This

wor~

ronty

IS

fhl'(O

only

worro."y

either

expreu,

implied,

or

statutory,

upon

which soid machinery is sold.

THIS

MACHINE

HAS

BEEN

DELIVERED

TO

ME

IN

GOOD

CONDITION

AND

I

HAVE

BEEN

INSTRUCTED

IN

ITS

CARE,

ADJUSTMENT

AND

SAFE

OPERATING

PRACTICES.

DELIVERED

BY:

Deoler

OWNER

BY,

________________________________

~-------

Dole OPERATOR:

__________

~~~~----------------------

3rd

Copy

-FOR CUSTOMER

BE

CAREFUL

1.

KEEP

ALL

SHIELDS IN PLACE.

~

2.

STOP

MACHINE

TO

ADJUST

AND

OIL. "

3.

WHEN

MECHANISM BECOMES CLOGGED,

~

DISENGAGE

POWER

BEFORE CLEANING.

KEEP HANDS,

FEET

AND CLOTHING

AWAY

FROM

POWER-DRIVEH PARTS,

KEEP OFF IMPLEMEHT UNLESS SEAT

OR

PLATFORM

IS

PROVIDED,

KEEP OTHERS OFF.

IE

A SAFE OPERATOR

AVOID

ACCIDENTS

Most

accidents,

whether

they

occur

in industry,

on

the

farm,

at

home,

or

on

the

highway,

are

caused

by

the

failure

of

some in-

dividual to fallow

simple

and

fundamental

safety

rules or pre-

cautions.

For

this

reoson

most

accidents

con

be

prevented

by

recognizing

the

real

cause

and

doing

something

about

it before

the

occident

occurs.

Regardless

ot

the

care

used

in

the

design

and

construction

at

any

type

of

equipment,

there

are

many

conditions

that

can

not

be

completely

sate

guarded

against

without

interfering

with reason-

able

accessibility

and

efficient

operotion.

A CAREFUL OPERATOR

IS

THE

BEST

INSURANCE AGAINST

AN

ACCIDENT,

THE COMPLETE OBSERVANCE

OF

ONE SIMPLE

RULE

WOULD

PREVENT

MANY

THOUSAND

SERIOUS

INJURIES EACH YEAR,

THAT

RULE

IS:

NEVER ATTEMPT

TO

CLEAN, OIL,

OR

ADJUST A

MACHINE

WHILE

IT

IS

IN

MOTION'

"NATIONAL

SAFETY

COUNCIL"

FOREWORD

This

book

is

written

for

the

purpose

of

providing

the

essential

information

regarding

the

day-to-day

care,

lubrication

and

adjustment

of

the

tractor.

Economical

operation

will

be

assured

if

these

instructions

are

followed*

The

instructions

given

in

this

book

cover

the

operation

of

the

Allis-Chalmers

H4

and

HD4

Standard

Tractors.

A

close

adher-

ence

to

these

instructions

will

result

in

many

hours

of

trouble-

free

operation

and

a

longer

operating

life

for

the

unit.

This

If

Green

Cross

for

Safety

I I

is

used

in

book

to

emphasize

safety

precautions

that

should

be

followed

by

operator

to

avoid

accident

and

possible

injury.

Where

you

see

this

emblem

heed

its

warning.

This

HGreen

Cross

for

Safetyll

is

used

only

by

lllembers

of

the

National

Safety

Council.

Many

OWners

of

Allis

-Chalmers

equipment

employ

the

Dealer!

s

Service

Department

for

an

work

other

than

routine

care

and

adjustments.

This

practice

is

encouraged

as

our

dealers

are

kept

well

informed

by

the

factory

regarding

advanced

methods

of

servicing

Allis-Chalmers

products

and

are

equipped

to

ren-

der

satisfactory

service.

To

assure

the

best

results

and

to

main:ain

the

original

quality

built

into

the

tractor,

it

is

important

that

Anis-Chalmers

Parts

be

used.

WARRANTY

ALLlS·CHALMERS

MANUFACTURING COMPANY Ithe Company) worrants

ito

new machinery

covered by this

order

or

contract

(excluding tires

and

B~Series

engines

and

engine accessories which

ore

warranted

by

the

respective monufocturers only)

to

be free

of

defects in workmonship

and

material

at

the

time

of

shipment

from

the

Company's factory.

This warranty

is

the

only warronty upon which

the

Companis

new machinery

is

said,

NO

OTHER

WARRANTY

SHALL

BE

IMPLIED

AND

ALL

STATUTORY

WARRANTIES

SHALL

BE

DEEMED

WAIVED.

No warranty

of

any kind, statutory, implied, or otherwise,

IS

mode

with

respect to second-hand machinery

or with respect to

new

machinery which,

after

shipment

from

the

Compony~s

factory, has been altered,

repaired

or

treated

in

any

manner

whatsoever.

The Company

will

repair or replace f.o.b, its factory

any

port

in

its new mochinery which under

normal use foils within twelve months (except six months instead of twelve months

in

the

case of products

of

the

Springfield

and

Deerfield Works

of

the

Company

and

engines sold

as

power

units,

from

dote

of

delivery

of

such machinery

to

the

first user/ proVided

that

the

Company is promptly notified thereof

and

that

the

port

is

returned

to

the

Company

or

to

an

authorized

dealer

properly identifred, charges prepaid!

and

is found to

the

satisfaction of

the

Company to have been defective in workmanship or material

at

the

time

af

shipment

of

the

machinery from

the

factory

as

aforesaid.

The

Company's liability

whether

in

contract

ar

in

tort

arising

out

of warranties; representations,

instructions, or defects from

any

cause

shall be limited exclUSively to repairing or replacing under the

canditians as aforesaid.

No representotlve

af

the

Company has outnority to

change

this warranty

and

no

attempt

ta

repair or premise to repair or improve

the

machinery by any representative

of

the

Company snail

change

or extend this warranty.

1

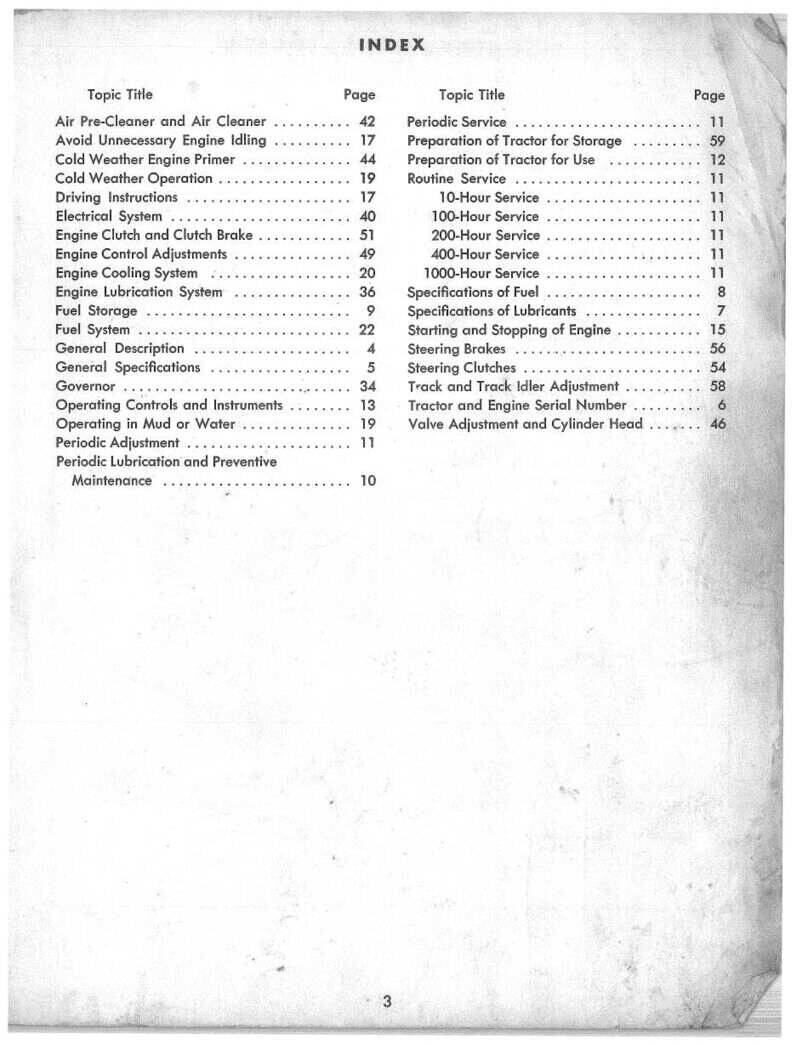

I~DEX

ADJUSTMENTS

Alternator

~

Carburetor.

Distributor

~

Drive

Belt.

Governor.

.

Ignition

Coil

Shuttle

Clutch.

Steering

Brakes

Steering

Clutch.

Timing

....

Track

Sag

.•.

Valve

Tappet

Clearance

DIAGNOSING

ENGINE

DIFFICULTY.

GENERAL

INFORMATIOK

.•

INSTRUMENTS'"

CONTROLS

AlTImeter

.....

Brake

Lock

Levers.

. . .

Brake

Pedals

••••.••

Choke

Control

Knob

(Gasoline)

Engine

Coolant

Temperature

Gauge.

Engine

Oil

Pressure

Indicator

Light

Fuel

Gauge.

• • . . • • • • • •

Fuel

Shut-Off

Knob

(Diesel)

•••

Governor

Control

Lever

~

Throttle

Hourmeter.

Key

Switch.

Light

Switch

Safety

Lock

Shuttle

Clutch

Control

Lever.

Starting

Switch

. . . . . . .

Steering

Clutch

Lever

Torque

Converter

Temperature

Gauge

LUBRICATIOK

&

SERVICE

GUIDE

Air

Cleaner

(Dry

Type)

Batteries

Clutch

Control

Valve

Control

Valve

Control

Valve

Section

Identification.

Drain

Cooling

System

. . .

Engine

Cooling

SystelTI

. • • . .

Engine

Lubricating

System

....

Eingine

Oil

F'ilter

-

Full

Flow

Type

Engine

QU

SUlnp

Final

Drives

. .

Fuel

Filter

Bowl

Fuel

Filt

er

-

Dies

el

.

Fuel

Specifications

Fuel

Storage

•.•.

Heat

Exc

hanger.

. .

Hydraulic

Reservoir.

Hydraulic

System

Breather

Hydraulic

System

Screen

&

Magnet

Operating

Temperature

Pressure

Line

Filter

.

Pressure

Radiator

Cap

Pump·

.•.•.

Return

Line

Filter

Continued

2

34

33

33

32

32

33

32

30

30

33

30

31

·

37,

38

• • • 7

24

26

25

25

25

25

25

25

25

25

24

24

24

24

24

25

25

23

22

16

17

18

10

• 9

12

14

•

13,14

21

II

12

•

10,11

12

17

17

18

18

· 9

15

• 9

17

18

Spark

Plugs.

. . .

Suction

Line

Filter.

Temperature

Gauge

Torque

Converter

.

INDEX

(Cont'd)

Torque

Converter

&

Shuttle

Clutch.

Torque

Housing

. . . .

Track

Idlers

&

Rollers.

Track

Support

Idlers

Transmission.

~

...

LUBRICA

TION

&

SERVICE

INSTRUCTIONS

OPERATING

INFORMATION

Check

Oil

Pressure

.

Degree

Slope

•

Diesel

Starting

Fluid.

Down

Hill.

• . . . .

Fast

Warm-Up

Gear

Shifting

-

Transmission

Shuttle

Clutch

Hydraulically

Operated

Starting

&

Stopping

Engine

Steering

of

Tractor

Track

&

Track

Shoes

SAFETY

PRECAUTIONS

SERVICE

&

LUBRICATION

LOCATION

GUIDE

SPECIFICATIONS

WIRING

DIAGRAMS

3

·

22

•

15

·

17

•

17

•

14

.17

• 21

· 21

·

21

· 8

.26

.28

.27

•

28

2.6,27

•

.28

• •

28

2.6,27

• 28

•

29

6

8

4

..35,36

ENGINE

Model.

Make.

Type.

Number

of

cylinders

Bore

......•

Stroke

• . • . . •

No.

of

Main

Bearings.

Piston

Displacement

Compression

Ratio

COlnpression

Firing

Order.

. •

Low

Idle

• . • .

Governed

@

Full

Load.

High

Idle

. . . • •

Fuel

Injection

Pump

Carbul'

eto!'

Nozzle

Holder

Valves

Intake

Clearance.

Exhaust

Clearance

~

Battery

• •

Type

.•

Volts.

.

Capacity

Quantity

Terminal

Ground

Circuit

Starter

.

Spark

Plugs

Thl'

ead

Size.

Reach

Gap

Heat

Range

Distributor

Make

••

Point

Gap.

Advance

Advance

Timing

GENERAL

SPECIFICATIONS

DIESEL

.

D2200

.

Allis

-Chalmer

s

.4

cycle

naturally

aspirated

4

3.88

4.2.5"'

5

200

Cll.

in.

16.25:1

500

PSI

@600

RPM

1-3-4-2

650-700

RPM

2100

RPM

2250-2310

RPM

Roosa

Master

Model

DBGFC

437-7AF

TiITIed

@

28°

BTDC

GASOLINE

G2200

Allis-Chalmers

4

cycle

naturally

aspirated

4

3.88

4.25"

5

200

cu.

in.

8.15:1

165

PSI@

150

RPM

1-3-4-2

450-500

RPM

2100

RPM

2300-2325

RPM

. . •

Zenith

Model

267

JX9

Opening

Pressure

2750

PSI

.015"

.015"

Standard

2-135

6

135AH

2

Neg.

Parallel

Optional

30H95

12

190

AH

2

Neg.

Series

Delco

Remy

111107589

4

.020"

.02.5"

Standard

24-53

12

53AH

1

Neg.

Optional

30H-95

12

95AH

1

Neg.

Delco

Remy

111107356

14MM

3/4"

.025"

AC

45

XL

Autolite

AG5A,

Champion

N8

Delco

Remy

111112665

.016"

Automatic

28

0

BTDC

@

2100

RPM

GENERAL

SPECIFICATIONS

GENERAL

DIMENSIONS

AND

WEIGHT

Overall

Length

• • • . • •

Overall

Height

• • • . • •

Overall

Width

(12"

grousers)

TRANSMISSION

Type

'.

Speeds

(At

Rated

2100

RPM)

One

to

1st

Forward

2nd

Forward

3rd

Forward

1st

Reverse

2nd

Reverse

3rd

Reverse

CAPACITIES

Cooling

System

• •

Engine

Cr

ankca

s e

Oil

Change.

Oil

and

Filter

Change

Hydraulic

System

(Tractor

only)

Transmission

.••.•

4

Shuttle

Clutch

&

Converter

Final

Drives

Each

..

Fuel

Tank.

• . • • • • •

STEERING

Method.

Type

...

Disc

DialTlcter.

SHUTTLE

CLUTCH

Method

•••

Type

.•.•

Number

Discs.

TRACK

One

Convertor

Ratio

. . • •

•.

108-7/8

inches

80.82

gasoline,

81.

26

diesel

••.••.•••

63

inches

Constant

mesh

helical

gear

1.

81

MPH

2.81

MPH

4.88

MPH

2.09

MPH

3.24

MPH

5.63

MPH

16

qts.

• 8

qt

•

• 9

qt.

.36

qt.

12.25

qt.

26

qt.

6. 7

qt.

18

gal.

Multiple

disc

clutch

• •

Dry

•

.•••.

9-7/8"

. • • • • •

Multiple

disc

Wet

hydraulically

operated

4

forward,

4

reverse

Tread

Width

(center

to

center

of

track)

.•••

Length

of

Track

on

Ground

(center

of

sprocket

to

Short

Track

center

of

idler)

Long

Track

Width

of

Shoes

Optional.

•

Number

of

Shoes

(Each

Track)

Short

Track

• • • •

Long

Track

• • • . •

Track

Pitch

(center

of

pin

to

center

of

next

pin)

.

Number

of

Truck

Wheels

(each

track)

•

Number

of

Support

Rollers

(each

track)

••••

.63-3/4"

•

69-3/4"

34

36

6"

5

I

The

Allis-Chalmers

Manufacturing

Co.

reserves

the

right

to

make

changes

in

the

above

specifications

or

to

add

to

the

irnprovement

at

any

time

without

notice

or

obligation.

5

(9

SAFETY

PRECAUTIONS

f)

Many

hours

of

lost

time

and

much

suffering

is

caused

by

the

failure

to

practice

simple

safety

Tules.

IT

IS

TOO

LATE

TO

REMEMBER

WHAT

SHOULD

HAVE

BEEN

DONE

AFTER

THE

ACCIDENT

HAS

HAPPENED.

1.

Do

not

fill

fuel

tanks

when

engine

is

hot

or

while

using

a

lantern

or

when

smoking.

2~

Do

not

attempt

to

oil

or

grease

a

machine

Or

tractor

while

it

is

in

operation~

3~

Do

not

wear

loose

fitting

clothing

that

may

be

blown

into

nloving

parts.

4.

Keep

all

shields

and

guards

in

place.

5.

Place

gear

shift

lever

in

neutral

position

when

starting

engine

or

dismounting

from

tractor.

6.

Machinery

should

be

only

operated

by

those

who

are

responsible

and

delegated

to

do

so.

7.

Only

one

person

-

the

operator

-

should

be

permitted

on

tractor

when

it

is

in

motion.

8.

The

rate

of

travel

on

hillsides

or

curves

should

be

regulated

so

there

is

no

danger

of

tipping.

9.

Do

not

remove

radiator

cap

when

engine

teITlperature

is

above

2lZoF.

10.

Steering

brakes

and

clutches

should

be

pro-

perly

adjusted.

11.

Do

not

drive

too

close

to

the

edge

of

a

ditch

12*

Never

operate

your

tractor

in

a

closed

gar-

age

Or

shed.

13.

When

tractor

is

hitched

to

a

stump

Or

other

heavy

loads,

always

hitch

to

drawbar

and

never

take

up

slack

in

chain

with

a

jerk.

14.

Always

keep

tractor

in

gear

when

going

down

steep

grades.

15.

Do

not

leave

the

engine

running

unattended

when

anyone

is

adjusting

or

repairing

a

driven

machine.

16.

Do

not

atterr;pt

to

operate

tractor

unless

you

are

in

the

driver1s

seat.

17.

Provide

a

first

aid

kit.

Treat

all

scrate

hes.!

cuts,

etc.,

with

the

proper

antiseptic

immediately.

18.

Never

stand

between

tractOr

and

drawn

im-

plement

when

hitching.

Use

an

iron

hook

to

handle

drawbar.

19.

Do

not

dismount

from

tractor

while

it

is

in

nlotion.

20.

Keep

a

fire

extinguisher

handy

at

all

times.

21.

Lock

shuttle

clutch

lever

in

neutral

position

when

dismounting

tractor.

UNDER

NO

CIRCUMSTANCES

SHOULD

ANYTHING

BE

PULLED

FROM,

HOOKED

TO

ANY

PART

OF

THE

TRACTOR

EXCEPT

THE

DRAWBAR.

OR

BE.

6

GENERAL

INFORMATION

The

standard

Model

tractor

is

available

with

either

a

gasoline

engine,

H4,

or

a

Diesel

engine,

HD41

which

are

naturally

aspirated,

open

combustion

chaInber

engines.

Power

from

the

engine

is

transmitted

through

the

torque

converter

and

to

a

constant

mesh

helical

gear

transmis

sion.

From

the

trans-

rnission

the

power

is

transmitted

to

the

spiral

bevel

gear

and

from

the

spi

ral

bevel

gear

through

the

multiple

disc

steering

clutches

to

the

final

drives

and

the

track

sprockets.

The

trans-

mission

provides

3

forward

speeds,

1.81

M.P.H.

in

1st;

2.81

M.P.H.

in

2nd

and

4.88

M.P.H.

in

3rd;

and

3

reverse

speeds

of

2.09

M.P.H.

in

1st;

3.24

M.P.H.

in

2nd

and

5.63

M.P.H.

in

3rd,

at

rated

engine

speed

of

2100

RPM,

and

1

to

1

converter

ratio~

The

standard

tractor

is

equipped

with

electric

starting

and

panel

lighting

equipment,

suction

type

cooling

fan

mounted

in

center

of

tractor,

muffler,

dry

type

air

cleaner

t

torque

con-

verter

J

neces

sary

gauges

and

sending

units

~

Fot'

a

complete

listing

of

all

available

equipment

consult

your

local

Allis-Chahners

dealer.

~

______________________________

FIG.

1

______________________________

~

SERLt"L

NUMBER

LOCATIONS

NOTE:

On

all

parts

orders

and

in

all

corres-

pondence

relative

to

the

tractor,

it

is

necessary

that

both

the

tractor

and

engine

Serial

Numbers

be

given.

This

will

properly

identify

the

parti-

cular

unit

and

will

assure

obtaining

correct

re-

placement

parts

for

it~

A.

TRACTOR

SERIAL

NUMBER

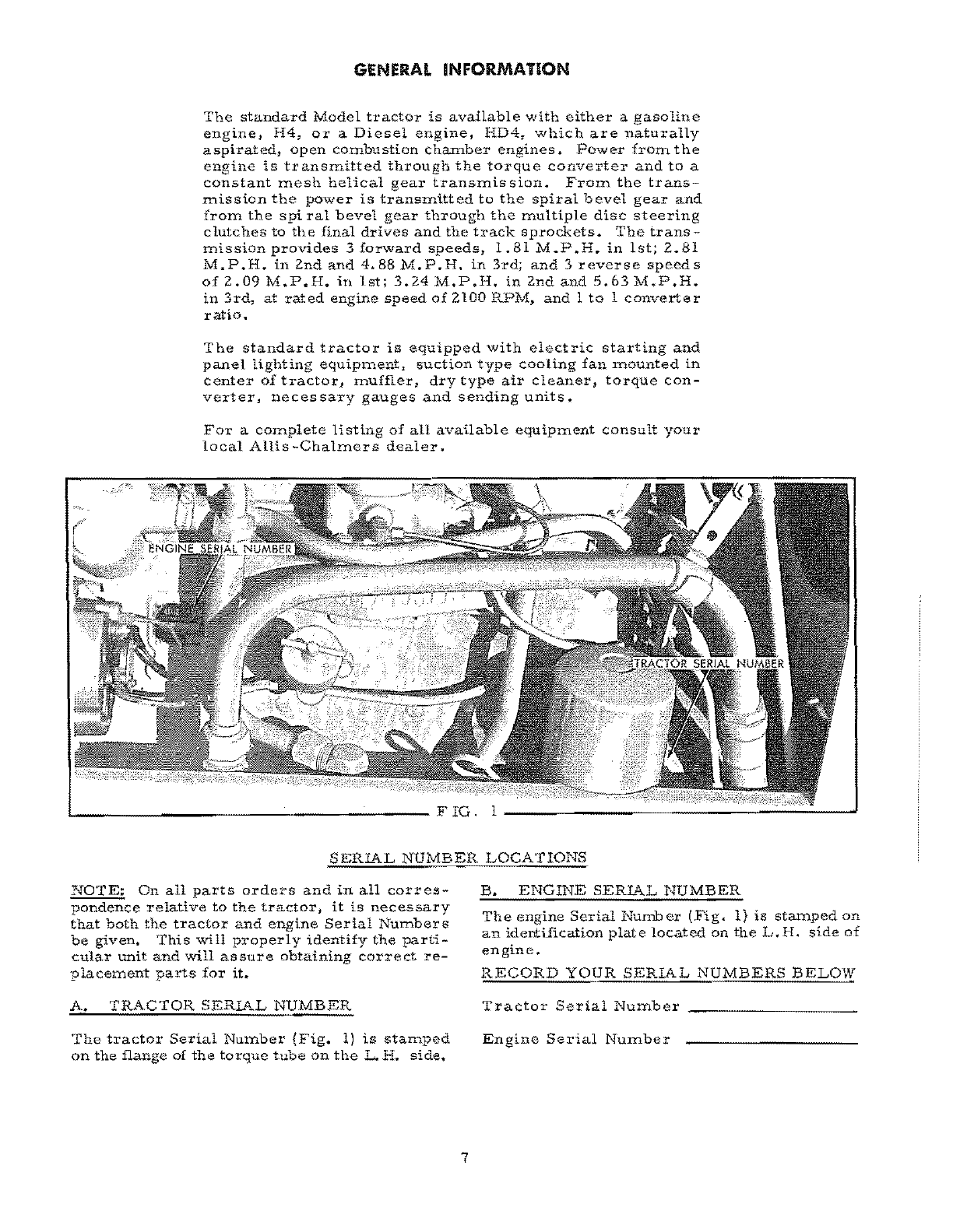

The

tractor

Serial

Number

(Fig.

1)

is

stamped

on

the

flange

of

the

torque

tube

on

the

L

H~

side~

7

B.

ENGINE

SERIAL

NUMBER

The

engine

Serial

Number

(Fig.

1)

is

stamped

on

an

identHication

plate

located

on

the

L.

H.

side

of

engine.

RECORD

YOUR

SERIAL

NUMBERS

BELOW

Tractor

Serial

Number

Engine

Serial

NUlllber

LUBRICATION

&.

SERViCE

INSTRUCTiONS

To

prevent

minor

irregularities

from

developing

into

serious

conditions

that

might

invo

lye

shut-

do'h'11

and

rna.jor

repair,

several

other

checks

and

services

must

be

included

at

the

same

intervals

as

lubrication.

These

checks

and

services

will

reveal

the

need

for

adjustment

or

change

due

to

normal

wear

1

which

if

neglected

could

result

in

failure

and

shut-down.

Refer

to

Lubrication

and

Service

Instruction

Plate

and

the

illustrations

and

instructions

in

this

Topic

for

points

to

be

serviced

and

their

relative

locations.

Thoroughly

clean

all

fittings,

caps,

plugs,

etc

~

before

servicing

to

prevent

dirt

from

entering

while

performing

the

service.

Lubricants

should

always

be

at

operating

tem-

perature

when

draining

fcr

oil

changes.

Oil

systems

equipped

with

an

oil

level

gauge

rod

having

1I0perating

Range

ll

marks,

are

safe

to

operate

when

oil

level

is

anywhere

within

the

1I0

pera

ting

Range

l1

~

After

refilling

systems

at

oil

change

intervals,

the

oil

level

should

be

checked

after

engine

has

been

run

at

low

idle

speed

for

a

few

minutes

to

insure

that

engine

clutch,

heat

exchangers~

filters,

lines,

etc.

are

fully

charged

before

oil

level

check

is

made.

NOTE:

Oil

levels

will

rise

higher

within

the

II

Operating

Range

ll

on

oil

level

gauge

rods

(due

to

expansion

of

the

oil)

after

unit

has

been

placed

in

service

and

operating

temperatures

have

stabilized

~

The

various

hour

intervals

given

in

this

Topic

are

based

on

normal

operation;

perform

the

services

more

often

(as

necessary}

when

oper-

ating

under

severe

or

abnorn1al

conditions.

Proper

operation

and

maintenance

of

the

engine

are

necessary

to

obtain

the

desired

results

from

the

lubricating

oil.

The

basic

engine

lubricating

oil

and

filter

change

interval,

assumes

use

of

the

proper

grade

of

a

"Series

3

11

oil

in

diesel

and

!viS

in

gasoline

and

lIaveragel!

operating

conditions

includLYlg

load

factor,

fuel

(particularly

sulphur

content),

terrperatures,

cleanliness

and

mechan-

ical

condition

and

many

others.

Where

condi-

tions

are

rn.:.>re

severe

than

lIaveraget!

the

change

interval

may

even

be

too

long.

SERVICE

&

LUBRICATION

LOCATION

GUIDE

13

10

[

~.---

____

FIG.

2

~"~

_______

....J

NOTE:

Refer

to

HLubrkation

and

Servic

e

Guide

H

section

for

detailed

information.

1.

Engine

oil

sutnp

2.

Engine

oil

filter

3.

Fuel

filter

(Diesel

only)

4.

Fuel

tank

filter

:;.

Engine

ai

r

cleaner

6.

Radiator

7.

Batteries

8.

Transmission

oil

level

9.

Transmission

Br

eather

10.

Final

drive

oil

level.

11.

Truck

wheels

t

support

rollers

and

idlers

1

Z.

Converter

oil

suction

strainer

13

~

Converter

oil

filter

14~

Converter

oil

level

15.

Hydraulic

oil

reservoir

(Check

level

with

ramS

collapsed)

16.

Hydraulic

reservoir

filter

17.

Hydraulic

reservoir

breather

18.

Hydraulic

reservoir

screen

and

magnet.

8

LUBRICATION

&

SE~VICE

GUIDE

1.

ENGINE

COOLING

SYST

EM

Check

cooling

system

every

day

for

propel'

coolant

level.

The

level

should

be

obtained

so

the

coolant

is

visable

in

the

radiator

neck.

Do

not

over

fill,

as

it

is

necessary

to

have

space

for

expansion

when

coolant

is

at

operating

tCtn-

peratures.

If

over

filled,

as

coolant

expands

J

it

will

be

forced

out

through

over-flow

pipe

..

PRESSURE

RADIATOR

The

pressure

radiator

permits

the

use

of

a

higher

operating

temperature.

The

cooling

so-

lution

(pure

water)

will

not

boil

in

the

pres-

sure

radiator

until

a

tctnperature

of

221°F.

is

reached.

To

remove

the

radiator

cap,

tUrn

to

the

left

until

it

stops.

Push

down

and

continue

to

turn

to

the

left

until

cap

is

released

..

f)

-

Do

not

remove

the

cap

when

the

temper-

~

ature

is

above

21ZCF.

as

the

cooling

solu-

.

tion

will

break

into

a

violent

boil

which

may

splash

onto

person

rernoving

cap.

Never

pour

co

ld

wa

ter

in

a

hot

engine.

Clean

rain

or

soft

water

should

be

used

in

the

cooling

system

if

available.

Hard

Or

alkaline

water

wiU

form

a

scale

which

will

impair

radiation

if

al-

lowed

to

build

up

in

the

cooling

system.

9

Pressure

Cap

Temperature

Gauge

'-------FIG.4

Soluble

oil

is

beneficial

to

the

cooling

system.

It

will

not

prevent

the

accumulation

of

lime,

but

will

retard

such

inforlT.ation.

This

water

soluble

oil

may

be

secured

from

your

Allis-

ChalrneTs

Dealer.

OPERATING

TEMPERATURE

The

operating

temperature

of

the

e..~gine

coolant

is

shown

on

the

temperature

gauge.

The

point

should

operate

in

the

green

portion

of

gauge,

with

a

range

of

160

0

to

220

0

F.

If

pointer

moves

iYlto

the

red

portion

of

gauge,

the

engine

is

Over-

heated.

If

engine

does

become

overheated

for

some

reaSOn

or

other_

allow

time

to

cool

fur

a

few

minutes~

then

add

water

slowly

to

radiator

while

engine

is

idling.

Low

engine

operating

terrperatures

cause

COn-

densatio:!1,

sludge

and

corrosion.

Keep

engine

hot.

The

temperature

is

therrrlOstatically

con-

trolled,

but

to

prevent

damage

to

the

engine

by

cold

operating

temperatures

the

engine

must

be

operated

in

the

operating

range

on

gauge

long

enough

to

boil

or

drive

off

the

moisture

collected

in

the

initial

warm-up

period~

Operate

engine

in

the

normal

range

for

a

period

of

time

equal

to

the

time

it

took

the

indicator

needle

to

reach

the

operating

range

before

shut-

ting

off

engine.

This

will

prevent

moisture

from

condensmg

and

damaging

vital

engine

parts.

Under

abnormal

or

cold

engine

temperature

operation,

the

oil

change

interval

should

be

per-

forrned

rrore

frequently

than

under

normal

oper-

ating

temperature

conditions*

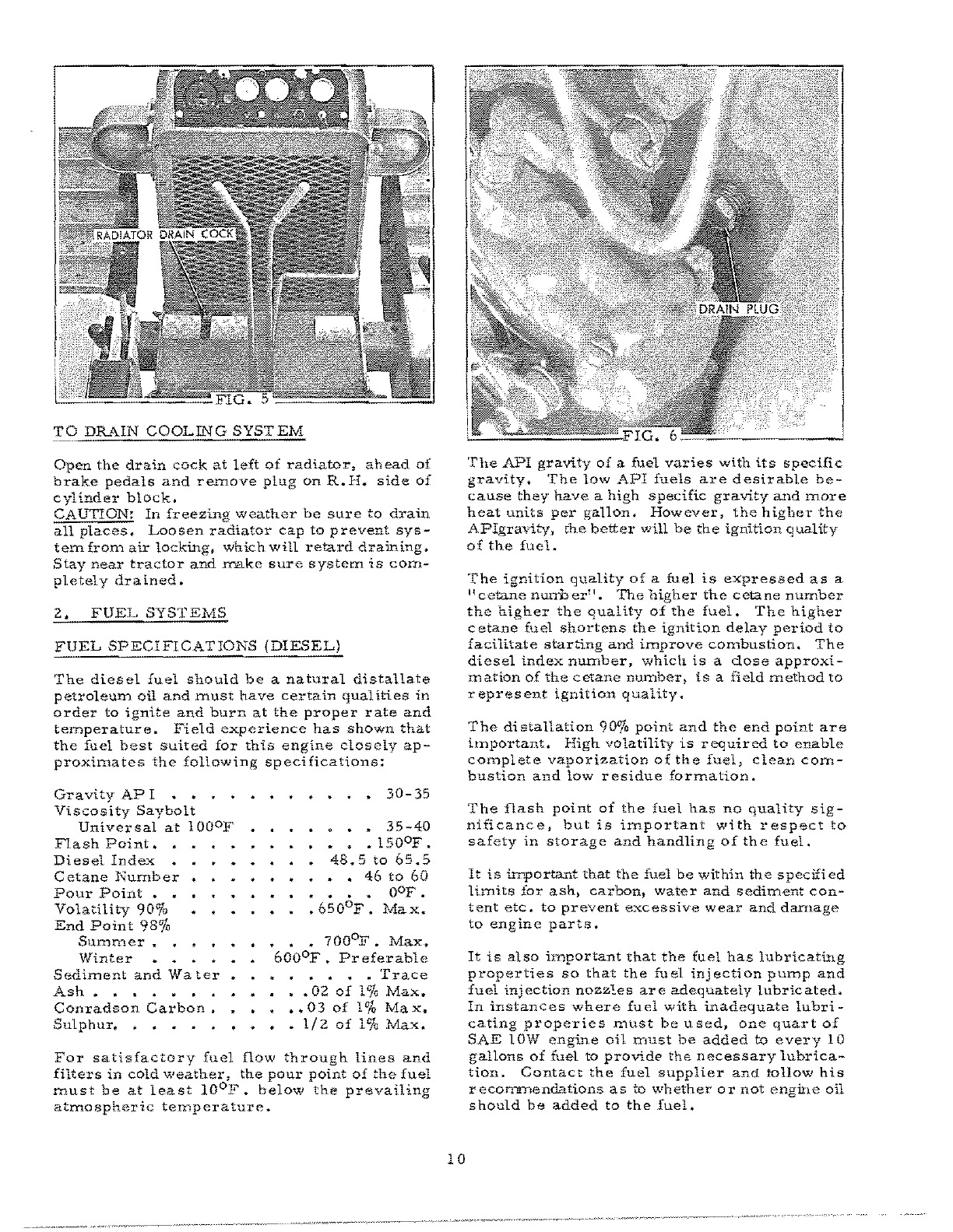

TO

DRAIN

COOLING

SYSTEM

Open

the

drain

cock

at

left

of

radiator,

ahead

of

brake

pedals

and

remove

plug

on

R~

H.

side

of

cylinder

block.

CAUTION:

In

freezing

weather

be

sure

to

drain

all

places~

Loosen

radiator

cap

to

prevent

sys-

temfrorn

air

locking.

which

will

retard

draining.

Stay

near

tractor

and

make

sure

system

is

com-

pletely

drained.

2.

FUEL

SYSTEMS

FUEL

SPECIFICATIONS

(DIESEL)

The

diesel

fuel

should

be

a

natural

distallate

petroleun1

oil

and

must

have

certain

qual

tties

in

order

to

ignite

and

burn

at

the

proper

rate

and

temperature.

Field

experience

has

shown

that

the

fuel

best

suited

for

this

engine

closely

ap-

proxi.mates

the

following

specifications:

Gravity AP

I

Viscosity

Saybolt

Uni.versal

at

lOooF

Flash

Point.

Diesel lndax

ectane

Number

Pour

Point

.. .,

Volatility

900/,

End

Point

98%

Summer

~

Winter

Sediment

and

Wa

tel'

Ash.

Conradson

Carbon.

Sulphur.

30-35

35-40

•

150

0

F.

48.5

to

65.5

• •

46

to

60

• • • •

OOF

•

.

650°F.

Max.

• •

700°F.

Max.

600°F.

Pr

e£erab1e

•

Trace

•

.02

of

1%

Max.

..03

of

1%

Max.

•

1/2

of

1%

Max.

For

satisfactory

fuel

flow

through

lines

and

filters

in

cold

weather,

the

pour

point

of

the

fuel

must

be

at

least

10°F.

below

the

prevailing

atmospheric

temperature.

10

The

API

gravity

of

a

fuel

varies

with

its

specific

gravity.

The

low

API

fuels

are

desirable

be-

cause

they

have

a

high

specific

gravity

and

more

heat

units

per

gallon.

However,

the

highet"

the

APIgraY;'ty,

t:he

better

will

be

the

ignition

quality

of

the

fuel.

The

ignition

quality

of

a

fuel

is

expressed

as

a

11cetane

nurrb

er

".

The

higher

the

ectane

number

the

higher

the

quality

of

the

fuel.

The

higher

c

etane

fuel

shortens

the

ignition

delay

period

to

facilitate

starting

and

improve

combustion.

The

diesel

index

number,

which

is

a

dose

approxi-

mation

of

the

ectane

number~

is

a

field

method

to

r

epres

ent

ignition

quality.

The

distallation

90%

point

and

the

end

point

are

lrnportant.

High

volatility

is

required

to

enable

complete

vaporization

of

the

fuel,

clean

com-

bustion

and

low

residue

formation.

The

flash

point

of

the

fuel

has

no

quality

sig-

nificance,

but

is

important

with

respect

to

safety

in

storage

and

handling

of

the

fuel

•

It

is

wportant

that

the

fuel

be

within

the

specified

linlits

for

ash)

carbon.

water

and

sediment

con-

tent

etc.

to

prevent

excessive

wear

and

danlage

to

engine

parts.

It

is

also

important

that

the

fuel

has

lubricating

properties

so

that

the

fuel

injection

pump

and

fuel

injection

nozz"!..es

are

adequately

lubricated~

In

instances

where

fu

e1

with

inadequate

lubri-

eating

properies

must

be

u

sed,

one

quart

of

SAE

lOW

engine

oil

must

be

added

to

every

10

gallons

of

fuel

to

provide

the

necessary

lubrica-

tion.

Contact

the

fuel

supplier

and

follow

his

recommendations

as

to

whether

or

not

engitlc

oil

should

be

added

to

the

fuel.

CAUTION:

The

sulphur

content

of

diesel

fuel

should

be

as

low

as

possible.

The

fuel

should

not

contain

a

sulphur

content

of

more

than

1/2

of

1%.

Generally

speakingJ

a

No.2

high

speed

diesel

fuel

purchased

froIT' a

reputable

oil

company

wilirr:eet

the

above

specifications.

FUEL

SPE

CIFICAT

IONS

(GASOLINE)

This

engine

is

designed

to

burn

regular

gasoline

having

an

octane

rating

(research

method)

of

89

or

higher.

Fuel

cornpanies

provide

fuels

tailored

to

f'reet

the

existing

weather

conditions.

These

fuels

are

changed

at

the

start

of

the

predorninent

seasons

according

to

regional

weather

trends.

Fuels

are

tailored

to

give

ease

of

starting

in

cold

weather

and

to

give

a

low

vapor

pressure

to

avoid

vapor

lock.

An

effort

should

be

made

to

purchase

fuels

in

such

quantity

that

they

are

not

carried

over

to

succeeding

seasOns.

FUEL

FILTER

BOWL

-

GASOLINE

&

DIESEL

Check

daily

and

clean

when

water

or

sediment

is

visable.

Clean

filter

element

when

necessary.

The

fuel

filter

is

located

at

bottom

of

fuel

tank

and

is

provided

for

the

purpose

of

keeping

dirt

11

A~,

JJ~~

VALVE

ASSEMBLY

~.

'

FILTERH::O

BOWL

GASKET

FILTER

BOWl

f'I~

~

\\&1

\©J

BAIL

ASSEMBLY

r?

!l

""

[\

1/

~

'--

______

FIG.

8

_______

..J

and

water

from

entering

the

carburetor,t

or

fuel

injection

pump.

However,

the

best

results

are

obtained

by

using

adequate

fuel

storage

handling

facilities.

If

the

fuel

is

kept

free

of

dirt

and

water

by

use

of

clean

containers

and

proper

handling,

the

filter

will

have

little

work

to

perform.

Excessive

cleaning

of

filter

indicates

dirty

fuel.

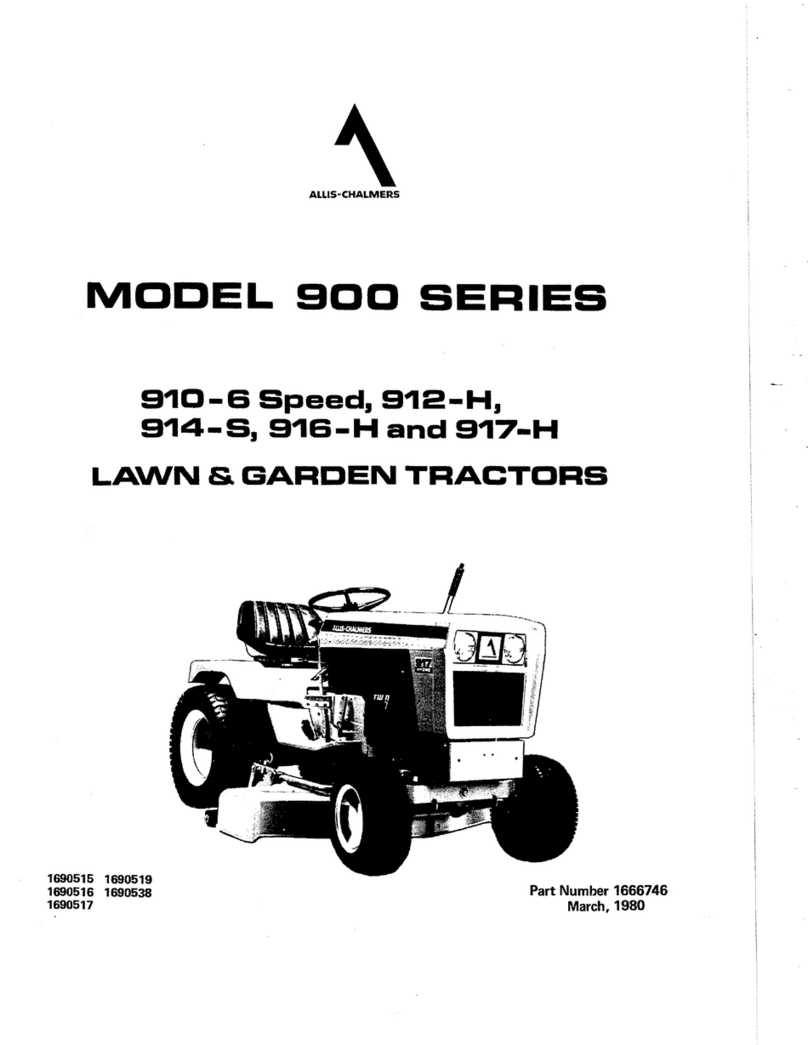

To

clean

the

filter,

shut

off

the

fuel

supply.

Loosen

the

bowl

retaining

nut

and

!nove

bail

to

one

side.

Remove

bowl,

gasket

and

screen~

When

installing,

a

ssemble

as

shown

to

provide

the

proper

seal.

Filter

screen

next

to

bowl

and

gasket

next

to

head.

The

element

can

be

cleaned,

using

a

small

stiff

brush.

It

is

advisable

to

keep

extra

bowl

gaskets

on

hand

as

the

gasket

is

liable

to

leak

after

cleaning

bowl.

Turning

the

shut-off

valve

wide

open

will

seal

fuel

from

the

packing

gland

and

prevent

leakage

in

the

open

positi.on~

When

valve

is

shut

off,

the

pack-

ing

gland

nut

Inust

be

snug

to

prevent

leakage.

FUEL

FILTER

(HD-4

DIESEL)

The

fuel

system

is

provided

with

a

primary

and

secondary

fuel

filter

nlounted

in

one

element

on

the

side

of

the

engine.

The

purpose

of

the

fuel

filter

is

to

renlovewater.

sediment

f$

abrasives

from

the

fuel,

before

the

fuel

enters

the

injection

equipment.

The

proper

handling

and

storage

of

fuels

will

increase

the

life

On

the

filters.

Replace

the

filter

element

at

each

500

hours

of

operation.

Poor

fuel

handling

and

storage

facil-

ities

will

decrease

the

effective

life

of

the

filter.

In

other

words,

dirty

fuel

will

decrease

the

life

of

a

filter.

while

clean

fuel

will

increase

the

life

of

a

filter.

Never

operate

until

filter

becomes

plugged,

or

to

a

point

to

where

a

decrease

in

engine

speed

Or

power

is

noticed.

SODle

dirt

may

seE'k

its

way

through

the

secondary

filter

and

cause

severe

damage

to

the

fuel

injection

equip-

ment.

Each

time

the

filter

element

is

removed,

it

may

be

necessary

to

bleed

out

air

by

remov1t:..g

the

plug

at

top

of

filter

head

assembly.

Remove

air

bleed

plug

and

turn

On

fuel

valve

at

tank.

Operate

the

hand

priming

pump

until

all

air

has

escaped

and

solid

fuel

is

to

the

level

of

the

air

bleed

plug

and

install

bleed

plug

at

top

of

filter

head.

FeEL

STORAGE

The

importance

of

proper

storage

of

fuel

cannot

be

too

strongly

stressed.

Storage

tanks,

drums,

or

service

tanks

must

be

free

of

rust,

scale,

sediment,

or

any

other

foreig:c.

matter

which

will

contaminate

the

fuel.

Contaminated

fuel

will

clog

the

engine

fuel

filters

and

eventually

damage

the

fuelilljection

puIl1'

and

the

fuel

injection

nozzles.

A

portable

storage

tank

provides

the

best

method

for

storing

fuel

on

the

jo

b.

In

such

a

tank,

the

sediment

and

water

can

easily

be

drained

and

the

fuel

can

be

pumped

into

the

tractor

fuel

tank

with

a

minimum

of

handling.

Since

condensation

will

occur

in

the

storage

tank"

it

is

very

important

that

a

sediment

sump

be

pro'vided

i1':.

botton)

of

tank

so

that

water

and

sediment

can

be

drai:!1ed

daily.

Fuel

should

be

allowed

to

settle

at

least

48

hours

i.n a

storage

container

before

being

added

to

the

fuel

tank

of

the

tractor,

It

is

advisable

to

use

a

pun1p

and

draw

the

fuel

frorn

storage

tank,

or

barrel,

rather

than

to

drain

it

from

bottom

of

fuel

container.

Vihere

conditions

are

such

that

drums

must

be

used

to

supply

fuel,

it

is

advisable

to

have

enough

drums

to

allow

sufficient

time

for

the

fuel

to

settle~

The

fuel

thus

left

in

a

number

of

drums

CaZ'l

be

collected

into

one

drum

and

used

after

the

usual

time

allowed

for

settling.

L"1

this

manner,

the

sediment

and

fo

reign

matter

will

be

disposed

of

and

no

fuel

will

be

wasted.

Whenever

drums

are

used

for

fuel

storage,

they

should

be

covered

Or

placed

under

shelter

so

that

the

fuel

will

not

becon1e

contaminated

by

water

I

which

will

enter

through

the

filler

plugs

when

it

rains,

even

though

plugs

are

ti.ght.

The

fuel

tank

of

the

tractor

should

be

filled

at

end

of

the

day's

run

rather

than

at

the

start;

this

will

reduce

the

water

content

J

as

a

full

tank

is

less

subject

to

cor.densati.on.

3.

ENGINE

LUBRICATING

SYSTEM

A.

ENGINE

CRANKCASE

(Lubricant

Specifica-

tion)

(Diesel)

The

specified

oil

for

use

in

the

engine

crankcase

is

a

lubricating

on

that

meets

both

of

the

follow-

ing

specifications:

1.

American

PctrolclUn

Institute

(API)

classi-

fication

nService

DS

Series

3

11

2.

Military

Specifications

"MIL-L-4S199A"

NOTE:

The

engine

crankcase

on

a

new

unit

when

shipped

from

the

factory,

contains

1lS

er

i.es

3!!

SAE

20W

engine

lubri.cating

oil

meeting

the

proper

API

Military

Specifications.

This

oil

is

completely

satisfactory

for

use

until

the

first

regular

oil

change.

B.

ENGINE

CRAA"KCASE

(Lubricant

Specifica-

tions)

(Gasoline)

Motor

oils

are

designated

by

code

letters

as

iollows:

ML

-

MM

-

MS.

The

letters

denote

the

type

of

service

for

which

the

unit

is

used.

ML

-

for

use

under

light

loads

and

favorable

conditions.

12

This manual suits for next models

1

Table of contents

Other Allis-Chalmers Tractor manuals

Allis-Chalmers

Allis-Chalmers 910-6 Speed User manual

Allis-Chalmers

Allis-Chalmers G User manual

Allis-Chalmers

Allis-Chalmers B Install guide

Allis-Chalmers

Allis-Chalmers ac130 series User manual

Allis-Chalmers

Allis-Chalmers U Installation and user guide

Allis-Chalmers

Allis-Chalmers 10 hp User manual

Allis-Chalmers

Allis-Chalmers regent hydro 14 User manual

Allis-Chalmers

Allis-Chalmers HD-9 User manual

Allis-Chalmers

Allis-Chalmers WD Use and care manual

Allis-Chalmers

Allis-Chalmers G User manual