Allis-Chalmers B Install guide

SHOPMANUAL

ALLIS-CHALMERS

ModelsB-C-CA-Gtractorserialstampedontopoftransmission.

ModelsRC-WC-WFtractorserial stampedrearfaceofrearaxlehousing.

ModelsWD-WD45tractorserialstampedrearfaceoftransmission.

ModelWD45Dieseltractorserialnumberislocatedatleftbrakecoveror

onleftrearsideoftransmissionhousing.

B-C-CA-RCengineserialstampedontopofleftrearengineflange.

Gengineserialstampedonsideofleftrearengineflange.

WC-WD-WD45-WD45Diesel-WFenginestampedonleftsideofcylinder

block.

Tractor

Model

BUILTINTHESEVERSIONS

TricycleTypeAxleType

SingleDoubleNon- Adiust-

WheelWheelAdjustableable

B

C

CA

G

RC

we

WD

WD45

WF

No

Yes

YM

No

YM

YM

YM

Yes

No

WD45DYM

No

Yes

YM

No

Yes

Yes

Yes

Yes

No

Yes

Yes

No

No

No

No

Yes

No

No

YM

No

YM

YM

YM

YM

No

YM

YM

YM

No

YM

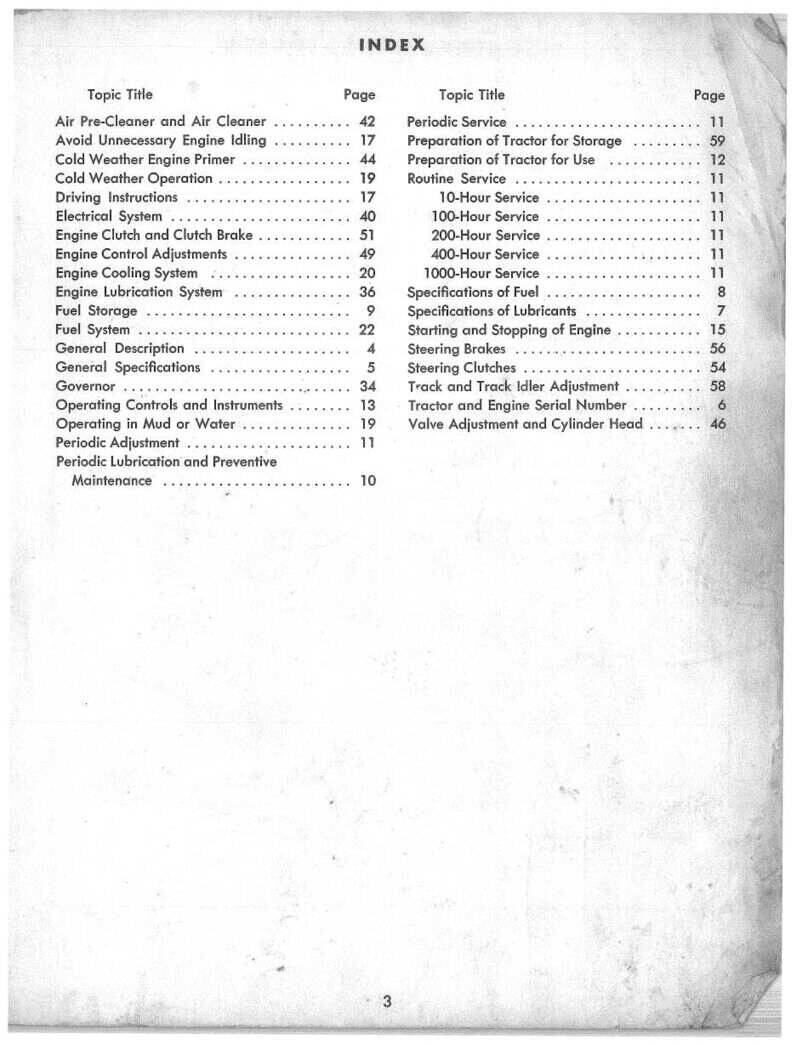

IN D

E

X (ByStartingParagraph)

MODELSB^CAO HCWC.WFm,.^WD45

BELTPULLEY

311311308310310310310

BRAKES

Adjustment300301304305305306306

DrumsR&R300303304B277277282282

R^ne...".*.*.*.*.**..300302304A 305A305A306A306A

CARBURETOR{NotLP-Gas)110110110110HOHO

LP-Gas1"

CLUTCH

Engineclutch160160164166166174174

Engineclutchshait215^

Finaldriveclutch284

Transmissionclutch1"91"9

COOLINGSYSTEM

Fan133133132133134134

Pump*'.;'.'.!'.'.'.'.135135135135135158

Radiator130130131130130130156

DIESELFUELSYSTEM

EnergyCells154

FuelFilters^ 1*"A

InjectionPump' *50

Nozzles1*°

Preheater•."5

QuickChecks. 147

DIFFERENTIAL

Adjustment240240242245247250250

R&Randoverhaul241241243246249251251

ELECTRICAL139139139139139139159

PrintedInU.S.A.COPYRIGHTI960BYTECHNICALPUBLICATIONS,INC.ALL,RIGHTSRESERVED.

INDEXCont.

MODELS

B-CCAG

ENGINE

Assembly

R&R6060

62,65

Cam

followers

737374

Camshaft

858586

Connectingrods

&

bearings

959596

Crankshaft

&

bearings

979798

Cylinderhead

666667

Cylindersleeves

9191

Flywheel

1O3103103

Front

oil

seal

102102102

Mainbearings

979798

Oil

pan105105105

Oil

pump

106106107

Pistons

919192

Pistonpins

939394

Piston

& rod

removal

888889

Pistonrings

919192

Rear

oil

seal

9999JOO

Rockerarms

7575

Tappets

737374

Timinggearcover

787879

Timinggears

828283

Valveguides

707071

Valves

&

valve

seats.

686869

Valvesprings

727272

Valvetiming

737677

FINALDRIVE

Axlehousings

286

Bevelgearsrenew253B254B255B

Bevelgears

adjust.

253254255

Bullgearrenew

266271

Bullpinionbearingsadjust

..267272

Bullpinionrenew

268273

Differentialoverhaul

241241243

Driveunitsoverhaul

285270

^Wheelaxleshafts

266271286

FRONTSYSTEM

Frontaxlemember

5 5 5

Frontsteeringgear

1 i

Main

steering,

Gemmer

IS

Main

steering,

Lavine

Main

steering.

Ross

222222

Pedestal,

adjust

1 1

Pedestal,

overhaul

3 3

Pivot

pin101112

GOVERNOR

Adjustment

115us117

Overhaul

nengna

IGNITIONSYSTEM

BatteryIgnitionTiming140AHOB

MagnetoIgnitionTiming140140

LIFTSYSTEM

Linkage33O

Pump320324328

Testing322325328

Troubleshooting322326

Workcylinder329329329

MechanicalType

POWERTAKE-OFF3U311

REARAXLERefertoFinalDrive

STEERINGGEARRefertoFrontSystem

TORQUETUBE185185

TRANSMISSION

AssemblyR&R2OS

Beisicprocedure205213

Bevelpinion203209222

Clutchshaft215

Countershaft203

Extralowgears', 218

Inputshaft202208220

Mainshaft202208220

Reverseidler204212221

Shiiterforks201207214

RCWCWFWD,WD45

63

73

85

95

97

66

91

103

102

97

105

106

91

93

88

91

99

75

73

80

82

70

68

72

76

246

256B

256

276

277

246

275

276

5

2

2

4

13

115

116

140

340

314

64

73

87

95

97

66

91

103

102

97

105

108

91

93

90

91

101

75

73

80

84

70

68

72

76

249

257B

257

276

277

249

275

276

5

2

26

22

2

4

13,14

119

120

140

340

314

64

73

87

95,95A

97

66

91

103

102

97

105

108

91

93

90

91

101

75

73

80

84

70

68

72

76

258B

258

280

281

282

25;

279

280

5

2

2

4

11

119

120

140A

140

334

324

325

326

329

314

186

223

256B

226

228

226

227

229

225

186

223

257B

226

228

190

WDWD

PriorAfter

Ser.

Ser.

127008

231

230

234

235

233

226

227

229

236

225

232

127007,

WD45

238

237

239B

239C

239A

239D

239

WD45

Diesel

141

142D

144

145B

145C

142

144C

146A

143B

145C

146

146B

144C

145A

144B

144C

145D

143

142D

143B

143C

142B

142/.

142C

143A

258B

258

280

281

282

251

279

280

2

4

11

153A

334

324

325

326

329

3U

190

238

237

239B

239C

239A

239D

239

CONDENSEDSERVICEDATA

(WD45Diesel)

WD45

GENERAL

Tractor

Model

EngineMake

EngineModel45D

Cylinders6

Bore.

Inches3 7/16

Stroke,Inches4 1/8

Displacement.CubicInches230

CompressionRatio15.5:1

PistonsRemovedFrom?Above

MainBearings,Numberof7

MainBearings,Adjustable?No

RodBearings.Adjustable?No

CylinderSleevesWet

Generator.MakeD-R

Starter,MakeD-R

InjectionNozzle.MakeBosch

InjectionPump,MakeBosch

InjectionPump.ModelPSB

TUNE-UP

FiringOrder

1-5-3-6-2-4

ValveTappetGap.Inlet0.010H

ValveTappetGap,Exhaust0.019H

InletValveFaceAngle45"

ExhaustValveFaceAngle45°

InletSeatAngle

45**

ExhaustSeatAngle45"

InjectionTiming.DegreesBTC' 21

TimingMarkLocationFlywheel

TUNE<UP(Conf.)

TractorWD45

ModelDiesel

EngineLowIdleRPM600

EngineHighIdleRPM1975

EngineLoadedRPM1625

BeltPulleyLoadedRPM1460

PTOLoadedRPM548

SIZES-CAPACITIES-CLEARANCES

(ClearancesinThousandths)

CrankshaftJournalDiameter

2.4975

CrankpinDiameter

1.998

CamshaftJournal

Diameter,

Numbers

1.2 and3

1.9985

CamshaftJournal

Diameter,

Number

4

1.2485

Piston

Pin

Diameter

0.9996

ValveStemDiameter

0.3095

Compression

Ring.

Width

1/8

OU

Ring.

Width

3/16

Main

Bearings,

DiameterClearance

2.3-4.5

Rod

Bearings,

DiameterClearance

1.5-3.5

PistonSkirtClearance

4-5

Crankshaft

End

Play

2-7

CamshaftBearingClearance

: 2-4.6

CoolingSystem.Gallons

4V4

CrankcaseOil.Quarts(WithFUter)7

TIGHTENINGTORQUE-Ft.-Lbs.

ConnectingRodNuts30-40

CylinderHeadNuts95-100

FlywheelScrews,...95-105

MainBearingScrews125-135

MODELWD45DIESEL

CONDENSEDSERVICEDATA

(All

Non-DieselModels)

TRACTORMODEL

B (S£

GENERAL•''^^o)

EngineMakeOwn

EngineModelBE

Cylinders4

Bore—Inches3V4

Stroke—Inch€JS

3 V4

Displacement—CubicInches116

CompressionRatioNonLP-Gas4.92

CompressionRatioNonLP-Gas4.67

CompressionRatioNonLP-Gas

CompressionRatioLP-Gas

PistonsRemovedFrom:Above

MainBearingir,Numberof3

MainBearingii,Adjustable?(1)

RodBearings,Adjustable?(1)

CylinderSleeiresWet

ForwardSpeeds3

Generator& StarterMakeD-R

•BandC - 3 speeds.CA- 4 speeds.

TUNE

UP

FiringOrder1,2,4,3

ValveTappetGapOIOH

ValveSeatandFaceAngle45

IgnitionDistributorMakeNone

IgnitionDistributorModel

IgnitionMagnetoMakeF-M

BreakerGap020

MagnetoLagAngle30*

MagnetoImpulseTripsTC

RetardedTimingInchesorDeg.TC

FullAdvancedTimingDeg30**B

MarkIndicating:

RetardedTijning

FullAdvancedTimingFire

MarkLocation—Flywheel,FanPulley.Fly.

SparkPlug—Make

ModelforGasoline

ModelforLowOctane

ElectrodeGap035

CarburetorMakeNonLP-Gaa

Model(Marvel-Schebler)

Model(Zenith)61AJ7

FloatSetting(Marvel-Schebler)

FloatSettincr(Zenith)1 5/32

EngineLowIdJerpm475

EngineHighIdlerpm1850

EngineLoadedrpm1400

SIZES-CAPACITIES-CLEARANCES

(Clearancesinthousandths)

CrankshaftJournalDiameter—Front2.2495

CrankshaftJoumalDia..CenterandRear.2.2495

CrankpinDiameter1.937

CamshaftJoumalDia.,FrontandCenter.

1.7495

CamshaftJournalDia.,Rear

1.7495

PistonPinDiameter8131

ValveStemDiameter11/32

CompressionRingWidth1/8

OilRing—Width3/18

MainBearings.Diam.Clearance.1-2

RodBearings.Diam.Clearance1-2

PistonSkirtClearance

2.5-4.5

CrankshaftEndPlay1-5

CamshaftBearingClearance2-4

CoolingSystem—Gallons2

CrankcaseOil—Quarts4

Transmission—(Quarts

Differential—Quarts

Transmission& Differential—Quarts6

FinalDrive,Each—Quarts75

AddlorPTOand/orBP1

B-C

CA

Own

CE

4

3%

125

6.2

5.75

5.2,4.7

Above

3

(1)

(1)

Wet

*

D-R

RC

Own

4

125

5.75

Above

3

(1)

(1)

Wot

4

D-R

we

WF

Own

4

4

4

201

5.5

Above

3

(1)

(1)

Wet

4

D-R

WD

Own

4

4

4

201

5.75

5.0,5.5

4.5.6.6

Above

3

(1)

(1)

Wet

4

D-R

Cont'L

N62

4

2%

62

6.5

5.4

Below

(3)

2

No

No

None

3

D-R

1,2,4,31,2,4,31,2.4,31,2,4,3

1.3.4.2

B&C.OIOH

CA.012H

45

D-R

1H1735

F-M

.020

30*"

TC

TC

DC

Fire

Fly.

.OIOH

45

None

F-M

.020

30*'

TC

TC

.012H

45

None

F-M

.020

30'

TC

TC

FireFire

By.Fly.

Auto-Lite,ACor

.012H

45

D-R

11H745

F-M

.020

30'

TC

TC

Fire

Fly.

.012C

45

D-R

1111708

Nono

.020

Notch

AN7

AHAuto-Lite

.032.035

-Marvel-Scheblerand

n47

.035

0orJ8Champion

orJllChampion

.035

161J7

15/32

475

2.2495

2.2495

1.937

1.7495

1.7495

.8131

11/32

1/8

3/16

1-2

1-2

2.5-4.5

1-5

2-4

2

4

6

(CA)8

.75

1

161J7

15/32

475

1850

1500

2.2495

2.2495

1.937

1.7495

1.7495

.8131

11/32

1/8

3/16

1-2

1-2

2.5-4.5

1-5

2-4

2

4

4

6

10

.5

i

TSX153

161X7

9/32

15/32

475

1575

1300

2.436

2.4775

2.3745(2)

1.8745

1.8745

.9892

3/8

1/8

3/16

2-3

1-3

2.5-4.5

3-7

2-3

4

6

4

6

10

75

TSX159

161AX

9/32

15/32

475

1720

1400

2.436

2.4775

2.3745

1.8745

1.8745

.9892

3/8

1/8

3/16

2-3

1-3

2.5-4.5

3-7

2-4

31/2

6

17

175

1

.025

Mar.-Scheb.

TSV13

475

2100

1800

1.9995

1.9995

1.4995

1.750

1.250

.5434

5/16

1/8

3/16

15-2.0

15-20

2.0

3-7

3-45

16*

3V2

WD45

Own

WD45

4

4

4.5

226

645

5.25

4.75

7.2

Above

3

(1)

(4)

Wot

4

D-R

h2,4,3

.012H

45

D-R

1111745

None

.020

TC

30^^B

DC

Fire

Fly.

.030

TSX464;

561

9/32

475

1720

1400

2436

24775

23745

1*8745

18745

9892

3/8

1/8

3/16

2-3

1-3

25-45

37

2A

17

^?iy ^'^ °^*^®"^^^' ^2)Onwepriortoserial3665crankpindiameteris1 9995

(3)Refertotextforalternativemethodofpistonremoval.(4)OnenginespriorW45FG1001,bearingshaveshimswhich

onlycontrolcrushofsheUinsert.OnenginesafterW45FG1001,thebearingsar«shimless.•Seeparagraph115

Paragraphs

1-2A

ALLIS-CHALMERS

FRONTSYSTEM-TRICYCLE

AND

AXLETYPES

ADJUSTMENT

OF

PEDESTAL

AND

FRONTSTEERINGGEAR

ModelsC-CA-RC-WC-WD-WD45

1.

C-CA

SINGLEFRONTWHEEL.

Toadjustverticalspindlebearings,

vary

the

shims(4—Fig.

ACl),

lo-

catedbetweentop

of

shaft

and

bearing

cone.

Radiatormust

be

removed

to

obtainaccess

to

shims.

Backlashbetweenbevelgears

of

front(auxiliary)steeringunitshould

be.002,

andis

adjusted

by

varying

the

shims

(9)

afterremoving

the

radiator.

Alternate

the

shimswithgaskets

to

prevent

oil

leaks.

lA.

C-CA

ADJUSTABLEFRONT

AXLE.

Thefrontsupportunit

on

these

modelshouses

the

frontsteeringgear

andcarries

the

pivot

pin

for

the

front

axle.

Internalconstruction,

Fig.AC2,

issame

as

singlewheelmodels.

Toad-

just,followsameprocedure

asout-

lined

for

singlewheel

C andCAin

precedingparagraph.

IB.

C-CADUALFRONTWHEELS.

Toadjustverticalspindlebearings,

vary

the

shims(4—Fig.

AC3)

under

capscrew

(2)at

top

of

shaft.

To

gain

access

to

shims, remove

the

pedestal

unitfrom

the

frontsupport.

Backlashbetweenbevelgears

of

front(auxiliary)steeringgearshould

be.002.Adjust

by

varying

the

shims

(9)beingsure

to

alternateshimswith

gaskets

to

prevent

oil

leaks.

2.

RC-WC-WD-WD45SINGLE

FRONTWHEEL.

On

RC-WC,

and

WD

modelspriorserialWD25129,thewheel

fork

and

verticalspindle

are

integral

asshown

in

Fig.AC4.

On

later

WD,

afterserialWD25128,

and

WD45,

the

wheelfork

is

flange bolted

tothe

verticalspindle

as

shown

in

Fig.ACS.

Adjustverticalspindlebearings

by

varyingshims

(4)

located

attopof

shaftunderneath

the

bearingcone

re-

tainer.

Toadjuststeeringwormshaftbear-

ings,

varyshims(46—Fig.AC6)

toob-

tainfreerotationwithzero

end

play.

Mesh

of

wormwithsector

isnotad-

justable.

Frontwheelbearings

are

adjusted

byvarying

the

number

of

shims(40—

Fig.AC4)locatedbetween

the

bearing

retainer

and

wheel

hub.

2A.RC-WC-WDWD45DUAL

FRONTWHEELS.

To

adjust

thever-

ticalspindleshaftbearings

to

thede-

sired.001-.003

end

play,varynumber

tr—2

20

Fig. ACI-MocfefsC and CA

singl9 wheeltric/cfever-

sionfront support and

front steering gear assem-

bly.

1. Radiatorsupport

2.

Cap

screw

a.Washer

4.

Shims

5.

Bearing:cone&

cup

6.Gasket

7.

Frontsupport

8.Bevelpinion

9.Shims

&

gaskets

10.

Bearing;retainer

12.

Verticalshaft

&

fork

13.

Oil

seal

14.

Bearing

cup&

eon«

16.

Steering

arm

shaft

16.

Oil

seal

17.

Bushinsrs

18.

Bevelsegmentgear

19.

Retaining

nut

20.

Draglink

Fig.ACa-ModefsCandCA

adfustobleaxleversion

frontsupport, front

steof'

ing gear,andaxlo assent'

bly.

1. Radiatorsupport

2.

Capscrew

3.

Washer

4.

Shims

6.Bearingcone

A cup

6.Gasket

7.

Frontsupport

8.Bevelpinion

9.Gasket

10.

Bearingretainer

13.

Oil

seal

14.

Bearingcone

& cup

16.

Steering

arm

shaft

16.

Oil

seal

17.

Bushings

18.

Bevelsegmentgear

19.

Retaining

nut

20.

Draglink

21.

Verticalspindle

&

center

steering

arm

22.

Pivotbracket

23.

Axlemainmember

24.

Spindlesupport

26.

Bushings

26.

Steeringspindle

27.

Bushing(radius

rod^

27

ALLIS-CHALMERS

Paragraphs2B-3

1.

Radiatorsupport

2.

Capscrew

3.

Washer

4.

Shims

6.Gasket

7.Frontsupport

8.Bevelpinion

9.Shims& gaskets

13.

Oilseal

14.

Bearingcone& cup

16.

Steeringarmshaft

16.

Oilseal

17.

Bushings

18.

Bevelsegment

19.

Retainingnut

20.

Draglink

29.

Pedestal

30.

Verticalspindle

31.

Sealretainer

32.

Seal

Fig.AC3—Mode/sC and CA dual wheeltrieyclo version

front support, pedestal, and front steering gear as^

sembly.

14

40

Fig.AC4-ModelsRCand WC single wheel

tricycle version front support and main

steering gear assembly, WD models prior

to serial WD 25129are similar.

1.

Cover

3.

Washer

4.

Shims

6.Bearingcone

7.Frontsupport

10.

Bearingretainer

12.

Verticalshaft&

fork

13.

Oilsea]

32.

Oilseal

34.

Snapring

36.

Sector

38.

Sectorkey

39.

Horizontalspindle

40.

Shims

41.

Bearingretainer

Fig.ACS-Models WD

&

WD4S

single wheel

tricycle version main steering gear and

wheel fork assembly. Effective on tractors

after serial WD 25129.kefer to Fig,AC 4

for

construction

details prior to WD 25T29.

2.

Capscrew

8.Washer

4.

Shims

6.Bearingcone&

cup

9.Gasket

10.

Bearingretains

cone&

18.

Oilseal

14.

Bearing

cup

34.

Snapring

36.

Sector

36.

Verticalspindle

87.

Wheelfork

ofshims(60—Fig.AC8)locatedat

bottomofspindle.

Toadjuststeeringwormshaftbear-

ings,

varythenumberofshims(46—

FigAC6)toobtainfreerotationwith

zeroendplay.Meshofwormwithsec-

torisnotadjustable.

2B.

WC-WDADJUSTABLEFRONT

AXLE.

Theverticalspindlebearings

andfrontsteeringgearonthesemod-

els.

Figs.AC7andAC9,aresimilarto

thesinglewheeltype,havingthe

bolted-ontypeoffork.Adjustment

procedureisalsothesameasoutlined

inparagraph2.

OVERHAULPEDESTAL& FRONT

STEERINGGEAR

ModelsC-CA-RC-WC-WD-WD45

3.

C-CASINGLEFRONTWHEEL.

Todisassemblepedestalandfrontgear

unit,removehoodandradiator,and

withtractorsupportedundertorque

tube,

removefrontwheelandhori-

zontalspindleassemblyfromfork.Re-

movecapscrew(2—Fig.ACl),washer

(3),

andshims(4)fromtopofver-

ticalspindleshaft(12).Removecap

screwsretainingbearingretainer(10)

tofrontsupport(7),andbumpshaft

downthroughupperbearingconeand

frontsupport.Withdrawshaft,gear

andbearingretainerassemblyasa

unitfrombottomoffrontsupport.The

needandtheprocedureforfurther

disassemblywillbedeterminedbyan

inspectionofthepartsandbyrefer-

encetoFig.ACl.Presizedbushings

(17)aresuppliedforsteeringarm

shaft,andifcarefullyinstalledre-

quirenosizingafterinstallation.

Fig.AC6-ModefsRC,WC, WD & WD45

single wheel, dual wheel, and adjustable

axle type steering gear assembly.

42.

Wormshaft

48.

Worm

44.

Retainingpin

46.

Spacer

46.

Shims

47.

Bearingcarrier

48.

Oilseal

49.

Expansionplug

Paragraphs3A-4ALLiS-CHALMERS

3A.Assembleretainer,

oil

seal,low-

erbearing,bevelpiniongearand

ver-

ticalshaft

asa

unit

and

install

in

frontsupportafterinstallingsteering

armshaft

and

segmentgear.Vary

the

number

of

shims

(9)

betweenretainer

andfrontsupporttoprovide.002back-

lashbetweenbevelpinion

and

bevel

segmentgears.Alternateshimswith

gaskets

to

prevent

oil

leaks.Pinion

gear

andtopof

verticalshaft

are

punchmarked

and

should

be

assem-

bled

asinFig.

ACIO.Piniongear

and

segmentgearshould

be

meshed

so

thatsteeringarm

isin

positionshown

in

Fig.

AC11whenfrontwheel

isin

straight-ahead,trailing(castering)

position

and

mainsteeringgear

isin

mid-position.Adjustverticalshaft

bearings

by

adding

or

removingshims

(4—Fig.

ACl)

between

topof

shaft

andbearingconeretainingwasher.

Fork Mounted Wheel.

To

remove

frontwheelandhorizontalspindle,

re-

move

cap

screws

and

axleretainer.

It

will

be

notedthat

the

corkseals

are

installedtoward

the

outside,

andthe

feltsealtoward

the

inside.

3B.

C-CA

ADJUSTABLEFRONT

AXLE.

Exceptthatverticalspindle

in

thefrontsupportterminates

ina

cen-

tersteering

arm

instead

ofa

wheel

fork,

the

externalparts

arethe

same

as

on

thesinglewheelmodelsoutlined

in

the

precedingparagraph.Refer

to

Fig.AC2.

7

35

1

38

.\

I /

61

5958

Fig, ACB-Models

kC, WC, WD &

WD45

dual wheel tricycle version front support,

and main steering gear assembly,

66.

Spindleblock

66.

Horizontalspindl*

67.

Spindlepin

68.

Capscrew

69.

Washer

60.

Shims

61.

Setscrew

1.

Cover

7.

Frontsupport

13.

Oilseal

28.

Sectorsetscrew

30.

Verticalspindle

82.

Oilseal

85.

Sector

88.

Sectorkey

54

2.

8.

4.

6.

9.

10.

18.

14.

22.

28.

24.

26.

26.

34.

86.

36.

60.

62.

64.

Capscrew

Washer

Shims

Bearingconeand

cup

Gasket

Bearingretainer

Oilseal

Bearingconeand

cup

Pivotbracket

Axlemainmem-

ber

Spindlesupport

Bushings

Steeringspindle

Snapring

Sector

Verticalshaft

Centersteering

arm

Thrustwashers

Radiusrodpivot

bracket

Fig, AC9-Models

RC,andWC

non-adjust-

abletype axle version front support

and

main steering gear assembly.

1.

Cover

8.Washer

4.

Shims

6.Bearingcone&

cup

7.

Frontsupport

10.

Bearingretainer

12.

Verticalshaft

13.

Oilseal

32.

Oilseal

34.

Snapring

36.

Sector

38.

Sectorkey

43.

Worm

Fig.ACJ-Models

WD and

WD45 adjustable axle version main

steering gear,

and

axle assembly.

3C.

C-CADUALFRONTWHEELS.

Todisassemblepedestal

and

front

steeringgear,supporttractorunder

torquetube

and

removefrontwheels.

Remove

cap

screwsretainingpedestal

(29—Fig.

AC3)to

frontsupport

(7)

andremovepedestal.Remove

cap

screw(2),washer

(3)and

shimsfrom

top

of

verticalspindleshaft

(30)and

pullpiniongear

(8)off

shaft.With-

drawshaft,bearingcone

andoil

seal

(13)frombottom

of

housing.Theneed

and

the

procedure

for

furtherdisas-

semblywill

be

determined

byanin-

spection

ofthe

parts

andby

reference

to

Fig.AC3.

Presizedbushings

(17)

aresupplied

for

steering

arm

shaft,

and

if

carefullyinstalledrequire

no

sizingafterinstallation.Removal

of

frontsupportfromtractorrequires

removingradiatorcore

and

detaching

supportfromengine.

3D.

Assemblesteering

arm

shaft

andsegmentgearbeforeinstalling

pedestalassembly.Piniongear

and

verticalspindleshaft

are

punch

markedandshould

be

assembled

asin

Fig.ACIO.Varynumber

of

shims(4—

Fig.

AC3)

between

topof

shaft

and

piniongearretainingwasher

tore-

move

all

bearingplay

but

permitting

shaft

to

turnwithoutbinding.Install

pedestalunit

in

frontsupportvarying

thenumber

of

shims

(9)to

provide

.002backlashbetweenpinionand

seg-

mentgear.Piniongear

and

segment

gearshouldbemeshed

so

thatsteering

arm

isin

positionshown

in

Fig.ACll

whenfrontwheels

arein

straight-

ahead,trailing(castering)positionand

mainsteeringgear

isin

mid-position.

4.

RC

-

WC" WD

-

WD45

W O R

M-

SHAFT.

To

disassemblewormshaft,

bump

pinoutof

steeringshaft

uni-

versaljoint

and

wormshaft

and

slide

universaljointback.Removesteering

shaftbearingbracket

(47)and

shims

ALLIS-CHALMERS

(46)fromrear

of

frontsupport

and

withdrawwormshaft

and

gear

as-

sembly.Shims

(46)canbe

varied

in

number

to

adjust

the

wormshaftbear-

ings.

4A.RC-WC-WD-WD45VERTICAL

SPINDLE.

On

singlewheelmodels,

theverticalspindle

is

supported

in

tworollerbearings;

onone

suchbear-

ing

inthe

dualwheelmodels.Refer

toFigs.

AC4,

ACS,AC7,

andAC8.

To

R

&

Ror

renew

the

verticalspin-

dle(30—Fig.

AC8)

and/orspindle

ta-

perrollerbearing,

it

will

be

necessary

tofirst supportfront

endof

tractor

underframerails

and

clutchhousing.

Remove

pin

fromstartingcrank

and

withdrawcrankfromfrontsupport.

Ondualwheeltype,removecover

(1)

PinionGear

TimingMarks

Fig.

ACIO—Correctposition

of

pinion gear

on vertical shaft

is

indicated

by

punch

marks.

Fig, ACll-Models

C and CA

dual,

and

single wheel tricycle versions. Pinion gear

and segment gear should

be

meshed

so

that steering

arm is in

position

as

shown

when front wheel

or

wheels

are in

straight-ahead, trailing (negative

caster^

ing) position,

and

main steering gear

is

in mid-position.

fromfrontsupport

andset

screw

(28)

fromsector

(35).

Using

a

suitable

puller,removesector

andkey.

With-

drawverticalspindle

and

horizontal

(axle)spindleunitfrombottom

of

support.Verticalspindletaperroller

bearingconeand/orcup,

andoil

seals

(13

or32),canbe

renewed

at

this

time.

Onsinglewheelmodels.Figs.

AC4

&AC5,first removeretainerplate(3—

Figs,

AC4& ACS)

and

shims

(4)

from

top

of

verticalshaft.Removestudnuts

whichholdretainer

(10)to

bottom

of

frontsupport.Removeverticalspindle,

bearings,sector

and

bearingretainer

as

an

assemblyfromfrontsupport.

4B.

Whenreassembling,adjust

ver-

ticalspindlebearings

of

dualwheel

models

by

varyingnumber

of

shims

(4—Fig.AC3).

On

single(forkmount-

ed)wheeltypes,adjustbearings

by

varying

the

number

of

shims(4—Figs.

AC4

&

ACS).

4C.

RC-WC-WD-WD45WHEEL

AXLE.

On

dualwheeltype,

the

hori-

zontalspindles(S6—Fig.AC8)

arein-

dividuallyavailable

for

service.Indi-

vidualspindles

canbe

removedfrom

thespindleblockafterremoving

the

frontwheels,retaining

pin(S7)and

adapting

a

combinationpuller.

Horizontal(axle)spindles

and

block

(S5)

canbe

removed

asan

assembly

afterfirst removing

the

wheels,

cap

screw

(58),

washer

(59),

shims

(60)

andspindleblockretaining

set

screw

(61).

Onsinglewheeltype

the

spindle

bearings

are

adjusted

by

varying

the

number

of

shimslocatedbetweenbear-

ingretainer

and

wheelhub.Shims

are

shown

at

(40—^Fig.

AC4).

Paragraphs4A-7A

FRONTAXLEMEMBER

AllModels

5.

Adjustable,Figs.

AC2,7,and

13,

or

non-adjustable.Figs.

AC14&

AC15typefrontaxles

are

either

of-

fered

orare

available

onall

models.

On

all

suchmodels,

the

axlemain

membercompletewithwheelspindles

orknuckles

and

wheels

canbere-

movedfrom

the

tractor

asa

single

unit.Exactprocedurevarieswith

the

variousmodels,

butis

self-evident

af-

terobserving

the

actualtractor.

On

B,

C,CA,G,WDand

WD45,

thera-

dius

rodis

integral

(by

beingwelded

thereto)with

the

axlemainmember.

SPINDLE(KNUCKLE)BUSHINGS

6.Steeringspindlebushings

and

axle

pivotbushingsshould

be

renewed

if

thediametralclearanceexceeds

.020.

Steeringspindlebushingsusually

re-

quirefinal sizing

to

provide.002-.005

clearancebetweenspindle

and

bush-

ing.

To

remove

all

wear

in

systems

employing

the

Lemoinetypespindles

as

in

(26—Figs.

AC2,7,and13),it

may

be

necessary

to

alsoinstall

new

spindles.Recommendedfrontwheel

toe-in

of

0-1/16inch

is

adjusted

by

varying

the

length

oftie

rods.

RADIUS

ROD

7.

MODELSB-C-CA.Rear

endof

radius

rodis

pivoted

ina

removable

bushing(27—Fig.

AC2)inthe

front

end

ofthe

torquetube(clutchhous-

ing).

Bushingrenewalrequired

re-

moval

of

frontaxle

and

integralradius,

rod.

7A.MODELSRC-WC.

To

remove

radius

rod,

detachfront

end

fromaxle

andsliderear

endoff

rear

endof

extendedaxlepivot

pin.

51

23.

Radiusrod(weldedtoasde

member)

24.

Spindlesupport

25.

Bushings

26.

Steeringspindle

33.

Steeringarm

60.

Centersteeringarm

61.

Pivot,radiusrod

63.

Bushing,axlepivot

66.

Dustshield

67.

Tierod& socket

68.

Pivotpin

Fig.

AC13—Model

G

adjustable axle

has

Lemoine type

knuckles, Pndius

rod is

welded

to

axle main member.

Paragraphs8-18

8.MODELSG-WD-WD4S.Radius

rodisintegralwithfrontaxleandis

supportedinanunbushedbracketon

WDandWD45buttheG isprovid4'd

witha removablebushing.

9.MODELWF.Toremoveradius

rod,detachfrontendfromaxleand

removeboltattachingrearendtosup-

portplateonclutchhousing.

PIVOTPIN(KINGPIN)

10.

MODELB.Pivotpiniswelded

tofrontaxlesupportplateandaxle

isretainedtopivotpinbya cotterpin.

Onadjustableaxlemodels,axleis

equippedwitha bushingforthepivot.

11.

MODELSCA-WD-WD4S.Pivot

pinisweldedtoaxlemainmember

andridesinanunbushedbracket.

12.

MODELG.Pivotpincanbe

pressedoutofaxlemainmember.It

isprovidedwitha splittyperenew-

ablebushinglocatedinfrontframe.

13.

MODELSRC-WC.Pivotpincan

beremoved,afterremovingradiusrod,

bydisconnectingpivotpinbracket,

removingsetscrewfromaxle,and

drivingpinrearwardoutoffrontsup-

portandaxle.

14.

MODELWF.Pivotpincanbe

drivenoutoffrontsupportafterre-

movingcotterpinfrombehindaxle

andretainingpinfromsupport.

MAINSTEERING

GEAR

Serviceinformation in this section applies

to models B, G,and WF, which have only a

main steering gear, and to the main steering

ing gear only on models C and CA, For in-

formationon the adjustment and overhaul oi

the front or auxiliary gear on models C, CA,

RC, WD, and WD45 refer to paragraphs 1

through 4A.

B-CGemmerGear

(Refer to paragraphs 1,lA,IB,3,3A,

3Band 3Cfor model C front steering

gear, and to paragraphs 22,23,and 24

for Ross main gear.)

16.

Endplayofwormshaftandsec-

torshaftmustbeinadjustmentbefore

adjustinggearbacklash.Disconnect

draglinkorremoveballarm(steering

arm)toremoveloadfromgearand

permitlocatingmid-position.

17.

WORMSHAFTENDPLAY.

Firststepinmakingthisadjustmentis

toremovethefueltank.Toreduce

playinwormshaftbearings,remove

thesteeringwheel,loosenclamp(81—

Fig.AC16)andslidetube(82)up

column.Removecapscrewsretaining

housingcap(80)tohousing(onB and

Cworkthroughtoolboxopeningto

removetwolowerscrews),andslide

tubeupandawayfrombearingre-

tainer.Removeshims(78)untilworm

shafthaszeroendplay,butrotates

freely.Whenre-positioningtube,be

ALLIS-CHALMERS

sureupperenddoesnotbindsteering

wheel.

18.

SECTORSHAFTENDPLAY.It

isadvisabletoremovethestarter

motorforbetteraccesstothisadjust-

ment.Toadjustsectorshaft(8S)end

play,placesteeringwheelabout%

Fig.AC14—ModelB non-ad/ustableaxle version—front and top views.

23.

Radiusrod(welded

toaxlemember)

26.

Bushings

26.

Steeringspindle

27.

Bushing(radiusrod)

68.

Pivotpin

26

72

Fig.ACI5~ModelsftC andWC non-adjustable axle version-front view.

20.

Drag link

22.

Frontsupport

23.

Axlemember

26.

Bushing

26.

Spindle

62.

Thrustwasher

68.

Pivotjpin

69.

Setscrew

70.

Oilseal,hub

71.

Spindlelockstud

72.

Expansionplag

73.

Spindlepia

10

ALLIS-CHALMERSParagraphs19-22

turnfromeitherextremeposition,

loosenlocknut(87)andturnadjusting

screw(86)clockwisetoreduceend

play.Besurehousingnuts(92)and

(93)aretightwhenmakingthisad-

justment.Allendplayinsectorshaft

75

87

90

88

Fig.ACI6--aeminersteering gear assembly as vsetfin early production B and

C

models.

75.

Expansionplug

76.

Housing

77.

Worm£ shaft

78.

Shims& gaskets

80.

Housingcover

81.

Tubeclamp

82.

Jackettube

83.

Bushing

86.

SectorA shaft

86.

Adjustingscrew

87.

Locknut

88.

Eccentricrivet

89.

Bushing

90.

Steeringarm(ballarm)

91.

Sectorshafthousing

92.

Housingnut

93.

Jamnut

94.

Conicallockring

96.

Eccentricsleeve

96.

Oilseal

907576

100

9689

,^

Hg, ACir—koss steering gear assembly (exploded view) as used in later and current

production B, C, and all

CA

tractor models.

76.

Expansionplug

76.

Housing

77.

WormA shaft

78.

Shimsft gaslcets

80.

Housingcover

81.

Tubeclamp

82.

Jackettube

83.

Bushing

86.

Sector& shaft

89.

Bushings

90.

Steeringarm

96.

Oilseal

99.

Sidecover

100.

Housingbracket

101.

Oilseal

103.

Snapring

104.

Bearingcup

106.

Bearingball

106.

Gasket

shouldbeeliminatedbutgearshould

notbind.

19.

GEARMESH.Toadjustgear

mesh,loosencolumnbracketclamp

andlocatemid-positionofgearby

turningsteeringwheelfromoneex-

tremepositiontotheotherthenback

halfway.Withgearinmid-position,

loosenhousingretainingnuts

V4,

turn

andeccentricsleevejamnut(93)V2

turn.

Slowlyturneccentricsleeve(9S)

clockwisewhilecheckingamountof

gearbacklashbyfeelingplayinball

arm.(Turningeccentricsleeveclock-

wisemovessteeringgearhousing

downinrelationtosectorshafthous-

ingbringingwormandsectorinto

deepermesh,therebyreducinggear

backlash.)Adjusteccentricsleeveun-

tilplayinballarmisbarlypercepti-

ble,

whensteeringwheelisinmid-

position.Makelastadjustmentofthe

eccentricsleeveintheclockwisedi-

rection.Aftermeshadjustmentiscom-

pleted,tighteneccentricsleevejam

nut,thenhousingnuts.

20.

CENTRALIZATION.Checkgear

centralizationbydeterminingamount

ofplayinballarmwhenwheelis

turned% turntotherightand%

turntotheleftofmid-position.Ifplay

isnotthesameonbothsidesofmid-

position,loosenhousingnutsandec-

centricsleevejamnutV4 turnand

centralizegearbyturningeccentric

rivet(88).Ifthereismoreplaytothe

right,turnrivetclockwiseandifmore

totheleft,turnrivetcounterclockwise.

Aftergearhasbeencentralized,re-

adjustgearijieshwitheccentricsleeve

aspreviouslydescribed.Ballarm

shouldbepositionedonsectorshaftso

thatsteeringgearisinmid-position

whenwheelsarestraightahead.

21.

OVERHAUL.Gearunitshould

beremovedfromtractor.Procedureis

readilyevidentfromanexamination

ofFig.AC16.Whenreassembling,in-

stallwormgearandshaftassembly

andadjustwormgearbearingsbefore

assemblingbalanceofsteeringgear.

Forcompleteadjustmentprocedure,

refertoparagraphs17through20.

B-C-CA-G-WF(RossGear)

(Refer to paragraphs 1,lA, IB, 3,

3A,3Band 3Cfor models C-CA front

gear and to 16through 21for Gemmer

main gear.)

Beforeadjustingthegear,discon-

nectdraglinkorremovesteeringarm

toremoveloadfromgearandpermit

locatinginmid-position.

22.

WORMSHAFT(CAM)END

PLAY.OnB,C,andCA,firststepin

makingthisadjustmentistoremove

thefueltank.Toreduceplayincam

11

Paragraphs23-27ALLIS-CHALMERS

Fig.ACl8—Ross steering gear installation

on models

B, C,and

CA. Wormshaff bear-

ings adjustment

can be

made after

re-

moving

the

fuel

tank.

76.

Housing

78.

Shims& gaskets

80.

Housingcover

82.

Jackettube

86.

Adjustingscrew

87.

Locknut

108.

Tube clampbolt

Fig.AC79—RosssfeeringgearInsfallaflon

onmodel

G

tractor.

78.

Shims& gaskets

80.

Housingcover

81.

Tube clamp

82.

Jackettube

86.

Adjustingscrew

99.

Sidecover

108.

Tubeclampbolt

109.

Housingcover

capscrews

(worm)bearings,removesteering

wheel,loosencolumnjackettube

clampFigs.AC17,AC18,AC19

andAC

20,

and

supportclamp;thenslide

tube

(82)up

column.Remove

cap

screwsretaininghousinguppercover

(80)

to

housing

(onB,C,andCA,

workthroughtool

box

opening

tore*

move

two

lower

cap

screws).Remove

shims

(78)

untilshaft

has

zero

end

play,

but

rotatesfreely.

23.

STUD(LEVERSHAFT)MESH.

OnB,

C,and

CA,

itis

advisable

tore-

move

the

startingmotorbefore

at-

temptingthisadjustment.Locate

mid-

position

of

steeringgear

by

turning

steeringwheelfrom

one

extremeposi-

tion

tothe

other,thenbackhalf-way.

Withgear

in

mid-position,loosenlock-

nut(87—Fig.AC18

or

AC20)

and

turn

adjustingscrew

(86)

clockwiseuntil

endplay

in

levershaft(crossshaft)

is

78

77

97

Fig.

AC70—ROSS

steering gear assembly

as

used

on

later production model

WF

fracfor.

76.

Expansionplug

77.

Worm& shaft

78.

Shims& gaskets

80.

Housingcover

81.

Tube clamp

82.

Jackettube

83.

Bushing

86.

Sector& shaft

86.

Adjustingscrew

87.

Locknut

89.

Bushings

90.

Steeringarm

96.

Oilseal

97.

Snapring

99.

Sidecover

barelyperceptible.

Be

surehousing

cover

cap

screws

areall

tightwhen

makingthisadjustment.Shaftshould

have

an

increasedamount

ofend

play

whengear

is

movedeither

wayoff

the

mid-or

highpoint.Steering

arm

should

be

positioned

on

levershaft

sothatsteeringgear

isin

mid-position

whenwheels

are

straightahead.

Onmodel

G,

steeringwheelshould

bepositioned

on

levershaftsplines

in

suchmannerthatwithfrontwheels

pointingstraightahead,

the

cutaway

section

of

steeringwheel

is

located

between

the

12

and4

o'clockpositions.

24.

OVERHAUL.

On

models

B,C,

and

CA,

removal

ofthe

gearunit

re-

quiresremoval

of

fueltank,starting

motor

andits

linkage,negative

bat-

terycable,steeringwheel

and

shroud

retainingbolts.Afterunboltingfrom

torquetube,withdrawunitforward

until

itis

freefromshroud.

The

inner

races

forthe

wormshaftballbearings

areformed

bythe

groundends

ofthe

worm

orcam

itself.

The

levershaft

is

supported

ontwo

renewablebushings,

which

are

pressedinto

the

gearhous-

ing.Whenreinstalling

the

jackettube

(82)

the

notch

atits

lower

end

should

be

up,to

preventgreaseleakage.

Of

the

cap

screwsretaining

the

column

shaftcover,

the

lower

oneor

ones

re-

ceive

the

greasesealingcopperwash-

ers;

the

other

cap

screws

are

provided

withlockwashers.

RC-WC-WD-WD45

Steeringgear

on

thismodel

islo-

cated

in

frontsupport.Refer

to

para-

graph

4 and4Afor

adjustment

and

repairdata.

WF(LavineGear)

Beforeadjusting

the

gear,discon-

nectdraglink

or

removesteering

arm

toremoveloadfromgear

and

permit

locatingmid-position.

26.

WORMSHAFT

END

PLAY.

To

reduceplay

in

wormshaftbearings,

removeshims(78—Fig.

AC21)

from

betweenhousinglowercover

(80)and

housing

(76).Allend

playshould

be

removedfromwormgear

but

shaft

should

not

bind.

27.

GEARMESH.Locatemid-posi-

tion

of

steeringgear,withdraglink

disconnected,

by

turningsteering

wheelfrom

one

extremeposition

to

theother,thenbackhalf

way.

With

gear

in

mid-position,loosenlocknut

andturnadjustingscrew

(86)

clock-

wise

to

reduce

end

play

in

trunnion

shaft

(8S).Be

surehousingcover

re-

taining

cap

screws

are

tightwhen

makingthisadjustment.When

end

play

inthe

trunnionshaft

is

reduced,

drive

nut(107)is

mesheddeeperinto

wormgear

(77)and

backlash

isre-

12

ALLIS-CHALMERSParagraphs28-65

77

78

76.

Housing

77.

Worm& shaft

78.

Shims& gaskets

80.

Housingcover

81.

Tubeclamp

82.

Jackettube

83.

Bushing

86.

Trunnionshaft

sr*.Adjustingscrew

8!>.Hushings

90.

Steeringarm

96.

Oilseal

98.

Thrustball

99.

Sidecover

107.

Drivenut

Fig.AC2I—tavinesfeeringgearassembly as used on early production model

WF

tractor.

duced.Steeringarmshouldbeposi-

tionedontrunnionshaftsothatsteer-

inggearisinmid-positionwhen

wheelsarestraightahead.

28.

OVERHAUL.Gearunitshould

beremovedfromtractor.Procedure

fordisassemblyisreadilyevidentfrom

anexaminationofFig.AC21.

NON-DIESEL

ENGINEANDCOMPONENTS

R&RENGINEWITHCLUTCH

Models

B-C-CA

60.

Removehoodanddisconnect

fuellines.Supporttractorunder

torquetube.Disconnectsteeringdrag

link(alsoradiusrodretainingnutif

used),

upperandlowerradiatorhoses,

andlightwires.Withfrontaxleand

radiatorandgrilleunitsupported,re-

movefournutswhichretainfront

supporttoengine.Movethefrontsup-

portradiatorandpedestaloraxleas

aunit,awayfromtheengine.Discon-

nectgovernorcontrol,wiresatcoil,

andgenerator,chokerod,andfuel

line.

Withweightofenginesupported

byhoist,removethefourboltsretain-

ingenginetotorquetubeandremove

engineunit.

ModelG

62.

Toremoveenginefromthetrac-

tor,draincoolingsystemandoilsump.

Shutofffuelsupplyattankconnec-

tion.Removehood,hoodsupport

(sheetmetalcoverfromtiminggear

coverendofengine)andupperand

lowerradiatorhose.Removethe

drawbarguide.Disconnectstarter

controlrod,chokerod,headlightwire,

andbatterycableatstarter.Discon-

nectfuellineandremovethrottlerod.

Theenginemaybesupportedfrom

theextremeendsofthefanshaft

bearingsupports,orbyusinga proper

lifthookthreadedintothenumber

threesparkplughole(cylindersare

numberedfromtiminggearend).Re-

movestartingmotorandboltsretain-

ingenginetoclutchhousing.Engine

may nowberemovedbypullingsame

forwardtoreleaseclutchshaftfrom

clutchplate.

ModelRC

63.

Removehoodanddisconnect

fuellines,electricalconnections,and

controls.Removeradiatorandcrank

pinlocatedjustbehindfrontsupport

andpullcrankforward.Supporten-

gineinhoistandremoveenginefront

support,flywheelcoverandcap

screwsretainingenginetoclutch

housing.

ModelsWC-WD-WF-WD45

64.

Removehoodandradiator.Dis-

connectfuelline,aircleanerhoseand

generatorwire.Disconnectchokerod

andthrottlerod.Supportenginewith

ahoist.Attachtheliftbrackettotwo

oftherockershaftsupportstuds.Re-

moveuniversaljointretainingpin

fromsteeringwormshaftandslide

steeringshaftanduniversaljointrear-

ward.

Removetwocap screwsandtwo

boltsretainingfrontenginesupport

toframerailsandtiminggearcover.

Removedustshieldfromfrontlower

faceofclutchhousing.Removecap

screwsretainingenginetoclutch

housing.Removestartingcranksup-

portandpullstartingcrankforward

against^ringi5ressure.Slideengine

forwarduntilfreeofclutchhousing

dowelpins.Raisefrontofengine

untilcrankshaftpulleyclearstheaxle

frontsupportandatthesametime

slidetheengineforwarduntilthe

clutchclearstheclutchhousing.Raise

engineclearofframerailsandatthe

sametimetipit^towardleftsideof

tractorsoastoclearsteeringshaft.

Shimslocatedbetweenenginefront

supportandlowersideoftiminggear

covershouldbevariedtoobtainpro-

perenginealignment.Thecheckfor

correctengine-to-clutchhorizontal

alignmentshouldbemadeafterthe

engineisboltedtotheclutchhousing

andbefore thefrontsupporttotiming

gearcovercapscrewsarereinstalled.

R&RENGINEANDCLUTCH

HOUSINGASA UNIT

ModelG

65.

Clutchhousingandenginecan

beremovedasa unitbyfollowing

theengineremovalproceduretothe

pointofremovingtheenginetoclutch

housingretainingbolts.Atthistime

disconnectclutchpedalrodfrom

throwoutbearingforkandunhook

thebrakereturnspringsatthebot-

tomoftheradiatorsupport.Usethe

sameliftarrangementasforengine

removal,exceptthebalancepointwill

beabout4 inchesclosertoflywheel

endofengine.Removeclutchhous-

ingtotransmissioncaseretaining

13

Paragraphs66-70

bolts.

Engineandclutchhousingunit

maynowberemovedbypullingsame

rearwardtounmeshclutchshaftgear

frommainshaftintermediategear.

CYLINDERHEAD

AllExceptModelG

66.

Toremovecylinderhead,re-

movehoodanddraincoolingsystem.

Removecylinderheadcover(rocker

levercover)androckerarmsassem-

bly.Unboltcarburetorfrommanifold

andallowsametohangonairfilter

hose.

Disconnectwateroutletcon-

nectionandoilconnectiontocylinder

head.Removecylinderheadcap

screwsornuts(alsoremovewater

manifoldonWC,WD,WD45andWF)

andliftoffhead.Whenreinstall-

ing,tightenheadnutsorcapscrews

progressivelyandfromthecenterout-

ward.Retightenafterenginehas

reachedoperatingtemperature.Tight-

enmodelsB,C,CA,andRCcapscrews

to60footpoundstorque.Tightenmod-

elsWC,WD,WD4SandWFV2inch

studsto70footpoundsand% inch

studsto2Sfootpoundstorque.

ModelG

67.

Toremovecylinderhead,first

removehoodandsupport,anddrain

coolingsystem.Removecarburetor

airintake,aircleaner,instrument

panel,fanassembly,sparkplugwire

bracket,andupperradiatorhose.Re-

movecylinderheadretainingcap

screwsandnutsandliftoffhead.

Whenreinstalling,tightenhead

nutsprogressivelyandfromthecen-

teroutward.Retightenafterengine

hasreachedoperatingtemperature.

Tightenthe% inchcapscrewstoS3-

S7ft.lbs.torque.

VALVESANDVALVESEATS

AllExceptModelG

68.

OnB,C,andRCtappetsshould

besethotto.010forinletandex-

Flg.

AC23-WDengines after engine serial

299173, and engines 262650 through 263-

224 andWD4S are factory equipped with

kotocap positive type valve rotators for

the exhaust valves, kotators are also

available for service on the WC and WF

engines.

haustvalves.OnCA,WC,WD,WD-

45andWFtappetsshouldbesethot

to.012forbothinletandexhaust.

Inletvalveswitha slightlylarger

headthanexhaustvalvesseatdirectly

inthecylinderhead.However,inlet

valveseatsinsertsareavailablefor

service.Oversizeexhaustvalveseat

insertsareavailableforinsertre-

newal.Bothinletandexhaustvalves

havea faceandseatangleof4Sde-

grees.

Desiredseatwidthis1/16inch.

Seatscanbenarrowed,using30degree

and60degreecutters.

EnginesinWD& WD4Safteren-

gine299173andengines262650

through263224,arefactoryequipped

withRotocappositivetypevalvero-

tatorsfortheexhaustvalves.Fig.

AC23.

Theserotatorsarealsoavail-

ableforserviceontheWCandWF

engines.Theyrequirenomaintenance

butshouldbevisuallyobservedwhen

engineisrunningtomakesurethat

eachexhaustvalverotatesslightly.

Renewtherotatorelementofany

exhaustvalvewhichfailstorotate.

ModelG

69.

Tappetsshouldbesetcold.012

inlet,andexhaust.Inletandexhaust

valvesarenotinterchangeable.Inlet

valveshaveroundpintypespring

lockswhiletheexhaustvalves,which

areprovidedwithRoto-valverelease

typerotators,havesplitconetype

locks.

Allvalvesseatdirectlyinthe

cylinderblockandhavefaceandseat

anglesof45degrees.Desiredseat

widthis3/64inch—recutifwiderthan

1/16inch.Seatsmaybenarrowed,us-

ingISdegreeand75degreecutters.

Agaporendclearanceofnotless

than.001andnotmorethan.006be-

tweenendofexhaustvalvestemand

bottomofRoto-valvecupshouldexist

whenvalveisonitsseat.Referto

Figs.

AC24andAC2S.

ALLIS-CHALMERS

VALVEGUIDES

AllExceptModelG

70.

Thecastironpresizedshoulder-

lessvalveguidesarepressedintothe

cylinderheadwitha piloteddriftuntil

scribelinemarkonguideisfiush with

machinedsurfaceofvalvespringseat.

RefertoFig.AC32,forWD& WD4S

installation.Inletguidesare7/32inch

Fig.

AC2S—A

gap or end clearance (O), of

.001-.006shouldexist in a koto-valve in'

stallation when the valve Is on Its

seat.

Fig, AC24—G tractor engine (N62 Confl-

nental) exhaust valves are provided with

koto-valve release type rotators. Fig, AC26—ModelsB, C, CA, and RCengine

valvesystem—end

view*

14

ALLIS-CHALMERS

longerthanexhaustguidesandextend

fartherintotheports.Desiredclear-

anceoftheinletandexhaustvalve

stemsintheguidesis.002S-.0045.

ModelG

71.

Inletandexhaustguidesare

interchangeable.Theyarepresized,

butshouldbereamedafterinstallation

to.316whichwillremoveanylocal-

izedhighspots.Guidesshouldbe

pressedordrivenintotheblock,using

apiloteddrift.002smallerthanbore

ofguide,untiltopofeachguideis

25/32inchbelowgasketsurfaceofthe

cylinderblock.Desiredclearanceof

inletvalvestemsinguidesis.002—

ofexhauststems.0035.Ifinletclear-

anceexceeds.005,orexhaustclear-

anceexceeds.007,renewtheguides.

VALVESPRINGS

72.

ModelG,inletandexhaustvalve

springsareinterchangeable.Each

springshouldrequire13-17lbs.pres-

suretocompressittoa heightof1%

inchesfromitsfreelengthof1 13/16

inches.

Springcanberemovedwithoutre-

movingheadbyscrewingadjusting

screwdownagainstlockandholding

valveupwithwirethroughspark

plughole.

Onothermodelsspringshould

require33-39lbs.pressuretocom-

Paragraphs71-75

Fig.

AC2a-ModelsWC,WD,WD45 and WF cylinder head and rocker arm assembly

showing exhaust valve seat inserts. Inlet valve seat inserts are available for service,

1.

Retainer4.Support7.Oiltube

2.

Washer 5.Rockerarm8.Rockerbusbinir

3.

Supportstudnut6.Oilcollar

pressittoa heightof1%inchesand

SS-65lbs.ata heightof1 S/16inches.

Springswhicharerusted,distorted,

ordonotmeettheforegoing pressure

specificationsshouldberenewed.On

overheadvalvemodels,springsmay

berenewedwithoutremovingthe

cylinderheadafterremovingthe

rockershaft.

CAMFOLLOWERS(Tappets)

AllExceptModelG

73.

Mushroomtypetappets(cam

followers)operatedirectlyinma-

1.

Pintypelock

2.

Inletvalve

3.Valvesuide

4.

Valvespring

6.Springretainer

6.Tappetscrew

7.

Locknut

8.Valvetappet

9.Camshaft

10.

Thrustplate

11.

Camgear

16.

Rotocap

18.

Splitconelock

Id.Exhaustvalve

IS-

IS-^

Fig.

AC27-Model G camshaft, valves and tappets. Note governor vent (X) in camshaft

and items (16) and (IB) which are used only on the exhaust valves.

chinedboresofthecylinderblock.

Tappetsarefurnishedonlyinstandard

sizeandshouldhavea clearancein

blockboresof.OOOSto.002witha

maximumallowableclearanceof.007

forservice.Anytappetcanbere-

moveda^terremovingtheoilpan,

rockerarmsandshaftsassembly,oil

pump,timinggearcoverandcam-

shaft.Tappetsshouldbeadjustedto

.010hotforB,C,andRC;.012hot

forCA,WC,WD,WD4SandWF.

ModelG

74.

Barreltypetappets(camfol-

lowers)operatedirectlyinthebores

machinedinthecylinderblock.Tap-

petscanberemovedbyfirst remov-

ingthevalvespringwhichisaccom-

plishedbyturningtheadjustingscrew

downagainstthelockandholdingthe

valveupwitha wirethroughthe

sparkplughole.Nowremovethetap-

petscrewandlockelementfromthe

tappet.Tappetsshouldbeadjusted

coldto.012forbothinletandexhaust

valves.Tappetsarefurnishedonlyin

standardsizeandshouldhave.001

clearanceinblockbores.

VALVEROCKERARMS

AllExceptModelG

75.

Rockerarmsandshaftsunit

canberemovedafterremovingthe

hood,valvecover,oillinefromcyl-

inderheadtorockerarmsandfour

shaftsupportretainingnutsandwash-

ers.

Todisassembletherockerarmsand

shaftsassembly,removehairpintype

retainerorcotterpinandwasherfrom

endsofshaft.Thevalvecontacting

surfaceofrockerarmscanberefaced,

butthesurfacemustbekeptparallel

torockerarmshaftandoriginalradius

maintained.Desiredclearancebe-

tweena rockerarmbushinganda new

15

Paragraphs76-80

shaftis.002-003. Ifclearanceexceeds

.008,

renewtherockerarmandbush-

ingunitand/orshaft.Earlyproduc-

tionengineswereequippedwith

forgedrockerarmswhichhavebeen

discontinuedandreplacedbybuilt-up,

stampedsteeltypeonallmodels.

Rockerarmbushingsarenotavailable

separatelyexceptforthediscontinued

forgedtyperockerarms.

Theinletvalverockerarmcanbe

identifiedbya millednotchlocatedon

itsuppersurfacebetweenshaftand

valvestemend.Reinstallrockerarm

shaftswiththeoilingholestoward

thecylinderhead.

OnB,C,CA,andRC,thegrooved

supportstudshowninFig.AC29

shouldbeinstalledinrearstudhole.

Thisstudactsasanoilpassageto

lubricaterockershaft.

Onallmodelsbesuretoinstall

copperorcompositionwashersbe-

tweencoverandcovernutstoinsulate

noise.

VALVETIMING

AllExceptModel

G

76.

Valvesarecorrectlytimedwhen

markedtoothofcrankshaftgearis

meshedwiththecorrectmarkon

camshaftgear.Ifcamshaftgearhas

twoidenticalmarks,theoneopposite

thekeywayshouldbemeshedwith

markedtoothofcrankshaftgear,and

theoppositeonewiththemarkonthe

magnetogear.All"CE"enginesand

"BE"

enginesnumberedBE12550and

higherhavecamshaftgearmarked

witha straightlineandan"O"ora

dot.Ontheseengines,meshthe

straightlineofthecamshaftgearwith

thesimilarlymarkedtoothonthe

ALLIS-CHALMERS

Fig, AC29~Models

B, C,

CA,

and

RCrocker

arms, kocker shaft rear support stud

is

grooved

to

provide

oil

passage

to

rocker

arms.

Fig, AC30

-

Timinggear

marks

on all "d"

engines

and

"BE"

engines

num-

bered BiJ25S0

and up. On

"BE" engines prior

to

BB-

12550,

the

camshaft gear

has

two

identical marks;

the

one

opposite

the key-

way should

be

meshed

with

the

crankshaft

gear.

crankshaftgearandthe"O"mark

withthe**O"markonthemagneto

gear.RefertoFig.AC30.

Numberonecylinderinletvalve

opensattopcenterandexhaustvalve

closes10degreesaftertopcenter.

Tocheckvalvetimingwhenengine

isassembled,adjustnumber1 inlet

valveclearanceto.014.Inserta .004

feelergagebetweenrockerarmand

valvestemandrotatecrankshaftuntil

aslightdragisfeltwhiletryingto

withdrawthefeelergage.Atthistime,

thetopcentermarkonfiywheel should

beinregisterwith,ornotmorethan

V4incheitherwayfromcenterofin-

spectionport.Resettappetgapto

properclearance.Onflywheelswhich

donothavea topcentermark,the

topcenterpointcanbeestablishedby

measuringbackfromthe"Fire"or

"F"

markorbyusingthestarterring

gearteethasa basisforcalculation.

OntheWD,whichhasa ringgearof

100teeth,TCwould be8 1/3teeth

(3yg"onrim)afterthe"Fire"mark,

asshowninFig.AC46.

Model

G

77.

Tochecktimingwhenengine

isassembled,adjustbothtappetsof

No.

4 cylinderto.020,thencranken-

gineuntilNo.4 pistonisattopcenter

ontheexhauststroke.Thispointis

indicatedwhenthenotchoncrank-

shaftpulleyisVsinchpastthecenter

oftheinspectionport,locatedinthe

hoodsupportasshowninFig.ACS3G.

Ifvalvesarecorrectlytimed,both

valveswillnowbeclosedanditshould

bepossibletorotatebothtappetb

withthefingers.

TIMINGGEARCOVER

ModelsB-C-CA

78.

Toremovecover,removetractor

hoodandsupporttractorundertorque

tube.

Removeradiatorandaxleor

pedestalandfrontsupportasa single

unit.Disconnectgovernorcontrols,

andremovegovernorcontrolhousing.

Removecrankshaftpulley,fanblades.

andfanbelt.Onsomeengines,the

front-centeroilpanretainingstudis

weldedtotheangleironontiming

gearcover,necessitatingremovalof

theoilpanassembly.Wherethesfud

isnotwelded,covercanberenewed

withoutremovingtheoilpan,butas

aprotectionagainstsubsequentoil

leaks,

itisadvisabletoalwaysremove

theoilpan.Ifoilpanisnotremoved,

theoilpangasketmustbeverycare-

fullyseparatedfromthetiminggear

cover.Screwsofthreedifferent

lengthsareusedtoretainthecover;

besuretheyareinstalledinthecor-

rectlocations.

Model

G

79.

Althoughitispossible torenew

crankshaftfrontoilsealwithout

removingthetiminggearcover,our

suggestionistoremovethecover,

whichentailslittleadditionalwork.

Toremovethetiminggearcover,re-

movethehood,hoodsupportand

crankjaw.Disconnectcarburetorlink

rodandgovernorspring.Remove

pulley,usinga pullerandtwo% inch

capscrew§toattachsame.Donot

threadscrewstoofarintopulley,as

theymaydamagethecasttiminggear

cover. Removethecovertocylinder

blockcapscrewsandwithdrawthe

cover.

Thesealwhichconsistsofanouter

feltwasherandaninnerfianged ring

oftreatedleather,shouldbeinstalled

withthelipoftheinnerelementfac-

ingthetiminggears.

ModelsRC-WC-WD-WD45-WF

80.

Itispossible torenewcrank-

shaftfrontoilsealwithoutremoving

thetiminggearcover. Theoilsealcan

berenewedafterremovingthehood,

radiator,crankshaftpulleyandfront

sealretainer.Loosentiminggearcover

retainingcapscrewstofacilitatecen-

teringoilseal.Latestsealsareoffelt

facedwithneoprene.

16

ALLIS-CHALMERSParagraphs82-85

Toremovetiminggearcover,first

removehoodandradiator.Remove

startingcrankextensionpinand

loosenextensionbracket.Loosenset

screwretainingpulleytocrankshaft

andremovepulley.Disconnectthrottle

andgovernorlinkage.Blockupfront

endofengineandremoveenginesup-

port.OnRC,thefront-centeroilpan

studmaybeweldedtotheangleiron

ontiminggearcover;inwhichcaseit

willbenecessarytoremovetheoil

pan.OnWC,WD,WD45& WF,itis

notnecessarytoremoveoilpan,but

removalisrecommendedasa means

ofprotectingagainstsubsequentoil

leakswherepanjoinsthebottomface

ofgearcover.Removetiminggear

coverretainingcapscrewsandtiming

gearcover.

RefertoGOVERNORsectionfor

overhauloflinkage.

Adjustcamshaftendplayaftertim-

inggearcoverisinstalledbyloosen-

ingthrustscrewlocknut(locatedon

frontfaceofcover)andturningthrust

screwinuntilitcontactsendofcam-

shaft;thenbackthescrewout^ to

%turn.

TIMINGGEARS

ModelsB-C-CA-RC

82.

Camshaftgearisa pressfit and

keyedonthecamshaftandshouldbe

removed,withthecamshaftasa single

unit.Forcamshaftremovalprocedure,

refertoparagraph85.Pressnewgear

onuntilrearsurfaceofgearhubis

flush withfrontsurfaceofcamshaft

frontjournal.Crankgearinstallation

canbefacilitatedbya mildapplication

ofheatonthegear.Forreplacement

ofgovernorandmagnetoordistribu-

torgear,refertoGovernor,paragraph

116.

ModelG

83.

Thedriveconsistsoftwohelical

gears.

Toremovethecamshaftgear,

first removethetiminggearcoveras

outlinedina precedingparagraph,and

Fig, AC33—Model6./Methodofremovingcamshaftgearusing two Va inch cap screws

and a suitable

puller.

Shaft

should

be bucked-up when reinstalling gear to shaft.

alsoremovethegovernorweightas-

semblyfromendofgear.Remove

camgearfromshaftwitha pullerand

two% inchcapscrewsasshownin

Fig.AC33.Crankshaftgearcanbere-

movedwitha suitablepuller.When

installinggears,removeoilpanordis-

tributorandbuck-upthecamshaftat

oneofthelobesnearfrontendof

shaftwitha heavybar.Meshthesin-

glemarkonthecrankgearbetween

thedoublemarkonthecamgear.

ModelsWC-WD-WD45-WF

84.

Timingdriveconsistsofthree

helicalcutgearswhichincludesthe

governorgear(driveforbothgover-

norandmagneto).OnWC,WD,WF

andWD4SpriorEng.Ser.No.45-

48556gearisattachedtoshaftbycap

screws,andcanberemovedafterre-

movingthetiminggearcover.The

capscrewholesinthecamshaftgear

areunevenlyspaced,permittingthe

geartobeinstalledtothecamshaft

inonlyoneposition.OnlaterWD4S

tractors,gearispressedontheshaft.

Crankshaftgearisa pressfit onthe

crankshaft,butcanberemovedwhen

timinggearcoverisoff,byusinga

suitablepuller.Reinstallationofthis

MACHINEDSURFACETOPOFHEAD

/X FLUSH

NEWSTYLEHEADVALVEGUIDEINSTALLATION

Fig,

ACa2—Valveguideinstallation on WD engines after serial W 289000andWD45,

Inlet valve guides are installed so that the top end of the guide is Va inch below the

machined surface as shown. Exhaust valve guides are installed sothat the top end is

flush with the machined surface.

gearcanbefacilitatedbyheating

sameinwateroroil.

Whenreinstallinggears,meshthe

singlemarkedcrankshaftgeartooth

witha similardoublemarkonthe

camshaftgear.RefertoGOVERNOR

sectionforgovernorandmagnetoor

distributordrivegeardata.

CAMSHAFTANDBUSHINGS

ModelsB-C-CA-RC

8S.

Toremovecamshaft^remove

timinggearcoverandoilpan.Remove

cylinderheadcover,rockerarm.sas-

semblyandpushrods.Holdtappets

uptoclearcamsandwithdrawcam-

shaftandgearasa unit.

OnRC,thesteeringgearpedestal

orfrontsupportunitinterferes,and

mustberemovedtoenablecamshaft

tobewithdrawn.Whenreinstalling

camshaft,becertainthatoilpassage

(8—Fig.AC34)isclean.Oilpassage

inhollowcamshaftdeliversoilto

crankshaftmainbearingsviathecam-

shaftbushings,totheconnectingrods

andcylindersbythrowholes(&)and

tothetiminggearsthroughflutes in

thrustplunger(11).Besurethrust

plungeroperatesfreelyincamshaft

andthatoilpumpdrivepin(6)is

securedincamshaft.

Clearancebetweennewcamshaft

andnewcamshaftbushingsshouldbe

.002-.004inch.Renewcamshaftbush-

ingsorcamshaftorboth,ifclearance

exceeds.007inch.

BushingsaresuppliedinStandard

sizeandundersizeof0.002S.Torenew

camshaftbushingsaftercamshafthas

beenremoved,itisnecessarytore-

movetheflywheelandoilpumpwhich

necessitatesengineremoval.

Thebushingscanbedrivenoutof

blockandnewonesdrivenin.Drive

rearbushinginfromthefrontuntil

rearedgeofbushingis

VA

inchfrom

17

Paragraphs86-89

Fig.

AC34—ModelsB, C, CA, and RCcamshaftinstallation. Camshaft rotates on three re-

newable split type bushings. Camshaft end play is controlled by thrust plunger (11) and

,spring (10),

1Camgear6,Oilpumpdrivepin10,Thrustplungerspring

2]Camshaftgearkey7.RearbushingU.Thrustplunger

3Frontbushing8.Centraloilpassage12.Oilslingerunit

4.

Valvetappet9.Oilholeforrodbearing13.Timinggearcover

5]Centerbushinglubrication

Fig, AC35-Models WC, WD, WD45 and WF camshaft installation. Camshaft rotates on

three renewable split type bushings.

1.

Expansionplug

2.

Pipeplug

3.

Rearbushing

4.

Centerbushing

5.

Valvetappet

6.Fronthushing

7,

Camgear

8,Gearretainingcapscrew

9,Timinggearcover

10.

Locknut

11.

Thrustscrew

12.

Meteredoili

rearofblock.Drivecenterbushingin

untilitextends1/16inchbeyondboth

endsofbearingboss.Drivefrontbush-

inginuntilfrontedgeofbushingis

flush withfrontfaceofblock.Bush-

ings arepresizedandshouldbedriven

inwitha plug-typedriver.Thediam-

eteroftheplugshouldbe1.751inches.

Besureoilholeinbushingsregisters

withoilpassageincylinderblock.

JournalDiameter(Mean)

1.749S

RunningClearance.002-.004

ModelG

86.

Toremovecamshaft,flrst re-

movethecamshaftgear,asoutlined

inprecedingparagraphs.Removethe

ignitiondistributorandcylinderhead

andeitherblockup,orremove,the

valvesandtappets.Removecamshaft

thrustplatefromfrontofcylinder

blockandwithdrawtheshaft.

Camshaftjournalsridedirectlyin

3machinedboresofthecylinderblock.

Shaftjournalsizesare:Frontandcen-

ter

1.7S0;

rear

1.2S0.

Recommended

clearanceofjournalsinboresis.003

to.004S.Themaximumpermissible

clearanceis.007andwhenitexceeds

thisamountitwillbenecessaryto

renewthecamshaftand/orthecylin-

derblock,orboth,ortomakeup

andinstallbushings.

Camshaftendplayiscontrolledby

thethicknessofthethrustplate(10—

Fig,AC27)locatedbehindthegear.

Renewthethrustplateiftheendplay

exceeds.007.Checktheventopening

(X)inthecamshaftdirectlybehind

thefrontcamshaftjournal.Ifthehole

isplugged,itwillbeimpossibletoob-

tainsatisfactorygovernoroperation.

ModelsWC-WD-WD45-WF

87.

Toremovecamshaft,remove

timinggearcover,flywheel cover,oil

panandoilpump.Removecylinder

headcover,rockerarmsassemblyand

pushrodsandremovecamgearfrom

camshaft.Holdtappetsuptoclear

camsandwithdrawcamshaft.When

reinstallingcamshaft,besureoilpas-

sagesareclean.Meteringholeinplug

(12—Fig.AC35)isdiscontinuedin

laterWDandallWD4Smodelswhich

havea solidplug.Adjustcamshaft

endplayaftertiminggearcoverhas

beeninstalled,bylooseninglocknut.

ALLIS-CHALMERS

turningthrustscrew(11)inuntilit

bottoms,thenbackl^% turn.

Clearancebetweennewcamshaft

andeachofthethreesplittypecam-

shaftbushingsshouldbe.002-.004

inch.Renewcamshaftbushingsorcam-

shaftorbothifclearanceexceeds,006

inch.BushingsaresuppliedinStan-

dardsizeandundersizeof0.0025,

Torenewcamshaftbushingsafter

camshafthasbeenremoved,itisneces-

sarytoremovethe

fl3^wheel

whichne-

cessitatesengineremoval.Bushingscan

bedrivenoutofblockandnewones