Allis-Chalmers WD Use and care manual

FOREWORD

The instructions given in this book cover the operation of the

Allis-Chalmers Model “WD” Tractor. A close adherence to

these instructions will result in many hours of trouble-free

operation and a longer operating life for the unit.

This book is written for the purpose of giving the operator

essential information regarding the day-to-day care, lubrication

and adjustment of the machine. Economical operation will be

insured if these instructions are followed.

Many Allis-Chalmers owners employ the dealer’s Service

Department for any work other than routine care and adjust-

ments. This practice is encouraged as our dealers are kept

well informed by the factory regarding advanced methods of

servicing Allis-Chalmers products and are equipped to render

satisfactory service.

*

*

*

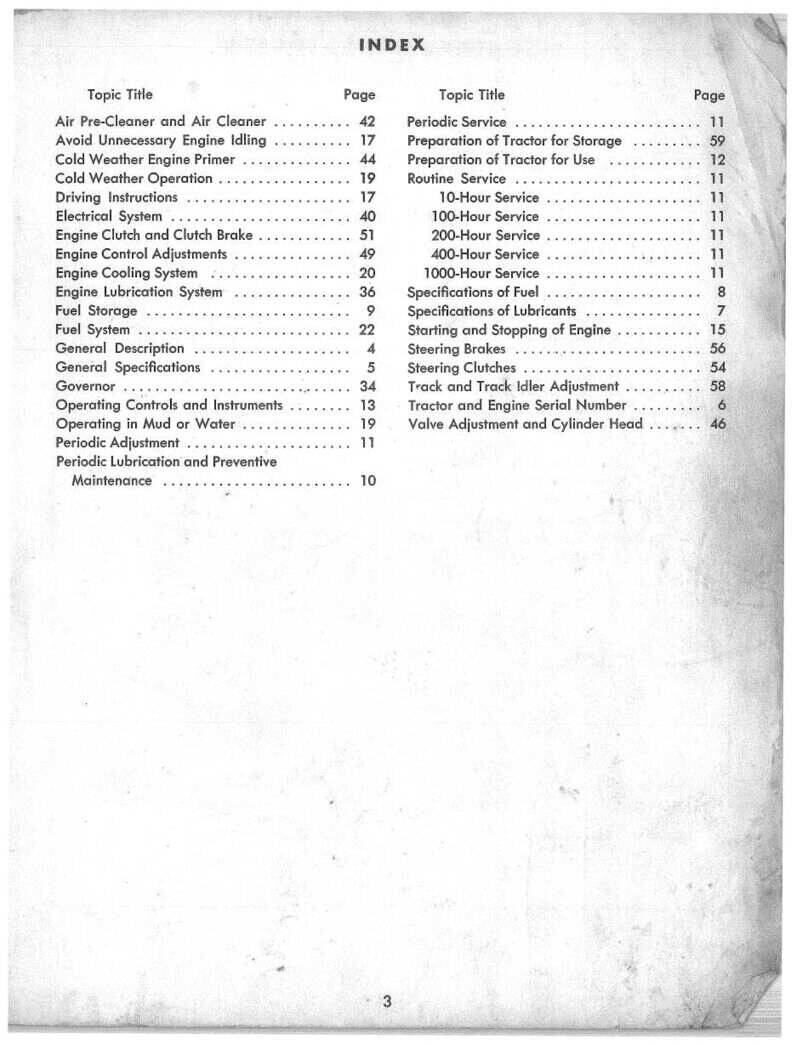

INDEX

BRAKES

Adjustment .............

26

Operation .............. 26

Type. ................ 26

CLUTCHES

Engine Clutch ...........

26

Transmission Clutch ........

26

DIAGNOSING ENGINE DIFFICULTY. . 28

DRAWBAR ...............

27

ELECTRICAL SYSTEM

Ammeter ..............

19

Battery ............... 22

Cut-out Relay. ...........

21

Fuse. ................

19

Generator. .............

21

Lights. ............... 20

Light Switch

&

Generator Control .

19

Starter ...............

21

Wiring Diagram

&

Information. .. 20

FRONT WHEELS

Adjustment ............. 25

Adjustable Wide Front Axle .... 25

Lubrication ............. 25

Maintenance ............

2 5

Single Front ............ 25

Spacing ............... 25

Tires ................ 25

Wide Front Axle .......... 25

FUEL SYSTEM

Carburetor .............

17

Fuels ................

16

Fuel Filter .............

16

Manifolds ..............

16

GENERAL INFORMATION

Fuels ................

5

Lubrication .............

5

Manifolds ..............

5

GENERAL SPECIFICATlONS .....

4

GOVERNOR. ..............

17

HYDRAULIC SYSTEM

Adjustments and Operation

Delayed Lift ...........

Drawbar Control. ........

Hold Position ..........

Lift and Lower. .........

Linkage. .............

Lubrication ............

Rams. ...............

Remote Ram. ...........

32

33

33

32

30

30

34

34

IGNITION SYSTEM

Magneto ..............

Spark Plugs ............

18

18

LUBRICATION

&

SERVICE CHART. .

6

LUBRICATION

&

SERVICE GUIDE . .

8

OPERATING INSTRUCTIONS

After Engine has Started-Check. .

Belt Pulley. ............

Break-in Period ..........

Hand Cranking ...........

Light Switch

&

Generator Control.

Operating Tractor .........

Power Take-off ..........

Starting Engine ..........

Stopping Engine ..........

Stopping Tractor. .........

Temperature Gauge ........

11

12

10

12

11

11

12

10

11

12

11

RADIATOR

&

COOLING SYSTEM

Anti-Freeze Solution .......

Draining Cooling System .....

Fan Belt Adjustment. .......

Operating Temperature ......

Pressure Radiator. ........

Radiator Capacity .........

Radiator Shutter ..........

Temperature Gauge ........

REAR WHEELS

Hydromatic Tractor Tires. ....

Tires. ...............

To Remove Rim from Wheel ...

Tread Adjustment .........

15

15

15

14

14

14

14

14

23

23

24

24

SAFETY SUGGESTIONS ........

13

SEAT. .................

27

STORAGE OF TRACTOR .......

29

VALVE TAPPET CLEARANCE. , . .

17

4

3

GENERAL SPECIFICATIONS

ENGINE :

Number of Cylinders . . . . . , , . . 4

Bore . . . . . . . . . . . . . . . . . 4”

Stroke . . . . . . . . . . . . . . . . . 4”

R.P.M. . . . . . . . . . . . . . . . 1400

Firing Order . . . . . . . . ,l-2-4-3

Piston Displacement . . . . 201 Cu. In.

Compression Ratio (Gasoline)

5-l/2

to 1

(Low Octane Fuel). . .

4-l/2

to 1

MAGNETO:

Impulse Coupling . , . . . . . Automatic

Lag Angle . . . . . . . . . . 30 degrees

Timing Advance . . . . . . . 30 degrees

Point Gap . . . . . . . . . . . . ..020”

Spark Plug Size . . . . . . . . . . 14mm

Spark Plug Point Gap. , . .030” to .040”

Spark Plug Heat Range

Gasoline . . . . . . . Autolite AN 7

or equivilent

Spark Flug Heat Range

Low Octane . . . . . . . Autolite A9

or equivilent

TRANSMISSION: (Selective Sliding Gear)

First . . . . . . . . . . . .

2-l/2

MPH

Second, . . . . . . . . . . .

3-l/2

MPH

Third . . . . . . . . . . . .

4-3/4

MPH

Fourth . . . . . . . . . . . . .

.9

MPH

Reverse . . . , . . . . . . . . . 2 MPH

ENGINE CLUTCH: (Spring Loaded)

Single Plate

-

Dry Disc

Diameter . . , . . . . . . . . . . .10”

TRANSMISSION CLUTCH: (Over Center)

Optional

Double Plate

-

Wet

Diameter . . . . . . . . . . , . . . . 7”

BELT PULLEY: (Optional)

Diameter . . . . . . , . . . . . . .9”

Face . . . . . . . . . . . . . . .

6-l/2”

RPM at 1400 Engine Speed . . . . . 1260

BRAKES:

Enclosed Contracting Type,

Foot Operated

RADIATOR:

Capacity. . . . . . . . . . . .

3-l/2

Gal.

OIL SUMP:

Capacity . . . . . . . . . . . .6 Quarts

TRANSMISSION, DIFFERENTIAL

AND CLUTCH

Capacity . . . . . . . . , . , . 17 Quarts

(18 quarts with P.T.O. Installed)

FINAL DRIVE GEARS:

Capacity

-

Each . . . . . . . . . 1 Quart

F UEI. TANK:

Capacity . . . , . . . . . . . . . .15 Gal.

Auxiliary Tank . . . . . . . . . . 1 Gal.

WHEEL TREAD:

Rear . . . . . . , . . . . . ,56” to 90”

TIRE SIZE:

Front . . . . . . . . . . . . . 5.50 x16”

Rear... . . . . . . . . . . . . 11x28

TIRE PRESSURE:

Front. . . . . . . . . . . . . . .

.28

lbs.

Rear . . . . . . . . . . . . . .12 lbs.

BATTERY:

6 Volt -- 15 Plate -- 95 Ampere Hour

HYDRAULIC PUMP (Optional)

Capacity . . . . . . . . . . . . . 5 Quarts

Lift Rams . . . . . . . Diameter

l-1/4”

Remote Ram . . . . . Diameter

l-3/4”

POWER TAKE-OFF

RPM at 1400 of Engine . . . . . . . 548

STEERING: (Semi-Reversible)

Ratio.. . . . . . . . . . . . . .

.12to1

HEIGHT

Overall . . . . . . . . . . . .

81-l/2”

Height of top of Steering Wheel . . , 68”

Wheel Base . . . . . . . . . . . . . 88”

Overall Length . . . . . . . . . . . 128”

Turning radius

-

With Brake . . . , 8’

The Allis-Chalmers Manufacturing Company reserves the right to make changes in the

above specifications or to add improvements at any time without notice or obligation.

4

GENERAL INFORMATION

LUBRICATION

IT PAYS TO PAY A LITTLE MORE FOR QUALITY LUBRICANTS

It has long been recognized that the life of a lubricated, therefore, it will cause undue wear

tractor is largely determined by the kind of and engine sluggishness. Oil that is too light

lubrication it receives. Therefore always use will not form a protective film between moving

oil and grease of high quality, manufactured parts. For best results and to assure lubrica-

by a dependable oil company who has established

tion between snug fitting parts refer to lubri-

a reputation for quality products and whose cants recommended in Lubrication Guide.

success depends on maintaining such quality.

In addition to using high quality oils it is also

Some parts need more frequent lubrication than

necessary to use oils of proper viscosity. Oil other parts. Lubrication intervals outlined in

that is too heavy cannot reach all points to be LUBRICATION GUIDE pages 8 and 9 should

be followed closely.

FUELS

FOR ECONOMY AND PERFORMANCE USE FUELS SPECIFIED FOR YOUR ENGINE

Engines for Model

"WD"

Tractors may be secured equipped to burn the above fuels are designated

with either a high or low compression ratio.

by the letter

"K"

following the engine serial num-

Each is designed to efficiently burn a particular ber located on the left rear of engine block.

class of fuel. For best performance use the (Example: WD110650 KA)

class of fuel for which the engine was designed. High compression engines are equipped to

Standard compression engines are equipped to burn gasoline only. For average loads use

burn distillate, tractor fuel or low octane gaso- 60 octane gasoline or higher. For continued

line. These fuels should have the following heavy loads use 70 octane gasoline or higher.

specifications: Gravity -- 38 or higher; End These engines are designated by the letter

Point --

525O

or less; Octane Rating -- 30 or

“G”

following the engine serial number,

(Ex-

more; Gasoline

-- 60 octane or higher. Engines ample: WD110650 GA)

MANIFOLD

Allis-Chalmers tractors are supplied with one uses gasoline only.

of two styles of manifolds. When using the two fuel manifold install the

The two fuel manifold is used with standard cover marked "K" when burning tractor fuel

compression engines and can be used for trac- or distillate. Install the cover marked

‘G”

tor fuel or gasoline. The gasoline manifold when using gasoline.

is supplied on high compression engines and

1

STEERING

SP!NDLE

SHAFT

7.-1

8.

FRONT WHEEL

19

STEERING WORM

AND GEAR

WATER PUMP

8.-

15

FILLER CAP

20.

GENERATOR . STEERING SHAFT

BEARING

9. BREATHER

10. AIR CLEANER

4 CLUTCH SHAFT

FUEL FILTER

16.

FINAL DRIVE

2. UNIVERSAL JOINT

8.-l

5. O

IL

SUMP

22.

OIL FILTER

Ii1

CLUTCH RELEASE

BEARING

5.

PULLEY

1.

HYDRAULIC PUMP

21.

TRANSMlm

~~

__.

_.

.,

TRANSMISSION AND DIFFERENTIAL

I:SlON

CLUTCH.

LUBRICATION AND SERVICE CHART.’

6

LUBRICATION AND SERVICE CHART

(Cont’d.)

-I

7

LUBRICATION AND SERVICE GUIDE

DAILY CHECK

Lubricate items 1 thru 6 with Chassis Lubricant.

1. STEERING SPINDLE SHAFT

2. UNIVERSAL JOINT

3. LOWER STEERING SHAFT BEARING.

4. CLUTCH SHAFT

5. PULLEY (when in use)

6. ENGINE CLUTCH RELEASE BEARING

-

Lubricate every 10 to 20 hours with chassis

lubricant. Do not over grease. Fitting can

be reached by removing small cover at

bottom of clutch housing. Lock clutch pedal

forward to locate fitting

50

it may be reached

by

gun.

7. FRONT WHEELS

-

If wide front axle is used

lubricate four king pins. (See 30 Day Check.)

8. OIL SUMP

-

Capacity 6 quarts. Maintain

oil level to full mark on oil gauge rod. When

using low octane fuel drain to level of drain

cock located on right side of oil sump, every

10 hours and refill with fresh motor oil.

Above

90°F.

use SAE 40

Above

32’F.

use SAE 30

Above lOoF. use SAE 20W

Below lOoF. use SAE

1OW

9. BREATHER CAP

-

Wash in gasoline and dip

in motor oil

-

throw off excess oil before re-

placing. Under extremely dusty conditions,

service the breather cap twice daily.

10. AIR CLEANER

-

Clean and refill oil cup.

Fill to level mark using motor oil of the

same viscosity as used in oil sump.

Under extreme dusty conditions service air

cleaner twice daily. Each season remove

the entire air cleaner and clean main body

and element thoroughly. Keep all connections

air tight.

11. HYDRAULIC PUMP

-

Oil used in hydraulic

pump must not foam. Check daily and keep

filled to high mark on bayonet gauge or to top

of filler neck on tractor not equipped with

bayonet gauge. Filler plug is upper front

plug on torque tube. NOTE: This same oil

also lubricates belt pulley bearings and

gears. Change oil twice a year.

Amagnetic drain plug is located at the bot-

tom of the housing. This plug should be

cleaned periodically. To completely drain

pump the pump control housing must also be

drained.Above

45OF.

use SAE

2OW

Below 45OF. use SAE

1OW

12. RADIATOR

-

Capacity

3-l/2

gallons. Drain

cocks are located at bottom of radiator and

engine block ahead of carburetor.

WEEKLY CHECK

13. RIGHT HAND BRAKE PEDAL

-

Lubricate

with chassis lubricant.

14. ENGlNE CLUTCH PEDAL

-

Lubricate with

chassis lubricant (not shown).

15. OIL SUMP

-

Drain and refill with fresh oil

every 60 hours when using gasoline. When

using low octane fuel drain completely and

refill every 40 hours. Drain plug is located

at bottom of oil sump. Keep filled to full

mark on bayonet gauge.

Above

90°F

use SAE 40

Above 32OF use SAE 30

Above lOoF use SAE 20W

Below lOoF use SAE

1OW

16. FINAL DRIVES

-

Capacity

l-3/4

quarts each.

Keep filled to level plug, For temperatures

above

32OF.

use SAE 140 gear lubricant; for

temperatures below 32’F. use SAE 90. Drain

and refill twice a year.

17. BATTERY

-

Electrolyte solution should be

l/4

inch above separators.

30 DAY CHECK

18. FRONT WHEELS

-

Clean and repack with

No. 2 wheel bearing grease every 30 to 60

days. (Applies to all types of front wheels)

19. STEERING WORM AND GEAR

-

Check every

30 to 60 days. Remove cover from top of

front support, maintain oil level so worm

gear is one-third submerged. Use SAE 140

gear lubricant. NOTE: With wide front

axle and single front wheel use SAE #250.

20. GENERATOR

-

Lubricate with motor oil of

same viscosity as used in oil sump at pre-

vailing temperature. Two or three drops is

sufficient.

21. TRANSMISSION, DIFFERENTIAL AND

TRANSMISSION CLUTCH

-

Capacity 17

quarts. Keep filled to level plugs. Use

+SAE 80EP all year. Drain plugs are

located on bottom of transmission, bottom

of differential and bottom of clutch housing.

Drain and refill twice a year. When power

take-off is installed on transmission add one

8

AIR CLEANER

A clean air cleaner adds life to your engine.

Service the air cleaner as mentioned in Item

number 10, Use the same viscosity oil as used

in the engine oil sump according to the pre-

vailing temperature. Keep the oil cup filled

to the proper level at all times. Do not dilute

oil or use used crankcase oil. The efficiency

/

of cleaner

depends

on the proper viscosity oil.

LUBRICATION AND SERVICE GUIDE (Cont’d.)

extra quart. Fill all three compartments 22. OIL FILTER

-

Replace when oil begins to

through transmission filler plug. darken. Replacement is usually necessary

after 200 hours when operating on gasoline

*his

oil is sold under varied listings. Any oil

following U.S. Army specifications of

2-105B

80 viscosity transmission oil is satisfactory.

and after 100 hours when operating on low

octane fuel.

FILTER ELEMENT

EAFFL OIL LEVEL

BAFFLE RETAINER

AIR CLEANER

BREATHER

Service the breather cap daily as mentioned in

Item Number 9. If breather should become

clogged with dirt, pressure will be created in

the crankcase, causing oil leaks.

OIL FILTER

Insure your engine life by regular replacement

machine packed, to a specific density and supplied

of filter. The oil filter is a highly efficient unit

by the Allis-Chalmers Mfg. Co. for the protection

for the purpose of filtering abrasive particles

of your engine.

from the crankcase oil. NOTE: A slight decrease in oil pressure is

The filter element consists of a metal container generally noted when a filter element is in-

packed with a special long thread filtering yarn.

stalled, until the element is thoroughly saturated

with oil.

CAUTION: Install only a new element which is

.

-.-“..

-._.

_

OPERATING INSTRUCTIONS

HYDRAULIC CO

GEAR SHIFT LEVER

AMMETER

\

BREAK IN PERIOD

-

The tractor engine is as-

sembled and tested and ready for work, how-

ever for best results operate tractor under

medium loads for the first 10 to 20 hours of

operation.. If possible it should be operated

at full governed

r.p.m.

of engine. If necessary

use a lower gear to keep from overloading

engine. In cold weather the oil should be

changed after the first 20 to 30 hours of

operation. However if the proper temperature

is maintained at all times the lubricating

interval outlined in lubrication guide may be

followed.

STARTING ENGINE

1. Before starting tractor make certain that all

points of care and lubrication outlined under

daily, weekly or 30 day check have been ser-

viced as specified.

2. Close radiator shutter by turning screw crank

located on right hand side of tractor.

3. If gasoline is to be used open valve under

large tank. If low octane fuel is used open

valve under small tank. Move throttle control

lever down about one fourth of quadrant.

Place gear shift in neutral position. In cold

weather hold clutch pedal down until engine

starts to relieve starter load.

4. Pull out magneto switch on instrument panel.

5. Pull carburetor choke rod located at right

side of steering column.

6. Pull out on starter pull rod located on left

side of steering column. Engage starter

firmly to insure good switch contact. Release

immediately when engine starts, When engine

has turned one complete turn, push choke rod

forward, If weather is extremely cold more

choking may be necessary.

AFTER ENGINE HAS STARTED

-

CHECK

1. OIL PRESSURE GAUGE. When operating

engine look at oil gauge at frequent intervals

to make certain oil is being circulated by

pump. The indicator needle should always

remain near the O.R. or M. in the word

NORMAL when the engine is hot and running

at its normal speed. A slight decrease will

be noted when engine idles. Do not operate

unless gauge registers,

2. THE TEMPERATURE GAUGE needle should

operate in the green portion of gauge, and

temperature should be maintained by shutter

adjustment.

3. THE LIGHT SWITCH

&

GENERATOR CON-

TROL is located on the instrument panel, To

turn on lights pull switch to first notch. The

generator has two charging rates, with switch

pushed all the way in the lights are off and

rate of charge about 3 amperes as indicated

on ammeter, when pulled to first notch lights

are on and charging rate remains about 3

amperes. When switch is pulled all the way

out about 10 to 13 amps. The high rate of

change should be used only when the battery

is in a partially discharged condition.

In

most tractor operation the trend will be to

overcharge the battery.

STOPPING ENGINE

-

Place throttle in idling

position and allow engine to idle a few mo-

ments. Shut off by pushing in on magneto

switch. If using low octane fuel close valve

under fuel tank and allow engine to run until

it stops from lack of fuel. This will drain

the carburetor so gasoline may be used for

starting.

OPERATING TRACTOR

-

The clutch is provided

for engaging or disengaging the power of

engine from the tractor. When using clutch

depress pedal fully and allow tractor and

clutch to come to a full stop before attempting

to shift gears. Reducing engine speed to low

idle before depressing clutch will help prevent

clashing gears. With the engine running, push

the clutch pedal forward to release clutch,

Hold in this position until the clutch stops

revolving. Move the gear shift lever to the

desired position as indicated on top of trans-

mission cover. Open throttle far enough to

avoid stalling. Release clutch pedal slowly to

avoid jerking. The transmission clutch is

provided to disengage the engine power from

the transmission and rear wheels, leaving the

power applied only to the P.T.O., hydraulic

pump and belt pulley, if used.

The transmission clutch is hand operated and

the lever is mounted to the right of the steer-

ing shaft support. Pushing lever forward

disengages clutch.

AMMETER

INSTRUMENT PANEL

When’using the belt pulley, the transmission

clutch should be engaged and the transmission

shifter lever placed in neutral position,

Easy turns may be made by simply turning

steering wheel to right or left as desired.

Foot brakes are provided for making ex-

tremely short turns. Turn steering wheel

in direction desired and then apply brake on

side towards which the tractor is being

turned. Do not attempt short turns when

traveling at high speeds. When using the

brakes for stopping, apply pressure to both

brakes so that the brakes are engaged evenly.

This will bring the tractor to an even stop

without skidding. The latch on brake lever

is conveniently located for locking the brake

in the engaged position to hold the tractor on

an incline, or for belt work.

Operate engine at full throttle or nearly full

throttle and select the desired transmission

OPERATING INSTRUCTIONS (Cont’d.)

gear to suit the work being done. To shift to

low or first gear with the gear shift lever in

neutral position, disengage clutch, move gear

shift lever to left and forward. Second from

neutral, left and back, third gear right and

forward, fourth gear to right and back. To

shift to reverse, push lever to extreme right

and back, always stop tractor before changing

gears. Severe overloads may be thrown on

engine if tractor is operated at reduced engine

speeds on heavy loads.

Adjust the

drawbar

height to recommended

height for the implement being drawn. The

drawbar should be placed as near in the

centerline of draft as possible. Rear wheel

weights are available for securing extra

traction on heavy loads.

STOPPING TRACTOR

-

Push clutch pedal for-

ward, allow tractor to stop or if necessary

apply brakes. Place gear shift in neutral

position, release clutch pedal.

HAND CRANKING

-

Push clutch pedal down and

engage

pedal

lock. Proceed as under “‘Starting

Engine . Engage crank grasping handle with

thumb on same side of crank as fingers.

Crank in quarter turns only, pulling

up

and

over. DO NOT ATTEMPT TO “SPIN’ EN-

GINE. When engine starts release clutch

pedal lock. Do not operate engine for long

periods with pedal locked forward.

OPERATING BELT PULLEY

-

Push clutch pedal

down and engage pedal lock. Loosen belt

pulley retaining screw and push pulley assem-

bly into the tractor. The dealer will stamp

an arrow on tractor frame and on pulley

tube. These arrows must be aligned to obtain

proper gear mesh. Tighten lock screw and

jam nut. Release clutch pedal, The clutch

pedal lock may be engaged when pulley is

stopped, however the engine should be stopped

if any work is to be done on the driven

machine.

OPERATING POWER TAKE-OFF

-

The power

take-off is used to furnish power to P.T.O.

driven machines and operates at a speed of

548 r.p.m. at 1400 r.p.m. of engine. The

speed of the P.T.O. remains at 548 regard-

less of what gear the tractor is operated in.

The P.T.O. is provided with a shift lever for

engaging or disengaging. To engage the

P.T.O., push the clutch pedal forward the

same as for shifting gears in the transmission.

Allow the clutch to stop and, if the tractor

is in motion, allow it to stop. Pull up on the

P.T.O. shift rod located

near

the steering

rod support. If the P.T.O. is engaged, do not

attempt to shift transmission gears until

12

P. T. 0. SHAFT

POWER TAKE-OFF

driven machine stops. This P.T.O. will keep

on running when the transmission clutch is

disengaged.

SAFETY SUGGESTIONS

Many hours of lost time and much suffering is

caused by the failure to practice simple safety

rules.

IT IS TOO LATE TO REMEMBER WHAT SHOULD

HAVE BEEN DONE AFTER THE ACCIDENT HAS

HAPPENED.

1. Do not fill fuel tanks when engine is hot or

while using a lantern or when smoking.

2. Do not attempt to spin engine when hand

cranking.

3. Do not attempt to oil or grease a machine

or tractor while it is in operation.

4. Do not wear loose fitting clothing that may

be blown into moving parts.

5. Keep all shields and guards in place.

6. Place gear shift lever in neutral position

when starting engine.

7. Machinery should only be operated by those

who are responsible and delegated to do SO.

8. Only one person -- the operator -- should be

permitted on tractor when tractor is in

motion.

9. The rate of travel on hillsides or curves

should be regulated so there is no danger

of tipping.

10. Do not remove radiator cap when engine

temperature is above 212 F.

11. Brakes should be properly adjusted.

12. Do not drive too close to the edge of a ditch

or creek.

13. Never operate your tractor in a closed

garage or shed.

14. When tractor is hitched to a stump or other

heavy load, always hitch to drawbar and

never take up slack in chain with a jerk.

15. Always keep tractor in gear when going down

steep grades.

16. Do not leave the engine running unattended

when any one is adjusting or repairing a

driven machine.

17. Do not attempt to operate tractor unless you

are in the driver’s seat.

18. Provide a first aid kit. Treat all scratches,

cuts, etc. with the proper antiseptic im-

mediately.

19. Always stop power take-off before leaving

driver’s seat.

20. Never stand between tractor and drawn

implement when hitching. Use an iron hook

to handle drawbar.

21. Do not put on or remove belt from belt pulley

while pulley is in operation.

22. Do not dismount from tractor while it is in

motion.

RADIATOR CAPACITY

3-l/2

gallons. Drain

cocks are located at bottom of radiator and on

engine block ahead of carburetor. Be sure to

remove cap when draining radiator.

TEMPERATURE GAUGE

-

The temperature

gauge is provided for a visual check on

operating temperature.

The gauge is marked in green indicating

normal with a range of

170°F.

to

220°F.

RADIATOR SHUTTER

-

The shutter is provided

for controlling the operating temperature of

engine. Turning the screw crank, located on

right hand side of radiator to the right, opens

the shutter.

Always close shutter before starting engine.

OPERATING TEMPERATURE

-

LOW ENGINE

TEMPERATURES CAUSE CONDENSATION--

SLUDGE AND CORROSION. KEEP ENGINE

HOT. Always close radiator shutter com-

pletely when engine is started and keep it

closed until engines reach operating temper-

ature (

170°F.

when using gasoline,

190°F.

when using low octane fuel). Then open

shutter amount necessary to maintain this

temperature,

If burning low octane fuels, operate

engine

on

gasoline until temperature reaches 190 F.

to 200

F.

before switching to low octane fuel.

This is readily done by shutting valve under

small tank and opening valve under large tank.

Never open valve under larger tank before

shutting valve under small tank as this will

mix the two fuels.

The minimum operating temperatures are

17OoF.

for gasoline and 190°F. for low octane

fuel. Strict adherence to these recommen-

dations will guard against excessive dilution

of lubricating oil, condensation and corrosion

14

PRESSURE RADIATOR

-

The pressure radiator

permits the use of a higher operating tempera-

ture. The cooling solution (pure water) will

not boil in the pressure radiator until a

temperature of

230°F.

is reached.

To remove the radiator cap, turn to the left

until it stops. Push down and continue to

turn to the left until the cap is released.

Do not remove the cap when the temperature

is above 212OF. as the cooling solution will

break into a violent boil which may splash onto

person removing cap.

=

TEMPERATURE GAUGE=

SHUTTER CONTROL HANDLE

..__.

RADIATOR AND COOLING SYSTEM

PRESSURE CAP STANDARD CAP

RADIATOR CAPS

Never pour cold water in a hot engine. Clean

rain or soft water should be used in the cool-

ing system if available. Hard or alkaline

water will form a scale which will impair

radiation if allowed to build up in the cooling

system. The use of washing soda will help

dissolve this scale. Where only hard water is

available, washing soda should be used at

intervals, and before the accumulation of

scale becomes heavy enough to scale off and

stop up radiator passages.

If soda is used’, mix with water thoroughly

before placing in radiator. Operate engine

about 2 hours. Drain and flush thoroughly

with clean water. Soluble oil is beneficial to

the cooling system. It will not prevent the

accumulation of lime but will retard such

formation. This water soluble oil may be

secured from your Allis-Chalmers dealer.

TO DRAIN COOLING SYSTEM

-

Open the drain

cock located on lower radiator outlet and the

drain cock on motor block ahead of carburetor.

CAUTION: In freezing weather be sure to

drain both places. Loosen radiator

cap

to

prevent system from air locking, which will

retard draining. Stay near tractor and make

sure system is completely drained.

ANTI-FREEZE

SOLUTION

-

If tractor is used

during freezing weather it is advisable to

fill the cooling system with anti-freeze

solution. If low octane fuel is used,

alcohol

should not be used in the cooling system,

because of its low boiling point. When low

octane fuel is used, a good grade of permanent

anti-freeze with a higher boiling point is

recommended because of the higher operating

temperature with this type of fuel.

FAN BELT ADJUSTMENT

-

To adjust loosen

the generator adjusting screw and move the

generator away from cylinder block until

about

1”

free movement at “A

"

is obtained.

Extreme tightness will reduce the life of the

belt, generator bearings and fan shaft bearing.

If fan belt bottoms in the

sheaves

indicating

belt wear the belt should be replaced.

ml.2 A

TNTNC

-

FUEL SYSTEM

.

FUELS FOR ECONOMY AND PERFORMANCE

USE FUELS SPECIFIED FOR

YOUR ENGINE.

Engines for Model “WD “Tractors may be

secured with either a high or low compres-

sion ratio. Each is designed to efficiently

burn a particular class of fuel. For best

performance use the class of fuel for which

the engine was designed.

Standard compression engines are equipped

to burn distillate, tractor fuel or low octane

gasoline. These fuels should have the fol-

lowing specifications: Gravity -- 38 or

higher: End Point

-

525O

or less; Octane

Rating -- 30 or more; Gasoline --60 octane

or higher. Engines equipped to burn the

above fuels are designated by the letter

“K”

following the engine serial number located

on the left rear of engine block (Example

WD-1106 50 KX.)

High compression engines are equipped to

burn gasoline only. For average loads use

60 octane gasoline or higher. For continued

heavy loads use 70 octane gasoline or higher.

These engines are designated by the letter

“G”

following the engine serial number.

(Example: WD-110650 GA.)

MANIFOLDS

-

The WD Tractor is supplied with

two types of manifolds.

The two fuel manifold is used with standard

compression engines and can be used for

tractor fuel or gasoline. The gasoline mani-

fold is supplied on high compression engines

and uses gasoline only.

When using the two fuel manifold install the

cover marked “K

”

when burning tractor fuel

or distillate. Install the cover marked

“G”

when using gasoline.

FUEL FILTER

-

The fuel filter is provided for

the purpose of keeping dirt and water from

entering the carburetor. However the best

results are obtained by using adequate fuel

storage and handling

facilties.

If the fuel is

kept free of dirt and water by use of clean

1containers and proper handling, the filter will

have little work to perform.

To clean the filter, shut off the fuel supply.

Loosen the bowl retaining nut and move bail

to one side.

Remove bowl, gasket and felt element. Note

which side of the element is up and be sure

to re-install with the same side up.

GASOLINE MANIFOLD

-

FUELFILTER

The element can be cleaned with ordinary

soap and water and a small stiff brush. The

element must be thoroughly dried before

re-installing.

It is well to carry an extra element on hand.

This will avoid delay in the drying operation.

CARBURETOR

-

The Zenith Model 161 Series

has three adjustments, one for controlling the

idling speed of the engine and two for correct-

ing changes in fuel and atmospheric condi-

tions.

To regulate idling speed of the engine

adjust the throttle stop screw on inner side

of the carburetor. For correct fuel mixture

at idling speeds of engine adjust needle valve

on front top of the carburetor. Turn needle

in for richer mixture. Normal setting is

approximately one and one-half turns out.

The main jet adjusting needle located on the

lower front of the carburetor body regulates

the fuel mixture at working speeds. Turn this

needle out for richer mixture. Normal setting

is two or three turns out depending on fuel

and atmospheric conditions. Always make

carburetor adjustment at normal operating

temperature.

The adjustments of the Marvel Schebler

Carburetor Model TS159 are the same as the

Zenith, except for the main jet adjusting

needle located on the front upper portion of

bowl. The normal operating adjustment is

approximately one and three eighths turns out.

VALVE TAPPET

Correct clearance between valve stems and

rocker arms should be maintained at all times.

To adjust clearance, turn engine with crank until

valvecloses and push rod is at its lowest posi-

tion.

Loosen valve adjusting screw lock nut and turn

screw until there is

.010"

clearance between

valve stem and rocker arm. Tighten lock nut

and recheck. The engine must be heated to its

normal operating temperature when making this

adjustment.

Lack of compression because of leaky valves

may be caused by either insufficient clearance

between rocker arms and valve stems or by the

collection of carbon on the valve stems or seats.

ZENITH CARBURETOR

MAINLOAD

ADJUSTING NEEDLE IDLING SPEED

ey

ADJUSTING SCREW

CHOKE LEVER

IDLING ADJUS

’

DRAIN COCK

-MARVEL SCHEBLER CARBURETOR

-

CLEARANCE

ADJUSTbiG SCREW

AND LOCKNUT

.010”

FEELER GAUGE

GOVERNOR

The engine speed is adjustable by throttle only.

To ensure good governor action it is important to

The governor, of the variable speed type, will have all linkage from governor to carburetor,

control the engine speed within the range of low work freely.

idle and 1725 r.p.m.

17

IGNITION SYSTEM

SPARK PLUGS

-

The spark plugs should be

removed every 200 hours of operation, cleaned

and the points respaced. The point gap should

be set from .030” to .040”. Make this ad-

justment by bending the outside electrode.

Never bend center electrode.

CAUTION: Failure to service spark plugs

as recommended, causes a severe bverload to

be placed on magneto.

For gasoline use autolite AN7 or equivalent.

For low grade fuel use autolite A-9 or

equivalent. Incorrect plugs are shorter lived

and cause poor engine performance.

Spark plug gap should be set properly; gap

too wide will cause missing on heavy loads

and lack of power.

Gap too narrow will cause missing, poor

idling and engine to die at slow speed.

The spark plugs and cables should be main-

tained in good condition and free of dirt and

grease.

MAGNET0

-

To time the magneto

-

Crank engine

until No. 1 piston is approaching top center

on its compression stroke and mark F or

firing mark appears in center of inspection

opening in bottom of clutch housing.

The compression stroke of No.

1

piston can

be determined by removing the spark plug

placing thumb in spark plug hole. Crank

slowly until air is forced past thumb.

The

mark F on flywheel will be very near the

inspection opening at this time. Turn until

centered.

I

-

SPARK PLUG ADJUSTMENT

Remove the distributor compartment cover

from the magneto that is retained by two

screws. Turn magneto impulse coupling

counter-clockwise until the rotor contact lines

up with the timing lug, located in upper left

hand corner of distributor compartment.

Couple magneto to engine. If rotor does not

exactly line up with lug, turn magneto on

engine until it does. The slotted holes in

mounting bracket are provided for this

pur-

NO. 1

ROTOR\

CONDENSER

K”l”K

wwt

PINION

&

ADJUSTING SCREW

pose.

OTOR VENTILATING HOLES

Attach number one spark plug wire to upper

terminal nearest cylender block. number two

DISTRIBUTOR CAP

FMX MAGNETO

to upper terminal farthest from block, number

four to lower terminal farthest from block, four screws. If contact points are pitted or

and number three in remaining terminal. In pyramided, file smooth with a fine cut file.

event of difficulty in the ignition system, plugs, If points are worn or badly pitted they should

wires having been checked, remove the

dis-

be replaced. Points should have .010" sepa-

tributor compartment cover held in place by ration when breaker points rest on high side of

18

cam. Points may be adjusted by loosening

lockscrews and turning adjusting screw.

Reassembling distributor cap to magneto

involves meshing of rotor pinion with dis-

tributor gear as follows: The marked tooth

of rotor drive gear (beveled tooth) must mesh

with tooth marked

“G

"

on rotor gear, If

gaskets are broken they must be replaced.

Make sure the vent holes are open in rotor

compartment. If these holes become plugged,

the magneto will not be ventilated. The mag-

neto was permanently oiled at factory and

needs no further lubrication.

For difficulties other than above mentioned

remove the magneto and take it to the nearest

authorized service station for check up and

repair.

ELECTRICAL SYSTEM

AMMETER

-

The ammeter indicates the charging

or discharging rate of battery. If ammeter

should register discharge

,with

lights off,

disconnect the battery cable, to prevent the

discharge of battery, until the difficulty is

located and corrected. Such a condition is

usually caused by a worn or frayed wire

making a short circuit or by cut-off relay

points being stuck together.

If ammeter fails to show a charging rate one of

the following may be the cause:

1. Loose or corroded wire connections.

2. Broken wires

3. Faulty ammeter.

4. Oily or g

ummy generator brushes or com-

mutator.

5. Worn generator brushes.

Commutator and brushes can be cleaned with

grade “00” sandpaper. (Do not use emery cloth.)

LIGHT SWITCH

&

GENERATOR CONTROL

-

The

generator has two charging rates. These are

controlled by the light switch.

When the light switch is pushed all the way

in, the lights are off and the charging rate is

about 3 amperes. When the switch is pulled

out to first notch the lights are on and the

charging rate remains about 3 amperes.

When the light switch is pulled all the way

out the lights are off and the charging rate

is increased to about 10 to 13 amperes. The

high rate of charge should only be used when

the battery is in a partially discharged condi-

tion. In most tractor operations the trend will

be to overcharge the battery.

FUSE

-

The light circuit is provided with a

20 ampere fuse. This fuse is located on the

inside-of the instrument box.

t-

Y-

AMMETER

NET0

RATE CONTROL SWITCH

INSTRUMENT PANEL

19

ELECTRICAL SYSTEM (Cont’d.)

LIGHTS

-

The head lights are adjustable in or

out and may be adjusted up or down, by

loosening the retaining thumb screw and

adjusting the lights to the desired position.

TAIL LIGHT,

WD TRACTOR WIRING DIAGRAM

WIRING DIAGRAM

WIRING DIAGRAM

&

INFORMATION

-

By re- #3

-

Magneto ground switch to ground.

ferring to the diagram the wires may be (White with black tracer)

placed in position correctly. The wires are #4

-

Light switch to headlight.

identified by either colors or numbers listed (Red with white tracer to junction;

below and may be checked as follows: black to light)

#l

-

Discharge side of ammeter to cutout

terminal (Black with white tracer).

#2

-

Resistor to generator field terminal.

(Green with white tracer).

#5

-

Charge side of ammeter to starter

(black). Short natural color with red

tracer wire goes from discharge side of

ammeter to fuse at terminal

"B"

Tail

light wire, black is connected to light

switch on terminal marked ‘S”.

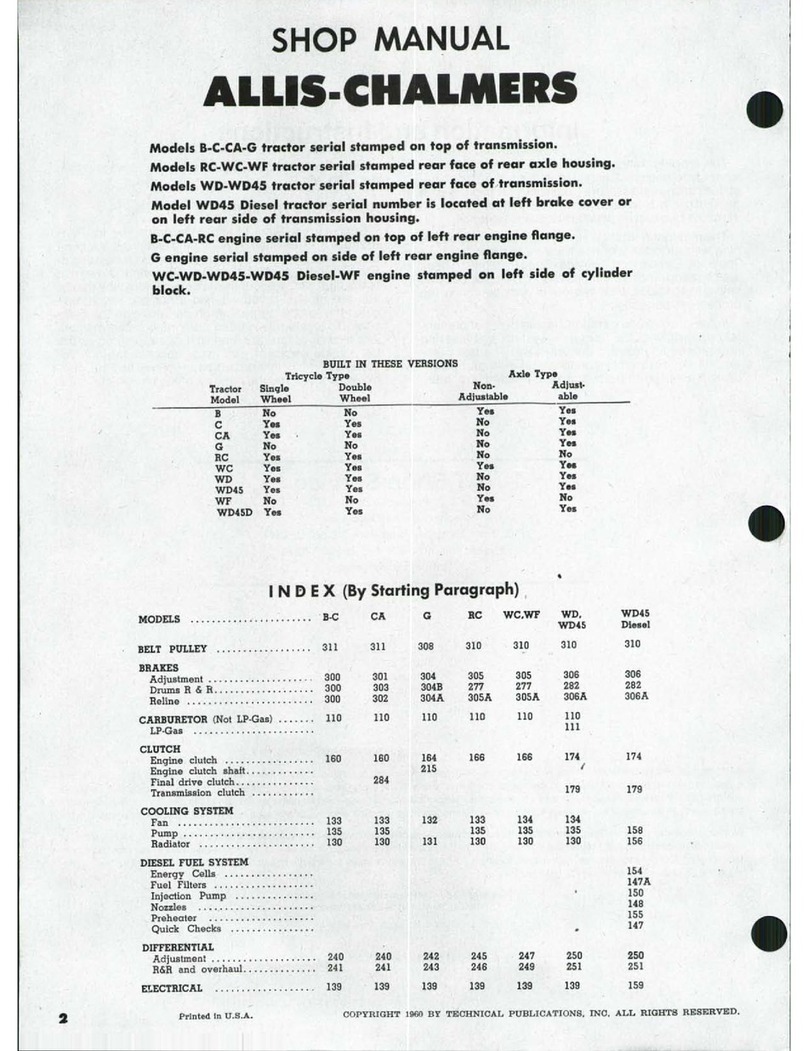

Table of contents

Other Allis-Chalmers Tractor manuals

Allis-Chalmers

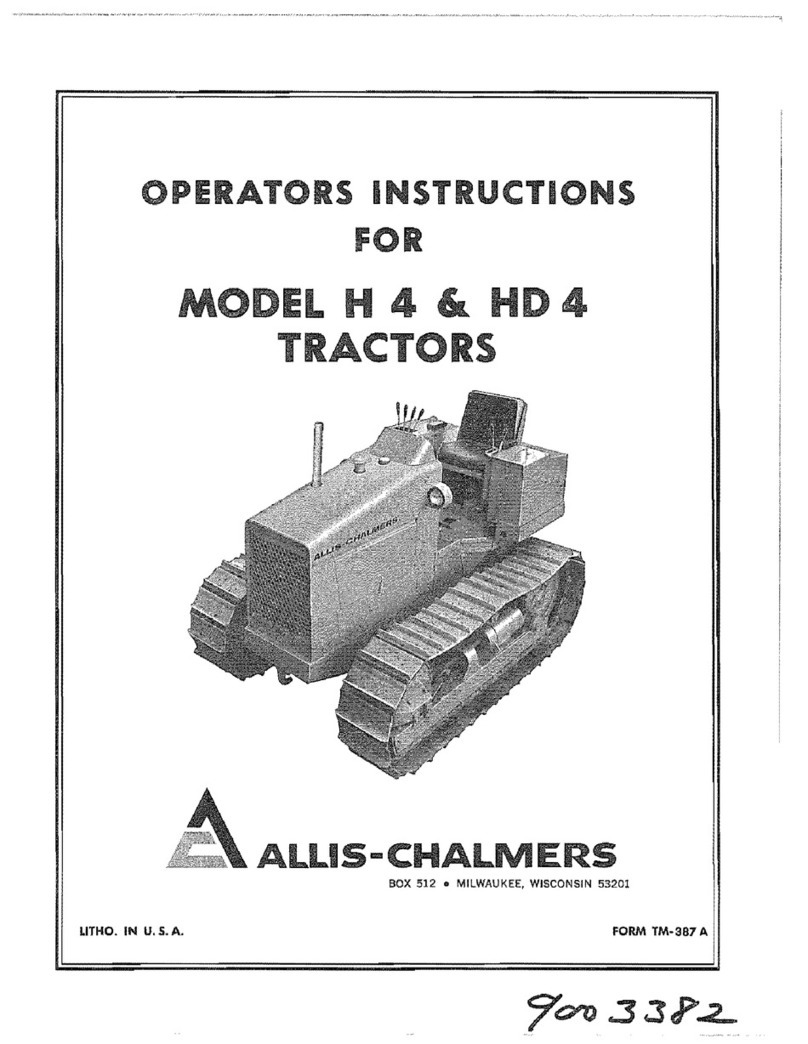

Allis-Chalmers H 4 Specifications

Allis-Chalmers

Allis-Chalmers G User manual

Allis-Chalmers

Allis-Chalmers HD 6B User manual

Allis-Chalmers

Allis-Chalmers B Install guide

Allis-Chalmers

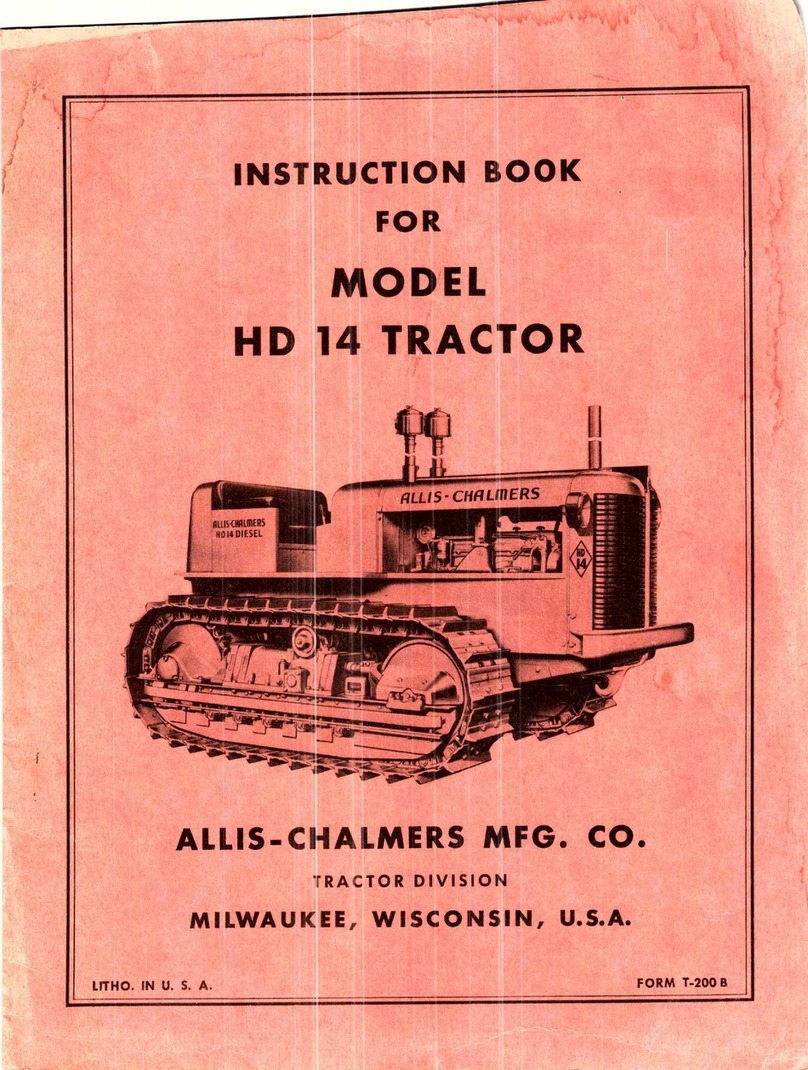

Allis-Chalmers HD-14 User manual

Allis-Chalmers

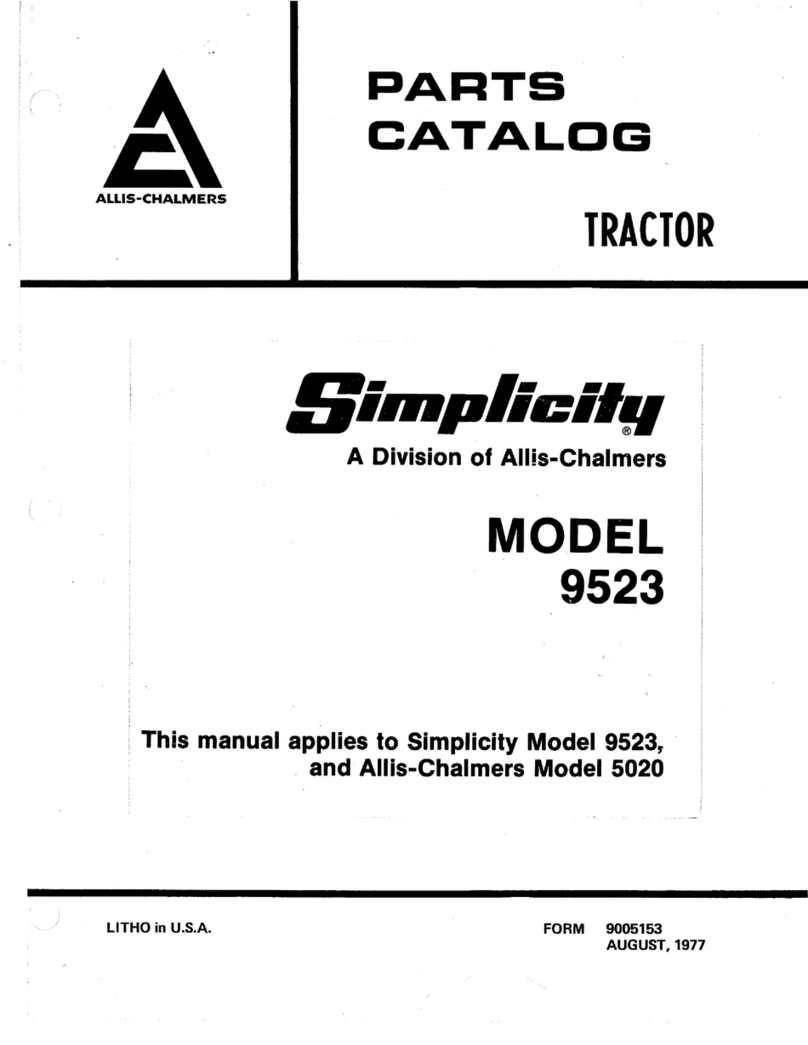

Allis-Chalmers Simplicity 9523 Instruction Manual

Allis-Chalmers

Allis-Chalmers HD-4 Specifications

Allis-Chalmers

Allis-Chalmers 10 hp User manual

Allis-Chalmers

Allis-Chalmers 910-6 Speed User manual

Allis-Chalmers

Allis-Chalmers G User manual