Allis-Chalmers HD-14 User manual

INSTRUCTION BOOK

FOR ·

MODiEL

HD 14 TRACTOR

ALLIS-CMALMERS MFG. CO.

i1'RACTOR DIVISION

LITHO. IN U. S. A.

FORM T-200 B

MILWAUKEE, WISCONSIN, U.S.A.

•

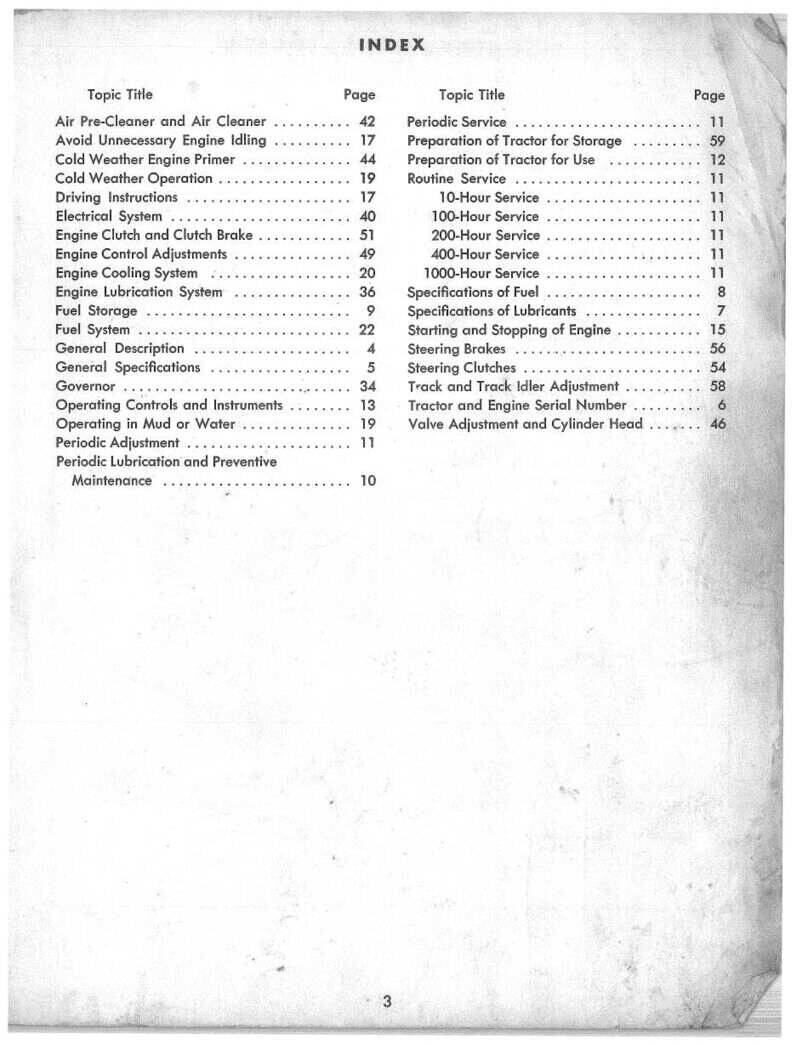

I N D E X

Air Cleaners . . . . . . . .

Battery

&

Generator, Care of

Bearing Adjustment, Sprocket Shaft

Brake Adjustment • . .

Brakes, Use of •......

Capacities •••......

Controls

&

Instruments, Use of

Cooling System . . .

Fan Belt ••.•.......

Filters, Lubricating Oil and Oil Cooler

F'IIters, Primary Oil - Hemoval

&

Cleaning

Filters, Primary Oil - Clean with Solvents

Filters, Secondary Oil ....

Filters, Secondary Oil - Removal and install new one

Filters, Fuel .•.•.

Final Drive Uil Seals

Front Idler, Lubricatlon

Front Idler, Adjustment .

Fuel Shut-off and Air Valve Control.

Fuel System

&

Filters

Fuel, Storage of .•••.

Gear Shift Levers, use of

Generator Belt Adjustment.

Governor . . • • . .

Hour Meter . . . . .

Injector Equalizing.

Injector Timing ...

Lubrication and Service Chart

Lubrication, Specifications of

Lu~rication of -

Truck Wheels

Front Idlers

Support Rollers

Master Clutch Adjustment

Master Clutch Lever, use of

Oil Cooler, Cleaning of

Oil Filter and Oil Cooler, Lubricating

Oil Seal, Final Drive .....

Operating in Mud and Water . . .

Operating Instructions, General

Pre-Cleaners . • • • • . .

Preparing Tractor for Use

Putting Tractor to work. .

Roller, Support Lubrication

Service, Routine .

Speeds of ·Tractor .

Specifications of Lubricant

&

Fuel Oil

Specifications of Tractor .•.

Steering Clutch Adjustment . .

Steering Clutch Levers, use of

Stopping Engine

Stopping Tractor . . . . . . .

Storage of Tractor . . . . . .

Storage of Fuel Oil .. " .

Sprocket Shaft Bearing Adjustment.

Track Adjustment "

Valve Lash •.........•.

.'

PAGE

14

20

28

27

19

2

15

20

28

10

10

11

11

12

12

29

10

30

25

12

21

18

28

25

22

23

23

5

3

TOPIC

9

10

10

26

19

12

10

29

20

15

14

15

17

10

8

2

3

2

26

19

20

19

22

21

28

30

24

FOREWORD

~ II

The instructions given in this book cover the operation of the Allis-Chalmers

"HD-14" tractor. A close adherence to these instructions will result in man y hours of

trouble-free operation and a longer operating life for the unit.

This book is written for the purpose of giving

t

he

operator essentialinformation

regarding the day-to-day care, lubrication, ana adjustment of the tractor. Economical op-

eration will be insured if these instructions are followed.

Many"Allis-Chalmers"owners employ the dealer's Service Department for any work

other than routine care and adjustments. This practice is encouraged as our dealers are

kept well informed by the factory regarding advanced methods of servicinc"Allis-Chalmers"

products and are equipped to render satisfactory service.

SPECIFICATIONS

Engine: Make •

Type •

Number of Cylinders

Bore •

st.rojce

R.P.M.

FuaL • ...

.

.

...

(Governed at Full Load)

General Motors Diesel

Two Cycle

·6

4-1/4"

5"

1500

Commercial D1esel Fuel Oil

TRACTOR SPEEDS MILF:SPER HOUR

First

Second

'l'hird

Fourth

Fifth

Sixth

Low Reverse

High Reverse

MAXIMUM

DRAWBAR HORSEP07JER

Belt Horsepower

Ground Clearance

Drawbar He

Ight

Shipping VJeight

(Wood blocking and tools not included).

1.72

2.18

2.76

3.50

4.06

7.00

2.00

3.20

132.19

150.48

13-1/2"

15-1/2"

• 28,800 Ibs. approximately

CAPACITIES

Crankcase for Refill (Filters Empty, Quarts).

(Filters Bull, Quarts)

Cooling System. .(U.S. Std. Gal.) .

Final Drive Case

.(U.S.

Std. Qal.) •

Fuel Tank • . .(U.S. Std. Gal.) •

Transmission Case.(U.S. Std. Gal.). •

Track

lee

Lease Sprint::

Hous

inc (,~uartsEach)

16

14

12

2 each

68

10

13

2

SPECIFICATIONS OF LUBRICANTS AND FUEL OIL

ENGINE CRANKCASE LUBRICANT:

USE NON-CORROSIVE DIESEL ENGINE LUBRICATING OIL CONTAINING ADDITIVES

PREVENTING SLUDGE OR GUM DEPOSITS.

ATMOSPHERIC TEMP. VISCOSITY

Abgve 900 Fo Use SAE. 30

32oF. to 900F. Use SAE. 30

10 F. to 32 F. Use SAE. 20

Below 100F. Use SAE. 10

WARNING: The main, connecting rod and idler gear bearings of this

engine are lead bronzed lined. UNDER NO CIRCUMSTANCES

SHOULD A CORROSIVE DIESEL ENGINE LUBRICATING OIL EVER

BE USED.

All manufacturers of lubricants have recognized the importance of the quaIl ties

required for use in our equipment and they are now co-operating fully to insure the use of

~nly those oils which fulfill these requlrements. The 011 distributor

and

011 manufacturer

are to be held responsible for the results obtained from their products.

TRANSMISSION. FINAL DRIVE. TRUCK WHEEL. FRONT IDLER AND TRACK SUPPORT ROUER

LUBRICANT.

Use a motor oil recommended by Allls-Chalmers Mfg. Company. See nearest Allis-

Chalmers factory branch or authorlzed"Allis-Chalmers"dealer for approved list. Copy of

approved l1st is shipped with each tractor.

ATMOSPHERIC TEMP·

ABove 320F

O

o

F.

to 32

F.

Below OOF.

VISCOSITY

Use SAE. 40 or 50

Use SAE. 20 or 30

Use SAE. 10

PRESSURE GUN FITTINGS

Use a pressure gun lubricant with a minimum melt1ng po1nt

of

3000F. This lubri-

cant should be in a viscosity range so as to insure easy handling in the pressure gun at

prevailing air temperatures.

~ In selecting the pressure gun lubricant make certain that it will not

wash away in presence of water.

FUEL OIL

1. Purchase from a reputable oil company a fuel within the 11m1ts

of No.1 or No.2 Diesel Fuel Oil according to the American

Society of Testing Materials. Some No. 3 fuel ol1s can be used.

2. The cetane number should be at least 40, since this quality 1s

a measure of smoothness of combustion and ease of starting.

3. The fuel oil should be free enough from high boiling fractions

to give clean combustion.

4. The pour point should be low enough to permit it to flow freely

under the required operating conditions.

5. The fuel oil must be free from alkali, mineral aCid,

gum,

free

sulphur, sediment and fibrous or other foreign matter.

3

I

o

I

A

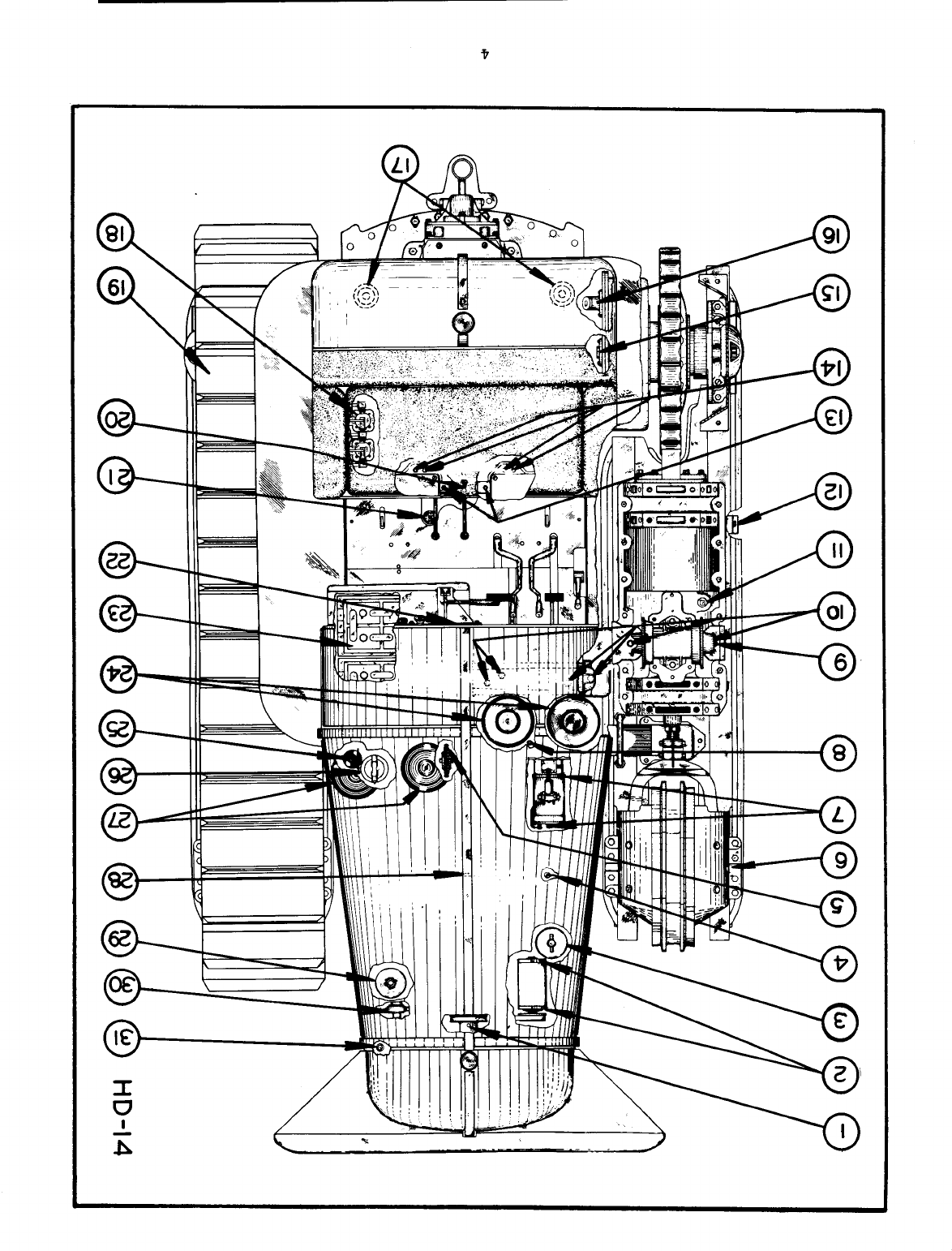

"HD 14" LUBRICATION AND SERVICE CHART

1.

FAN - One lubrication point. Lubricate 17.

every 200 hours of operation with pres-

sure gun lubricant.

GENERATOR - Two lubrication pOints. Lu-

bricate every 200 hours of operation

with light motor oil. 18.

2.

3.

SECONDARY OIL FILTER - Install

element in the secondary filter

240 hours of operation or every

oil change. Refer to Topic 10.

a new

every

fourth 19.

20.

4.

CRANKCASE 13AYONNET GAUGE - Inspect oil

level every 10 hours of operation.

THROTTLE LEVER DISC - Lubricate when

necessary for easy operation with pres-

sure gun lubricant; do not over-lubricate.

FRONT IDLER - Two lubrication pOints.

Lubricate every 200 hours of operation

with

18

strokes of the gun. Use approved

motor oil. Refer to Topic 7.

STARTER - Two lubrication points. Lu-

brica te every 200 hours of opera tion

with light motor oil.

CLUTCH SHIFTI<.:RBEAlUNG -Lubricate every

10 hours of operation with pressure

gun

lubricant of high heat resistance.

TRACK SUPPORT ROLLER - Two lubrication

points. Lubricate every 200 hours of

operation with 10 strokes of the gun.

Use approved motor oil. Hefer to Topic

8.

STABILIZER CEANK ASSEMBLY - Twelve lu-

brication points. Lubricate every 10

hours of operation with pressure gun lu-

bricant.

TRACK RELEhSE SPEING MECHANISM--Inspect

011

level every 200 hours of operation.

Keep filled to filler plug with motor

oil same viscosity as used in trans-

mission. Drain, flush and refill with

motor oil same viscosity as used in

transmission every BOO hours of opera-

tion. Capacity 13 quarts.

TEUCK WHEELS--Ten lubrication points.

Lubricate every 200 hours of operation

with B-l/2 strokes of the gun. Use ap-

proved motor oil. Refer to Topic 6.

BELL CRANK THHUST PIN - Two lubrication

points. Lubricate every 10 hours of op-

eration with pressure gun lubricant.

STEEEING CLUTCH THROVlOUT BEAEING - Four

lubrication pOints. Lubricate every 10

hours of operation with pressure gun

lubricant of high heat resistance.

FINAL DHIVE DRAIN PLUG - Drain flush,

and refill every ;~OOto 400 hours of op-

eration. Capacity B quarts each.

FINAL DElVE FILLE.:ll,.PLUG -- Inspect oil

level every 10 hours of operation. Keep

filled to level of filler elbow with

approved motor oil.

5.

6.

7.

B.

9.

10.

11.

12.

13.

14.

15.

16.

5

21.

SEDIMENT TRAPS - Drain traps every mor-

ning before starting, or more often if

necessary. In freezing weather, drain

after stopping so water will not freeze

in traps.

FIRST STAGE FUEL OIL FILTERS - Install

new elements when necessary. Eefer to

Topic

11.

TRACKS - No lubrication necessary.

TRANSHISSION DRAIN PLUG - Drain, flush,

and refill every BOO hours of operation

with approved motor oil. Capacity 40

quarts.

TRANSMISSION CASE FILliE PLUG AND OIL

LEVEL BAYONNET GAUGE -Inspect

011

level

every' 10 hours of operation and keep the

oil level between "Low" and "Full" on

the bayonet gauge.

LUBEICATING OIL PRESSUEE GAUGE - Normal

operating pressure when engine is warm

at 'full throttle is 25 to 35 on the

gauge; if gauge does not register stop

engine immediately and determine the

cause.

BATTERIES - Keep the top and terminals

clean. Keep filled with clean distilled

water to 3/B" above separator plates;

inspect water level daily. Test with a

hydrometer.

AlE CLEANEf-S - Inspect and service every

10 hours of operation. Refer to Topic

13.

CRANKCASE FILLER CAP - One filler point.

Change oil every 30 to 60 hours of

operation. USE NON-CORROSIVE DIESEL

LUBRICATING OILS CONTAINING ADDITIVES

PHEVENTING SLUDGE OR GUM DEPOSITS. Cap-

acity 14 quarts.

SECOND STAGE FUEL OIL FILTEE - Install

new element when necessary, that is,

when pressure drops below normal range

(25 to 65) due to filter clogging. Re-

fer to Topic

11.

PRE-CLEANERS - Inspect and service ev-

ery 10 hours of operation. Refer to

Topic 12.

CRANKCASE DRAIN PLUG - One drain point.

Drain and refill with new oil every 30

to 60 hours of operation. Eefer to Topic

lAo

PRIMAEY OIL FlITER - Clean the Primary

Oil Filter at each crankcase oil change.

Eefer to Topic 10.

WATER PU},!PDEAIN - Periodically drain

and flush out system. Refer to Topic 18.

RADIATOR DRAIN - Periodically drain and

flush out system. Eefer to Topic lB.

Capacity 12 gallons.

22.

23.

24.

25.

26.

27.

28.

29.

30.

31.

6

7

ROUTINE SERVICE

The operating life of a tractor can be materially increased and fewer shut downs

will be experienced if the unit is properly serviced at regular periodic intervals. Often

major repairs and shut downs can

be

avoided

if

the tractor is inspected regularly and the

trouble corrected when it is of a minor nature.

The following outline gives the operator the pOints that should be lubricated and

inspected at each inspection period.

TEN (10) HOUR SERVICE

Lubricate:

(a) Stabilizer Crank Assy. (All Button-Head Fittings)

(b) 8ell Crank Thrust Pin

(c) Master Clutch Shifter Bearings

(d) Steering Clutch Release Bearings

Inspect:

Lubrlcating 011 Level

Air Cleaners

Pre-Cleaners

Cooling System

Fuel Sediment Traps

Batteries

Transmission Case Oil Level

Fuel Level

Final Drive Case Oil Level

Inspect Tractor for Loose Nuts and Bolts

Steering Clutch Throwout Adjustment

Master Clutch Adjustment

Brake Adjustment

Front Idler and Track Adjustment

SIXTY (60) HOUR SERVICE

Drain and refill crankcase. The oil should be changed every

30 to 60 hours depending upon the quality of Oil,

the kind of fuel used and the working conditions.

Clean primary lubricating oil filter. Install a new element

in the secondary filter with every fourth oil change or

every 240 hours.

ONE HUNDRED (100) HOUR SERVICE

Inspect:

Generator Belt

Fan Belts

Wire insulation and Connections

Track Shoe Bolts

Final Drive Packing Adjustment

~NO

HUNDRED (200) HOUR SERVICE

Lubricate:

Truck Wheels

Front Idlers

Track Support Rollers

Fan

Generator

Starter

Master Clutch Cams

Inspect:

Track Release Spring Mechanism Oil Level

Drain, flush and refill cooling system.

Drain, flush and refill final drive cases.

The oil in the final drive cases should be

changed every 200 to 400 hours of operation

depending upon the operating conditions.

EIGHT HUNDRED (800) HOUR SERVICE

Drain, flush and refill the transmission case;

change sooner if conditions warrant lighter or

heavier oil.

Drain, flush and refill the

housing, track release

8

TRUCK WHEEL LUBRICATION

Approximately 17 quarts of

will be required for each complete

of truck wheels, front idlers and

rollers.

The truck wheels, which employ the use

of positive seals, are lubricated at the fac-

tory but must be re-lubricated upon delivery

and every two hundred hours thereafter.

The lubrication of these truck wheels is

a process of flushing out the old lubricant

by forcing it out with the new lubricant. The

lubricating.equipment for the truck wheels

consists of a special lubricator which is

included in the tool equipment of the tractor.

lubricant

servicing

support

Before lubricating the truck wheels, wash

the ends of the shafts and the nozzle of the

lubricator hose thoroughly. Before inserting

the nozzle into the truck wheel, pump the

lubricator plunger up and down several times

to make sure that it is discharging the full amount of lubricant.

Remove the plug from the end of the truck wheel shaft and insert the nozzle as

far as it will go (approximately 6 inches) into the shaft. Holding the nozzle firmly in

this position, pump the lubricant slowly into the wheel. The plunger should be lifted slowly

and to its full height so that the full amount of lubricant will be drawn into the plunger

barrel. 8-1/2 such strokes are reQ,!ired to f111 each truck wheel. Each stroke of the lu-

bricator delivers four (4) ounces of lubricant.

CAUTION: Never put too much pressure on the lubricator handle because of the

danger of developing extreme pressure which is injurious to truck wheel seals.

Immediately after injecting the lubricant into the wheel assembly, replace the

plug and gasket to prevent the new lubricant from running out. The nozzle should always be

inserted into the carrying handle when the lubricator is not in use to prevent dirt from

entering the nozzle or hose.

9

TRUCK WHEEL LUBRICATION (Cont'd.)

Use only motor oil recorrmended by Allis-Chalmers--see the nearest Allis-Chalmers

dealer or Allis-Chalmers factory branch for the current approved list of oils.

FRONT IDLER LUBRICATION

The front idlers are lubricated with the same equipment and in the same manner

with the same 011 as the truck wheels. Each front idler should

be

serviced with 18 strokes

of the lubricator.

SUPPORT ROLLER LUBRICATION

The track support rollers are lubricated with the same equipment and in the same

manner as the truck wheels and front idlers. Each support roller should be serviced with

10

strokes of the lubricator•

...I

HOUSINGI

~

ELEMENT

RETAINER BOLT

GASKET

WASHER

LEMENT

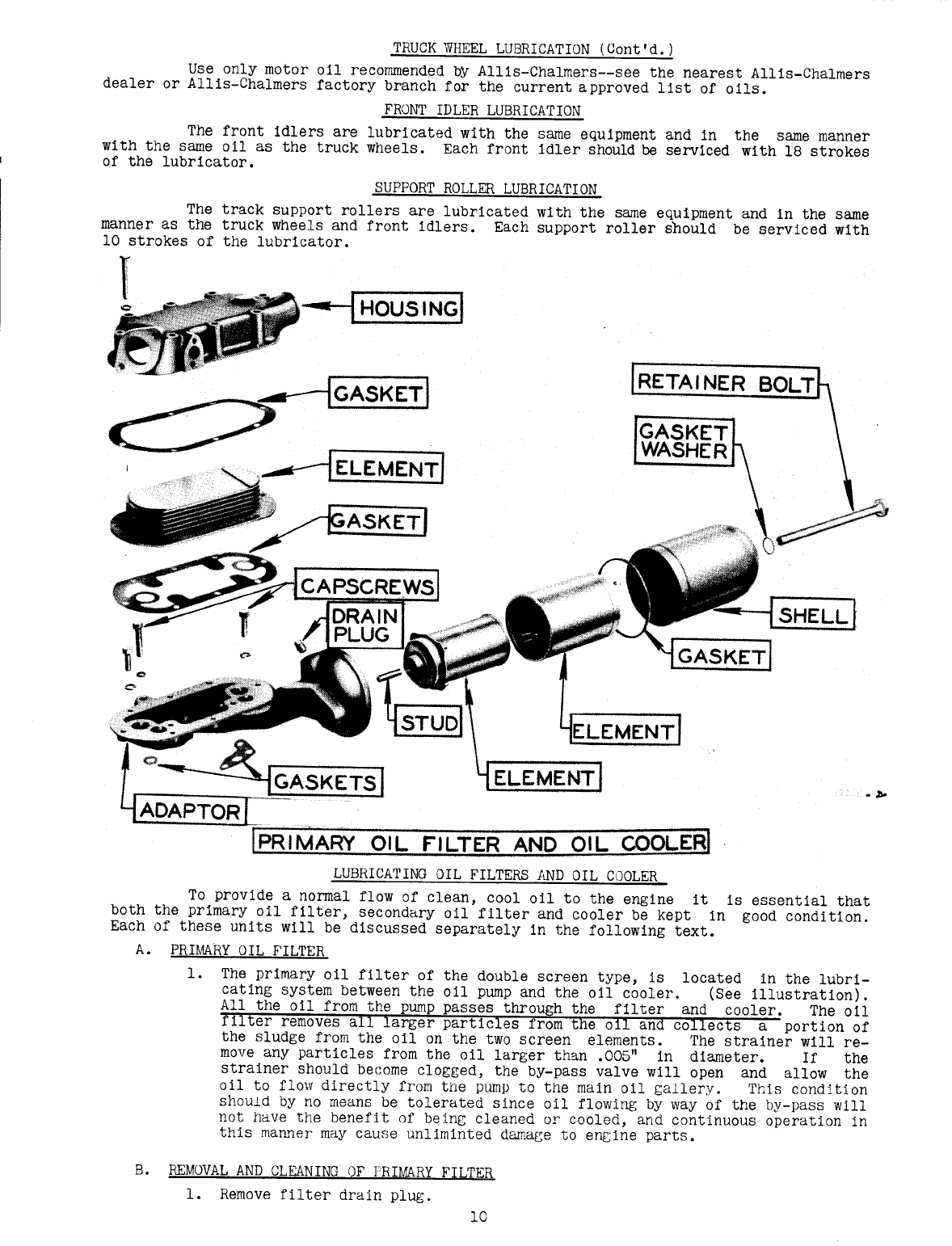

LUBRICATING OIL FILTERS AND OIL COOLER

To provide a normal flow of clean, cool oil to the engine it is essential that

both the primary oil filter, secondary oil filter and cooler be kept in good condition.

Each of these units will be discussed separately in the following text.

A. PRIMARY OIL FILTER

1.

The primary oil filter of the double screen type, is located in the lubri-

cating system between the oil pump and the oil cooler. (See illustration).

All the oil from the pump passes through the filter and cooler. The oil

filter removes all larger particles from the

011

and collects a portion of

the sludge from the oil on the two screen elements. The strainer will re-

move any particles from the 011 larger than

.005"

in diameter. If the

strainer should become clogged, the by-pass valve will open and allow the

all to flow directly from the pump to the main 011 gallery. This condition

ShOUld

by no means be tolerated since all flowing by way of the by-pass will

not have the benefit of being cleaned or cooled, and continuous operation in

this manner may cause unliminted damage to engine parts.

B. REMOVAL AND CLEANING OF PRIMARY FILTER

1.

Remove filter drain plug.

10

LUBRICATING OIL FILTERS AND OIL COOLER (Cont'd.)

2. Remove the oil filter retainer bolt.

3. Remove the oil filter shell and filter elements from the filter base.

4. The f11ter elements must be washed after every 011 change. Wash the elements

in fuel oil with a soft brush. Do not scrape the elements with a sharp or

metal Instrument or wash them with a wire brush. Wash the filter base and

outer shell before reassemblIng.

After washing, reassembly the filter on the filter base. After assembling

check to see whether copper gasket under retaIner bolt prevents oil leaks.

Also be sure oil filter shell gasket fits properly. Run the motor for a few

minutes and inspect for oil leaks.

C. CLEANING PRIMARY FILTER ELEMENTS AND OIL COOLER WITH SOLVENTS.

A filter element that has become loaded with impurities due to neglect can

usually be cleaned only through use of special solvents in conjunction with

some type of circulating system that will create a flushing action.

NOTE: When a filter element Is removed from an engine it should be cleaned

immediately. Do not allow a dirty element to dry, since this will cause lac-

quer or sludge deposits to harden. Keep submerged in a pail of fuel oil be-

fore cleaning.

1.

Effective solvents

Excello Floor cleaning compound

Bendix cleaning compound

Turco cleaning compound

#70

stripper

A mixture of Qaklte

#7

and fuel oil. 3 parts Oakite and 5 parts of fuel oil.

NOTE: The solvents listed above should be

used according to the directions of manufac-

ture. After cleaning operation Is completed

all traces of the cleaning solution should

be washed from the filter elements. In the

event that the above procedure does not

eliminate the clogged condltion, a new fllter

element must be installed.

2. Another very effective solvent Is

the new BendIx cleaner which dissolves or

loosens the sludge or other foreign matter

that may be collected on the metal of the

oil cooler or filter elements.

Its applIcatIon is very simple since all

that is required is submersion of cooler or

filter in solution for a sufficient length

of time to allow the chemical action of the

fluid to properly remove the impurities. The

length of time for the submersion will de~

upon the condition of the cooler or filter

elements.

PLUG

SECONDARY OIL FILTER

FIL TER

SHELL

The impurities, etc., removed from ele-

ments will settle in the bottom of the con-

tainers used for this cleaning operation.

After the above operation, the cooler

or filter elements should be left to drain

for a few minutes, then followed up with a

thorough washing with spirits or live steam

to remove all traces of the cleaningsolution.

If solution In containerIs properly covered

to prevent evaporatlon, it may be used again.

NOTE: The above informatlon Is submitted in

a general manner in order to explaln the

principles of this cleaner. However, it is

recommended that the more specific instruc-

tions supplied by the manufacturer of clean~

er be studied carefully before using any

cleaning solution.

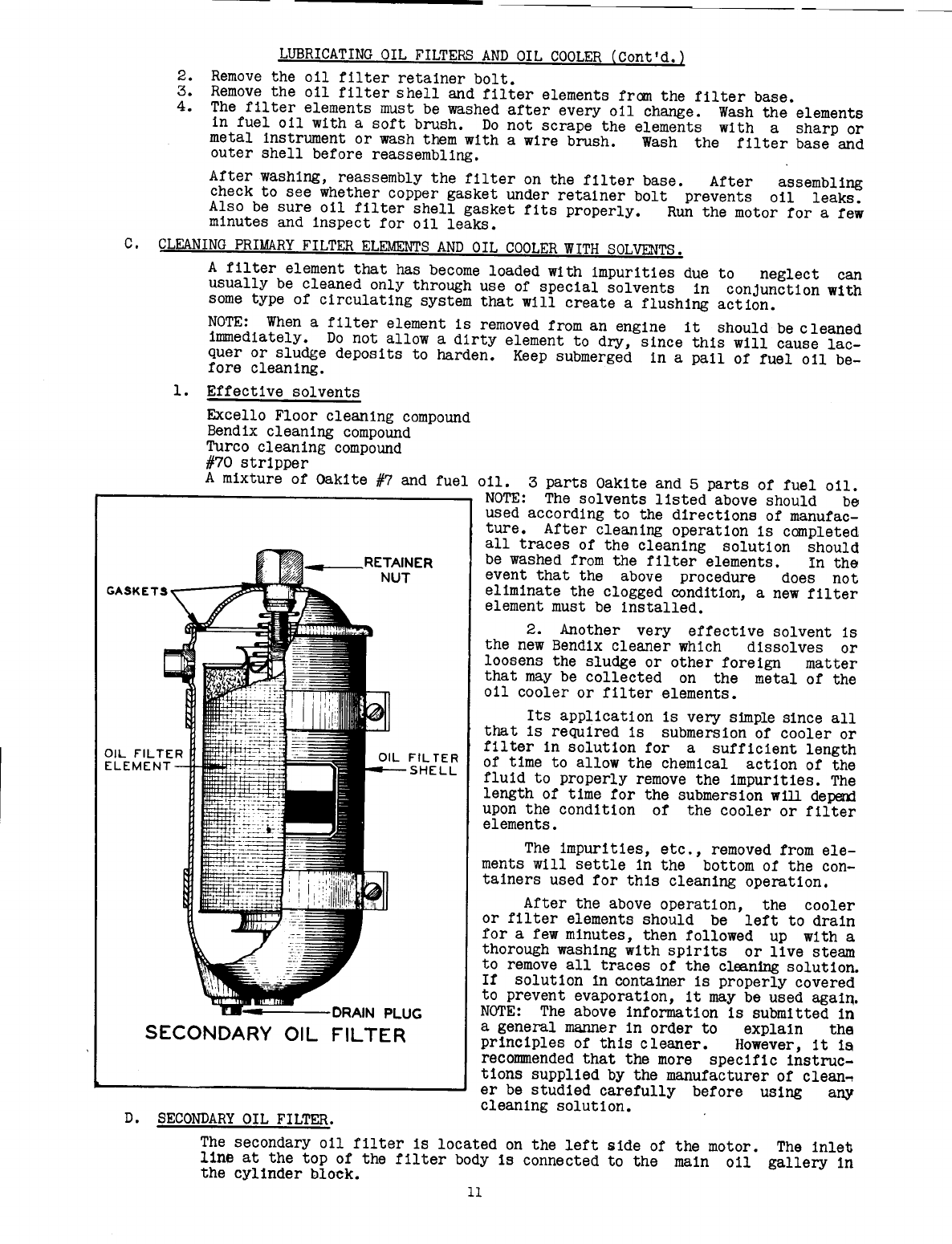

D. SECONDARY OIL FILTER.

The secondary oil filter is located on the left side of the motor. The inlet

line at the top of the filter body is connected to the main oil gallery 1n

the cylinder block.

11

LUBRICATING OIL FILTERS AND OIL COOLER (Cont'd.)

The outlet line from the filter body is at the bottom and drains back into

the crankcase.

Only a portion of the oil flows through this filter. This filter has a re-

placeable element and must be changed every 4th oil change or every 240 hours

of operation.

E.

REMOVAL OF SECONDARY FILTER ELEMENT AND INSTALLATION OF A NEW ONE.

1. Remove the drain plug at the bottom of body and loesen the cever. Let the .oil

drain .outbefore removing the element.

2. Remeve the filter element and discard it.

3. Clean out the filter body and replace drain plug.

4. Install new element, new cover gasket and tighten cever securely.

5. When installing new element one extra quart of oil is required for crankcase

f11l1ng. NOTE: When filling crankcase with 011 fill only to full mark on

crankcase bayonet gauge.

6. Start motor, inspect for leaks and run for a few minutes. Then step motor and

let it set long enough for the oil to drain back inte crankcase. Check crank-

case bayonet gauge te see if more .oilis needed.

7. In cold weather the motor should be run long enough to attain operating temp-

erature before checking the oil level.

F. OIL COOLER

1.

The lubricating 011 cooler lowers the oil temperature as the 011 travelS

through the small passages inside the cooling element. If these passages

become entirely clogged, no cooling of the oil can take place, and the oil is

by-passed without filtering or cooling directly to cylinder block oil galler~

It is absolutely necessary that the oil cooler element be kept clean for pro-

per oil cooling.

2. Cleaning of a clogged cooler is sometimes very difficult. A cooler that has

become loaded with impurities over a long period of operation can usually be

cleaned only through use of special solvents in conjunction with some type of

circulating system that will create a flushing action. However, in most cases

the use of any of the special solvents, as listed perviously, in a hand oper-

ated force pump will dislodge any accumulation. In the event that such treat-

ment does not eliminate the clogged condition, a new cooler element must be

installed.

NOTE: A clogged 011 cooler or filter is a contributing factor in low engine

oil pressure which may be the cause of one or many operating difficulties.

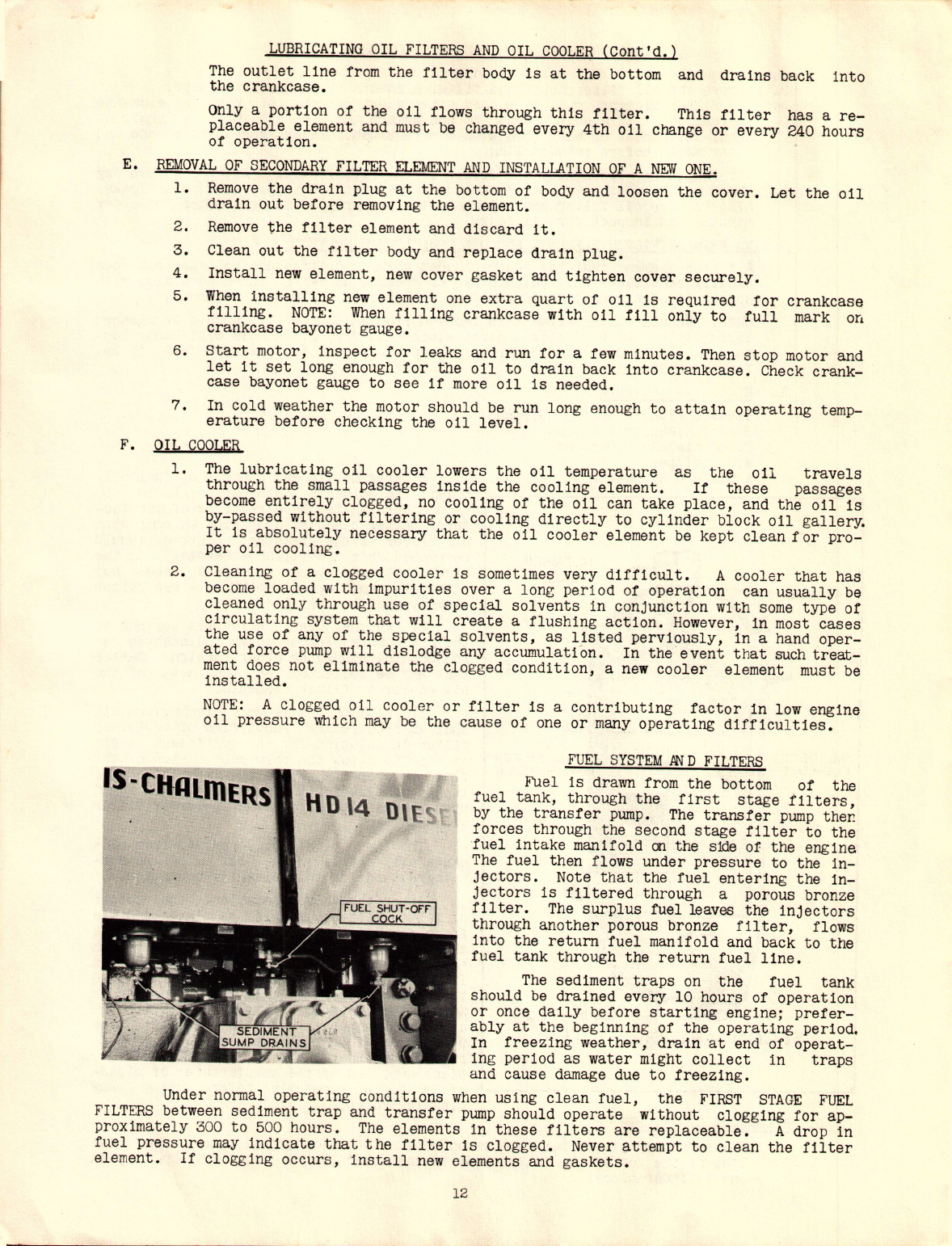

FUEL SYSTEM

.AN

D FILTERS

Fuel is drawn from the bottom of the

fuel tank, through the first stage filters,

by the transfer pump. The transfer pump ther.

forces through the second stage filter to the

fuel intake manifold on the sideof the engine

The fuel tnen flows under pressure to the in-

jectors. Note that the fuel entering the in-

jectors is filtered through a por.ousbronze

f11ter. The surplus fuel leaves the injector-s

through an.otherperous bronze filter, flews

into the return fuel manifold and back te the

fuel tank through the return fuel line.

The sediment traps on the fuel tank

sh.ouldbe drained every 10 hours .of.operation

or once daily befere starting engine; prefer-

ably at the beginning .ofthe operating period.

In freezing weather, drain at end of operat-

ing period as water might collect in traps

and cause damage due t.ofreezing.

Under normal .operatingconditions when using clean fuel, the FIRST STAGE FUEL

FILTERS between sediment trap and transfer pump should .operate witheut clegging fer ap-

preximately 300 to 500 h.ours. The elements in these filters are replaceable. A dr.opin

fuel pressure may indicate that the filter is clegged. Never ~ttempt te clean the filter

element. If clegging occurs, install new elements and gaskets.

12

FUEL SYSTEM AND FILTERS (Cont'd)

The SECOND STAGE FUEL FILTER between

transfer pump and the injectors is a replac-

eable element type. When clean fuel is used

under normal operating conditions, the ele-

ment should last from 300 to 500 operating

hours. When clogging of this filter occurs,

install a new element. Do not attempt to

clean the clogged filter elements.

Open the drain at the bottom of the SEC-

OND STAGE FUEL FILTER every morning or every

10 hours of operation to drain off any water

and sediment which may have accumulat~d~ NOR-

MAL FUEL OIL PRESSURE IS

25

TO

65-

ON GAUGE AT

HIGH IDLE. DO NOT OPERATE ENGINE WHEN FUEL

PRESSURE IS NOT WITHIN THIS RANGE.

The Diesel engine in this tractordepends

upon the circulation of fuel

011

through the

injectors to keep the injectors cool. The

transfer pump Circulates approximately

25

gal-.

Ions of fuel per hour through the injection

system. If this quantity is allowed to de-

crease, it will cause serious damage to the

injectors because of their becoming over-

heated. As the fuel filters begin to clog,

the quantity of fuel circulatrlng through the

injectors becomes less. Although this flow

may be sufficient to keep the engine operating

normally, it may be reduced to yhe point where

the injectors are becoming dangeroust.yover-,

heated. Therefore, proper p'erformanceof the,

engine does NOT necessarily mean that eno~

fuel is being Circulated, so we recommend that,

the fuel filtering system be cheCked and the

necessary filter elements replaced at the

first indication of a deviation in fuel oil

pressure from normal.

The first two or three timesthe operator

has to change the fuel filter elements will

give him a good indication as to about

hOW.

often it will be necessary for the

t

11

ter el-

ements to be replaced thereafter. That is,

if

the f11ters clog on an average ofevery 400

hours for the first two or three times, the

fuel filters should be changed, as an item of

routine service, every 400 hours of operation

thereafter without waiting for a drop in fuel

pressure.

The length of time that the fuel filter elements will operate, of course, depends

upon the type of fuel being used and the method of handling fuel oil on the job. In ac-

cordance with the above paragraphs, change the filter elements in the FIRST AND SECOND

STAGE FUEL FILTERS after a reasonable number of hours of operation even

thoughthey are

hot completely clogged, in order to safeguard the injection system.

FUEL.

13

PRE-CLEANERS

The purpose of the pre-cleaners must not

be underestimated, as their duty is to remove

a large percentage of the foreign material

before it enters the air cleaner. Dirt is

trapped in the pre-cleaner shells where it

can easily be removed. The pre-cleaners are

provided with an eye glass through which the

dirt accumulation may be seen. The pre-clean-

ers will not function properly if the dirt

level in the shell covers over one-half the

eye glass.

To service pre-cleaners remove wing nut

and cap assembly. Lift pre-cleaner shell

from cleaner body and remove dirt from shell

by shaking. Be sure louvers on cleaner body

are not bent or clogged with leaves or other

foreign material.

CAUTION: When replacing cap and nut assembly be sure gasket is in

good condition and in proper place with wing nut tight

to prevent leakage so purpose of pre-cleaner will not be

defeated.

AIR CLEANER

The air cleaners IllUStbe cracked every

ten (10) hours of operation. Remove the

011

cups and check the amount and condi-

tion of the filtering oil. In extreme

dusty conditions the oil w111 have to be

changed every eight or ten hours. The oil

must be kept level with the top of the

cone in the oil cup. Use SAE 40 in the

summer and SAE 30 in the winter. Do not

use anything lighter and DO NOT USE A

DIESEL ENGINE LUBRICATING OIL IN THE AIR

CLEANER. These lubricatingoilsare likely

to foam thus reducing air cleaner effic-

iency and possible

011

pull-over with ser-

ious injury to the engine

In extreme dusty conditions the air

inlet tube of the air cleaner must be swabbed out every ten hours of operation. Oil from

the oil cup splashes up on the inside of the tube and collects dust on the sides of the

passage, this dust accumulates and reduces the volume of air going through the air cleaner.

A broken hose, loose clamps, or a leak of any kind between the air cleaners and the

blower will defeat the purpose of the cleaners. ALL CONNECTIONS MUST BE TIGHT. Improper

care of the air cleaners will result in abnormal wear of blower, rings, pistons and cy-

linder liners.

14

GENEI~L OPE~TING INSTRUCTIONS-PREPARING T~CTOR FOR USE

Make a complete inspection of tractor for any shortage or damage which may have oc-

curred while in transit or in storage.

Remove the air cleaner cups to make sure they contain the correct amount and grade

of 011. Refer to topic, "Care of Air Cleaner".

Inspect the oil level in the engine crankcase, transmission case, final drive gear

cases, and the track release spring housings. Change engine crankcase oil after first

30

hours of operation.

The truck wheels, track support rolle~s and front idlers, have been lubricated at

the factory for test purposes only. It is essential that all parts be lubricated before

the tractor is put into service.

Inspect the fuel tank and fill, if necessary, with the correct fuel oil. Refer to

topic, "Fuel

011".

Special care must be taken to prevent the entrance of dirt or foreign

'materialswhile filling the tank.

Fill the cooling system with clean water that is free from lime or alkallnes,and re-

move plug in thermostat housing to release the air that is trapped in housing. In freezinm

weather, we recommend using a standard anti-freeze solution in the cooling system. The

solution should be tested daily and kept to the proper strength for the prevailing temper-

atures. The anti-freeze used should have a higher boiling point than the recommended op-

erating temperature of the engine

(175 - 185

0

F).

OPERATE A NEW TRACTOR VIITHA LIGll'l'LOAD DURING THE FIRST SIXTY HOUnS.

After the first ten hours of operation, the tractor should be stopped and inspected

for loose bolts and nuts. The steering clutch throwout and the master clutch adjustments

shouid be inspe~ted and adjusted if necessary.

The valve lash, injector equalizing and injector timing should be inspected and ad-

justed if necessary after sixty hours of light load operation.

USE OF CONTROLS AND INSTRUMENTS

The first thing the operator of a new tractor must do is to familiarize himself with

the various controls provided for its proper operation. This does not apply to the beginner

alone, as, although there are many points of similarity among.all tractors, there are also

important differences, and it is not Wise, regardless of prevlOus experience, to operate a

new tractor before fully understand1ng what ea.chcontrol is for and how to use it.

15

FUEL SHUT-OFF - The fuel shut-off knob controls the air and fuel to the eng1ne. To

stop eng1ne, pull shut-off knob all the way 6ut thus shutt1ng off the flow of a1r and fuel

to the eng1ne. Leave knob in this posit1on unt11 eng1ne 1s aga1n to be started, at which

time shut-off knob must be pushed in as far as it will go.

STARTER PEDAL - Push on the starter pedal to engage the starter pinion with the fly-

wh~el ring gear and to operate the starter switch. Each time the starter pedal is depressed

it must be allowed to return to its original position (all the way out), and starter given

time to cease spinning before the starter can again be used. Otherwise starter runs but

~111 not turn engine. NOTE: If the engine does not start in less than one half minute

allow the starter and battery to cool for 15 minutes before it is used again. See Topic -

"Starting Engine".

DASH LIGHT AND HEATER SWITCH - The "dash light and heater" switch completes the cir-

cuit between the battery and the air heater push button switch. Turn the switch lever to

the left for the ON position and to the right for OFF pOSition.

AIR HEATER PUSH BUTTON SWITCH - The air heater push button switch completes the cir-

cuit between the dash light switch and the air heater coil. To operate, turn the dash light

switch lever ON and depress the push button switch while operating the air heater pump.

AIR HEATER PillJP- The air heater pump delivers the fuel oil under pressure to the

air heater spray nozzle where it is ignited by a continuous spark, thus heating the air

box to aid cold weather starting. To operate the air heater pump the dash light and heater

switch must be ON and the air heater push button switch held in. Then pump the heater

pump handle slowly, with the starter turning engine until it starts. For further instruc-

tions see Topic "Starting Engine".

THROTTLE LEVER - The throttle lever is connected to the variable speed governor. Push

the throttle lever forward to decrease, and pull back to increase the engine speed.

RADIATOR SHUTTEg CONTRO~ LEVER - The radiator shutters aid in maintaining proper en-

gine temperature (175 to 185 F.) and are adjusted by means of the lever under the left

hand side of the cowl. The shutters are tllly open when the control lever is moved forward

as far as it will go. To close the shutters, pull the lever back.

HEAD LIGHT SWITCH - To turn headlights on move head light switch lever to the right.

(Picture shows ON position)

ENGINE OIL PRESSURE GAUGE - The oil pressure gauge indicates the oil pressure in the

engine lubricating system. At full throttle and under normal operating conditions, the

pressure should be between 25 and 35 on the gauge. CAUTION: STOP engine immediately if

no oil pressure is shown on the gauge and determine cause.

FUEL OIL PRESSURE GAUGE - The fuel oil pressure gauge indicates the oil pressure in

the fuel system. Under normal operating conditions, the fuel pressure at full governed

engine speed should be from 35 to 65 on the gauge. CAUTION: Do not operate engine when

fuel pressure, as indicated on the gauge, falls below its normal range. See topiC, "Fuel

System and Fil ters" •

ENGINE TEMPERATURE GAUGE - The engine t~mperatuoe, indicated by the temperature gauge,

should be maintained at all times between 175 to 185 F. Use radiator shutters to main-

tain the proper temperature.

AMMETER - The ammeter registers the amount of charging current delivered to the batt-

eries. Through the action of the voltage regulator, the ammeter reading will be reduced

when the battery approaches full charge and increased as the battery approaches a dischar-

ged condition.

HOUR METER - The hour meter registers the number of hours that the engine has opera-

ted. For instruction on how to read the hour meter see topiC, "Hour Meter".

MASTER CLUTCH LEVER - The master clutch lever controls the master clutch which tran-

smits the power between the engine and the transmission. The master clutch is disengaged

and the clutch brake applied when master clutch lever is in the forward

posrtton,

The clutch

is engaged when the lever is pulled all the way back and snaps over center.

AUXILIARY SHIFT LEVER AND GEAR SHIFT LEVER - These levers are used to select the de-

Sired transmission gear ratio. The auxiliary shift has two positions - forward and back-

ward, while the gear shift lever has the conventional four positions. Refer to topic "Use

of Gear Shifting Levers." NOTE: Both gear shift levers are provided with a locking device

to hold them in the desired gear. The auxiliary shift lever must be moved sideways to the

left to unlock it when shifting. The gear shift lever must be moved

s1deways

away from

the neutral pOSition when it is desired to shift into another gear.

I

16

STEERING CLUTCH LEVERS - The steering clutch levers control the two steering clutches

which transmit the power from transmission to the track. These levers are used for steer-

ing the tractor. Pull the right lever all the way back to turn the tractor to the right.

Allow the lever to return to its forward position when turn is completed. Operation of

left steering clutch lever will turn tractor to left. CAUTION: The steering clutch lev-

ers should always be pulled back as far as possible when making a turn. ~hold lever

in an intermediate position. Refer to Topic "Steering".

BRAKE PEDALS - The brakes are used to retard the spee~ of, or facilitate turning the

tractor. To turn the tractor to the right press on the right brake pedal and to turn to

the left press the left brake pedal with the corresponding steering clutch released.CAUTION

Never use brakes for turning tractor with first pulling steering clutch lever as far Qack

as possible on side toward which turn is being made.

BRAKE PEDAL LOCK LEVER - The brake locks are used

to

hold the brakes in their applied

or ON position. To hold the brakes in the locked position the brake pedal lock lever will

have to be held forward while applying the brakes. To release the brake locks press the

brake pedal and it will automatically release the lock.

PUTTING TRACTOR TO VIORK

A. Starting the Engine

Before the engine is started, the operator should check the following pOints on

the tractor:

1. Inspect the fuel supply.

2. Inspect the crankcase oil level.

3. Inspect the water or anti-freeze solution in the cooling system.•

4. Inspect the entire unit for loose bolts or nuts. This is es-

pecially necessary when repairs have been made sincethe previous

oPerating period.

5. Disengage master clutch. (Lever forward) and put gear shift

lever in neutral position.

6. Close the radiator shutter by pulling on the shutter control

lever.

7. Push the fuel shut-off knob in.

8. Open the throttle control to the fullest extent.

9. Push the starter pedal. WARNING: If the engine does not start

in less than one half minute, allow the starter and battery to

cool for 15 minutes before it is used again.

10. As soon as the engine fires and begins to run, Cbse the throttle

to about 3/4 engine speed and allo~ the engine to warm up. When

the engine temperature reaches 175 F open the shutter;the shuJter

Sho~ld be adjusted so that an operating temperature of 1?5 to

185 F is maintained at all times.

11. Inspect the oil pressure. At full governed speed and with. the

engine heated to normal operating temperature, the oil pressure

should be between 25 and 35 on the gauge; at part throttle the

reading may drop to about 5 on the gauge. If the oil is cold,

no pressure may register for about 15 seconds after the engine

starts, but if the pressure does not then rise to between 25 and

35, the engine should be ~opped and the cause determined.

12. Inspect the fuel

011

pressure. The fuel pressure at full gov-

erned speed should be between 25 and 65 on the gauge.

13. Open the throttle to meet the operating conditions.

14. In cold weather (+32

0

F to OOF) when it is necessary to use the

~ir Heater, proceed as stated above for the first eight opera-

tions. Then turn the dash light.switch on, press on the air

heater switch, pump the air heater pump handle slowly, and press

on the starter pedal all at the same time. The air heater will

heat the air box and aid starting. Then proceed as stated above.

WARNING: Do not operate the air heater before stepping on the

star-terpedal.

17

B. Use of Gear Shifting Levers

1. Two levers are used to shift the gears. The left lever (looking

forward) has four positions and is called the gear shift lever;

the right lever is an auxiliary lever for shifting the auxiliary

gears in the front part of the transmission case and has two po-

sitions, indirect (forward) and direct (backward). When the aux-

iliary lever is in the direct position, the tractor can be run

in third, fourth, sixth and high reverse; when the lever is in

indirect position the tractor can be run in first, second, fifth

and low reverse.

2. Both gear shift levers are provided with a locking device to hold

them in the des ired gear. The aux lliary shif t lever must be

moved sideways to the left to unlock it ~~en shifting. The gear

shift lever must be moved sideways away from the neutral position

when it is desired to shift into another gear.

3. The following chart shows the position of the two gear shift

levers to obtain any of the six fonvard and two reverse speeds:

REVERSE IN DIRECT

DIRECT

GEAR GEAR SHIFT LEVER AUXILIARY SHIFT LEVER

First •Left and Back .

.

.Indirect

Second. .Right and F'orward •Indirect

Third . .Left and Back. .Direct

Fourth. .R1ght and Forward .Direct

Fifth. .Right and Back •Indirect

Sixth . .Right and Back .Direct

Low Reverse .Left and Forwarn .Indirect

High Reverse. Left and Forward. .Direct

4. To shift gears, push master clutch lever forward and shift gears

to the desired speed. When the master clutch lever is pushed

forward it forces the release bear1ng carrier against the clutch

brake assembly that is fastened to the clutch shaft, thus bring-

ing the

t

ransmrss

t

on gears to a stop. This stopping of the gears

enables the operator to shift without clashing the gears.

18

C. Use of Master Clutch

1. The Master clutch is of highest quality and workmanship and if

given proper care and operated correctly it will give many

hours of carefree operation.

2. To obtain maximum clutch life it is important that in starting

a load, operator must select a gear low enough to insure easy

pick up without clutch slippage. When the correct gear is en-

gaged to handle the load open throttle approximately half way

and pull back steadily on master clutch lever until all slack'

is taken up between tractor and load. Then pull back firmly on

clutch lever to lock clutch in its engaged posi tion at the same

time opening throttle to attain desired speed. To shift to a

higher gear with tractor in motion close throttle at the same

time master clutch is disengaged, select desired higher gear,

engage master clutch and at the same time open throttle.

3. If conditions are such that the tractor can negotiate in sixth

gear with load, start tractor in fifth gear

and

then shift into

sixth gear after tractor has obtained rated speed. Do not slip

the master clutch in an effort to pull an overload. Avoid ex-

cessive wear on the clutch disc facings by using a lower speed

being sure to close throttle to half-way position every time

master clutch is disengaged. When it is necessary to let en-

gine idle for short periods do not idle engine with master

clutch disengaged but shift gears into neutral postt

im

and en-

gage the master clutch.

D. Steering

1. Steering the tractor is accomplished by the use of steering

clutches which are operated by steering levers. Turn the trac-

tor in the desired direction by pulling back

to

the

full

extent

the steering lever on the side toward which the turn is to be

made. The clutches must be engaged slowly and evenly to avoid

excessive wear on them. DO NOT release the leversand let them

fly forward. Do not operate tractor with steering clutches

partially disengaged. Avoid excessive wear of the steering

clutches by releasing and engaging the steeringclutchessmooth-

lyand completely. See topic "Steering Clutch Adjustment.

n

2. In steering the tractor down steep grades with the load pushing

the tractor, the use of the steering clutches is oppOSite to

that of a tractor pulling a load. If it is desired to make a

turn toward the right, the left steering clutch should be re-

leased. The engine being connected to the right track acts as

a brake retarding its progress while the left trackis released

and free to travel faster.

E. Use of Steering Clutch Brakes

1. The steering clutch brakes are for retarding the speed of

01

holding track stationary when the steering clutch on that side

is released for making a turn. In making a turn alwaysrelease

the steering clutch before depressing the brake. They are also

used as service brakes for retarding speed of tractor when

going down grade and to hold tractor stationary. DO NOT OPER-

ATE TRACTOR WITH FEET RESTING ON BRAKE PEDAlB.

2. The brakes can be locked and used as parking brakes when park-

ing the tractor. To hold the brakes in the locked position

the brake pedal lock lever will have to be

held

forward while

applying the brakes. When the brakes are to be released again

a slight pressure on the brake pedal will automatically re-

lease the pedal lock lever.

F. Stopping the Tractor

1. Stopping the tractor is accomplished by disengaging the master

clutch (push lever forward) and applying the steering clutch

brakes. Then SHUT OFF motor. (See topic "Stopping Engine

n)

DO NOT allow tractor to stand with engine idling. If tractor

is to be stopped for ONLY a few minutes, let the engine run at

not less than TWO-THIRDS throttle (approximately 1000 r.p.m.)

with gear shifting lever in neutral position and Master Clutch

engaged to eliminate unnecessary wear on master clutch parts

and pilot bearing.

If

tractor is to be stopped Tanger than a

few minutes, STOP SNGINE.

19

Table of contents

Other Allis-Chalmers Tractor manuals

Allis-Chalmers

Allis-Chalmers H 4 Specifications

Allis-Chalmers

Allis-Chalmers WD Use and care manual

Allis-Chalmers

Allis-Chalmers HD-5 User manual

Allis-Chalmers

Allis-Chalmers HD 6B User manual

Allis-Chalmers

Allis-Chalmers G User manual

Allis-Chalmers

Allis-Chalmers 10 hp User manual

Allis-Chalmers

Allis-Chalmers regent hydro 14 User manual

Allis-Chalmers

Allis-Chalmers ac130 series User manual

Allis-Chalmers

Allis-Chalmers Simplicity 9523 Instruction Manual

Allis-Chalmers

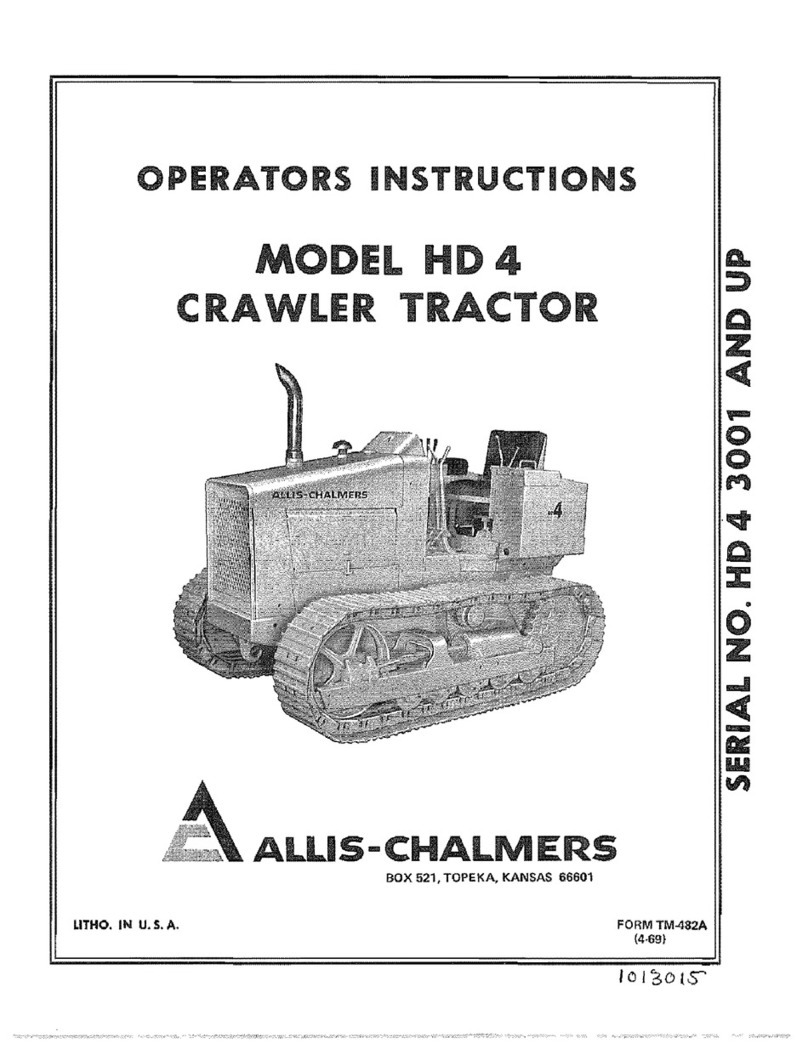

Allis-Chalmers HD-4 Specifications