Allis-Chalmers HD-5 User manual

FOREWORD

This

manual

is

prepared

to'

provide the customer

and

the organiza-

tion personnel with complete information

and

instructions on the

maintenance

of

the Model

HD-5

Trador.

Extreme care has been

exercised

in

the designing, seledion of malerials and the assembly

of

the traefor. By proper maintenance

and

skillful operation

of

the

tractor, the utmost satisfaction in performance

and

service can

be

obtained.

In

order

to

become familiar with the various parts

~f

the tractor, it

is

urged that the mechanic study the instructions

in

the manual

and

use

it as a reference when performing repair

or

maintenance operations.

All information

and

illustrations shown throughout this manual are of

the "Standard

JJ

Model

HD-5B

Trador,

unless otherwise stated.

Where

special tools are required, their application and use are

illus-

trated.

Sections I through

XIX

contain a detailed description

of

the various

assemblies of the tractor and instructions

for

the proper ad;ustment

and

repair

or

rebuilding

of

these assemblies.

Section XX describes the Special Equipment available

for

the tractor

and

outlines the service on these parts.

General Maintenance Instructions are given

in

Section

XXI,

and

Fits

and

Tolerances in Section

XXI/.

Trouble Shooting Information given

in

Section

XXIII

will aid in deter-

mining the cause

of

operating irregularities that

may

occur and indi-

cates what

may

be done to correct them.

To

obtain the best results

and

to maintain the original quality built

into the tractor,

it

is

important that genuine Allis-Chalmers Parts

be

used when new parts are required.

IMPORT

ANT: Always furnish the dealer with both the Tractor

and

Engine Serial Numbers when ordering parts.

Many Allis-Chalmers owners employ the Dealer's Service Department

for all work other than routine care

and

adjustment.

This

practice

is

encouraged as our dealers are

kept

well informed

by

the factory

regarding advanced methods

of

servicing Allis-Chalmers products

and

are

equipped

to render satisfactory service.

1

2

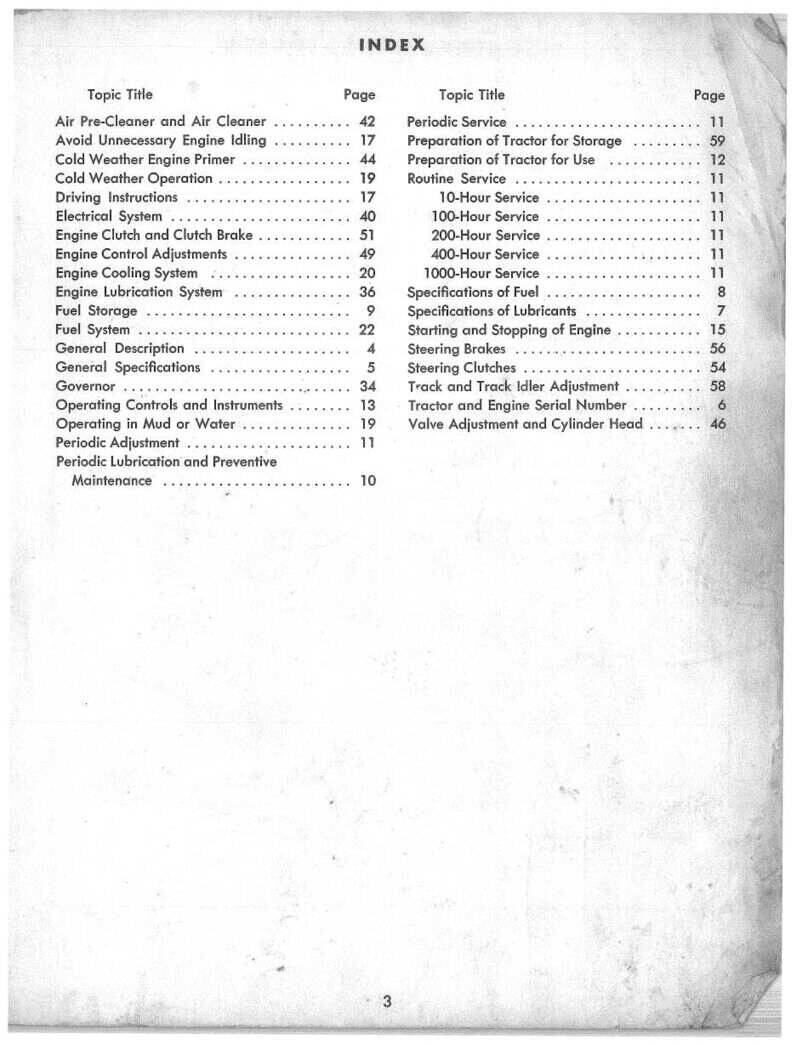

SUBJECT

INDEX

SUBJECT

Page

SEC

TIO)'!

Description

and

Specifications 5

Fuel System -Engine

11

Air Intake System -Engine 36 !

Cooling System -Engine

55

. . I

-

Lubrlcatmg System Engine 64

Governor

and

Governor Controls

71

,

Electrical System 78

Instruments

88

Engine 90

Engine Clutch

and

Clutch Broke 130

Transmission

and

Bevel

Gear

136

Steering Clutches

150

Steering Brakes

155

Final Drives

158

Truck Frames

168

Draw Bar

179

Tracks

180

,

Main Frame

and

Equalizer Spring

183

Fenders

and

Seat

186

Special Equipment !

187

General

Maintenance Instructions ,

193

Fits

and

Tolerances 197

Trouble Shooting 203

3

4

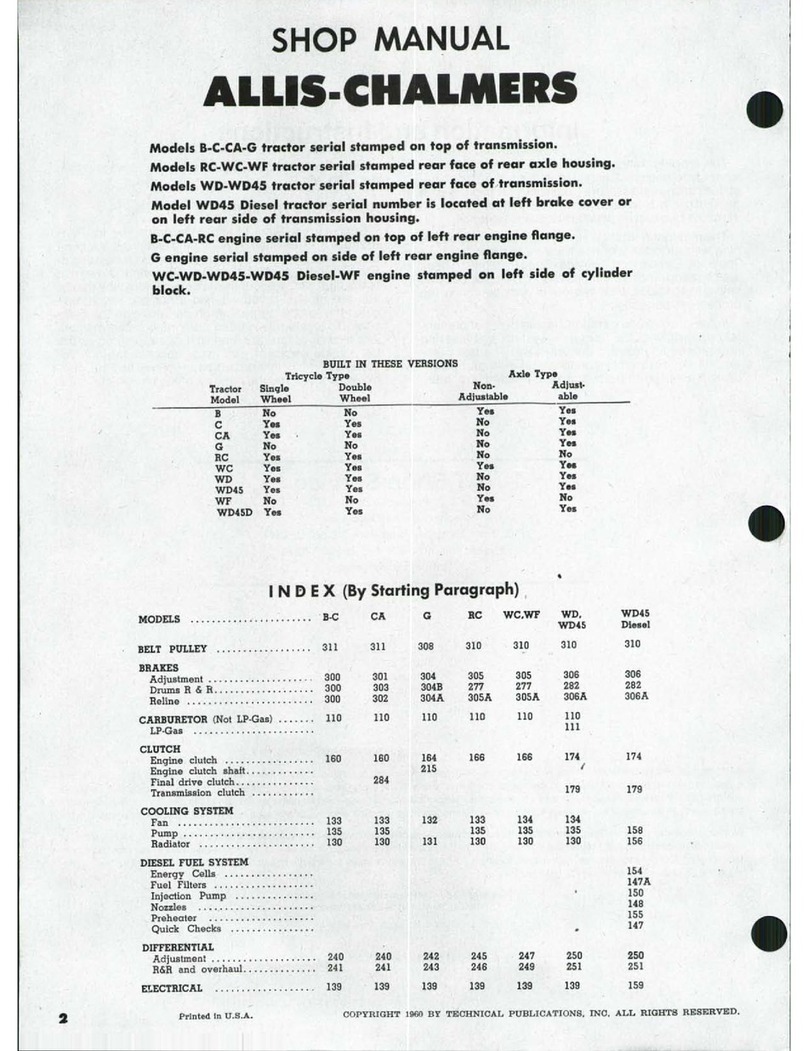

SECTION I - DESCRIPTION AND SPECIFICATIONS

Topic Title

General

Description

...............

. Topic No.

1

General

Specifications

.............

. 2

Specifications of

lubricants

.........

. 3

Specifications of

Fuel

Oil

...........

. 4

Fuel

Storage

.....................

. 5

Tractor

and

Engine Serial Numbers

...

. 6

1.

GENERAL

DESCRIPTION

The description given herein

and

the

information

contained

in

this

manual

pertains only to the

Model

HD-5B

Tractor

(Standard

Model) unless

otherwise stated.

The model

HD-5B

Tractor

is

a

11,250

pound track-

type

tractor

powered

with a

54.6

horsepower, 2

cylinder, 2 cycle Diesel Engine. Power from the

engine

is

transmitted through a single

plate

over-

center

type

clutch

and

a universal joint drive shaft

assembly to

the

transmission. The final drive

gears

and

track drive sprockets

are

driven

by

two

multiple-disc steering clutches,

one

on

each

end

of

the

steering clutch cross shaft.

At

full

governed

engine

speed

(under load)

of

1800

R.P.M.

the transmission provides 5

forward

speeds,

ranging

from 1.46 M.P.H. to

5.47

M.P.H.,

and

a reverse speed of 1.99 M.P.H. Mechanical

self-energizing brakes insure

easy

and

positive

control of

the

tractor

at

all times.

The

tractor

is

equipped

with electric starter,

head

lights, full width crankcase

guard,

hinged

radiator

grille, front bumper,

and

positive seal truck

wheels,

track

idlers

and

track

support

rollers.

FUEL

ARM

"U>HIUN

REAR

FENDER

TRACK

RELEASE

HO,USING':r,..

ADJUSTING

SCR:EW..J

TRACK

RELEASE

v,"","-,

TRACK

IDLER

SHOE

FRAME

HEADLIGHT

CRANKCASE

GUARD

'_

______________

Fig. I

-Model

HD-58

Tractor

______________

-'

5

II

2.

GENERAL SPECIFICATIONS (STANDARD TRACTOR)

GENERAL:

Weight

(60"

tread)

.....................•....................

Overall

length

..................•..........................

Overall Width (60" tread)

...................................

.

Overall Height (including air pre-cleaner

and

exhaust pipe)

........•

(Air pre-cleaner

and

exhaust pipe removed)

....

, . ,

............

.

Tread Width -

Wid.

Tread

.....•..............•..............

Turning Radius

(60"

tread)

.....•

, . , , , ,

.............

,

....•.

, ,

..

length

01

Track on Ground

..................................

'

Track Shoe Width

(Standard)

..............................•..

Ground Contact Area

(~tandard

Shoe)

........•.••..............

Ground Pressvre (6011

tread)

............

, ,

...

,

...•..•.

,

......

.

Ground

Clearance

........

, , ,

............

, . , . ,

......

,

......

.

Drawbar

Height

.....•......................................

Lateral Movement

of

Drawbor

.........

,

....

, . ,

..•......

, ,

....

.

MAXIMUM

SPEEDS:

lst

Gear

.................................................

.

2nd

Gear

................................................

.

3rd

Gear

....................•.•.•........................

4th

Gear

........•.•.........................•••....•••....

5th

Gear

.................................................

.

Reverse

•••••.

,

•......•.•.

,

......•.......

,

......•..••.•••••

ENGINE:

Make

............•......•...........•..........•••.•..••••

Type

..........................................•••....•.•.

Number

of

Cylinders

.......................................

.

Bore

and

Stroke

.,.

, ,

.•........•............•.•......

, ,

....

.

Piston Displacement

.,

........

"

.................•....

,

.•...•

Full

Governed

Speed

(under load)

.............................

.

Maximum Net

Torque.

,

............................

,

........

.

Drawbar Horsepower

(at

rated

speed of 2.44 M.P.H.)

.............

.

Belt Horsepower

•............

,

......................•.

,

....

.

Fuel Used

....•....................................•••....•

Fuel injection System

......•......

: . . •. • . • • . . . . . . . . . . . .

..

.

..

Lubricotion

..••••

,

.........

"

..•.........

,.".,.,

..•.......

11,250 Ib,.

10 ft. 4% in.

6

ft.

6l-!>

in.

6 ft. 1

Y.

in.

5 ft. %

in.

60

in.

6

It.

10%

in.

5 ft. 4\4 in.

131n.

1670'h sq.

in.

6.73 Ib,.

per

sq. in.

1110\

in.

13·15/16 in.

21

in.

1.46

M.P.H.

2.44

M.P.H.

3.30 M.P.H.

3.96 M.P.H.

5.47 M.P.H.

1.99 M.P.H.

General

Motors Diesel

2.Cycle

2

4%

x 5

in.

142 cu. in.

1800

R.P.M.

179.1 ft. lb. @ 1270

R.P.M.

43.S

51.9

No.1

and

2 Dle,.1

Unit

Injectors

Forced Feed

CAPACITIES

(Fuel, Oil

and

Coolant-

U.

S.

Standard

Measure):

Fuel Tank

....................................••.......••..

Cooling System

......•.•................................•.••

Engine Crankcase . ,

.....

,

..............

, . , . ,

......

,

........

.

Transmission

..............................................

.

Final Drives (each)

.........................................

.

Air

Cleaner

•..........

,

....

,

.......................•....•..

Approximate

Capacity

37

Gollons

3%

Gallons

2 Gallons

5 Gallon,

3 Gallons

2'1.!

Quarts

The

Allis·Chalmers Manufacturing Company reserves the right to

make

changes

in

the

above

specifications

or

to

add

improvements

at

any

time without notice

or

obligation.

6

3.

SPECIFICATIONS

OF

LUBRICANTS

A.

Engine

Crankcase

Lubricant.

USE

NON-CORROSIVE

DIESEL

ENGINE

LUBRI-

CATING

OIL

CONTAINING

ADDITIVES

WHICH

WILL

PREVENT

SLUDGE

OR GUM DEPOSITS.

UNDER

NO

CIRCUMSTANCES SHOULD A COR-

ROSIVE

DIESEL

ENGINE

LUBRICATING

OIL

EVER

BE

USED.

Atmospheric

Tel)1peroture Viscosity

Above

32°

F.

Use

SAE

30

0°

F.

to

32°

F.

Use

SAE

20

0°

F.

and

below

Use

SAE

10

Manufacturers

of lubricants

recognize

the

impor-

tance

of

the

qualities

required

for use

in

our

equip-

ment

and

they

are

co-operating

fully

to

insure

the

use

of

only those oils which fulflll these require-

ments. The oil distributor

and

oil

manufacturer

are

to

be

held responsible for

the

results

obtained

from their products.

The

outstanding

lubricating

requirements

for effi-

cient

operation

of

this

engine

are:

The

maintaining

of

piston rings

in

a

clean,

free

condition;

absence

of

hard

carbon

and

"varnish"

deposits

on

or

within

engine

parts;

the

prevention

of

bearing

corrosion

and

the

promotion of

general

cleanliness within

the

engine.

Proper

operation

and

maintenance

of

the

engine

is

necessary

to

obtain

the

desired

results from

the

lubricating oil.

Operating

and

maintenance

fac-

tors

can

be

effectively controlled by

the

engine

user.

B.

Transmission

and

Final

Drive

Lubricant.

Lubricate these assemblies with

engine

oil. A list

of

the

various

brands

of

engine

oils which

have

7

been

tested

and

found satisfactory for use

in

these

assemblies

is

shipped

with

each

tractor

and

is

also

available

from Allis-Chalmers

dealers.

Use

only

an

oil shown on this list,

as

the

use of untested

oils

may

result

in

deterioration

of

the

Neoprene

boots

and

rings

in

these assemblies.

Use

oils with

the

following viscosity:

Atmospheric

Temperature

Viscasity

Abave

32°

F.

Use

SAE

50

32°

F.

and

below Use

SAE

30

C.

Truck

Wheel,

Track

Idler

and

Track

Support

Roller

Lubricant.

Lubricate these assemblies with a

grease

that

has

been

tested

and

found satisfactory by Allis-

Chalmers

Manufacturing

Company.

The

type

of

grease

used for lubricating

these

assemblies

was

selected

because

of

its

good

pumpability

and

cold

temperature

characteristics

and

because

of

its havir.g a minimum effect on

the

synthetic

rubber

seal

boots.

It

is

also

an

extremely

stable

grease

and

will not

deteriorate

excessively

with long use.

A revised list of

approved

oils

and

greases

is

issued

every

six months

and

new oils

and

greases

which

have

been

tested

and

approved

during

each

period

are

added

to

the

list. Ask

your

nearest

Allis-

Chalmers

factory

branch

or

authorized

dealer

for

the

latest

list.

D.

Pressure

Gun

Lubricant.

Use a pressure

gun

lubricant

with a minimum

melting point

of

300°

F.

This lubricant should

be

in

a viscosity

range

so

as

to insure

easy

handling

in

the

pressure

gun

at

prevailing

air

temperatures.

4.

SPECIFICATIONS

OF

FUEL

OIL

Use

No.1

Diesel

Fuel

Oil purchased from a reputa-

ble

oil

company.

In

worm weather,

No.2

Diesel

Fuel Oil may be used.

This

fuel must

be

within the

classification limits

as

established by the American

Society for Testing Material. Tentative Diesel Fuel

Oil Specifications

(ASTM

- D975).

For commercially satisfactory engine life

and

per-

formance, fuel

oil

requirements must comply with

four basic qualifications:

1. Physical cleanliness.

2. Absence of Chemical contamination.

3. Proper burning characteristics.

4. Cold starting ability.

Physical cleanliness means freedom from water,

dirt

and

other incombustible ingredients. Since all

present

day

high

speed

engine fuels

ore

completely

distilled, they leave the refinery

in

clean condition.

Transport

and

subsequent storage account for the

addition of most foreign matter found in the fuel.

Proper burning characteristics

are

dependent

upon

ignition quality

and

volatility.

The

fuel should have a cetone number of

at

least

40,

and

should

be

free from alkali,

odds,

gum,

and

water.

The

sulphur content should not exceed

0.5%

for summer operation

and

0.3%

for winter

operation. Fuel oils having these specifications

are

available from most

oil

companies.

The

use

of

fuels

having more than the specified sulphur con-

tent

are

conducive to harmful engine deposits,

rapid wear,

and

sticking rings and valves.

Volotility

is

determined by the boiling temperature

range. Fuels having a

low

final boiling point will

vaporize

ClOd

burn more completely than fuels with

a high final boiling point.

The

preferred high speed diesel fuels

range

in

color from white to light amber.

5.

FUEL

STORAGE

------

______

Fig. 2 -

Fuel

Storage

rank

The importance

of

proper

storage

of fuel cannot

be

too strongly stressed.

Storage

tonks, drums

or

8

service tanks must

be

free from rust, scale, sedi-

ment or

any

other foreign matter which

will

con-

taminate the fuel,

dog

the fllters

and

eventually

damage

the fuel pump

and

iniectors.

A portable storage tank provides the best method

for storing fuel on the job.

In

a tank, the sediment

and

water can easily be drained

and

the fuel

can

be pumped into the tractor fuel tank with a mini·

mum

of handling. Consult your local Allis·

Chalmers

dealer

for details

about

this type of

storage

tank. Since condensation

will

occur

in

the

tank,

it

is

very important

that

a sediment sump be

provided

in

the bottom of the storage tank where

the

water

and

settlings

can

be

drained daily.

Fuel

should be allowed to settle

at

least

4B

hours

in

the

storage

container before

it

is

put

in

the fuel

tank of the tractor.

It

is

advisable to use a pump

and

draw

the fuel from the tank or barrel rather

than from the bottom of the container by means

of a faucet

or

through the bung hole.

Where conditions

are

such

that

drums must be

used to supply fuel,

it

is

advisable to have enough

drums to allow sufficient time for the fuel to settle.

The fuel should

be

used only to within

about

three

inches from the bottom.

The

fuel thus left

in

a

number of drums can be collected into one drum

and

used after the usual time allowed for settling.

In

this manner, the sediment

and

foreign matter

will

be disposed of

and

no

fuel

will

be wasted.

Whenever drums

are

used for storage, they should

be

covered or placed under shelter to avoid the

fuel becoming contaminated by water which

will

enter through the flller plugs when

it

rains, even

though the plugs

are

tight.

The fuel tank of the tractor should be fllled

at

the

end of the day's run rather than

in

the morning.

This

will

reduce the water content, as a

full

tank

is

less

subject to condensation. The fuel tank

is

provided with a drain elbow

and

drain cock.

Sediment

will

settle into this elbow

and

can be

drained.

6.

TRACTOR

AND

ENGINE

SERIAL

NUMBERS

9

On all parts orders

and

in

all correspondence

relative to the tractor,

it

is

necessary that both

tractor

and

engine serial numbers be given.

This

will

properly identify the particular tractor

and

will

insure obtaining the correct replacement parts

for it.

Prior to engine Serial Number 2·71·111

BO,

the

engine serial number

is

stamped on a plate

at-

tached to the left side of the cylinder block below

the governor control housing. On engines Serial

Number 2·71·11180 to 2·71-15635 the number

is

stamped directly

in

the cylinder block

in

the same

relative location. Effective on engines after

2-71-15635 the engine serial numbering system

was changed.

In

the new system of numbering,

the preflx numbers

2-71

were changed to

read

2A-l, 2A-2, etc.,

and

are

stamped

in

the cylinder

block.

10

The

tractor

serial number

is

stamped

in

the

rear

face of the steering clutch housing

near

the

upper

right corner.

..

1

::e

I

~

~

-

::a

U

!

SECTiON

II

-ENGINE

FUEL

SYSTEM

Topic Title

Description of System

..............

.

Checking

Fuel

Supply System

........

.

Fuel Tank

and

Drain Elbow

.........

.

Fuel Filters

....•..................

Fuel Pump

...............

,

......

.

fuel Pump Drive

..•................

Fuel Iniectors

....................

.

Injector

Copper

Tubes

.............

.

Fuel Manifolds

...................

.

Topic No.

1

2

3

4

5

6

7

a

9

1.

DESCRIPTION OF SYSTEM

The engine fuel system consists of the fuel tank,

first stage fuel filter, fuel pump,

seCOl)d

stage

fuel

filter, iniectors

and

fuel lines.

The

fuel

is

drawn

from the bottom

of

the tank

and

through the first

stage

filter

by

the fuel pump.

The

pump circulates

the

fuel under pressure through the second

stage

fuel filter

and

inlet fuel manifold

in

Ihe cylinder

head,

and

Ihrough

the

inieclors.

As

the

fuel enlers

each injeclor, it passes through a small porous

metal filter

in

the iniector body. The amount

of

fuel required by the engine

is

injected into

the

cylinders by the injectors. Surplus fuel not required

for combustion, leaves each iniector through a

second porous melal filter, enters the relurn fuel

manifold

in

the cylinder

head

and

relurns

to

the

fuel tank. A pressure

of

25

to 45 pounds

is

main-

lained within the system by a restricted fitting

located

at

the cylinder

head

return manifold

open-

ing.

The

continuaus circulation

of

the fuel through

fhe injectors helps to cool them

and

eliminates the

possibility of air pockets

in

the fuel supply system.

fUEL

TANK

SED

JMENT

SUMP,~;;c;;:::;:::::;;=:;:;:;;rI!---.J

DRAIN COCK

fUEL

LINE

VALVE

INJECTOR FUE.L LINES",

RETURN

FUEL PASSAGE

, .

~INJECTORS

RESTR1CTED FITTING

RETURN TO TANK

N~.~!:'.

':hi

B!~i

I!

;:

c~;:--o

2ND

STAGE

FUEL

FlL

TER----.

\

(~

\. / I i

'U

~I;

V'I

II

~j

.,

"

1ST

STAGE

FUEL

F;~

TE:

\

FUEL

NLET

fUEL

PASSAGE

PUMP

1---

__________

Fig.

I-Schematic

Fuel

Flow

Diagram

-------------'

11

2.

CHECKING

fUEL

SUPPLY

SYSTEM

A.

General.

Under normal conditions with

the

engine operating

at

full

throttle,

25

to 45 pounds pressure

will

be

indicated on the fuel pressure

gauge,

if

the

tractor

is

equipped

with a

gouge.

If the tractor

is

not

equipped

with a fuel pressure

gauge,

and

condi-

tions occur which indicate incorrect fuel pressure,

the

pressure can

be

checked by installing a

gouge

in the delivery line

of

the fuel pump

at

any

point

between the pump

and

the inlet manifold opening.

Fuel pressure below normal, uneven running of the

engine, excessive vibration, stalling when idling,

and

a loss of power

are

indications of insufficient

fuel supply to the injectors.

To

determine

the

couse for the

above

conditions

check for the following:

Air

being drown into system

Clogged fuel filter elements

and

fuel lines

Clogged injector fuel filters

Inoperative fuel pump

To

check the flow of fuel through the system, dis-

connect the fuel return line

at

any

point between

the

fuel return manifold

and

the fuel tonk. With

the engine operating

at

full

throttle, the system

will

be

functioning properly when a

full

stream of

fuel with considerable force can

be

observed re-

turning to the fuel tonk through the fuel return

line.

If

only a small stream

is

observed returning

to

the tank, all

the

causes listed

above

must

be

checked

and

eliminated

in

turn.

B.

Check

for

Admission

of

Air

Into

System

and

for

Clogged Filter Elements

and

Fuel Lines.

To

check for

air

being admitted into the system,

remove the va

Ive

rocker arm cover

and

loosen

or

disconnect

one

of the injector fuel lines, then start

the engine.

If

air

is

entering the fuel system, foam

or

bubbles

will

be

observed

in

the fuel

that

emerges

from the loosened connection. Correct this condi-

lion by tightening

any

loose fuel lines

and

filter

connections between the fuel pump

and

the fuel

tonk. Test for smooth operation

and

full

flow

of

fuel.

If

the fuel lines

or

filters

are

dogged

remove the

fuel lines,

dean

both filter shells

and

install new

12

elements.

Blowout

the

lines while they

are

dis-

connected.

This

should eliminate the difficulty.

Check for

full

flow of fuel

after

engine

is

again

started.

C.

Check

for

Clogged

Injector

Filters.

If

the

engine

still

runs

"ragged"

with suitable fuel

return, the injector filters for one

Or

both cylinders

may

be

partially

dogged.

Locate the faulty injec-

tor as follows:

1.

Run

the engine

at

idling speed

and

cut out

each injector

in

turn by holding the injector

follower down with a screwdriver

or

small

block of wood while the engine

is

running,

as illustrated

in

Figure

No.2.

CAUTION,

Do

not allow the screwdriver to slip olf

the follower

as

damage

to the valve assemblies

con easily result.

If

the engine speed decreases

when the follower

is

held down

it

will

indicate

that

the injector for

that

cylinder

is

functioning properly.

If

the engine continues to run with no decrease in

speed, the injector

is

inoperative

and

should

be

removed for further inspection.

2. Stop

the

engine

and

remove the fuel feed line

that connects the injector

to

the return fuel

manifold. Hold a finger over the injector fuel

outlet

and

crank the engine with the starter.

If

the fuel gushes from the injector while the

starter

is

cranking the engine,

on

ample fuel

supply

is

indicated. Remoye the injector

and

check for clogged injector filters. Refer to

"INJECTOR

REMOVAL"

in

this section.

D. Check

for

Inoperative

Pump.

Assuming

that

there

is

a sufficient supply of fuel

in

the

fuel tank,

ond

that

the fuel

is

reaching the fuel

pump, remove the pipe plug from the

top

of the

second stage fuel filter. With the engine running

the

fuel

will

gush from the opening

in

the filter.

If

it

does not,

the

fuel pump

will

be

considered

inoperative

and

must

be

removed

and

repaired or

replaced.

E.

Excessively High Pressure.

A relief valve

is

installed

in

the fuel pump

to

pre-

vent high fuel pressure. When the relief valve sticks,

high pressure

will

develop

and

will

be

indicated

on the fuel pressure

gauge,

if

the tractor

is

equipped with a fuel pressure

gauge.

When high pressure occurs, the valve

in

the fuel

pump should

be

inspected

and

the

cause

deter-

mined for

its

sticking. The second

stage

fuel filter,

the restricted fitting

in

the fuel return line

at

the

return manifold

and

all fuel lines should

be

in-

spected for clogged passages.

Continued operation with excessively high pres-

sure (over

60

pounds) may result

in

damage

to

the

fuel system.

3.

FUEL

TANK

AND

DRAIN ELBOW

A. Description.

The fuel tank, located

at

the

rear

of

the tractor has

a capacity of approximately

37

gallons.

The drain elbow on

the

bottom

of

the fuel tank

provides a means of flushing the tank

and

also acts

as

a sediment sump.

Open

the drain cock on this

elbow before the engine

is

started

at

the beginning

of the day's operation

in

warm

weather

or

shortly

after the end of the

day's

operation

in

freezing

weather. Close the cock when clean fuel runs out.

Drain the tank, when

an

accumulation of rust

and

scale

is

evident,

by

removing the plug

in

the end

of the drain elbow, then flush the tank thoroughly.

B.

Maintenance.

If

a large accumulation of rust

or

scale

in

the tank

13

becomes

apparent,

remove the drain elbow

and

the fuel lines from the bottom of the tank

and

flush

the tank with clean fuel

or

clean the tank with live

steam.

This

will

prevent frequent clogging of the

fuel filters

and

will

eliminate possible trouble

in

the fuel system.

C.

Removal.

When

it

becomes necessary to remove the fuel

tank, proceed

as

follows:

1.

Remove the arm cushions from the top of

each

battery

box

and

remove the capscrews

used

in

fastening each battery box to

the

fuel tank.

2. Remove

the

bolts attaching the tank to

the

rear

fenders.

3. Close the fuel shut-off valve

at

the bottom

of

the tank

and

disconnect the fuel supply line

and

the fuel return line from

the

fuel tank.

4. Place a suitable chain or rope around the

fuel tank

and

remOve the tank from the trac-

lor. Protect all openings of

the

fuel tank

and

disconnected lines againsl the entrance

of

foreign material.

4.

FUEL

FILTERS

A. Description

of

First

Stage

Fuel Filter.

This filter, mounted

at

the

left side

of

the

engine,

contains a

replaceable

element. Dirt

and

sedi-

ment

in

the fuel

is

collected by this filter

and

pre-

vented from passing on

to

the fuel pump. A

drain

cock

in

the bottom

of

the filter shell allows

drainage

of

the sediment collected.

t_----COvER

SCREW

O,.·-----GASKET

~---C:OVER

,\-+---COVER

GASKET

~-4

__

---SPRING

<CIJ";_'

-----

WASHER

e'"'"'----GASKET

i"----

ELEMENT

_--SHELL

~

___

-DRAIN

COCK

-fir.t

Stage

fuel

filter

-----'

B.

Service

of

First

Stage

Fuel

Filter.

Open

the filter

drain

cock

daily,

before

the

en-

gine

is

started

at

the

beginning

of

the

day's

opera-

tion in

warm

weather

or

shortly

after

the

end

of

the

day's

operation

in

freezing

weather,

and

allow

the

water

or sediment to

drain.

Close the

drain

cock

when

clean fuel runs out. Remove

and

dis-

card

the

old

element

and

install a new

one

after

every

300

to

500

hours of

operation

(more often

if

conditions

warrant)

or

when

the filter becomes

clogged.

A

clogged

filter

is

usually

indicated

by

irregular

engine

performance.

To

change

the element, remove the filter cover,

drain

the filter, lilt out the spring

and

element

and

wash the inside of the filter shell. Place a

new

element

and

the spring

in

position

and

re-instali

the

cover, using the new cover

gasket

furnished

with the new element.

Start

the

engine

and

check

to

be

sure

that

the filter

does

not

leak.

C. Description

of

Second

Stage

Fuel

Filter.

This

filter, mounted on

the

right side

of

the

engine,

contains a

replaceable

element. Any small

par-

ticles

of

dirt, which may

have

passed

through

the

first

stage

filter

are

collected by this filter

and

prevented

from reaching

the

injectors. A

drain

cock,

in

the bottom

of

the filter shell, allows for

drainage

of

the sediment collected.

f'"'"'----CAPSCREW

o

...

~

___

_

-GASKET

_--HEAD

c~

~GASKETS

_--ELEMENT

§l

~93:-'

----SPRING

i---SHELL

~...-_--DRAIN

COCK

L-

__

fig.

5-Second

Stage

fuel

filter---....l

14

D.

Service

of

Second

Stage

Fuel Filter.

Open the filter drain cock daily, before the engine

is

started

at

the beginning of the day's operation

in

warm weather or shortly

after

the end of the

day's operation

in

freezing weather,

and

allow

the

water

or sediment to drain. Close the drain

cock when clean fuel runs out. Remove

and

dis-

card

the old element

and

install a new

on'O

after

every

300

to

500

hours of operation (more often

if

conditions warrant) or when the filter becomes

dogged.

A

dogged

filter

is

usually indicated by

irregular engine performance.

To

change the element, drain the filter

and

re-

move the shell from the filter head. Remove

and

discard the old element. Wash the shell thor-

oughly. Install a new element.

NOTE:

The

spring

is

installed below the element

in

this

filter

and

above the element

in

the

first

stage filter.

Re-

install the shell, using the new gasket furnished

with the new element.

Start

the engine

and

check

to be sure

that

the filter does not leak.

5.

FUEL

PUMP

A.

Description.

The tractor may be equipped with either an

"Eaton" or a "Barnes"

Fuel

Pump, mounted to the

engine

as

shown

in

Figure

No.6.

The

"Eaton"

Fuel

Pump

is

a rotor type pump having

a delivery capacity of approximately

35

gallons

per hour

at

1000

R.P.M.

The pump

is

bolted to an

adapter,

and

is

driven by

an

adapter

shaft through

a hollow sleeve which acts os a universal joint.

The

adapter

shaft

is

driven by a helical

gear

on

the

balancer

shaft of the engine.

The pump rotates

in

a counter-clockwise direction,

viewed from the cover end.

The

four lobe inner

rotor rotates the outer rotor eccentrically when the

pump

is

in

operation to open

and

close the pas-

sages

in

the pump housing.

The

four lobe inner

rotor

is

attached to the pump shaft by a ball

lock

and

rotates the outer rotor which

is

free to turn

in

the pump housing cover.

As

the rotors revolve

in

the housing, fuel

is

displaced from the inlet

passage

to the outlet passage.

Two

pump shaft

oil

seals

are

used inside the body

at

the inner end. The sealing

edge

of

one

seal

faces the pump cover

and

retains the fuel within

the pump, the other faces the opposite direction

and

prevents engine lubricating

oil

from entering

the pump. The seals

are

located approximately

1/16"

apart.

A drain hole, located between the

two seals, vents to the atmosphere. A neoprene

g'asket fitted into the machined recess

in

the cover

is

compressed between the housing

and

the body

when the attaching bolts

are

drawn tight.

This

seal prevents fuel

oil

from leaking out

as

well

as

preventing air leaking inta the pump between the

15

cover

and

the housing.

A spring loaded relief valve, located on the inlet

side of the pump (right side of pump viewed from

cover end)

is

provided to by-pass fuel back to the

inlet side when the outlet pressure exceeds

37

to

47

P.S.1.

This

valve normally does not open since

its

purpose

is

to relieve excessive pump pressure

in

case of

dogging

in

any

of the fuel lines or

f1Iters.

The "Barnes" Fuel Pump

is

a constant flow

gear

type pump, having a delivery capacity

of

approx-

imately

35

gallons per hour

at

40

pounds pressure

and

1000

R.P

.M.

The

Barnes Pump

is

bolted to

an

adapter

and

is

driven

in

the same manner as

the Eaton Pump.

Two

steel gears revolve inside

the pump housing to create a vacuum

in

the intake

chamber, thus drawing fuel from the fuel tank.

The

fuel

is

carried around the gears

in

the spaces

between the teeth,

and

is

forced out of the pump

under pressure.

The

driving

gear

is

mounted on a free-floating type

drive shaft

and

is

keyed fo the shaft by a shear pin.

The

driven

gear

is

supported

in

the bore of the

pump housing by

its

supporting journals which

are

an

integral

part

of the driven

gear.

Two

pump shaft ail seals

are

used inside the stator

at

the inner end. The sealing

edge

of one seal

faces the pump housing

and

retains the fuel within

the pump, the other faces the mounting flange end

of the stator,

and

prevents engine lubricating ail

from entering the pump. The seals

are

located

approximately

1/16"

apart.

A drain hole, located

between the two seals, vents to the atmosphere.

A spring loaded relief valve, located

on

the inlet

side of the pump (right side of pump viewed from

cover end)

is

provided to by-pass fuel back to the

inlet side when the outlet pressure exceeds

47

10

60

P.S.I.

This

valve normally does nol open since

its

purpose

is

10 relieve excessive pump pressure

in

case clogging occurs

in

any

of the fuel lines or

filters.

B.

Service.

If

the fuel pump

is

removed for reconditioning, the

pump drive assembly should also be removed for

inspection.

p..:J:JCf\l\t)lY

C.

Removal

of

Fuel Pump

and

Pump Drive

Shaft

Assembly.

1. Disconnect Ihe fuel lines from Ihe pump.

2. Remove the nuts attaching Ihe fuel pump

and

drive

ada

pier 10 Ihe engine block.

3.

Pull

the pump off the attaching studs

and

remove Ihe square, lubular fuel pump cou-

pling.

4. Remove the flat

head

capscrew attaching

Ihe drive

adapter

10 the engine block

if

cap-

screw

is

used for altaching.

NOTE:

A flat

head capscrew

is

used to hold the

adapter

assembly

in

place on the early model engines,

and

a dowel

is

used on the later model en-

gines.

5. Tap the drive

adapter

flange lightly to loosen

and

withdraw it from the engine block.

D.

Disassembly

of

"Eaton" Fuel Pump.

The relief valve assembly may be removed from

the pump body without disassembly of the other

parts of the pump, by removing the fuel pump plug

and

jarring the valve parts from the body.

ROTOR

(OUTER)

\

PLUG

STEE\

BAllBUSHINGG\

j,

~

~

1.

C)

'/HI~~l

(INNER)

SH~

<{'

Q9

Ill-

~

SPRING;j{

\

GASK~

.,

./

.....

\

VALVE

.

"\

PLUG

GASKET

BODY

ASSEMBLY

SEAL

(OUTER)

GASKET

ROTOR

(INNER)

L---

_________

.!ig.

7

-"Eaton"

Fuel

Pump Details:

____________

.....J

16

When removing the relief valve assembly, note the

position of each

part

so that the parts may be

reassembled

in

their same relative position.

If

the relief valve only

is

to be inspected,

no

further

disassembly

is

necessary.

If

the entire pump

is

to

be dismantled proceed

as

follows:

1.

Remove the cover to body altachi

ng

bolts

and

install capscrews

1/4"

x 20 x

3"

long,

so

that the heads of the capscrews extend out

3/4"

from the pump cover.

2. Holding the pump assembly

in

hand,

tap

on

the heads of the capscrews with a soft ham-

mer,

separating

Ihe body

and

cover.

DO

NOT

PRY

BODY

AND

COVER

APART.

3. Remove the ouler rolor,

and

move the shaft

out toward the cover end of the pump, slide

the inner rolor forward on Ihe shaft

and

remove Ihe locking ball, Ihen remove Ihe

inner rotor from the rotor shaft.

4.

Remove the rotor shaft from the pump body

carefully, so as nat to

damage

the oil seals.

5. Drive the dowels from the pump body

if

necessary by means of a small punch

and

hammer.

6.

If

it

is

necessary to remove the seals, a tool

of the proper design may

be

used to

remOve

them

so

Ihey

will

nol be

damaged.

E.

Inspection

of

"Eaton"

Fuel

Pump

Parts.

1. Wash

alllhe

parts

in

clean fuel oil or solvent

and

inspect them carefully. The oil seals,

once removed from the pump, should

be

re-

placed.

If

the sealing

edges

of the seals

are

damaged

in

any

way,

so

that they do not

form a perfect seal around the shaft, either

a fuel

oil

leak or lubricating

011

leak

will

result.

2.

Inspect the rotors

and

the wearing surfaces

of the pump cover

and

body for

wear

and

scaring.

If

the rotors show excessive wear

or

are

scored they should be replaced.

If

the wearing surfaces

in

the pump cover

are

worn or scored, causing excessive looseness

of the rolors

in

Ihe cover

and

body, the pump

17

should be replaced.

3. Install the inner rotor on the pump shaft with

the locking boll

in

place.

If

excessive

wear

between these parts

is

found, new parts must

be installed.

4.

Check the

fit

of Ihe pump shaft

in

the pump

body bushings.

If

the shaft

and

bushings

show excessive wear they must

be

replaced.

The

specified diameter of the shaft

is

.4992"

and

the specified inside diameter of the

bushings

as

installed

is

.5015" making a

clearance of .0023" between the shaft

and

bushings.

5. Check the pump relief valve.

If

the valve

does

not form a light seal on

its

seat, lap the

valve using fine valve lapping compound.

A piece of wood

about

Ihe size of a pencil

makes a

good

holder for hand lapping.

CAUTION,

Use

only a small amount of com-

pound

50

that only the

seat

on the valve

and

in

the body

will

be affected. The ideal

seat

is

a ring about

1/64"

to

1/32"

wide

in

the

pump body. Thoroughly wa5h all Ihe lap-

ping compound

and

foreign material off the

valve

and

out of pump body.

6. Inspect the pump cover sealing gasket

and

the pump shaft seal gasket

and

replace

if

necessary.

F.

Assembly

of

"Eaton"

Fuel Pump_

1. Instal! Ihe bushings for the pump shaft

in

the

pump body

if

they were removed for replace-

ment, then, ream the inside diameter of the

bushings to .5015".

2. Install the pump shaft seal gasket

in

place

in

the pump body, then instal! pump shaft

inner seal with the sealing

edge

towards the

cover end of the pump. Make certain the

seal

is

instolled tight ogainst the seal gasket.

3. Install the pump shaft outer seol

with

the

sealing

edge

towards the mounting flange

end

of the pump.

4.

lubricate

the pump shaft end seals

and

in-

stall the shaft

in

the pump body. Install the

shaft from the cover end pushing it through

the bushings

and

then through the seals being

exceptionally careful not to

damage

the

seals.

Use

an

oil seal pilot tool on

the

drive

end

of

the

shaft

if

tool

is

available.

Before

inserting

the

shaft completely into position

in

the

pump body, install the inner rotor

and

locking ball on

the

shaft.

5. Install

the

outer

rotor

in

place on the inner

rotor.

6. Install the pump cover sealing

gasket

in

the

recess

of

the

pump cover, then place the pump

cover

in

position on

the

dowels

and

pump

body. Install the cover attaching bolts

and

tighten securely.

7. Turn

the

pump shaft

and

test it for bind.

The

shaft

should turn smoothly, with a slight

drag,

but should not bind

or

have

tight spots.

8. Install

the

relief valve parts,

make

certain

that

the

parts

are

installed properly

in

their re-

spective places on the inlet side of the pump

(right side when viewed from pump cover

end).

H'LJLJJING

9. Install the pump

body

plug

and

gasket

in

the

side opposite the relief valve.

10. Install the fuel pump on

the

engine

by direct

reversal of the removal procedure.

G.

Disassembly

of

"Barnes"

Fuel

Pump.

The relief valve assembly

may

be

removed from

the

pump

stator

without disassembly of

the

other

parts of the pump, by removing the pressure relief

spring plug

and

jarring

the

valve parts from

the

body.

When

removing

the

relief valve assembly, note

the

position of

each

part

so

that

the

parts

may

be

re-

assembled

in

their

same

relative position.

If

the relief valve only

is

to

be

inspected, no further

disassembly

is

necessary.

If

the

pump

is

to

be

dismantled proceed

as

follows:

1.

Remove the screws

attaching

the pump hous-

ing to

the

stator

and

install capscrews

1/4"

CAPS

CREW

DRIVING

GEAR

S

STATOR

FT

D

PLUG

SEAL

(INNER)

SEAL

(OUTER)

'--------------Fig.

a-"Barnes"

Fuel

Pump

Details

____________

....J

18

Table of contents

Other Allis-Chalmers Tractor manuals

Allis-Chalmers

Allis-Chalmers 10 hp User manual

Allis-Chalmers

Allis-Chalmers HD-14 User manual

Allis-Chalmers

Allis-Chalmers G User manual

Allis-Chalmers

Allis-Chalmers G User manual

Allis-Chalmers

Allis-Chalmers H 4 Specifications

Allis-Chalmers

Allis-Chalmers HD-4 Specifications

Allis-Chalmers

Allis-Chalmers 910-6 Speed User manual

Allis-Chalmers

Allis-Chalmers Simplicity 9523 Instruction Manual

Allis-Chalmers

Allis-Chalmers HD 6B User manual

Allis-Chalmers

Allis-Chalmers ac130 series User manual