Allis-Chalmers U Installation and user guide

FOREWORD

This book, covering the Service and maintenance of the Model "A",

"U" and "UC" tractors manufactured by "Allis-Chalmers" contains

material formerly incorporated in the loose leaf Farm Equipment Service

Manual, "Knowledge Means Power".

-:••• --A: :. ••.•••.••

A

It is material now seldom used but never the less very valuable when

needed. This is the last r.~~sion that will be made of these sections and

you should retain this book for your permanent file.

For information listed under "General Section" in indexes refer to

"General Sect ion" in loose leaf Farm Equipment Service Manual.

This book, like the material in loose leaf Farm Equipment Service

Manual "Knowledge Means Power", is printed for the exclusive use of

"Allis-Chalmers" Dealers in servici.ng and maintaining farm equip-

ment manufactured by "Allis-Chalmers".

PRICE $1.00

ALLlS-CHALMERS MFG. CO.

FARM EQUIPMENT DIVISION

MILWAUKEE, WISCONSIN

U.S.A.

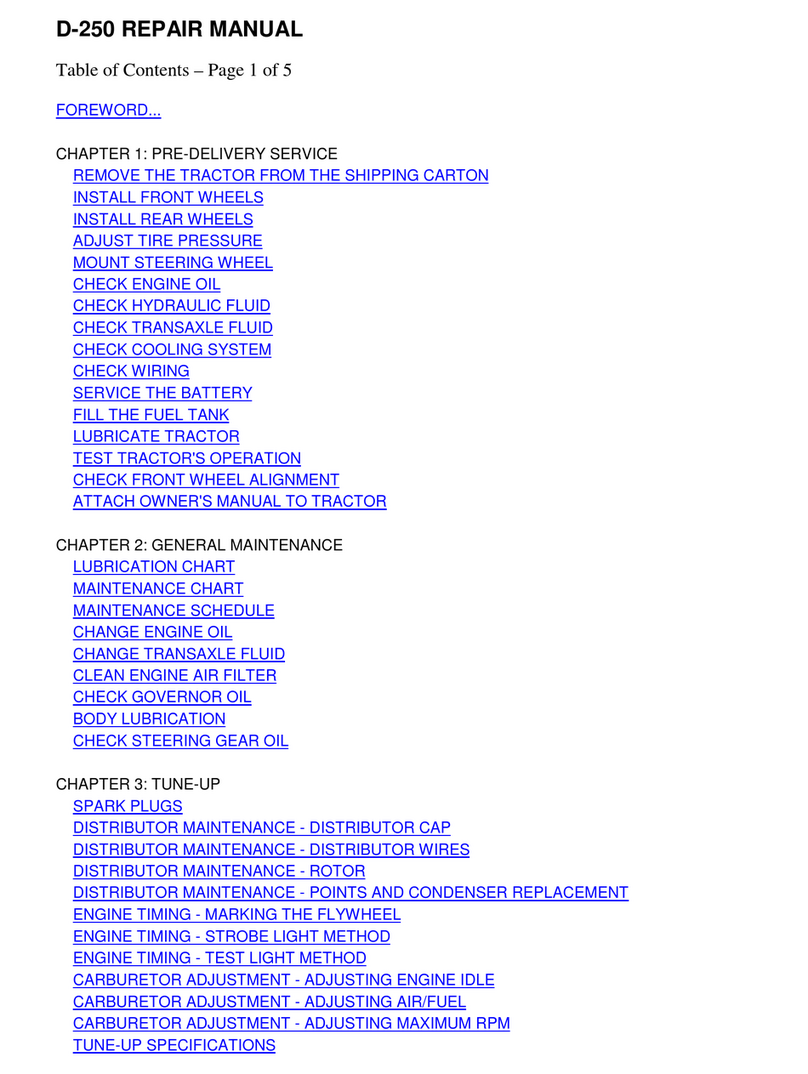

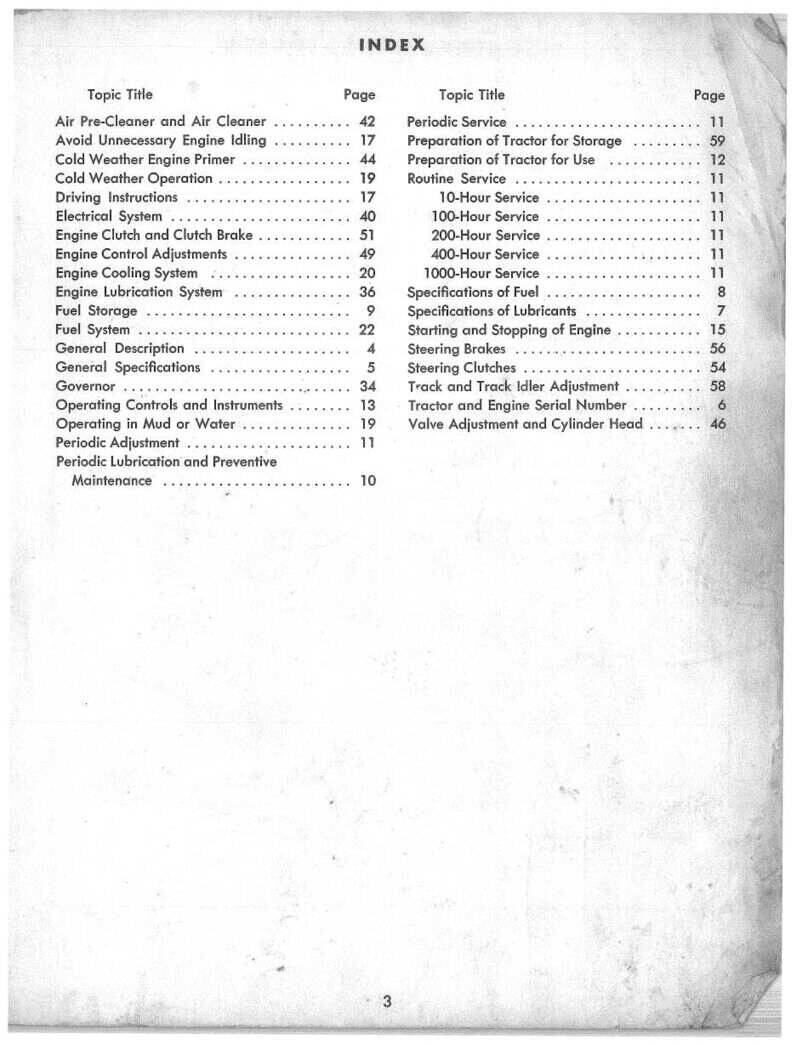

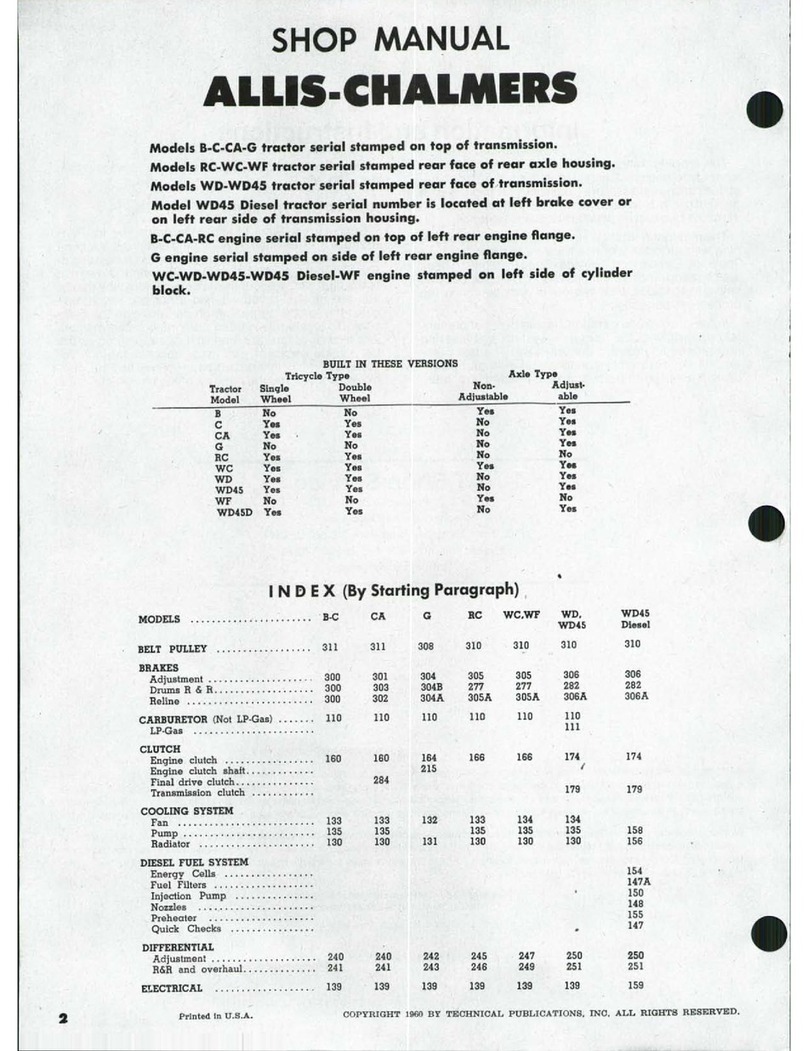

MODELr~"TRACTORINDEX

SUBJECT SEC. PAGE PAGE PAGE PAGE PAGE

AIR CLEANER A1417

BELT PULLEY

Construction U239

*Construction U239

Lubrication A4

Specifications A2

7

*Specifications A27

BREATHER, ENGINE A420

BREA THER, TRANSMISSION A4

CAMSHAFT A111

CARBURETOR A1624 25

CARE

&

OPERATION A3456

CLEANING RADIATOR A8

CLUTCH

Adjustment A2

6

28

*Adjustment A2631

Lubrication A3

Removal A28

*Removal A31

Repair A28 29

*Repair A31 32

CONNECTING RODS A1513

COOLING SYSTEM A168

CRANKSHAFT A114

Oil Seals A

11

Main Bearings A11

CYLINDER HEAD A20 4Q

CYLINDER LINERS A1 11

DIAGNOSIS, HINTS FOR GENERAL, 32

OIFFERENTIAL U37

A24

DRAINING COOLING SYSTEM A68

ENGINE BLOCK A11

FAN BELT ADJUSTMENT A1

6

9

FRONT WHEELS

&

AXLES A

2-A

4627

FITTING PISTON PINS A214

FLYWHEEL A14

FUEL A·4

GEARSHIFT U332

*GEAR SHIFT A333

GOVERNOR

Adj ustment A1519

Construction A19

Removal A19

Type A1519

LINERS, CYLINDER A111

MAGNETO RV4 U18

MAGNETO FM GENERAL, 14

MAIN BEARINGS

Crankshaft A111

MANIFOLDS A 1 24

OIL FILTER A516

OIL LINES A16

OIL PRESSURE A315

OIL PUMP A15

OIL RELIEF VALVE A15

PISTONS A2513

PISTON PINS A214

*

Refers to Tractors No. 26526 and Up

MODEL

A

TRACTOR INDEX (Cont'd)

SUBJECT SEC. PAGE PAGE PAGE PAGE PAGE

PISTON RINGS A213

POWER TAKE-oFF U40

A

2-A

PUSH ,ROD ADJUSTMENT A 2 5 21

RADIATOR A1 6 8

REAR AXLE A

2-A

38

SPARK PLUGS A

1

6

SPECIFICA TIONS A 1 2

2-A

STARTING ENGINE A

3

STARTING TRACTOR A 3

STEERING GEAR A

2-A

421 22

TEMPERATURE, OPERATING

A

4

TIMING, IGNITION A 14

TIMING, MAGNETO U18

TIMING, MAGNETO GENERAL, 14

TIMING VALVES A211 12

TRANSMISSION

Bevel Pinion U 2 35

*Beve1 Pinion A

2-A

36

Cross Shaft

U

236

*Cross Shaft ;A

2-A

37

Sp1ine Shaft U2 34

*Spline Shaft A

2-A

35

Reverse Shaft U233

*Reverse Shaft A

2-A

34

Lubrication A4

VALVES

Adjustment A 25 21

Guides

A

221

Grinding A 5 21

Seat Inserts A 2 21

Lubrication A 20

Springs A 2 21

WATER PUMP A 3

939

*Refers to Tractors No. 26526 and Up

"

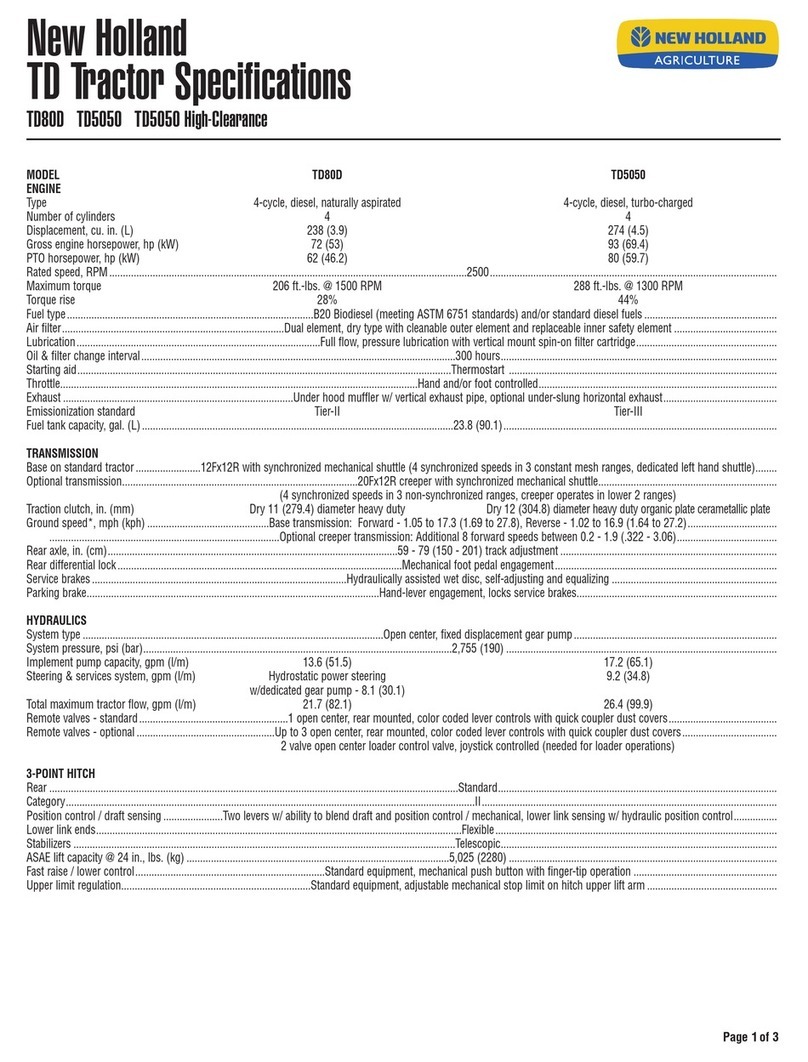

MODEL -A" SPECIFICATIONS

CRANKSHAFT

ENGINE

DATA

No. or cylinders 4

Bore 4-3/4" gasoline

S" low grade tuel

Stroke 6-1/2"

Gasol1ne motor:

Compression ratio 4.4 to 1

Compression pressure 86 Ibs.

Displacement - 460.7 cu. In.

Low Grade Fuel motor:

Compression ratio 4 to 1

~ompresslon pressure 76 Ibs.

Displacement Sll cu. In.

Firing order 1-3-4-2

R.P.M.

Low Idle 200-250

Full load 1000

High Idle 1100-1150

AIR CLEANER

Type - 011 bath

011 capac.1ty or cup - 2-1/2 pts.

Summer S.A.E. 20

Winter S.A.E-. 10

lhlst always splash rreely.

c.A.WHAFT

Drive - gear

Valve timing - marked gear

Journal dla.-2.l235"+ .OOOS"

or - .0005"

Bearings - 3 bronze bUShl~

Bearing dla.-2.128" •• OOOS

Bearing clearance .003S- to .OOSC"

End thrust - Spring controlled

CONNECTIOO ROD

Bearing - Spun type

Bearing length - 3.245" •• 001"

or - .001"

Journal length - 3.250- •• 004"

or - .001"

Bearing dla. - 2.753" + .OOOS"

or - .000S"

-Journal dla. - 2.750" .,..OOOf\"

or - .00>lS·

Dla. clearance .000" to .005"

Adjustment - Shims

COOLING SYSTDi

Capacity - 11-1/2 gallons

~ooled - Pump and Fan

Pump am ran dr1ve - two V Belts

Belt size -

Pitch length - S2"

Width - 21/32·

Depth - 7/16·

Angle - 40 degrees

Belt adjustment - eccentrl~ pump hag.

Pump bearing - Ball and Bushing

Pump lubrication ~ Grease tlttlng

Pump adjustment - Packing nut

Fan - 4 blade - 22· In dla.

Bearings - 3

Type - Bronze Back Babblt

Bearing length:

Front and Center - 3.500-

Rear - 4.747"-.001"

Journal length

Front - 3.734"

Center - 4.0132"

Rear - 4.750"

+

.004"

or - .001"

Bearing dla. - 3.003"

T

.001"

or - .001"

Journal dla. - 3.000" .,..OOOS"

Dla. Clearance .002- to .0055"

End thrust taken on rear main bearing

Smtt end clearance .006" to .008"

FUEL SYSTEM

Carburetor - Zenith C6EV

Size - 1-1/2"

Type - compound nozzle

Adjustment - Main jet out ror richer

mixture - Idle jet In tor richer

mixture.

Fuel delivery - gravity

Tank Capacity - 28 gallons

Fuel filter - strainer and sediment

bowl.

GOVERNOR

Variable Speed type

Adjustment by throttle

LIJ-4"ERS-CYLINDER

Removable type

Inside dla.

Gasoline Motor 4.750" •• 001"

or - .001"

Low Grade ruel motor 5.00" .,..001"

or - .001"

~UBRICATION - ENGINE

capacity - 14 quarts

011 used summer S.A.E. 40 \

winter S.A.E. 30 or lighter

Filter - Purolator

MAGNETO

Make - Falrbanks Morse

Model -

Fl4

Type - High Tension

Rotation - Anti Clockwise

Automatic Impulse - Yes

Lag Angle - 300

Advance 260

Lubrication - Sealed

Breaker Point Gap - .020"

Spark Plugs - 7/8-

Point Gap - .030"

MANIFOLD

Two distinct types used.

One ror gasoline motor

One for low grade fuel motor

1

OIL PtUP

Type - Gear

Drive - Gear Driven

Oiling system - Pressure

Pump location - Oil sump

Gears in pump body end, clearance

.006" to

.on"

Backlash of 011 pump gears

.001" to .004"

PISTONS - Gasoline Motor

Piston Dia.

First land 4.728" to 4.732"

Second land and third land

4.734" to 4.738·

Fourth land 4.738" to 4.742"

Skirt 4.743" to 4.744"

Piston clearance in liner

First land .017" to .023"

Second and third land

.on"

to .017"

Fourth land .007· to .013"

Skirt .005" to .008"

Ring land wIdth

FIrst land .250" ~ .001"

Second land .250" ~ .001"

Third land .250"

+

.001"

Fourth lartd .250"

+

.001"

PISTON RINGS

End Gap - .014" to.021"

RIng wIdth

All .249"

Land clearance - .001" to .002"

PISTONS - Low Grade FUel

PIston Dla.

FIrst land 4.978" to 4.982"

Second and third land

4.984" to 4.988·

Fourth land 4.988" to 4.992"

SkIrt 4.993" to 4.994"

PIston clearance in lIner

FIrst land .017" to .023·

Second land .011" to .017"

ThIrd land .011" to .017"

Fourth land .007" to .013"

Skirt .005" to .008"

RIng land width

FIrst land .188" to .189"

Second land .187" to .188"

Third land .18~ to .188"

Fourth land .250" to .251"

PISTON RHUS

End Gap - .015" to .023"

RIng wIdth

CompressIon - .187"

011 RIng - .248"

Land clearance - .001" to .002·

PISTON PIN

Clamp In pIston

BushIng In connectIng rod

Pin dla. - 1.501"

Bu

shmg

dla. 1.502·

+

.0005· -.0005·

P1n clearence In bushing .0005·to .0015"

VALVES

Exhaust dia. - 2-7/32"

Intake dia. - 2-7/32"

Stem dia. - .434"

+

.0005"

Face width - 1/8"

Seats exhaust - removable

Seat wIdth - 1/8"

Seat angle - 45

0

Guides removable

Guide insIde dIa. - .437" to .438"

Stem clearance in guIde

.0025" to .0045"

V.ALVE SPRINGS

Free 1ength 3-1/16"

Spring compressed to 2-5/16" or

closed 50 Ibs.

Spring compressed to 1-27/32" or

open 85 Ibs.

Tappet type - cylindrIcal

Tappet clearance .012" (hot motor)

Intake valve opens 5 degrees after

top center, closes 40 degrees

after lower center.

Exhaust valve opens 44 degrees

before lower center, closes

9 degrees after top center.

CHASSIS

BELT PULLEY (Before ;3erIal #26526)

Type - Clutch

BearIngs - Pinion shaft - ball

Idler Gear - Hyatt roller

Pulley shaft - Taper roller

Dla. - 13"

Face wIdth - 8-1/2"

R.P.M. - 948

Belt feet per min. 3200

BELT PULLEY (SerIal

126526

and Since)

R.P.M. - 925

Belt feet per mIn. - 3150

BRAKE

Type - ContractIng hand operated

LInIng - Woven

LInIng sIze - 3/16" x 2" x 22-3/16"

LocatIon - Left hand end

or

cross shaft

Adjustment - Nut

CLUTCH

Type - SIngle plate sprIng loaded

dry dISC

DIa. - 14"

faCIng thIckness and quantIty -

sIx 1/8· and six 5/32"

Number of pressure sprIngs - 12

Adjustment - 1/4" clearance between

release levers and throwout bearIng

DI

FJi'ERE}Il'IAL

Type - Four pInIon

BearIng - Taper roller

BearIngs and rIng gear adjustment-

threaded adjustIng rIng.

2

DIF·FERENTIAL (Cont'd)

Thrust for differential side

gears - Bronze washers

Lubricant required - 12 gallons

including transmission

Summer - S.A.E. 140

Winter - S.A.E. 90

DRAWBAR

Type - SWinging - 17-1/2"

Height above ground - 17-1/2"

FRONT AXLE

Toe-In - 1/4" to 1/2"

SpIndle bushing InsIde dla. 1.252· to

1.254"

Spindle dla. - 1,249" to 1.2485"

Wheel tread - 58"

Turning radius outSIde - 14-1/2'

FRONT WHEEI..S

BearIngs - Taper roller

Adjustment - by bol t and shims -

maintain a free rolling fit

Tire size - 7.50

x

18

AIr pressure - 26 to 28 lbs.

POWER

TAKE-OFF

TYPe - Clutch

Spllne - 1-3/8· - 6.B.

R. P .ll.- 531

Location - 3-3/4· to rIght of

center lIne of tractor

RelatIon to hItch pIn - 3" ahead

He1ght above ground - 21-3/4"

Bear1ngs - Taper roller-

adjustment sh1ms under rear cover

REAR AXLE

Type - Live

Bearings - Double roller outside end

LubrIcation - from rear axle housing

adjustment - free rolling - by shIms

Grease retainer - Cork seals

Rear WheelS - Taper hub

Tire size -"13.50

x

28

Wheel tread - 61-1/2"

TIre pressure - 12 lbs.

SPEEDS (Before serial #26526)

F1rst

Second

Th1rd

Fourth

Reverse

- 2.6 M.P.H.

- 3.5 ll.P.H.

- 4.5 ll.P.H.

- 9.5 M.P.H.

- 3

M.P.H.

SPEEDS (Ser1al #26526 and since)

First - 2.5 M.P.H.

Second - 3.75 M.P.H.

Third - 5 M.P.H.

Fourth - 9 M.P.H.

Reverse - 3 ll.P.H.

STEERING

TYPe - Cam and

1

ever

Adjustment - Column end play - Screw

Trun10n sbaft adjustment - Screw

Lubr1cant - 140 ste~ring gear lubricant

TRANSMISSION (Before serial #26526)

Clutch sbaft bear1ng - Ball

Spllne sbaft bearings - Taper roller,

nut adjustment front and rear

Cross sbaft - Taper roller

bear1ngs, adjustment - Shims

Bevel P1nion bearing - Ball

adjustment - ShimS at rear

Reverse shaft bearIng - BushIng

Lubricat10n capac1ty with

different1al - 12 gallons

TRANSMISSION (Ser1al #26526 and since)

Sp11ne shaft bear1ngs - Taper roller -

adjustment - nut on rear end of shaft

2a

S'fARrINGTHETRACTOR

Serial #26526 and After

WHENTRA~TORIS DELIVERED

CAREANDOPERATIONOF MODEL

n

A" TRA~TOR

Before starting a new tractor inspect

it thoroughly and see tmt no parts have been

removed from it, or any adjustments tampered

with since the tractor left the factory.

BEFORESTARTINGTHEENGHIE

Inspect oil level in engine oil sump.

For correct level and viscosity see heading,

nEnginenunder nLubricationn•

Inspect 011 in a1r cleaner cup. Refer

to air cleaner 1nstructions.

F111 cooling system w1th clean water.

Check all points of lubrication and

grease those equipped with gr'ease

gIID

fittings.

Fill fuel tank with gasoline and open

tu.el valves.

STARrINGTHEElmINE

Place the gear shift lever in neutral

position. If in cold weather, lock the clutch

pedal in fornard posit1on. Open throttle one-

third way. Turn ignition switch to the nONn

posl tion. Pull the choke rod forward ani crank

engine over two compress10n strokes by LIFT-

INGthe crank. Release the choke rod. Eng-

ine should now start readily when cranked.

However if the weather ls cool, more choking

may be necessary. CAUTION:Donot spin motor.

To do so may d1sengage the automatic 1mpulse

coupling and allow mo.tor to kick.

Whenthe engine is started, see that

the oil gauge is registering pressure. Do

not operate the engine unless 01l gauge reg-

isters.

NOTE: After the first few hours of

operation, tighten all nuts, boLts and cap-

screws that hold together parts having asbes-

tos lined copper gaskets between them. 'f.his

applies espec ially to cylinder head stud nuts.

Whencylinder head gasket is compress ed 1

t

causes the valve clearance to be taken up.

After the cylinder

lmd

stu:1ruts are t1ghtened,

be sure to adjust the valve clearance.

STARrINGTHETRACTOR

Before Ser1al #26526

With the engine runntng, press forward

on the clutch pedal. Allow a few seconds for

the gears to stop, then move the gear shift

lever to the des1red speed pomtlon,whlch is

as follows: to central posit1on ani roreard,

reverse; central and back, low; to extreme

right and back, second; to extreme right and

forward, third; to extreme left and back,

fourth. Release the clutch pedal slowly to

avoid a sudden jerk in starting, out; nave

throttle far enough open to avoid stallIng

the motor.

Gears shIft as follows: First; shift

lever to center and forward. Sdcond; shift

lever to center arid back. T:'lirdj shift lever

to right and forward. FrJurth; shift lever to

extreme left and back. J{eversej shift lever

to the riGht and back.

LUBRICATION

u.JGINE: :aintain 011 level in 011 sump

to the full mark on 011 gauge rod.

Use only pure mineral 011 s of th e

following S.A.E. v1scosity numbers.

Summer- No, 40 Winter - No. 30

For extremely cold tempera tures, a

mineral 011 that will flow freely at prevall-

ing temperatures should be used.

If gaso Ltne or other fuels of Similar

qualities are being used drain oil sump and

refill with fresh oil of the proper quality

and viscosity after each 60 hours opera

t

i

on,

If low grade fuel such as distillate

or tractor fuel is being used, drain ~ oil

down to the drain cock, located on side of

oil sump, after each 10 hours of operation

and refill to the full mark on gauge rod with

rr'esh oil. After each 30 hours of operation,

dra1n 011 sump completely and refill with

fresh 011.

Use only 011 of high quality of the

proper viscosity. The best assurance of se-

curing such 011 is to purchase the better

grade manufactured by a dependable oil com-

pany who has established a national reputa-

tion for quality products and whose success

depends upon maintaining such quality.

Look at the oil pressure gauge

$

re-

gular intervals to make sure 011is be~ cir-

culated by the 011 pump. The cauGe should

register approximately 15 pounds whenengine

is running at normal governed speed and is

heated to running temperature.

The governor, timing gears, clutch

pllot bearing and rocker arm assembly are

lubricated from the 011 sump supply am need

no outside attention.

FANANDWATERPUW:P- Lubricate each

10 working hours. Lubricate front bearing

through grease connection on fan pulley hub

with grease gun until grease comes out at the

rear around maft. Lubricate rear connection

on the pump body with five or six strokes of

the grease gun.

CLU'fCH: Lubricate throwout bearing

each 30 hours of operation with two or three

strokes of the grease gun. The grease fit-

1;1ng is accessible through an opening in left

3

sIde of clutch housIng. Donot over-lubr1-

cate th1s point as the excess grease

IIBY

work

on to the clutch plate and cause clutch to

slIp or becomeslugg1sh 1n actIon.

The clutch fork sha ft bear1ngs are

also

e

qu1ppedw1th grease gun fl tt 1ngs and

should receIve two or three strokes of the

grease gun da11y.

Lubr1cate clutch pedal bear1ng dally

through fitt1ng on bottom of pedal.

GEARSHIFTLEVERSHAFT: Lubr1cate

dally through fitting

(J1

top of shaft

housmg ,

TRANSMISSIONANDDIFFERENTIAL:These

two un1ts are lubrIcated from the oll supply,

carr1ed In the transmissIon case and f111ed

through the open1ngcovered by the breather

cap located on the t.ransmtasfon case cover.

Keep filled to the level of the top p1pe plug

located

(J1

the left-hand

s

tde of

t

ransmtaston

case. The capac1ty 1s approxImately 12 gal-

lons and only ol1s of the proper bodyto meet

prevailIng temperatures should ever be used.

For Summeruse S.A.E. 140

For W1nter use S.A.E. 90

'.¥henoperat1ng in extremely co1d wea-

ther, li~t motor oil should be added to the

transmission 011 supply to thin the heavy 011

and insure proper c1rculat1on

ani

lubrication.

NOTE:Keeptransm1ssion case breather

cap clean by wash1ngin gasoline and satura-

tIng with lubrIcating oil before replacing.

FRONT'NHE}';LS:Lubricate da ly with

grease gun until grease Is forced out at in-

ner end of hub.

ST~I~G SPINDLES:LubrIcate all flt-

t

tngs wIth two or three strokes of the grease

gun dally.

STBERINGBALLJOI~TS: Keeppacked In

grease.

STEERINGGEARHOUSING:Keep filled to

level of filler plug with S.A.E. #140 steer-

Ing gear lubricant.

BELTPULU.Y:Lubricate t~h fittIng

located on pulley shaft outer bearing cover,

dally,

VIi

th two or three strokes

0

f grease

gun whenusIng pulley_

FUEL

EngInes of model A tractors are buIlt

in two combInatIons of compressIons, carbu-

retors, and manIfolds. Each combInatiQn is

designed to efficIently burn a part Icular

class of fuel. For best results, the class

fuel f or whIch the engIne was des1gned must

by used.

For eng1nes equIpped to operatestrictly

on gasoline. -These engines are des

t

gnated

by the letter nGnfollowing the eng me num-

ber. Examp'le 206540. (Use gasoline havtng

octane ratIng of not less than 70).

For eng1nes equipped w1th

low

grad e

fuel attachments. These eng1nes are desIg-

nated by the letter "K" followIng the engme

number. Example20654K. (Anyfuel havIng

the follow1ng spec1f1catIpns: Grav1ty -

3B

to 44; End poInt - 5250or less; Octane ra-

tIng - 30 or more.)

E.'ng1nenumbersare located

(J1

tre left

hand SIde of engine blOCk.

Whenburning low grade fuels certaIn

precautIons are necessary to prevent exces-

sIve d11utlon of the lubrIcatIng 011.

Always select a fuel to meet the spe-

ct

rtcatt ons outlined In a prooed1ngparagI'alil.

Cover radIator to let engIne warm up thor-

oughly on gasolIne. Never turn on the low

grade fuel untll the temperature of

tre

cool-

tng

system Is near the bollIng point, and

whenoperating In cold weather, keep suffi-

cIent cover on the radiator front to mal

n-

taln thIs temperature.

Always turn off the low grade ftlel

ani

swItch to gasolIne before engIne Is stopped

so that carburetor will contain gasol tne

wtm.

engine Is agaIn started.

FUELFILTER

A fuel fllter Is located just below

the fuel tank and should

re

cleaned at regu-

lar Intervals. Removethe glass bowl and

screen, and wash out any sedIment or water

that mayhave accumulated.

AIRCLEANER

Inst.ruct.t ons as to care 0f the air

cleaner are given on the aIr cleaner body.

Follow these Instructions carefully. BeSEe

the 011 cup Is filled to th e level of the

bead stamped on the sIde of the cup. Used

crank case 011 Is satisfactory if thin and

clean. The use of heavy 011 In the cup wIll

result in a restrIction

or a

tr; to the carbu-

retor, result1ng in an over-rIch mIxture and

excessIve dilutIon

Of

the lubricatIng oil.

Inspect after each 10 hours of operation,and

If the 011 Is heavy wIth dirt, or if the cup

contains a layer of sediment, draIn and re-

fIll with fresh 011.

Inspect the hose connections on aIr

Inlet frequently and keep them tight and In

good condlt1on.

BREATHERS

The crankcase breather caps, located

ont op of the cyl1nder head covers, should

be Inspected dally. Theymust not beallowed

to becomeclogged with d.lrt as pressure wIll

be created In crankcase, causIng 011 leaks

at na.tn bear-Ings, magneto shaft and other

poInts. Washbreather caps in gasol1ne, dIp

In lubrIcatIng 011

am

replace after throwIng

off excess 011.

4

OIL FILTJ::R

To clean; after each thi rty hours of

operation turn cleaning handle to right and

baCk fro~ four to six times.

Drain base of fll ter by removing the

pipe plug each time crankcase is drained.

OIL PUMP

The oil pump requires very little at-

tention. It is of the geared type drIven by

a gear whIch meshes with the crankshaft tlm-

in~ gear. It is consIdered good practice to

clean the oil pump screen each season. ThIs

can be done by removtng the front cylinder

block InspectIon cover.

The oil pressure gauge shCllld register

between 5 and 15 pounds when engine IS run-

nIng at full governed speed and Is heated to

normal running temperature. T~e 011 pressure

Is regulated by a relief valve located In the

oil pump body. It Is made accessIble by re-

moving the front crankcase

t

nspe ction cover

and purolator.

By

r emovtng cotter key and

turning ad just tng screw to r 1

e;

h t the

0

il

pressure wIll be increased. Turn to left to

decrease. Cotter key must be replaced after

adjusting.

GOVERNOR

The governor Is of the va~iable speed

fly weight type, mounted en the magneto shaft

and Is completely sealed from dust. and dirt.

To adjust engIne governed speed, loo-

sen

t

humb screw on governor link boot clamp

located at rIght hand side of engl ne block

ahead and above magneto, and pull boot back.

Loosen rear nut, which is

a

lock nut, and

turn front nut to the r

t

grrt for increasIng

and to the left for dec reasing speed. The

.correct engt ne speed Is

1000

r.p.m. und er

normal load~

VAIN BEA.RING ADJUSTMENT

'l'he natn

bear-Ings

are of the bronzed

back type, and due to the la rge stze of the

bearings and to the

~JPe

of lubricatIon used,

they seldom need adjustment. However, shims

are provided so that adjust~ents can be made

If it becomes necessary.

Never adjust a bearIng too tight. They

must have

.003

inch clearance. The maximum

end play for crankshaft IS

1/32

inch. When

adjusting the bearings always remove tte same

number of shtms from each side. Always re-

pla.ce the bearing cap in its original posi-

tion so that crank sra rt will no t be forced

out of alignment.

CONNECTING ROD ADJUSTMENT

Shims are provided in the connecting

rod bearl ngs, for ad justment • They s hou Id

have not less than

.003

inch clearance

0

n

crankshaft. End clearance should not exceed

.010

inch.

When adjustIng rod bearings, remove

the same number of sntms from each stoe and

replace the cap on its original rod ~nd In

its orielnal pOSitIon.

When coupling up the rods be sure the

nuts are drawn tiZ;ht and are locked with the

proper sized cotter keys.

If new piston ptn bus

hf.ngs

are In-

stalled they should be reamed to a light

push fit on the pin.

CYLINDER LH1ERS, PISTONS AND RINGS

The engine has rene wable cy linder

liners which makes reboring unnecessary.

Oversize pistons and rings are not

supplied. If wear on the cylinder liners is

sufficient to require oversize pIstons and

rIngs a ne~ motor assembly, consisting of

lIners, pIstons, rinGS, etc. should be in-

stalled.

The old liners can bereadily removed

from the top of the engine block

tu

the use

of a suitable puller.

Vlhen InstallIng newliners, trey shcuJd

be forced straIght down In the bore of the

block to prevent possible damage to the rub-

ber packIng rIngs.

Always use new pack tng rings whEnin-

stall1ng lIners, as the danger of a water

leak at this potnt is too great to rUk treir

use the second time.

VALVE CLEARANCE AND VALVES

Correct clearance between the valve

stems and rOCker arms should be maintaIned

at all times.

To adjust clearance, turn engine w1th

crank

-unt

i

I valve closes am push rod Is at

its lowest posItion. Loosen valve adjusting

screw lock nut and turn scrav until there is

.012"

inch clearance between valve stems and

rocker arms with engine at normal operating

temperature. Use a thIckness

a;t1.lge

for :nalc-

ing thIs measurement. Tighten lock nut and

recheck.

Lack of compression because of leaky

valves may be caused by either Insufficient

clearance between rocker ams an: valve stems,

by the .collection of carbon at the ValWlseats

or by carbon or a

gtL.'TIl:1Y

su bstance on the

valve stems preventing the closing ~f the

valves.

If, when cranking the motor over,there

is a lack of resistance on one or more <:<)'11n-

ders at the compression stroke, the pistons

and rrngs beIng in good condition and there

is suffic rent clearance bet'seen the roe leer

arms and valve stems, it indicates that the

valves need regrinding.

5

Because of the har1ened steel exhaust

valve seat Inserts In the exhaust valve posI-

tions, It Is recommendedthat the valves be

refaced on a nnchlne IIBdefor th 1s purpose

and the seats be reground wIth a hIgh speed

valve seat grInder

As a final operat ton, the valves and

seats maybe pol1shed by Iappfng theminwlth

a s:Jall amount of valve gr-tndtng compozid,In

thIs mannera perfect seat can be obt arned

which VillI gIve manyhours

0

f satisfactory

servIce.

:::ARBJRETOR ADJUSTI.:il~TS

The carburetor has two adjustment ~

dle valves for correcting changes in fuels ami

atmospheric condItions. These adjustments are

knownas the nIdl1ng Adjustment Needle" and

the "L a.inAdjustment Needle".

The idlIng adjustment needle, located

to the rear on outside of carburetor upper

body, controls the flow.af air for the idl1ng

mixture. Turning in this needle shuts off the

flO¥lof air and makesa richer fuel mixture.

Turntng out makesa leaner mixture. A good

place to start for adjustment

w

one and one-

half turns open. Donot expect a newmotor,

that is too "stiff" to rock freely ancomprea-

Sion, to idle smoothly.

To get the proper idl1ng speed, set

the stop screw on the throttle valve arm of

carburetor. Turn stop screw to right to in-

crease idle speed, to left to decrease idle

speed.

The main jet adjusting needle, located

on side toward engine block on the rear of

carburetor upper body, is for admitting more

fuel to the engine than is supplied by the

min jet, which maybenecessary due to the

variation of fuels andatmospheric comttaons,

Turning out admits more fuel andmakes a rich

mixture. DOnot force the needle downen its

seat as this w111cause damageto these parts.

JlAGNETO

The contact points must be kept clean

and properly spaced. If they are pyra.mided

or pitted, they should be madesmoothwith a

tongsten file or a stone, andadjusted to al-

Iowa gap of

.012"

to

.015"

when open on RV4

ma.~etos, and

.020

on FMmagnetos.

The spark plug points should lBvea

IJlP

of

.030

to

.035

Inch.

The magneto Is manufactured

tu'

a reU-

able co:n~ny and is serviced through tts many

authorized service statIons.

RAiJIATOR AND COOLING SYSTI::M

Only rain or soft water should beused

in the radiator if ava11able. Hard or alka-

line water will froma scale whIchwIll Impair

radiatIon if allowed to build up in the cool-

ing system. Tne use of washing soda

will

help

to loosen thIs scale; and where~'onlyhard or

alkal1ne water 15 available tie washing

SCXh

should be used at regurar intervals and be-

fore the accumulation of scale beconesmavf

enoughto scale off and stq>up tie radiator

passagea,

In cold 'weatheranantI-freeze solu-

tion can be used in the radiator.

1)0

not run engtne wlthout water or

somecooling solution in radiator.

Never pour cold water in a hot motor

whenthe water is low.

To drain coolIng system removepipe

plug from bottom of radIator on right hand

side.

CUJTCH

The clutch Is of the spr

t

ng loaded

sIngle plate dry dtsc type. The release

engagement;Is by movement,of the clutch sntr-

ter a nd the throwout bear-Ing contacting the

3 release levers.

Each release lever has an adjustIng

screw whIch Is for the p.lI1)OOeof regulating

the level' contact

wIth

the throwout bearing.

As the clutch racrngs wear, the release le-

vers movenearer to the throwout bearingam

the only clutch adjustment necessary Is to

prOVideclearance at thIs poInt.

To adjust: Turn adjustIng screws to

allow a clearance of 1/4" between the ends

of each of the three release levers andthe

throwout bearIng.

FAN BELTS

To adjust fan belts, loosen

tlE

four

capscrews holdIng the air cleaner bracket to

the front of the motor, andby using a smll

bar turn pumphouslni clock-wIse unt11 the

fan belts have

1-1/2

slack lII1d-waybetween

the pulleys. TIJhten the capscrews evenly

to prevent leakaee.

Donot tighten fan belts moreor of-

tener than necessary to prevent slippage.

FRONT WHEEL BEARING AUJUSTMalT

The front wheels are mounted<ntaper

roller bearings. At frequent intervals re-

movethe we1ght from the wheels am examIne

for stde PlaY. If si de play exrata it will

be necessary to adjust bearIngs.

To adjust beartngs , relnorethe hub

cali

and tap bolt and spIndle washer. Between

spindle washer and endof spIndle is a series

Of sntma, Removeenough sh1ms to take up

play but not enough to bind bear mga, Tap

bolt must be tightened securely to prevent

its backing out.

The insIde of the wheel hub is pro-

vIded with a felt washer 10protect

tm

bEar'-

tngs from dirt and to retaIn the grease In

the hub. ThIs washer should be replaced each

season when\vorkingunder average <Xnllti<l18.

6

BELTPULLEY

The belt pulley assemble is attached

to the right hand side

0

f the transmission

case. A 13 inch pulley is provided running

948 H.P.M. at normal engine speed ontractors

prior to 26526 and 925 H.P.M. on tra ctors

sinoe 26526. The motor should always be run

at normal speed where constant power~need-

ed and heavy belt load is encountered.

To figure the speed of dri v'en units

and determine the size

ot

the necessary pul-

ley, multiply the diameter of the driving or

engine pulley by its revolutions per minute,

and devide

tu

the H.P.M.of the driven unit.

Example: 13 inch diameter x

948

=

12324

+

1000 H.P.M. of the drtven

unt

=

12.3.

In this case use a 12-1/2 inch pulley as it

is the nearest regular size

Wecannot over-emplasize the impor-

tance of having the proper s

i

z e pulley on

the driven unit. Muchpower is lost and an

unnecessary load put on the motor unless the

proper pulleys are used. Thepliley ~shed

with the tractor is the correct size.

GENERAL

All tractors are thorwghly tested

before leaving the factory. Neverthele s s

they require some attention on the part of

the owners. The amountof attention required

is negligible but IMPORTANT.

In the foregoing instructions an ef-

fort has been madeto cover the points nec-

essary to help you in the care andoperation

of your tractor in an understandable manner.

7

RADIATOR

(Group

280101)

TheradIator IS of the tubular type If grease or 011has entered the coca-

and consists of six major parts: the top Ing system In any way, It wlll collect par-

tank (45), bottom tank (49), aide frames(47 tlcles trom the water, such as dIrt, rust,

and 48), core, (52), and shroud (53). etc •• and adhere to the sides

ot

the radiator

tubes and cool1ng jacket or the cyll nder

blOCk. As this coatIng Is a poor conductor

ot

heat, the heat generated 1nthe motorwill

not be readily absorbedbythe cool1ng solu-

tion, ne1ther wll1 It be dissipated fromthe

cool1ng solution to the air currents passing

through the radiator core or around the mo-

tor. In event

ot

this difficulty somesol-

vent should be used that w111 dlss 01ve or

loosen tars coating and then flush the cool-

Ing system thoroughly. There are several

solvents on the market that are very good

tor

this purpose and they should be used as the

manutacturer recommend.

By

removingcapscrews that hoId the

tanks, side frames, and core together, the

radiator can be dIsassembled for the repair

or any IndivIdual part. Alwaysuse newgas-

kets 1fbenreassembl1ng.

Apipe plug to drain toocool1ng sys-

tem Is located on the bottom right handside

ot

the radiator.

If dirt, weedseed, l1nt, or other

foreign particles collect around the radia-

tor tubes, between the cool1ng

r.ma,

It will

restrict the amountof air passing through

the core and cause the motor to overheat.

This can be dlslod,ged by the use

ot

a steam

jet, water pressure, or compressedan-, Some-

tImes It Is necessary to loosen the accumu-

lation with a small wire before It can be

rorced out. Be very careful that the tubes

are not damagedby the wire.

ll.;... . _

' he radiator hose should be kept In

good condition. Manytimes the Inside of the

hose will disintegrate

srn

obstruct the flow

ot

the cool1ng solution while the outatde Is

undamaged.

(Reter to Radiator and Cool1ng sys-

tem under Care and Operation.)

8

GROUP 280053 - WATER PIlMP AN ) ,AN

WATER PUMP AND FAN

(Group

The water pump assembly is cl&~ped to

front of engine block by the air cleaner brace

and four capscrews. Water pump gasket (1) is

placed between water pump body(2) and block.

The pump body (2) is eccentric. To tighten

fan belts loosen caps crews and by means of a

small bar turn pump body clockwise. Tighten

caps crews evenly so even pressure will be ex-

erted on gasket (1) to prevent water le~.

To remove and disassemble pump, remove

radiator and pump assembly from engine. Re-

move capscrews (28), fan blade assembly (31),

nut(ll) and pull ,fan pulley (25) from shaft.

Remove key (27) and pUSh pump shaft(lO) back

far enough to remove snap ring (18) • Loo s en

stuffing box nut (17) and pull shaft(lO) with

rotor (7) from housing.

Rotor (7) is attached to shaft wi th

pointed set screw (8).

By removing stuff Ing nu t (17), gland

(16), and headless set screw(3) stuffing box

(14) may be pressed or driven out of body.

280053) .

Shaft (10) must have a free rolling fit in

stuffing box. The normal inside diameter of

stuffing box is .789" and diameter of shaft

is .787

11•

When installing new box be sure

011

hole registers with passage in pump body.

Water pump packing (15) is located in

stuffing box (14) and is held in position by

stuffing gland (16). Stuffing box nut (i7)

should never be tightened more than is neces-

sary to prevent leakage. To replace packing

(15) it is necessary to pull shaft (10) back

until front end is about flush with front em

of stuffing box.

The rear of collar (19) is counter

bored to fit over snap ring (18). Cork seal

(22) is inserted from the front, into a re-

cess in the pump body and over collar (19).

A dished retainer (21) is placed on each side

of bearing (20) with dished sides towards

bearing. Cork seal (23) is placed in the

dished side of a third retainer(21) with the

retainer to the front. This seal fits over

hub of fan pulley (25) and the entire bearing

and seal assembly is held in pl ace by snap

ring (24).

9

".,;

o

0

...J

m

Cl:

w

Cl

Z

...J

>-

()

~

0

0

m

N

CII

a.

=>

0

Cl:

( )

10

•

CYLINDERBLOCK

(Group 280041)

The cylinder liners (2) are sealed at sheLLs to obtain the correct end play of

the bottom against water leakage by tworubber crankshaft. Onnew bearings the minimumend

packing rings (3), while the head gasket forms play should be .003" and the maximum.OOS".

the seal at the top. Because of the removable The condition of the bearings ~an be

liner constructions, oversize pistons andrings inspected by removing the inspection covers

are not furnished. Whenappreciable wear oc- from left hand' side of engine block.

curs, new parts of standard size should be

installed, as are supplied in the regular mo- Oil seals are installed around the

tor kits. crankshaft at each endto prevent the leakage

of oil. Each seal is made up of two halves.

The upper half of front seal is in the timing

gear cover and the lower half in crankcase

bottom. The upper half of rear seal

.::'0

in

the motor block with lower half

in

crankcase

bottom. To install new seals the crankshaft

must be removed. Removeold seals and clean

the grooves, shellac the newseals in place,

let them dry a short time, grease the face

of the cork before installing the crankshaft.

The ends of the new seals will be sli ghtly

longer than the grooves, but donot cm; them

off as they will compressinto position mak-

ing a tight seal. In event of an oil leak

around the crank shaft, the crankcasebreathers

on top of cylinder head covers should be ex-

amined. If they are clogged, oil will be

forced out even if seals are in goodcondition.

The camshaft (27) is carried in the

motor block on three bushings (30). It can

be removed by removing rocker armassemblies,

push rods (40), valve case covers from right

hand side of engine block, tappets(39), ra-

diator, front wheels and axle, and timing

case cover.

To remove liners, removecylinder heads,

crankcase bottom, and connecting rod and pis-

ton assemblies. Wrap clean rags around main

bearings and connecting rod throws to prevent

sediment from entering the bearings or

0

il

passages. Usea cylinder liner puller to pull

the liners. After the liners are out, clean

the inside of the block thoroughly.

Wheninstalling, clean liners andplace

packing rings (3) in grooves. A small amount

of white lead on the pac king rings will aid

when installing the liners. Be sure the liner

is entered straight in the bore of the blo ck

to prevent possible damage to the pa cking

rings. They can be easily driven to place by

using a clean block of woodand hammer.

Newpacking rings should always be used

when liners are removed and replaced for any

reason. The danger of a water leak into the

crankcase is too great to risk the use of pack-

ing rings the second time.

RemovableShell type

nain

bearings are

used. The front and center bearings(22) are

alike. The rear bearing (23) is flanged and

controls the end play of the crankshaft. All

shells are held in bearing caps and block by

dowel pins (24).

Laminated shims (25 and 26), built up

of sheets.003" thick are placed between the

bearing caps and block to provide for correct

bearing adjustment. Whenadjusting bearings,

do not adjust too tight. The minimumdiame-

trical clearance should be .003" to allow for

a film of lubrication between the bearing and

journal. Whenthis clearance exceeds .010"

the bearings should be readjusted. Remove

tte

same amount of shim stock fro meach side of

bearing when adjusting. It is very important

that bearing caps be replaced in their origi-

nal position to prevent forcing the crankshaft

out of alignment. After the bearing nuts are

tightened, lock them securelyw prevent them

loosening up.

It is necessary to seperate the motoF

from the transmission and remove the crank-

shaft to install new main bearings. ~~en the

new shells are put in place, see that they fit

over the dowels and in the block and capsfirm-

ly, then if the ends extend beyond the edge

of block or caps, file them off flush. It is

usually necessary to scrape newbearingsslight-

ly to obtain the proper fi t on crankshaft.

The amount of scraping necessary can be deter-

mined by the use of bearing blue.

In some instances it is necessary to

file the

r

Ianged ends of the rear bear ing

Camshaft timing gear(33) is attached

to camshaft by three capscrews(28) that are

laced together by wire (29). The holes in

the gear and camshaft are drilled off center

so the gear can be installed in only oneposi-

tion. Whenreinstalling be sure the timing

marks on the gear registers with the proper

mark on the intermediate timing gear so the

camshaft will be in correct time with cranx-

shaft. The end play of camshaft is controlled

by the spring loaded thrust screwassembly(34~

For correct adjustment loos~n jam nut (35),

turn screw(34) in tight and

back

off one turn

and tighten jam nut.

The timing gears are lubricated byoil,

from

011

pump, forced through oil tube (41)

into timing gear compartment.

The camshaft bushings are held in posi-

tion by setscrews (31), throughthe right hand

side of block that mesh with 5/16" holes in

the bushings. To install new bushings, in

addition to removing the camshaft it

:is

necessary

to seperate engine fromtransmission, andre-

movethe flywheel. Removeset screws (31) and,

with a bushing driver, drive oldbushings out

from the front. Whenthe rear bushing is

driven out, expansion plug (8) will also be

removed.

Wheninstalling the neNbushings be sure

the 1/2"

011

hole is turned towards the front

and the 5/16" hole registers with the setscrew

hole in the side of the

oIock,

After the rear

bushing is in place, reinstall expans

tcn

plug

(8).

Be sure it

is

seated firmly to prevent oil

leaking by into the clutch housing.

11

INTERMEDlATETIMINGGEAR

(Group 280095)

The intermediate gears ( 2 and 12 )

equipped with bronze bushings(3) are carried

on studs (4 and 5). The studs are installed

through front of engine block andheld in place

by nuts (6). It is important that these nuts

be kept tight. Dowelpins (7) are driven in

studs and fi t into recesses in bIock to pre-

vent studs from turning. The studs are also

grooved on top so oil mayreach the bushings.

Oil to lubricate the timing gears is

forced, by the oil pump, through a tube into

the gear compartment and is d

i

s

t

r Ibuted to

all the gears by the large gear (12).

To time the camshaft to the crank-

shaft in event the gears have been removed,

proceed as follows: Turn crankshaft until

the mark on crankshaft gear is up; place

large idler gear (12) on stud so one mark

on gear will be in line with mark on crank-

shaft gear and the other markwill be towards

the cam shaft; rotate the camshaft un t il

mark on cam shaft gear is in li ne with the

mark on idler gear and meshthe gears in this

posit1on.

260072

12

The connectlng rod

t

I ) has a spunbear-

Ing. The crankshaft Is drilled from the

nearest maln bearlng to each

of

the crankshaft

throws for

Lubr

i

catn on of the connecting

rod

bearlngs. The piston pin bearing is lubrl-

cated by oil forced from crankshaft bearlng

through oil tube (2} to the

uppe

r end of rod.

The crankshaft bearlng has an

I/o"

lamlna ted shlm on each side to allow for cor-

rect adjustment. Each layer of the laminated

shlms Is 0.003" thlck. By peeling off the

requlred number of snrms, the correct bearing

can be obtained. Whenadjustlng bearings,

remove the same number of shims from each

slde. Always replace the bearing cap on the

rod from whlch it was removed, and In its

origlnal posl tlon; this is important. Never

adjust bearlngs too tlght. They should have

0.003" clearance on the crankshaft to allow

for lubricatlon. The bearings should never

be allowed to have more than 0.010" clearance

before they are adjusted.

A good method to use when adj usting

bearlngs to provide for correct clearance,

is to place a plece of 0.002" shim stock 3/4"

long and 1/2" wlde In the bearing cap; then

remove enough bearlng shims so that a slight

drag can be felt when turning the crankshaft

wlth the nuts dra¥m down tlght. Then remove

the piece of shlm stock from the bearlng cap,

and the correct clearance for lubrication

wl11 be retalned.

Always draw the connecting rod nuts

tight. Never loosen nuts to obtain the neces-

sary clearance on the journals. If the bear-

Ing is too tight, add the necessary numberof

shlms for correct adjustment.

Lock

the nuts

with the proper size cotter

keys ,

If keys

are too small, they will work loo s e In the

holes and maybreak off, allowing the nuts

to work loose and cause a great amoun t

0

f

damage.The maximumallowable end thrust for

the connecting rod bearing Is 0.010". An ex-

cessive amount of clearance at thls point may

cause amotor to use an unreasonable amount of

oil, as too much

011

will be thrown from the

En:ls

of the bearing into the cylinder.

In replacing a connecting rod bearing,

especlally

if

It was burnt out, be sure the

oil passages in the crankshaft are

open;

other-

wlse the bearing will not receive lubrication.

It Is also very important that tre connecting

rod be In correct alignment. In other words,

when installed" the plston pin must be para-

llel with the throw of the crankshaft. If

they are not parallel, the piston will not

be held straight In the cylinder and exces-

sive wear on both cylinder wall and pis ton

will result. Very,often a condition of this

klnd produces a decided knock in the motor.

To properly align rods, It is necessary

to have a connecting rod aligning fixture,

and use it according to the manufacturer's

recommendations.

PISTONANDRINGSANDCONNECTINGRODS

(Group 280072 and 280045)

Each plston has four rings; the three

..:.;;er rings (2) are compression rings and the

~ ~~~ ring (3) is a ventilated 011 rlng.

Wheninstalling new rings on old pis-

tcns ,

clean all carbon from the rings grooves.

A

good tool to use for this is a piece of an

:i

ring filed squarely on one end. Always

fit

the rings in the cylinder liner. The end

gap

should be 0.015

11•

Do not guess; measure

wlth a thickness gauge. Also, try the rlngs

~'1

the piston grooves to see that there are no

burrs on the rings or the grooves. If rings

are too tight in the ring grooves they can not

conform to the shape of the cylinder walls and

will result in stuck rings. Therefore the

rings must have 0.0015" side clearance in the

grooves.Oversize pistons, rings and pins are

not furnished nor do we recommendtheir use.

Whenenough wear has taken place, it Is much

better to install a new motor kit consisting

of pistons, rlngs, liners, etc. You are then

assured of having parts that are properly fit-

ted and can expect the same performan ce as

received from a new motor in as far as these

parts are concerned.

Care must be exercised in the handling

of pistons and rods to prevent distortion. If

a piston is dropped a very snort distance, or

if a piston pln is carelessly started and then

driven in roughly, the skirt of thepiston will

invariably become distorted. The amount of

out-of-roundness maybe detected by the use

0

f

a micrometer.

In placing rings on the piston, a ring

tool should be used t9 avoid ruining a good

ring by distorting it out of

shape

beyond the

elastic limi t of the metal.

Lubricate pistons, rings, and pins be-

fore installing them. To install rings and

pistons in the motor block, a ring compressor

should be used to hold the rings in pas

i

t ion

while installing.

The piston pin (5) is held in the piston

boss bya

pt

ston pin setscrew (4) and a setscrew

lock

(6).

To remove a connecting rod and piston,

remove the oil sump, turn the eng i ne over

until the crank throw of the connecting rod

and piston to be removed is at the bottom of

the crankcase. Then remove the cotter keys

(8)

and nuts

(9)

from the connecting rod bolts

(7). Removethe rod cap and shlms

(6).

Then

lift the connecting rod off the crankshaft.

Next revolve the crankshaft to side position;

this will give the piston sufficient room to

be removed from the bottom of the engine crank-

case. The plston and rod can also be taken

out at the top if the cylinder head Is removed.

Pistons canbe put in the block at the top

or at the bottom. The liners have a small

taper at the bottom to

ard

in installing pistons

from the bottom. To install pistons from the

top a ring compressor of somekind must be used

until rings have passed the offset in the top

part of the liner. 13

PISTONANDRINGSAi\JDCONNECTINGRODS

(Continued)

Bronze bushing (5) is installed in

upper end of connecting rod for the pi ston

pin bearing. To replace this bushing, drive

out old bushing and press newbushing in rod

if a press is available. If not, drive the

bushing in, but care must be exercised not

to burr the bushing when instaliing th is

way. Be sure oil hole in bushing (5) regis-

ters with oil hole in the connecting rod.

After the bushing is in place, it must

be-

reamed to insure the correct fit of the pis-

ton pin. The size of piston pin is 1.501"

+0000"

11

and the bush~ng mus t be reamed to

-.00025 1.502

~:gggg".

With these clear-

ances the pin, when oiled and the same tem-

perature as the bushing, will just float

through the bushing when the rod is he 1 d

horizontal.

CRANKSHAFT

A1\JD

FLYWHEEL

(Group 280043)

The main bearings are lubricated by

oil forced from the oil pumpthrough passages

in the cylinder bLock, The crankshaft (2)

is drilled from each main bearing to the

nearest connecting rod throw for connecting

rod lubrication. There is also a hole drilled

through the rear end of the crankshaft para-

llel to the rear main bearing in which wick

(5) is inserted to lubricate the clutch pi-

lot bearing. This wick Should extend slightly

beyond the shaft at either end, and it can

be inserted by the use of a small wire.

Timing gear (3), installed on crank-

shaft ahead of front main bearing is a press

fit and is driven by Key (4). The fan pulley

(6) is driven by woodruff (9) and held to

the shaft by set screw (7).

The flywheel (10) is attached to flange

of crankshaf t

wi

th seven b

0

1ts (11) • The

rim is stamped, "CENTER",indicating top cen-

ter for Nos. 1 and 4 pistons, and "SPARK"

indicating position for magneto con t ac t

points to begin to open for No. 1 cylinder.

These marks may be seen through opening in

the housing adapter on rear, right hand side

of motor.

If the flywheel is removed for any

reason, be sure to reinstall it in its origi-

nal position on crankshar

t,

whi eh is shown

by a cross stamped both on flywheel and

crankshaft flange. If it is

i

n s

t

alled in

any other position the timing marks will be

of no assistance when r'e

t

tmtng the igni tion.

14

8

OIL PUMP

(Group 280046)

The 011 pump is a gear pumpand is gear

driven. The pumpis attached to the lower part

of the front main bearing with two capscrews.

Drive gear (8) is attached to shaft (11) by

key (12) and pin (10), and is dri ven by the

crankshaft timing gear. These gears should

have a clearance from .004"· to .0010" and the

adjustment is made by the addi tion or removal

of shims (23). Gear (7) is attached to rear of

shaft(ll) by key(12). Shaft (13) is pressed

into pump body and carries idler gear (9).

011 pump cover (5) with gasket (22) is

attached to the 011 pump body (1) by two 5/16"

X

2-'1/2" capscrews and two 5/16" x 3/4" Cap-

screws. It is very important to note that

there are no leaks between the pwnp body and

the cover.

A

hole is tapped into rear of co-

ver (5) for suction pipe (17). Screen (18)

is attachedtopipe(17) by clamp (19). Screen

(18) removes heavier foreign particles from

the

011 that would clog the 011 passages, there-

fore, it must be kept in good condition at all

times. The 011 pan Should be removed at least

once a year, to clean the 011 pan and the screen.

If the screen is damaged in any way, replace

it at once. The oil relief consisting of a

9/16" hardened steel ball (16) , a spring (14),

and an adjusting

screw

(15) which is locked by

a cotter key (6), is installed in the 011 pump

cover by the side of suction pipe (17).

If the oil pressure in this motor should

drop at any time, it generally indicated loose

bearings, loo se or broken oil lines, broken

011 gauge, plugged pumpscreen, or diluted oil.

However if this is not the case and the pwnp

is not supplying sufficient oil, then the 011

pressure may be increased by removing cotter

key (6) and turning in on the adjusting screw

(15). If this fails to increase the oil pres-

sure, then remove the pump and check pump for

excessive wear.

15

Tolerances on 011 pumpparts: The shaft

(11) must have a free rolling fit in the pump

body

(1).

Gears (7) and (9) in the pump body

(1) should have from 0.006" to

o.on"

end

clearance and a backlash of 0.001" to 0.004".

OIL LINESANDFILTER

(Group 280055)

The method of lubricating the various

parts of the motor has been explained under

their respective groups. By studying the dia-

gram of the lubrication system, the f low of

011,

from the

011

pan to various parts, and

back to the oil pan, can easlly be traced.

Instructions for the care of oil fllter

is on oil filter. It reads as follows: "To

clean: first, stop engine or machine. Second,

turn cLeantng handle in clo ckwise direction

untll it stops then turn handle back to start-

ing position. Third, repeat this

0

peration

four times. Fourth, drain purolator by remov-

ing drain plug. Fifth, replace plug, add extra

quart of

011

to engine before starting.

11

The

011

pressure of this motor should

be from five to fifteen pounds; if the pressure

should drop below five pounds, stop the motor

at once and make a complete checkup onall

011

lines and bearings to which

011

is forced. For

more information see Oil

Pump

Group (280046).

IX

W

t-

...J

L;:

o

z

<

w

Z

16

-

...J

...J

o

This manual suits for next models

2

Table of contents

Other Allis-Chalmers Tractor manuals

Allis-Chalmers

Allis-Chalmers HD-14 User manual

Allis-Chalmers

Allis-Chalmers regent hydro 14 User manual

Allis-Chalmers

Allis-Chalmers HD 6B User manual

Allis-Chalmers

Allis-Chalmers Simplicity 9523 Instruction Manual

Allis-Chalmers

Allis-Chalmers B Install guide

Allis-Chalmers

Allis-Chalmers HD-5 User manual

Allis-Chalmers

Allis-Chalmers G User manual

Allis-Chalmers

Allis-Chalmers 10 hp User manual

Allis-Chalmers

Allis-Chalmers ac130 series User manual

Allis-Chalmers

Allis-Chalmers WD Use and care manual