Allmand SH-750 User manual

Not for

Reproduction

Operator’s Manual

SH-750 Enhanced Flameless Heater

Copyright © 2015 Briggs & Stratton Corporation

Milwaukee, WI, USA. All rights reserved.

Part No.: 107577USCN

Revision: A

en

fr

es

Manual del operador

Calentador sin llama mejorado SH-750

Manuel d’utilisation

Appareil de chauffage sans flamme

amélioré SH-750

Not for

Reproduction

2www.allmand.com

Record Important Information

Recording the equipment information will help when placing

an order for replacement parts and/or decals.

Company Equipment No:____________________________

Unit model No:____________________________________

Unit Vin:_________________________________________

Engine Model No: ____________Serial No:_____________

Generator Model No:__________Serial No:_____________

Accessories:_____________________________________

_______________________________________________

_______________________________________________

Manual Contents:

Introduction ........................................................................2

Safety...................................................................................2

Features and Controls.......................................................6

Transporting........................................................................8

Operation ......................................................................... 14

Maintenance .................................................................... 21

Specifications.................................................................. 26

Troubleshooting .............................................................. 27

Warranty........................................................................... 28

Introduction

About This Manual

TAKE TIME TO READ THIS MANUAL THOROUGHLY

This instruction manual provides necessary instructions for

the Allmand SH-750 enhanced flameless heater.

The information found in this manual is in effect at the time

of printing. Allmand Bros Inc. may change contents without

notice and without incurring obligation.

Any reference in this manual to left or right shall be deter-

mined by looking at the trailer from the rear.

If you are uncertain about any of the information in the man-

ual, contact Allmand service department at 1-800-562-1373,

or contact us through the Allmand website, www.allmand.

com.

Save these original instructions for future reference.

Products Covered by This Manual

The following products are covered by this manual:

SH-750 Enhanced Flameless Heater

Safety

Safety Definitions

Safety statements are one of the primary ways to call your

attention to potential hazards. Follow the precautions listed

throughout the manual before operation, during opera-

tion and during periodic maintenance procedures for your

safety, the safety of others and to protect the performance

of equipment. Keep the decals from becoming dirty or torn

and replace them if they are lost or damaged. Also, if a part

needs to be replaced that has a decal attached to it, make

sure to order the new part and decal at the same time.

This safety alert symbol appears with most safety

statements. It means attention, become alert, your

safety is involved! Read and abide by the message

that follows the safety alert symbol.

DANGER

Indicates a hazardous situation which, if not avoided, will

result in death or serious injury.

WARNING

Indicates a hazardous situation which, if not avoided, could

result in death or serious injury.

CAUTION

Indicates a hazardous situation which, if not avoided, could

result in minor or moderate injury.

NOTICE

Indicates a situation which can cause damage to the equip-

ment, personal property and/or the environment, or cause the

equipment to operate improperly.

NOTE:

Provides key information to make procedures easier or clear-

er.

Safety Precautions

The following section contains general safety precautions

and guidelines that must be followed to reduce risk to per-

sonal safety. Special safety precautions are listed in specific

procedures. Read and understand all of the safety precau-

tions before operating or performing repairs or maintenance.

Not for

Reproduction

3

en

DANGER

Electrocution Hazard

• Servicing electrical components while the engine is

running will result in death or serious injury. Always

shut down the engine before servicing electrical com-

ponents.

• Capacitors are capable of discharging high volt-

age that will result in death or serious injury. Always

shutdown the engine, then discharge capacitors by

grounding them with an insulated device.

• Contact with wires that have been made bare by dam-

aged, cut, or worn insulation will result in death or

serious injury. Always replace damaged wiring before

starting the engine or operating the unit.

WARNING

Unsafe Operation Hazard

• Never permit anyone to install or operate the equip-

ment without proper training.

• Read and understand this Operator’s Manual and the

Engine Operator’s Manual before operating or servic-

ing the light tower to ensure that safe operating prac-

tices and maintenance procedures are followed.

• Safety signs and decals are additional reminders for

safe operating and maintenance techniques.

WARNING

Fall Hazard

• Never carry riders on the equipment.

WARNING

Modification Hazard

• Never modify the equipment without written consent of

the manufacturer. Any modification can effect the safe

operation of the equipment.

WARNING

Exposure Hazard

• Always wear personal protective equipment, including

appropriate clothing, gloves, work shoes, and eye and

hearing protection, as required by the task at hand.

WARNING

Explosion Hazard

• While the engine is running or the battery is charging,

hydrogen gas is being produced and can be easily

ignited. Keep the area around the battery well venti-

lated and keep sparks, open flame and any other form

of ignition out of the area.

• Always disconnect the negative (-) battery cable

before servicing equipment.

• Only use the starting procedure as described in the

Engine Operator’s Manual to start the engine.

• Never charge a frozen battery. Always slowly warm

the battery to room temperature before charging.

WARNING

Fire And Explosion Hazard

• Diesel fuel is flammable and explosive under certain

conditions.

• Never use a shop rag to catch fuel.

• Wipe up all spills immediately.

• Never refuel with the engine running.

• Store any containers containing fuel in a well venti-

lated area, away from any combustibles or sources of

ignition.

WARNING

Exhaust Hazard

• All internal combustion engines create carbon monox-

ide gas during operation and special precautions are

required to avoid carbon monoxide poisoning.

• Never block windows, vents or other means of ventila-

tion if the equipment is operating in an enclosed area.

• Always ensure that all connections are tightened to

specifications after repair is made to the exhaust sys-

tem.

WARNING

Alcohol And Drug Hazard

• Never operate the light tower while under the influence

of alcohol or drugs, or when ill.

Not for

Reproduction

4www.allmand.com

WARNING

Entanglement / Sever Hazard

• Always stop the engine before beginning service.

• If the engine must be serviced while it is operating,

remove all jewelry, tie back long hair and keep hands,

other body parts and clothing away from moving/rotat-

ing parts.

• Verify that all guards and covers are attached properly

to the equipment before starting the engine. Do not

start the engine if any guards or covers are not prop-

erly installed on the equipment.

• Attach a “Do Not Operate” tag near the key switch

while performing maintenance on the equipment.

WARNING

Control Hazard

An underrated tow hitch could cause loss of control of the

towing vehicle or trailer, resulting in death or serious injury.

Always:

• Make sure that the vehicle’s towing capacity exceeds

that of the trailer load.

• Make sure that the vehicle’s hitch and ball are rated to

accept the trailer load, and are the appropriate size for

the trailer coupler socket.

• Dragging safety chains on the road surface could

cause them to fail in an emergency, resulting in death

or serious injury. Always attach safety chains properly

and securely between the tow vehicle and the trailer,

and do not let them drag on pavement.

WARNING

Flying Object Hazard

• Always wear eye protection when cleaning the equip-

ment with compressed air or high pressure water.

Dust, flying debris, compressed air, pressurized water

or steam may injure your eyes.

WARNING

Coolant Hazard

• Wear eye protection and rubber gloves when handling

engine coolant. If contact with the eyes or skin should

occur, flush eyes and wash immediately with clean

water.

WARNING

Burn Hazard

• Rapid release of hot coolant under pressure could

result in death or serious injury. Use extreme caution

when opening the radiator cap, and always wear eye

protection and heat resistant gloves.

• Contact with hot surfaces of the heater unit could

result in death or serious injury. Always keep clear of

heater unit chimney, air outlet components and other

hot areas of the heater unit.

WARNING

California Proposition 65

• Certain components in this product and related

accessories contain chemicals known to the State

of California to cause cancer, birth defects, or other

reproductive harm. Wash hands after handling.

WARNING

California Proposition 65

• Battery posts, terminals and related accessories con-

tain lead and lead compounds, chemicals known to

the State of California to cause cancer and reproduc-

tive harm. Wash hands after handling.

CAUTION

Tool Hazard

• Always use tools appropriate for the task at hand and

use the correct size tool for loosening or tightening

equipment parts.

CAUTION

Slip Hazard

• Immediately clean up any spilled liquid on the shop

floor.

• Clean up accumulated dirt and debris on the shop

floor at the end of each shift.

NOTICE

The statements that follow have NOTICE level issues.

Damage to equipment or property can result if not fol-

lowed.

• Any part which is found defective as a result of inspection

or any part whose measured value does not satisfy the

standard or limit MUST be replaced.

• Always tighten components to the specified torque.

Loose parts can cause equipment damage or cause it to

operate improperly.

Not for

Reproduction

5

en

• Follow the guidelines of the Environmental Protection

Agency (EPA), Environment Canada (EC) or other gov-

ernmental agencies for the proper disposal of hazardous

materials such as engine oil, diesel fuel and engine cool-

ant.

• Only use replacement parts specified. Other replace-

ment parts may effect warranty coverage.

• Clean all accumulated dirt and debris away from the

body of the equipment and its components before you

inspect the equipment or perform preventative mainte-

nance procedures or repairs. Operating equipment with

accumulated dirt and debris will cause premature wear of

equipment components.

• Never dispose of hazardous materials by dumping them

into a sewer, on the ground, or into groundwater or water-

ways.

• Retrieve any tools or parts that may have dropped inside

of the equipment to avoid improper equipment operation.

• If any alert indicator illuminates during equipment opera-

tion, stop the engine immediately. Determine the cause

and repair the problem before continuing to operate the

equipment.

Notification of Safety Defects

If you believe that your vehicle has a defect that could

cause a crash or could cause injury or death, you should

immediately inform the National Highway Traffic Safety

Administration (NHTSA) in addition to notifying Allmand.

If NHTSA receives similar complaints, it may open an inves-

tigation, and if it finds that a safety defect exists in a group

of vehicles, it may order a recall and remedy campaign.

However, NHTSA cannot become involved in individual prob-

lems between you, your dealer, or Allmand.

To contact NHTSA, you may either call the Vehicle Safety

Hotline toll-free at 1-888-327-4236 (TTY: 1-800-424-9153),

go to http://www.safercar.gov; or write to:

Administrator

NHTSA

1200 New Jersey Avenue S.E.

Washington, DC 20590

You can also obtain other information about motor vehicle

safety from http://www.safercar.gov.

Safety Decals

Before operating your unit, read and understand the follow-

ing safety decals. The cautions, warnings, and instructions

are for your safety. To avoid personal injury or damage to the

unit, understand and follow all the decals.

WARNING

If any safety or instructional decals become worn or dam-

aged, and cannot be read, order replacement decals from

your dealer.

Tire Information

WARNING - Hot surface

could burn exposed skin

which could result in death

or serious injury. Hot com-

ponents must be cool before

handling, or handle hot com-

ponents with heat resistant

gloves.

DANGER - Contacting

High Voltage Components.

Contact with high voltage

components within this com-

partment will result in death

or serious injury. Do not enter

electrical compartments when

engine is running. Always

close cover before operating

the machine.

DANGER - Ground Rod.

Operating the machine with-

out first installing the ground

rod will result in death or seri-

ous injury. Drive the ground

rod into the earth and attach

ground wire to grounding lug.

Emergency Stop

Pre-Heat System

Not for

Reproduction

6www.allmand.com

Fire Extinguisher

Grease Points

Operation Icons

The following table contains operation icons that may be

found on the unit, along with the meaning of each icon.

Icon Meaning Icon Meaning

Read Operator’s

Manual

Earth Ground

On (Power) Off (Power)

Tie Down Lift Point

Diesel Fuel Fuel Tank

Heater Trailer Interior

Light

Hourmeter

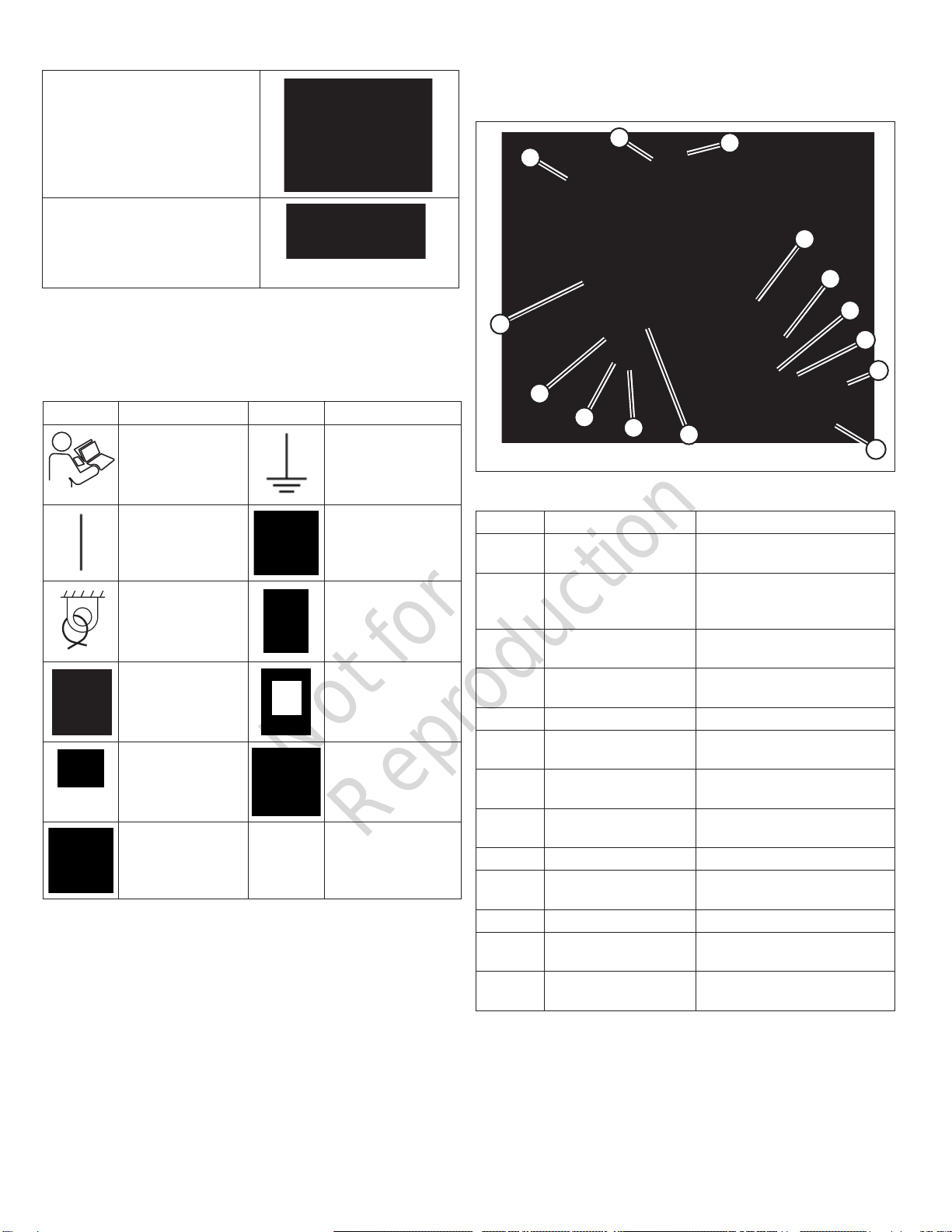

Features and Controls

Overview

The Allmand SH-750 Enhanced Flameless Heater delivers

safe and efficient electric heat to areas where conventional

combustion heaters cannot be used.

Ambient air is pulled in through dual intake ducts into an

electric heating element, powered by a 480-volt 3-phase

generator driven by a Caterpillar diesel engine, then forced

out by a belt-driven fan through a single discharge duct. The

result is safe, clean, reliable heat, anytime, anywhere.

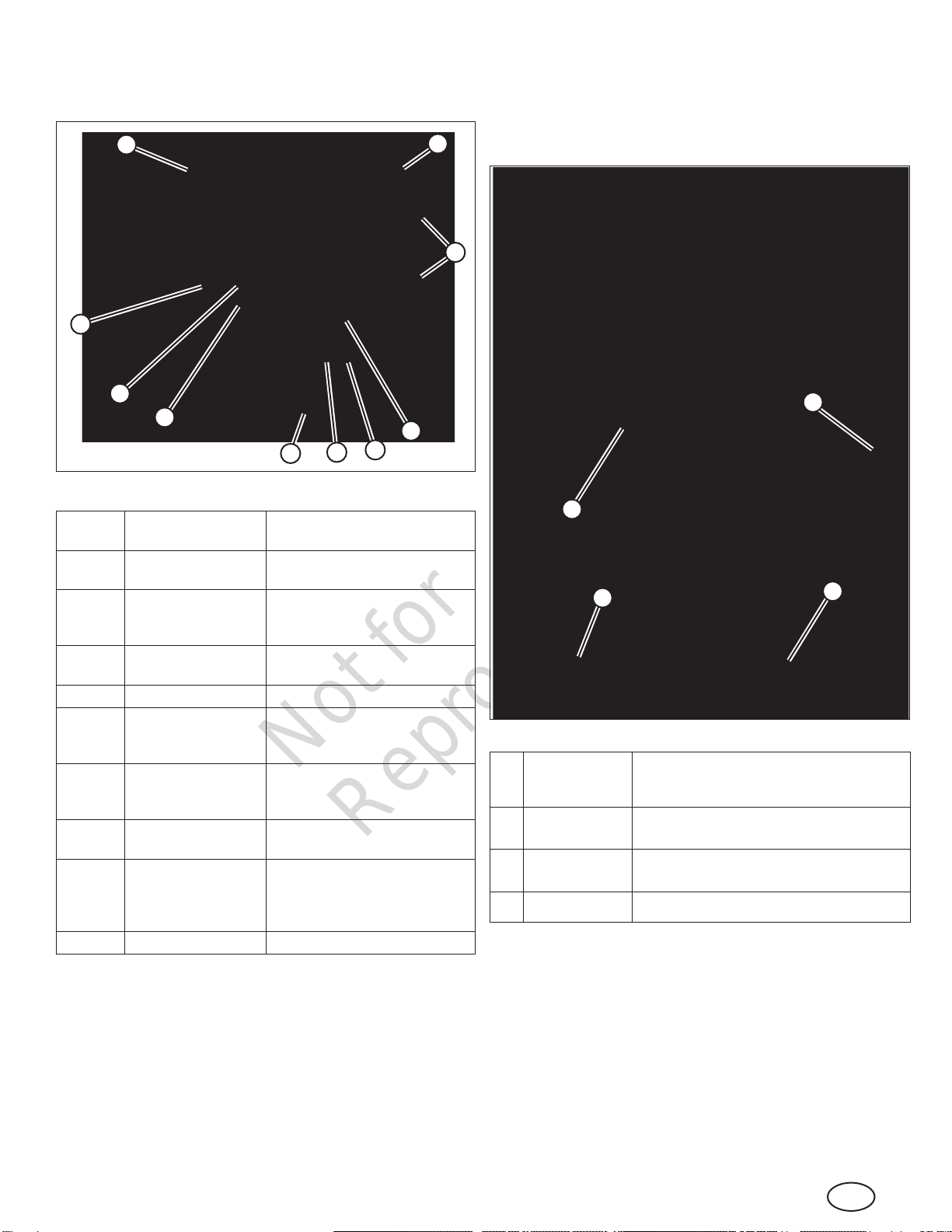

Exterior (Front / Right Side)

Compare Figure 1 with the table following.

Figure 1

E

F

G

D

C

B

A

K

J

H

I

N

L

M

AFire Extinguisher

BTongue Jack (retract-

able)

Supports and levels unit. See

Transporting; Operation.

CBreak-Away Brake

System Switch / Cable

Engages axle brakes in the

event unit separates from tow-

ing vehicle. See Transporting.

DTrailer Lighting Cable Powers trailer lights. See

Transporting.

ETrailer Coupler / Lu-

nette Eye

Couples unit to towing vehicle.

See Transporting.

FSafety Chains (2) See Transporting.

GHeater Discharge

Duct

See Operation.

HTie-Down Point (4 - 2

each side)

See Transporting.

IForklift Pocket (4 - 2

each side)

See Transporting.

JFluid Drain Station See Maintenance.

KEngine Compartment

Access Door

Accesses engine compart-

ment. See Operation.

LEngine Air Cleaner

MExterior Light (4 - 2

each side)

See Operation.

NLift Point (4 - 1 each

corner)

See Transporting.

Not for

Reproduction

7

en

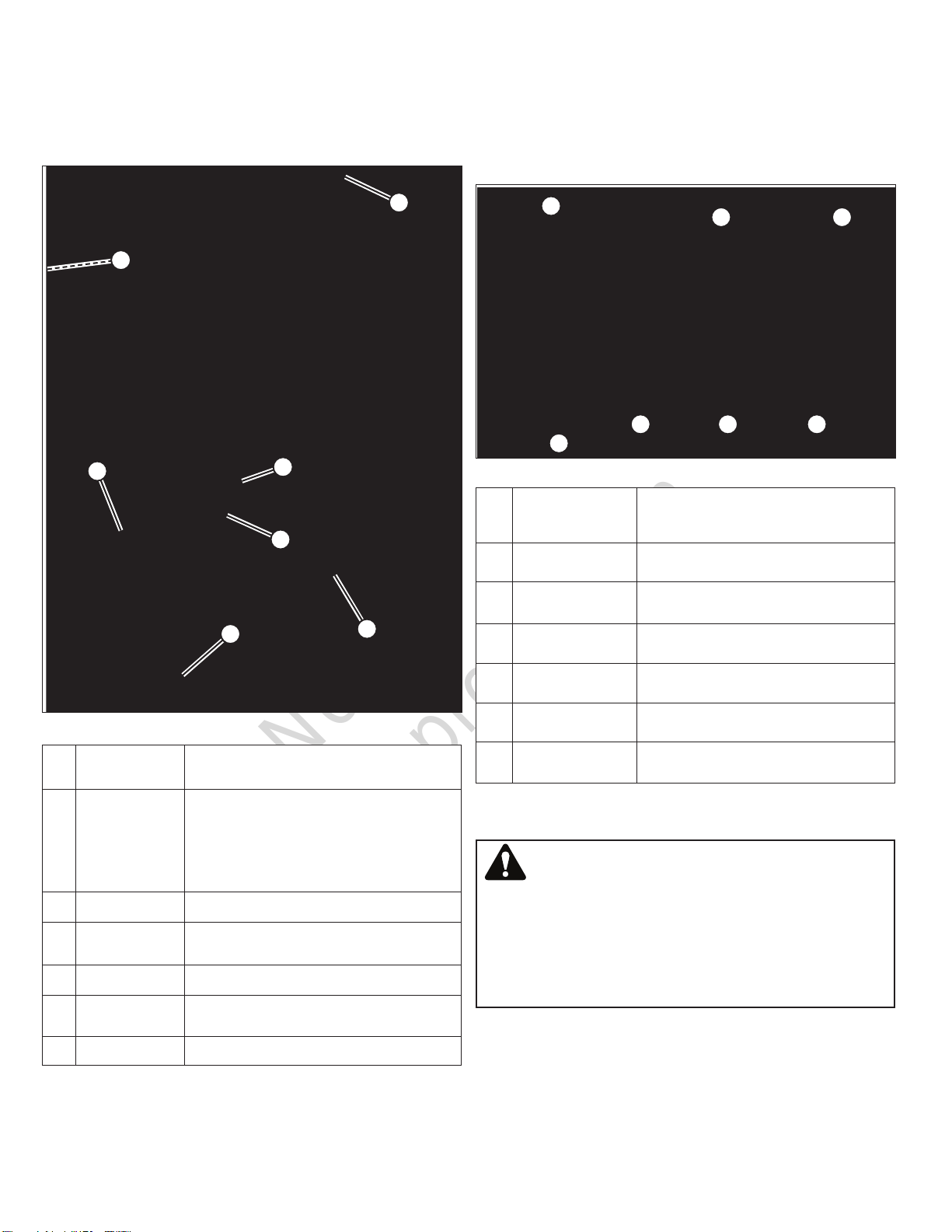

Exterior (Rear / Left Side)

Compare Figure 2 with the table following.

Figure 2

D

C

B

A

E

I

H

F

G

J

ACoolant Fill Access

Plate (on roof)

Access for engine coolant. See

Operation; Maintenance

BHeater Intake Duct

(2)

Heater air intake. See Opera-

tion.

CGround Lug Attachment point for grounding

rod (not supplied). See Opera-

tion.

DLicense Plate

Bracket / Light

ETaillight (2)

FAuxiliary Fluid Con-

tainment Drain (1

each side)

Auxiliary drain points for fluid

containment tray. See Mainte-

nance

GPreheat System Plug Preheats engine coolant,

engine oil, and battery. See

Operation.

HEmergency Stop

Button

All-system shutdown in case of

emergency. See Operation.

IControl Compart-

ment Access Door

Accesses control compartment.

See Features and Controls -

Interior (Control Compartment);

Operation.

JOperational Beacon Indicates unit is operating.

Interior (Control Compartment)

The control compartment is located behind the control com-

partment access door (I, Figure 2).

Compare Figure 3 with the table following.

Figure 3

DC

B

A

AControl Panel Controls operation of engine, heater, and

other accessories. See Features and

Controls -‘Control Panel’;Operation.

BPrime Rod Used to prime engine in the event unit runs

out of fuel. See Operation.

CDoor Lock Rod Locks control compartment access door in

open position. See Operation.

DFuel Cap See Operation.

Not for

Reproduction

8www.allmand.com

Interior (Engine Compartment)

The engine compartment is located behind the engine com-

partment access door (K, Figure 1).

Compare Figure 4 with the table following.

E

D

CG

F

A

B

Figure 4

ACoolant Level

Indicator

Indicates level of engine coolant. See

Operation; Maintenance.

BAir Filter Location of engine air lter (hidden). See

Maintenance.

NOTE: Access to the air lter requires body

panel removal. Replacement should be

performed only by an authorized dealer.

CBattery See Maintenance.

DDoor Lock Rod Locks engine compartment access door in

open position. See Operation.

EGrease Station See Maintenance.

FEngine Oil

Dipstick

Indicates level of engine oil. See Operation.

GEngine Oil Fill Fill point for engine oil. See Operation.

Control Panel

The control panel features controls and informational displays

necessary for the operation of the engine, heater, and other

accessories.

Compare Figure 5 with the table following.

AB C

D

E F G

Figure 5

AEngine Monitor

and Control

Center

Monitors various engine functions;also

controls engine speed. See Operation.

BThermostat Controls target heater temperature. See

Operation.

CDischarge

Temperature

Actual air temperature at heater

discharge duct. See Operation.

DKey Switch Starts engine and powers accessories.

See Operation.

EMaster Switch Turns on power to the unit. See

Operation.

FInterior Light

Switch

Turns on interior compartment lights.

See Operation.

GExterior Light

Switch

Turns on exterior work site lights. See

Operation.

Transporting

WARNING

Operating or towing a machine with worn, damaged or

missing parts can result in death or serious injury. Always

replace worn, damaged or missing parts promptly. Do not

operate or tow this machine until all worn, damaged or

missing parts have been replaced, and proper operation of

the machine has been verified.

Pre-Transport Check List

1. Check that the operator’s manuals are with the heater

trailer, in the manual storage container.

2. Check that all safety decals are legible and in place on

the heater trailer. See ‘Safety Decals’ in the Safety sec-

tion of this manual.

Not for

Reproduction

9

en

3. Check the heater trailer for proper operation:

a. Use an appropriate means to safely support the trailer

tongue. Check that the tongue jack operates properly.

See ‘Operating The Tongue Jack’.

b. Check that the trailer coupler operates properly, and

that the trailer coupler or lunette eye is securely fas-

tened to the heater trailer tongue. See ‘Using The

Trailer Coupler’ and ‘Lunette Eye’.

c. Check that the safety chains are properly secured to

the heater trailer tongue, and check the safety chains

and hooks for damage. Replace damaged safety

chains and hooks.

d. Check the trailer lighting connector for damage, and

the trailer lighting wires for damage. Replace or repair

damaged lighting connector or wiring.

e. Check the break-away trailer brake system, and make

sure the break-away brake system battery is fully

charged. See ‘Break-Away Brake System’.

f. Check the condition and inflation pressure of the tires.

See ‘Checking the Tire Pressure’ in the Maintenance

section.

WARNING

Towing a trailer with worn, damaged or underinflated tires

could result in death or serious injury. Always replace worn

or damaged tires promptly. Always keep tires inflated to

proper cold tire inflation pressure.

4. Check that the ground lug on the rear of the unit is clean

and undamaged.

NOTE: Ground rod and cable not supplied. Contact your

authorized dealer.

5. Check the engine oil level and add as necessary. See

‘Engine Oil’ in the Maintenance section.

6. Check the engine coolant level and add as necessary.

See ‘Engine Coolant’ in the Maintenance section.

7. Check the engine air cleaner for damage and replace

as necessary. Check the engine air intake system and

make sure all connections are air tight.

8. Check to be sure the heater intake and discharge ducts

are clean, undamaged, and unobstructed.

9. Check to be sure the canvas heater duct covers are in

place over the heater ducts.

10.Check the battery for adequate charge. Use a 12 volt

battery charger to bring the battery back to full charge.

See ‘Maintaining the Battery’ in the Maintenance section.

11.If the trailer was stored with the battery disconnected,

reconnect the battery, negative (-) cable last.

12.Check that there is sufficient fuel in the fuel tank, and

add if needed. See ‘Fueling’ in the Operation section.

13.Check that the engine starts and runs properly. See

‘Operating The Engine’ in the Operation section.

14.Check that the heater operates properly. See ‘Operating

The Heater’ in the Operation section.

15.Check that there is sufficient ducting of the correct diam-

eter for the heater trailer.

NOTE: Ducting not supplied. Contact your authorized

dealer.

16.Make sure all covers and doors are closed and securely

latched.

Preparing The Unit For Towing

WARNING

Towing a trailer with an underrated tow vehicle, or an

underrated or undersized hitch could result in death or

serious injury. Always use a tow vehicle that has a rated

towing capacity that exceeds the Gross Vehicle Weight

Rating (GVWR) of the trailer, and is equipped with the

appropriate size tow hitch rated for the GVWR of the trailer.

1. Check the tow vehicle’s owner / operator manual for

the maximum rated towing capacity. Make sure the tow

vehicle and its trailer hitch are rated to tow the heater

trailer. See ‘Heater Trailer Weight’ for detailed information

on trailer weight.

2. Check the tow vehicle’s lighting connector and make

sure it will mate with the trailer lighting connector on the

heater trailer. Check that the auxiliary power wire on the

tow vehicle is connected and powered to operate the

break-away brake system.

3. The heater trailer is equipped with both an SAE J684

coupler (for 2-5/16 inch / 59 mm diameter ball), and

an SAE J847 lunette eye (3 inches / 75 mm diameter).

Determine which is to be used for towing the trailer. See

‘Trailer Coupler / Lunette Eye’ for detailed information on

changing between the trailer coupler and the lunette eye.

4. Check that the safety chains are properly secured to the

heater trailer tongue, and check the safety chains and

hooks for damage. Replace damaged safety chains and

hooks.

5. Check the trailer lighting connector for damage, and the

trailer lighting wires for damage. Replace or repair dam-

aged lighting connector or wiring.

6. Check the break-away trailer brake system, and make

sure the break-away brake system battery is fully

charged. See ‘Break-Away Brake System’ for detailed

information on the break-away brake system.

7. Check the condition and inflation pressure of the tires.

See ‘Checking the Tire Pressure’ in the Maintenance

section for detailed information on tires and tire inflation

pressures.

Not for

Reproduction

10 www.allmand.com

WARNING

Towing a trailer with worn, damaged or underinflated tires

could result in death or serious injury. Always replace worn

or damaged tires promptly. Always keep tires inflated to

proper cold tire inflation pressure.

8. Use an appropriate means to support the trailer tongue.

Check that the tongue jack operates properly. See

‘Operating The Tongue Jack’.

9. Connect the trailer coupler or lunette eye to the tow vehi-

cle trailer hitch or pintle hook. Connect the safety chains

and trailer lighting connector to the tow vehicle. See

‘Connecting The Trailer To The Tow Vehicle’ for detailed

information.

10.Make sure all covers and doors are closed and securely

latched.

Trailer Coupler / Lunette Eye

The heater trailer can be equipped with either a standard

adjustable-height trailer coupler or lunette eye. The SAE

J684 trailer coupler for a 2-5/16 inch / 59 mm diameter ball

is rated at 15,000 pounds (6,804 kg) GVWR with a 2,250

pound (1,021 kg) tongue weight. The 3-inch (75 mm) diama-

ter lunette eye, conforming to the requirements of SAE J847,

is rated at 25,000 pounds (11,340 kg) GVWR with a 3,000

pound (1,361 kg) tongue weight.

To change between the trailer coupler and lunette eye:

1. Check the tongue, trailer coupler and lunette eye for

missing and damaged parts. Replace any part that is

missing or damaged.

2. Remove the two lock nuts and hex head screws (A,

Figure 6) securing the trailer coupler (B) or lunette eye

(C) to the tongue. Discard the lock nuts.

3. Select either the trailer coupler or lunette eye (whichever

is required to couple the heater trailer to your tow vehi-

cle), and position it at the front of the tongue. Determine

the height which works best for your tow vehicle.

4. Insert the two hex head screws removed in Step 2

through the appropriate holes in the tongue and trailer

coupler or lunette eye.

5. Install new lock nuts (Grade 5 or stronger) onto the two

hex head screws and tighten securely.

WARNING

Failure to securely tighten the hardware securing the trailer

coupler or lunette eye to the heater trailer tongue could

cause the heater trailer to separate from the tow vehicle,

resulting in death or serious injury. Always check and

securely tighten the hardware holding the trailer coupler or

lunette eye to the tongue.

Figure 6

A

B

C

Connecting The Heater Trailer To The

Tow Vehicle

1. Place wheel chocks (not supplied) against the front of the

front wheels, and against the back of the rear wheels, on

both sides of the heater trailer.

2. Use the tongue jack to raise the trailer coupler or lunette

eye above the tow vehicle’s hitch ball or pintle hook. See

‘Operating The Tongue Jack’.

3. Position the tow vehicle’s hitch ball or pintle hook under

the trailer coupler or lunette eye.

4. Lower the trailer coupler or lunette eye onto the hitch ball

or pintle hook with the tongue jack.

5. Lock the trailer coupler or pintle hook. See ‘Using The

Trailer Coupler’ or ‘Using A Pintle Hook’ for detailed cou-

pling information.

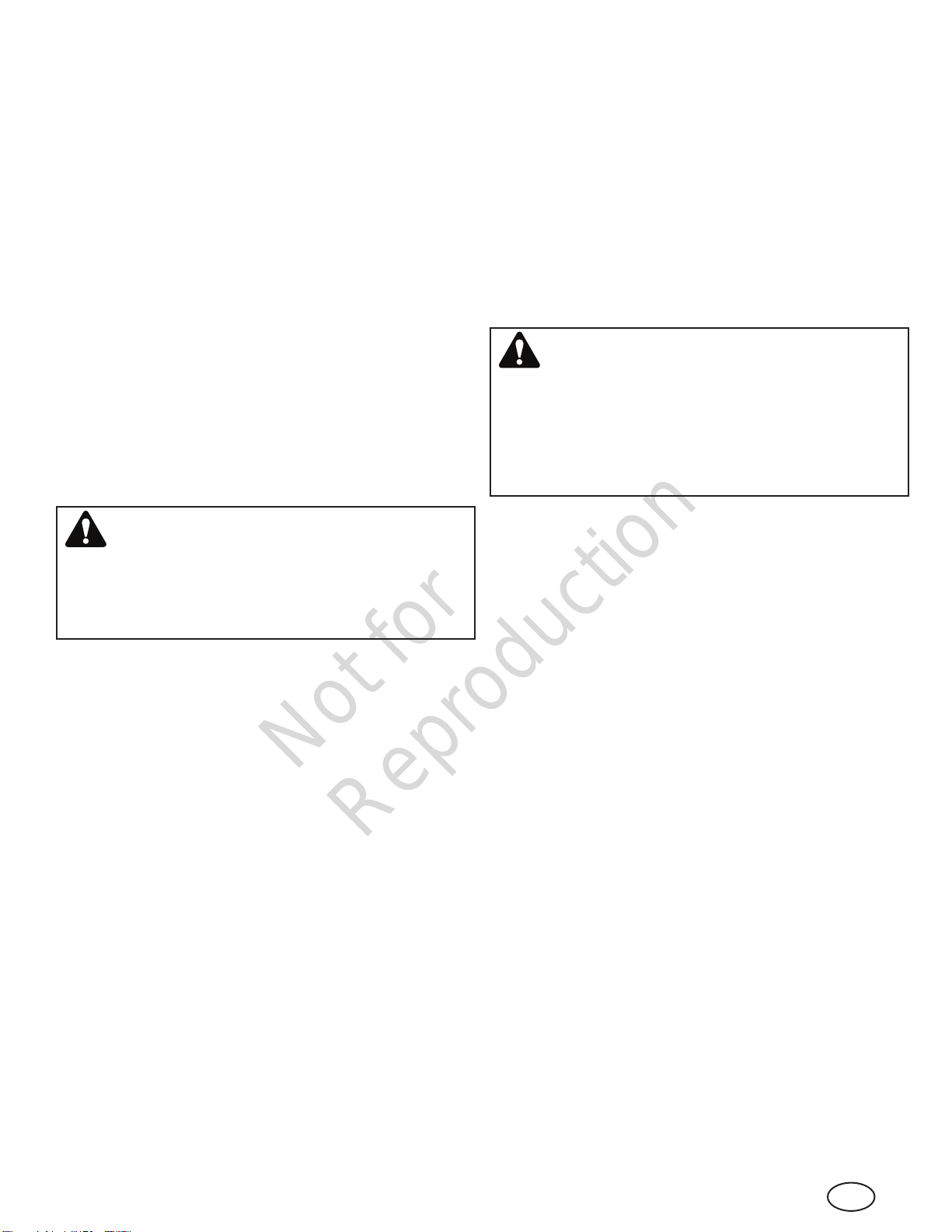

6. Attach the safety chains (A, Figure 7) to the tow vehicle’s

hitch frame. Cross the chains under the tongue as

shown in Figure 7. Leave enough slack in the chains to

allow for turns, but not so much that the chains will con-

tact the road surface.

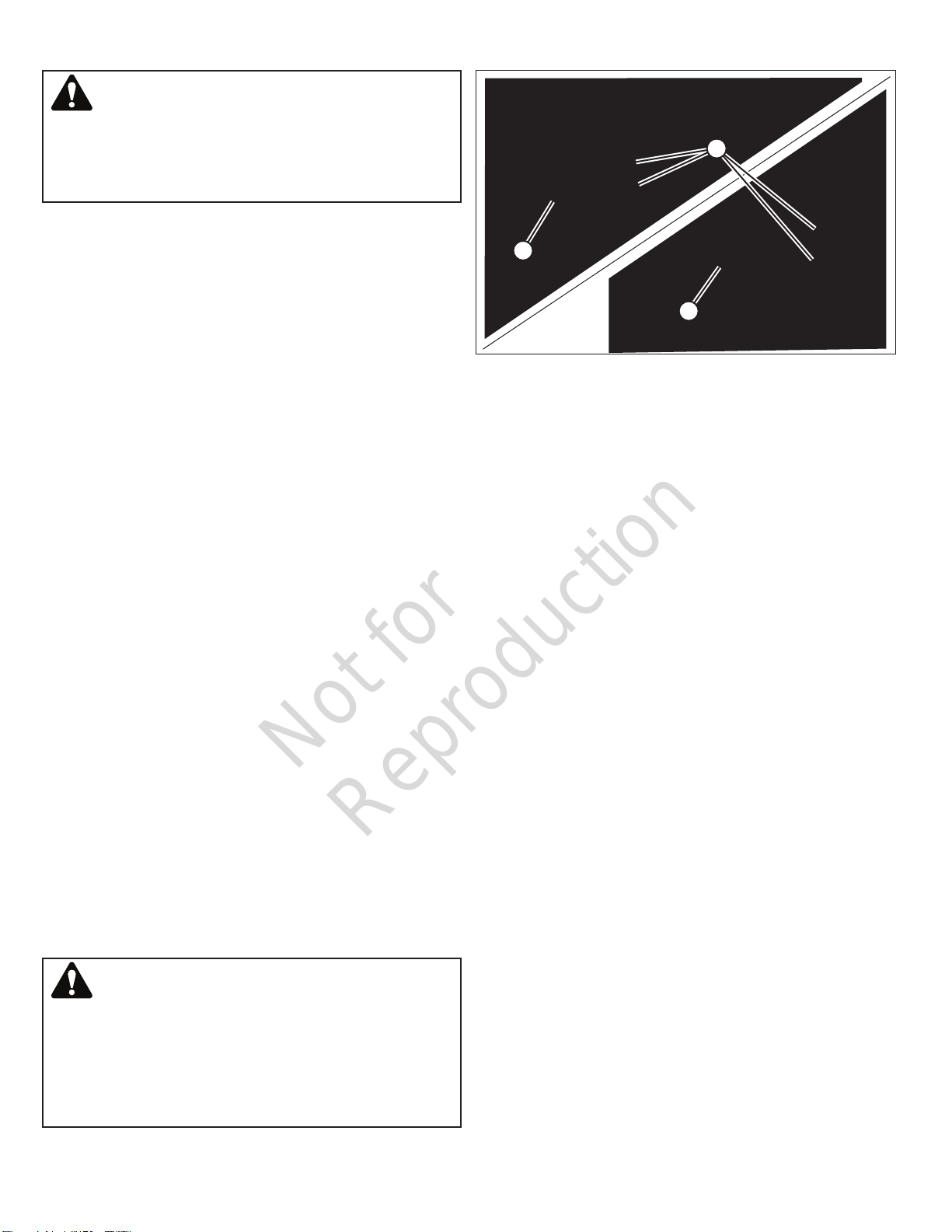

7. Connect the trailer lighting connector (A, Figure 8) to the

tow vehicle’s connector (B). Make sure the trailer lighting

harness has adequate length to prevent disconnection

when turning, but not so much length that the harness

will contact the road surface. Check the stop, turn sig-

nal, tail, side marker and license plate lamps for proper

operation.

8. Connect the break-away brake switch cable (C, Figure 8)

to the tow vehicle (D). See ‘Break-Away Brake System’

for detailed information on the break-away brake system.

9. Raise the tongue jack all the way, and retract the jack

foot into the transport position. See ‘Operating The

Tongue Jack’.

10.Remove the wheel chocks from both sides of the heater

trailer wheels.

Not for

Reproduction

11

en

Figure 7

A

Figure 8

A

B

C

A

Operating The Tongue Jack

The heater trailer is equipped with a tongue jack to support

the trailer tongue and to level the trailer front-to-rear.

To lower the tongue jack (raise the front of the trailer)

• Turn the jack handle (A, Figure 9) clockwise (B).

To raise the tongue jack (lower the front of the trailer)

• Turn the jack handle (A, Figure 9) counter-clockwise (C).

To extend or retract the jack foot

1. Use an appropriate means to support the trailer tongue.

2. Remove the pin (D, Figure 9) securing the jack foot (E) to

the tongue jack.

WARNING

Removing the jack foot pin without supporting the trailer

tongue could cause the jack to collapse, resulting in death

or serious injury. Always make sure the trailer tongue is

safely supported by appropriate means prior to removing

the jack foot pin.

3. Extend or retract the tongue jack foot as needed.

4. Secure the jack foot with the locking pin. Be sure to lock

the pin in place.

Figure 9

A

E

B

C

D

Using The Trailer Coupler

The heater trailer is equipped with a heavy duty SAE trailer

coupler rated for Gross Vehicle Weight Rating (GVWR) of

15,000 pounds (6,804 kg). This coupler complies with SAE

J684 and VESC V-5 standards.

To couple the trailer to the tow vehicle

1. Pull up on the locking trigger (A, Figure 10), and lift the

locking lever (B, shown lifted).

2. Adjust the coupler to the hitch ball (F, Figure 10) by

pushing the channel lock (D) up, away from the adjusting

nut (E).

3. Tighten the adjusting nut by turning the nut clockwise,

or loosen by turning counter-clockwise. Proper adjust-

ment is obtained when the coupler is as tight as possible

on the ball and the locking lever can still be opened and

closed.

NOTE: Check adjustment frequently and tighten the

adjusting nut as necessary.

Not for

Reproduction

12 www.allmand.com

4. Make sure the hitch ball is completely engaged in the

coupler socket (C, Figure 10).

5. Push the locking lever down into the locked position.

Insert the locking pin (G, Figure 10) into the hole in the

locking lever, or use a padlock for added security.

6. Check that the coupler is securely attached to the ball

hitch.

To uncouple the trailer from the tow vehicle

1. Remove the locking pin (or padlock, if used) from the

hole in the locking lever.

2. Pull up on the the locking trigger, and lift the locking lever.

To couple the trailer to the tow vehicle:

Figure 10

B

A

FG

E

D

C

Using A Pintle Hook

The 3-inch (75mm) diameter lunette eye meets the require-

ments of SAE J847 for Gross Vehicle Weight Rating (GVWR)

of 25,000 pounds (11,340 kg). Couple the lunette eye to

a pintle hook meeting the requirements of SAE J847 for a

GVWR of not less than 25,000 pounds (11,340 kg).

When using the lunette eye with a pintle hook, follow the pin-

tle hook manufacturer’s instructions for coupling and locking

the lunette eye to the pintle hook, and uncoupling the lunette

eye from the pintle hook.

Break-Away Brake System

The heater trailer is equipped with electric brakes and a

break-away brake system. The break-away brake system

is designed to bring the heater trailer to a stop by activating

the electric brakes should the heater trailer become discon-

nected from the tow vehicle while moving.

The auxiliary power wire on the tow vehicle must be con-

nected and powered for this system to work.

The break-away brake system is not intended to be used as

a parking brake.

The break-away brake system consists of a break-away box

with 12 volt battery, a break-away brake switch, and a break-

away brake switch cable.

The break-away brake box is equipped with a battery test

button to check the battery condition. The battery should be

charged and tested before towing the trailer.

To check the break-away brake system

WARNING

Towing the heater trailer when the break-away brake sys-

tem battery charge is low, or when the electric brakes are

not functioning properly could result in death or serious

injury should the heater trailer become disconnected from

the tow vehicle while moving. Always perform the break-

away brake system tests prior to towing the heater trailer.

Always repair the break-away brake system if the system is

not operating properly.

1. Before connecting the tow vehicle trailer lighting cable

to the heater trailer, push the “Test” button on the break-

away brake box. The green light indicates a charged bat-

tery, while a red light indicates that the battery charge is

low.

2. If the battery charge is low, recharge the battery before

towing the trailer. To recharge the battery, connect the

tow vehicle’s trailer lighting cable to the heater trailer. An

amber light indicates that the battery is charging.

3. With a fully charged battery, test the break-away brake

system. Pull firmly on the break-away brake switch cable

until the pin disconnects from the break-away brake

switch. The battery should activate the electric brakes.

To connect the break-away brake switch cable to the

tow vehicle

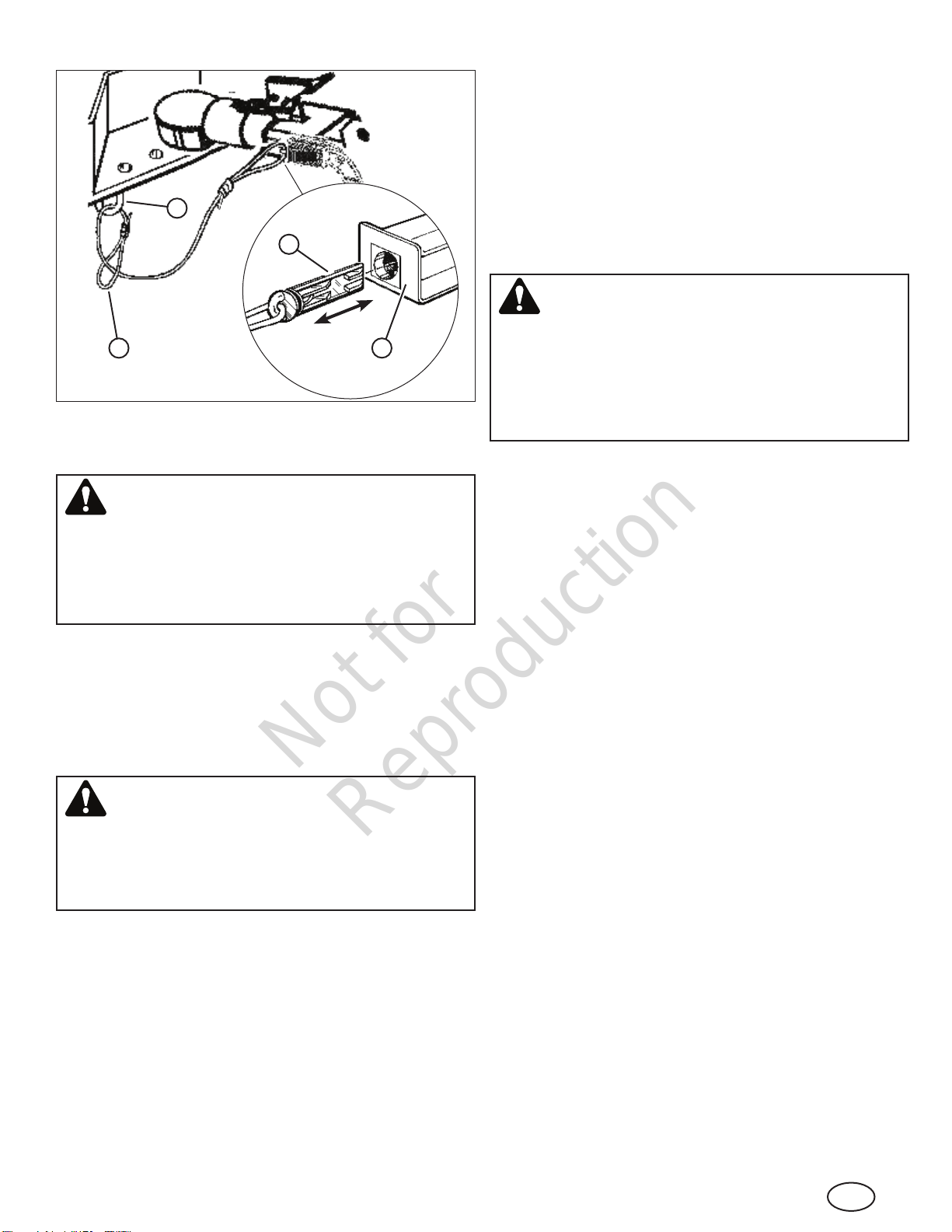

1. Pull the pin (A, Figure 11) out of the break-away brake

switch (B).

NOTE: Image is representative, and may differ according

to model.

2. Locate the safety chain pocket on the tow vehicle that is

on the same side as the break-away brake switch. Do

not cross the break-away brake switch cable to the oppo-

site side safety chain pocket, as this could cause the

break-away brake switch to fail. Do not cross over the

hitch ball, as the cable may become disconnected as the

tow vehicle moves over rough roads.

3. Route the pin through the safety chain pocket (C, Figure

11), then through the break-away brake cable loop (D).

4. Re-insert the pin in the break-away brake switch.

NOTE: Some break-away brake switch cables feature a

carabiner that hooks to the safety chain pocket. Refer to

Figure 8.

Not for

Reproduction

13

en

Figure 11

A

B

C

D

Heater Trailer Weight

WARNING

Towing the heater trailer when it is loaded beyond the

Gross Vehicle Weight Rating (GVWR) as stated on the

serial plate could result in death or serious injury. Always

maintain a GVWR less than the GVWR stated on the serial

plate.

The heater trailer is an SAE Class 4 trailer, with a Gross

Vehicle Weight Rating (GVWR) as stated on the serial plate

and in the Specifications section of this manual. Do not

exceed the GVWR by attempting to carry additional tools or

equipment. Do not carry riders. See Safety.

Towing The Heater Trailer

WARNING

Excessive speed when towing the trailer could result in

death or serious injury. Always maintain a safe towing

speed for road conditions. Never exceed 55 MPH (90

km/h) when towing the heater trailer.

The rated maximum highway towing speed for the heater

trailer is 55 MPH (90 km/h). Be sure to check your state or

province laws regarding maximum legal towing speeds for

trailers.

When towing the heater trailer off-highway or on rougher

terrain, the maximum towing speed is 20 MPH (32 km/h).

Slower speeds may be required for very rough terrain.

The heater trailer is designed to be towed with the engine

and heater units shut down.

Disconnecting The Heater Trailer From

The Tow Vehicle

1. Select a firm, level and stable surface at the work site.

See ‘Work Site Considerations’ in the Operation section.

2. Position the heater trailer with the tow vehicle so that the

heater discharge duct (right side of the trailer) is toward

the area to be heated.

3. Chock the front and rear wheels on both sides of the

heater trailer.

WARNING

Attempting to move or position the heater trailer by manu-

ally pushing or pulling it could present a crush hazard

resulting in death or serious injury. Always position the

heater trailer with the tow vehicle, chock the wheels and

lower the tongue jack before uncoupling the trailer from the

tow vehicle.

4. Disconnect the trailer lighting connector from the tow

vehicle’s connector.

5. Extend the tongue jack foot, and lower the tongue jack to

support the front of the heater trailer. See ‘Operating The

Tongue Jack’.

6. Disconnect the trailer coupler or lunette eye from the tow

vehicle. See ‘Using The Trailer Coupler’ or ‘Using A Pintle

Hook’.

7. Use the tongue jack to raise the trailer coupler or lunette

eye above the tow vehicle’s hitch ball or pintle hook.

8. Disconnect the safety chains from the tow vehicle’s hitch

frame.

9. Disconnect the break-away brake cable from the tow

vehicle.

10.Move the tow vehicle clear of the heater trailer.

Transporting On A Trailer

The heater trailer is equipped with four tie down points. See

Features and Controls.

Always secure the heater trailer with appropriate chains or

straps. Do not apply more than 600 pounds (272 kg) force

on the chains or straps.

The truck operator is responsible for securing the load prop-

erly to his trailer.

Not for

Reproduction

14 www.allmand.com

Lifting The Heater Trailer

WARNING

Attempting to lift the heater trailer with a lifting device that

is underrated or damaged could result in death or serious

injury. Always make sure the lifting device is rated to lift

the weight of the heater trailer. Make sure that the lifting

device is not damaged and is in operable condition before

beginning the lift.

WARNING

Standing or walking under elevated equipment could

result in death or serious injury. When elevating or lifting

the heater trailer, always keep clear of the area around

and under the heater trailer, and do not allow others in the

area.

Lifting Eyes

The heater trailer is equipped with four lifting eyes at the top

of the trailer. See Features and Controls for lifting eye loca-

tions. See ‘Heater Trailer Weight’ for the weight of the heater

trailer.

Each lifting eye is rated for 10,000 pounds (4,536 kg). Use

all four lifting eyes when attempting to lift the heater trailer.

The lifting eyes are intended carry the weight of the heater

trailer only, and no additional weight.

The heater trailer is not intended to be suspended for long

periods of time.

Forklift Pockets

The heater trailer is equipped with four forklift pockets, two on

either side. One is located forward of the front wheels, and

one between the front and rear wheels.

Use a forklift with a lifting capacity greater than the weight of

the heater trailer. See ‘Heater Trailer Weight’.

Operation

Work Site Considerations

Prior to setting up and operating the heater trailer, the opera-

tor must determine where to place it on the work site. When

placing the heater trailer, consideration must be given to

ground conditions, proximity to combustible or flammable

material, and ventilation.

It is the operator’s responsibility to ensure that the heater

trailer is properly and safely positioned on a stable surface at

the work site. Be sure to follow rules or instructions for your

work site for locating the heater trailer.

Ground Conditions

The heater trailer must be placed on a firm stable surface

that will support the total weight of the trailer, and support the

force exerted on the ground at the tongue jack. The surface

should be level, but must not exceed a grade of 2.5% (1.4°

incline) in any direction. Grades greater than 2.5% may

cause the heater trailer to roll away. Always chock the front

and rear wheels on both sides of the heater trailer prior to

disconnecting the heater trailer from the tow vehicle.

Proximity To Combustible Or Flammable

Material

The heater must be kept away from combustible or flam-

mable material. Maintain a distance of at least 8 feet (2.5 m)

from the heater discharge duct, and 5 feet (1.5 m) from the

heater air intake ducts, from any combustible or flammable

material.

Carbon Monoxide Asphyxiation

WARNING

Operating the engine or the heater units in a non-ventilated

enclosed area could result in death or serious injury.

Always operate the engine and the heater units in a well

ventilated area.

The engine exhaust contains carbon monoxide gas which

can cause asphyxiation when the engine is run in an

enclosed area. Make sure that the heater trailer is in a well

ventilated area before starting the engine.

NOTE: Because this unit features an electric heating ele-

ment, carbon monoxide gas is not present at the heater dis-

charge duct.

Using A Ground Rod

The heater trailer utilizes an earth grounding system, a safety

device that reduces the chance of personal injury from stray

electric currents. Use of this earth grounding system is

strongly recommended whenever the heater trailer is in use.

The heater trailer is equipped with a ground lug, located on

the left rear of the trailer. See Figure 12. A ground rod and

grounding cable are also required, and can be obtained

through your authorized dealer.

It is the user’s responsibility to determine the requirements

and / or applicability of national, state or province and local

electrical code, which governs the use of a ground rod.

To install the ground rod

1. Locate a point on the ground not more than 5 feet (1.5 m)

from the ground lug (A, Figure 12). Drive the ground rod

(B) into the earth at this point.

2. Attach one end of the grounding cable (C, Figure 12) to

the ground rod.

Not for

Reproduction

15

en

3. Loosen the cable mounting screw inside the ground

lug. Insert the loose end of the grounding cable up into

the ground lug, then tighten the cable mounting screw

against the cable end.

To remove the ground rod

1. Loosen the cable mounting screw, remove the ground-

ing cable from the ground lug, then retighten the cable

mounting screw.

2. Remove the ground rod from the earth. Be careful not to

damage the grounding cable when removing the ground

rod.

3. Wind the grounding cable around the ground rod, and

store in a safe place.

Figure 12

A

B

C

Compartment Access Doors

Most of the controls and maintenance points for the heater

trailer are located behind two access doors, one on either

side of the heater trailer. Both doors operate similarly.

To open

1. Pull the latch (A, Figure 13) to open the compartment

access door. (Control compartment access door shown).

2. Lock in the open position by inserting the lock pin (C)

into the hole in the door lock rod (B). Be sure the hole is

on the outside of the trunion.

To close

1. Pull the pin securing the door lock rod in the locked posi-

tion.

2. Close and latch the door. (Each door features a key lock

for added safety and security.)

Figure 13

B

C

A

Fueling

WARNING

Attempting to fuel the heater trailer with the engine run-

ning could cause fire, resulting in death or serious injury.

Always make sure the engine is shut down before adding

fuel to the fuel tank.

The heater trailer is equipped with a 270-gallon (1022 L) fuel

tank. The fuel cap (A, Figure 14) is located inside the control

compartment to the left, beneath the control panel.

See ‘General Engine Fuel Information’ in the Maintenance

section for information on the engine fuel that may be used.

NOTICE

Using engine fuels other that those recommended could

cause damage to your engine or its emission control system

and void the engine manufacturer’s warranty. Always read

and follow the engine fuel recommendations.

The fuel level (% max fuel capacity) is diplayed in the engine

monitor and control center. See ‘Operating the Engine’.

Adding Fuel

1. Open the control compartment access door and lock in

the open position. See ‘Compartment Access Doors’.

2. Turn the fuel cap (A, Figure 14) counterclockwise 1/4 turn

and remove.

Not for

Reproduction

16 www.allmand.com

3. Add fuel to the tank. See ‘General Engine Fuel

Information’ in the Maintenance section.

4. Replace the fuel cap and turn clockwise 1/4 turn to lock.

Figure 14

A

Preparing To Operate The Heater Trailer

1. Place wheel chocks against the front and rear wheels on

both sides of the heater trailer.

2. Level the heater trailer front to back with the tongue jack.

See ‘Operating The Tongue Jack’ in the Transporting sec-

tion.

3. Open the engine compartment access door and secure

with the lock pin. See ‘Compartment Access Doors’.

4. Check the engine oil level. See ‘Engine Oil’ in the

Maintenance section.

NOTICE

Failure to maintain engine oil level could result in engine

damage.

5. Check the engine coolant level. See ‘Engine Coolant’ in

the Maintenance section.

NOTICE

Failure to maintain engine coolant level could result in engine

damage.

6. Check the fuel level in the fuel tank and add as needed.

See ‘Fueling’.

7. Remove the canvas covers (A, Figure 15) from the heater

intake ducts and the heater discharge duct. Unhook

the elastic cover cord from the four corner hooks (B),

and slip the cover from the heater duct. (The cover is

attached by a lanyard to the heater trailer.)

WARNING

Failure to remove the heater duct covers could cause a

fire, resulting in death or serious injury. Always remove the

heater duct covers before operating the heater trailer.

Figure 15

A

B

B

B

B

Heater Ducting

The heater intake and discharge ducts on the heater trailer

are designed to be fitted with 16-inch (406 mm) diameter

flexible heater ducting, available through your authorized

dealer.

WARNING

Do not install or remove heater ducting while the heater

trailer is in operation. High-velocity discharge could result

in death or serious injury. Always install heater ducting

before starting the heater trailer.

WARNING

Use of ducting other than that designed for use with heater

trailers could cause a fire, resulting in death or serious inju-

ry. Always use ducting designed only for use with heater

trailers.

To install heater ducting

1. Remove the canvas covers from the heater intake

ducts and the heater discharge duct. See ‘Preparing To

Operate The Heater Trailer’.

2. Open the clamps (A, Figure 16, not all models) by mov-

ing the clamp levers outward away from the heater duct.

3. Install the cuff of the flexible heater ducting (B, Figure

16) over the heater duct. Secure with the clamps (if

equipped). Adjust the threaded clamp pads (C) to make

sure the ducting is secured to the heater duct.

Not for

Reproduction

17

en

Figure 16

B

A

A

C

C

To remove heater ducting

1. Open the clamps (if equipped) and pull the cuff of the

flexible heater ducting from the heater duct.

WARNING

Do not remove the heater ducting during or immediately

after operation. The heater ducting and the heater duct

will be extremely hot, and could result in death or serious

injury. Shut down the heater trailer and allow ample time

for the components to cool before removing the heater

ducting.

2. Replace the canvas covers onto the heater ducts. See

‘Preparing To Operate The Heater Trailer’.

Operating The Engine

Before starting the engine

1. Check to be sure the canvas covers are removed from

the heater intake and discharge ducts. See ‘Preparing To

Operate The Heater Trailer’.

2. Check to be sure the emergency stop is disengaged.

See ‘Emergency Stop’.

To start the engine

1. Open the control compartment access door and lock in

the open position. See ‘Compartment Access Doors’.

2. Turn the master switch (A, Figure 17) to the ON position.

NOTE: Turning the master switch to the ON position pro-

vides power to the interior light switch (D) and exterior

light switch (E).

3. Turn the key switch (B, Figure 17) to the RUN position.

The glow plug indicator lights (C) on the engine monitor

and control center will illuminate. Wait for the lights to

turn off (approximately 15 seconds).

Turning the key switch to the RUN position also powers

up the engine monitor and control center. See ‘Engine

Monitor and Control Center’.

4. Turn the key switch all the way to the right to the START

position until the engine starts. Release the key switch.

It will remain in the RUN position.

NOTE: If the engine has run out of fuel, you will need to prime

the engine after refueling. Twist the prime rod (A, Figure 18)

counterclockwise to unlock, pull out, pump 3-4 times or until

firm, then push in and twist clockwise to lock.

NOTICE

Operating the starter for more than 10 seconds without allow-

ing time between starting attempts could damage the starter.

Always give the starter time to cool, by allowing at least 30

seconds between starting attempts.

NOTICE

Engaging the starter while the engine flywheel is still rotat-

ing could damage the starter pinion or flywheel ring gear.

Always allow the engine to come to a complete stop before

re-engaging the starter.

B

AD E

Figure 17

C

Not for

Reproduction

18 www.allmand.com

Figure 18

A

To shut down the engine

1. Make sure the heater unit has had ample time (5 - 10

minutes) to cool down. See ‘Operating The Heater Unit’.

2. Turn the key switch to the OFF position.

3. Turn the master switch to the OFF position.

Emergency Stop

The emergency stop, located to the right of the control com-

partment access door (left side of the heater trailer), is a

safety device that shuts down the engine and heater trailer in

the event of an emergency. It is to be used only in instances

when the unit must be stopped immediately, such as the

threat of injury, death, or property damage. Do not use as an

alternative to the key switch or master switch.

NOTICE

Use of the emergency stop when the unit is in full operation

could result in equipment damage, as the unit requires ade-

quate time to cool down.

To engage

Press the emergency stop button (A, Figure 19).

To disengage (reset)

Pull out on the emergency stop button until the button clicks.

NOTE: The unit will not start or operate until the emergency

stop is disengaged.

Pre-Heat System

The heater trailer is equipped with a pre-heat system that

pre-heats the engine coolant, engine oil, and battery prior to

starting.

The pre-heat system should be used at least 30 minutes prior

to starting the engine in temperatures below 32°F (0°C).

To use

Connect a grounded (3 prong) extension cord from the pre-

heat system plug (B, Figure 19) to an appropriate electric

power source (120 volts AC, 60Hz). Disconnect after starting

the engine.

Figure 19

A

B

Jump Starting The Engine

WARNING

Attempting to jump start or charge a frozen battery could

cause explosion resulting in death or serious injury.

Always be sure that the battery is not frozen, split open or

damaged before attempting to charge or jump start it.

In the event that the battery is insufficiently charged to start

the engine, check the battery to make sure it is not frozen,

split open or damaged. If any of these conditions exist,

replace the battery, and do not attempt to jump start or

recharge it.

If these conditions do not exist, it is permissible to jump start

the engine taking care to follow the proper procedure.

To jump start the engine

WARNING

Allowing the ends of the jumper cables to touch each

other or metal surfaces while connected to a battery could

cause sparks that may ignite battery gases resulting in

death or serious injury. Always keep jumper cable ends

from touching each other or metal surfaces while connect-

ing or disconnecting them.

1. To gain access to the battery, open the engine compart-

ment access door and secure in the locked position. See

‘Compartment Access Doors’.

2. Connect one end of the red jumper cable to the positive

(+) terminal of the booster vehicle battery.

Not for

Reproduction

19

en

3. Connect the other end of the red jumper cable to the

positive (+) terminal of the heater trailer battery.

4. Connect the one end of the black jumper cable to the

negative (-) terminal of the booster vehicle battery.

5. Connect the other end of the black jumper cable to an

unpainted surface of the heater trailer engine or chassis.

6. Make sure that the jumper cables are not near any mov-

ing parts of either engine.

7. Start the engine of the booster vehicle and let it idle for

several minutes.

8. Start the engine of the heater trailer and let both engines

run for several minutes.

9. After the engine has started and stabilized, remove the

jumper cables in the reverse order. Remove the black

jumper cable from the unpainted surface of the heater

trailer engine or chassis first. Do not allow the end of this

cable to touch any metal or other jumper cable ends.

10.Remove the remaining cables starting with the black

jumper cable at the negative (-) terminal of the booster

vehicle battery, then the red jumper cable from the posi-

tive (+) terminal of heater trailer battery and finally the red

jumper cable from the positive (+) terminal of the booster

vehicle battery. Do not let the cable ends touch any

metal or each other.

Engine Monitor and Control Center

The engine monitor and control center (Figure 20) monitors

critical engine functions, and controls engine speed.

Turning the key switch to the RUN position powers up the

engine monitor and control center. Once the engine is start-

ed, the following information is displayed on the monitor:

A. Coolant Temperature *

B. Engine RPM *

C. Oil Pressure *

D. Battery Voltage

E. Fuel Level (% of max tank capacity) *

F. Hourmeter

The control center adjusts the engine RPM range from 1000

to 1800, in increments of 50 RPM.

G. Increase Engine RPM

H. Decrease Engine RPM

NOTE: The ‘Menu’ (I) and ‘Enter’ (J) buttons have been pre-

set at the factory, and should not be touched.

* Engine shutdown will occur in the event of:

• High coolant temperature (>245°F (118° C))

• High engine RPM (>1800)

• Low oil pressure (<15 psi)

• Low fuel level (<15%).

See also ‘Automatic Engine Shutdown System’ and

‘Engine Air Intake Shut-Off Valve (Shocker Valve)’.

ABC

DEF

G

I J

H

Figure 20

Automatic Engine Shutdown System

The engine is equipped with an automatic engine shutdown

system. This system will automatically shutdown the engine

in the event of low engine oil pressure or high coolant tem-

perature.

If the engine has automatically shutdown, locate the source

of the failure and repair the failure before re-starting the

engine.

Engine Air Intake Shut-Off Valve (Shocker

Valve)

The heater trailer is equipped with an engine air intake shut-

off valve (shocker valve). The valve is intended to prevent the

diesel engine from going into an overspeed condition in the

event that flammable gas or vapor is present at the engine air

intake. Should an overspeed condition occur, the engine air

intake shut-off valve automatically closes, preventing air from

getting into the cylinders, thereby stopping the engine.

The engine air intake shut-off valve is intended only to protect

the engine against damage from overspeed conditions. It

is not intended to be used as any part or indicator for a per-

sonal protective device, nor does it provide an indication of

whether an area is safe from flammable or explosive gas.

The engine air intake shut-off valve should be tested daily.

To test the engine air intake shut-off valve

1. Start the engine. See ‘Operatng The Engine’.

3. Locate the covered switch on the right side of the control

panel. Lift the cover and move the switch to the up posi-

tion. The engine should shut down immediately. If the

engine shuts down, close the red cover on the switch to

reset the switch to the operational mode.

4. If the engine does not shut down immediately, shut the

machine down with the key switch, and do not use the

machine. Close the cover on the switch to reset the

switch to the operational mode. Tag the machine “Do not

Not for

Reproduction

20 www.allmand.com

operate”, and notify your service or maintenance depart-

ment to get the machine repaired.

To reset the engine air intake shut-off valve

DANGER

Resetting and re-starting the engine after the engine air

intake shut-off valve has automatically shut down the

engine could ignite an explosive atmosphere that will result

in death or serious injury. Always leave the area immedi-

ately when the engine air intake shut-off valve automati-

cally shuts down the engine, and do not return until safety

and supervisory personnel have given an “all clear” to

return to the area.

1. If the air intake shut-off valve has tripped and shut down

the engine automatically, leave the area immediately and

follow the safety instructions and procedures for your job

site. Do not reset or restart the engine until the source of

the problem has been determined, and safety and super-

visory personnel at your job site have given an “all clear”

to return to the area.

2. When permission is given to return to the area, open the

control compartment access door and lock in the open

position, and locate the blue knob on the engine air

intake shut-off valve, located on the right side of the con-

trol panel. Turn the knob so that it aligns with the intake

hoses to and from the valve body. You will hear and feel

a distinct “click” as the engine air intake shut-off valve is

reset to the operating position.

3. Start the engine. See ‘Operating The Engine’.

Operating The Heater Unit

The heater trailer is equipped with an electric, thermostat-

controlled heat exchanger, which results in clean, safe heat.

Max heat output is 750,000 BTUs/hr; maximum temperature

output is 300° F (150° C). See Specifications.

To operate the heater unit

1. Remove the heater duct covers and install heater duct-

ing. See ‘Preparing to Operate the Heater Trailer’ and

‘Heater Ducting’.

WARNING

Failure to remove the heater duct covers could cause a

fire, resulting in death or serious injury. Always remove the

heater duct covers before operating the heater trailer.

2. Start the engine. See ‘Operating the Engine’.

3. Adjust the thermostat (A, Figure 21) to the lowest tem-

perature setting (50°F (10°C)).

4. Allow the engine to run until coolant temperature reaches

150° F (65°C).

5. Increase engine RPMs to 1400 - 1800. See ‘Engine

Monitor and Control Center’.

6. Adjust the thermostat to the desired target discharge

temperature. (Temperature range of heater unit is 50°F

(10° C) to 300°F (150°C)).

7. Monitor discharge temperature (B, Figure 21). Depending

upon ambient air temperature, it may take several min-

utes for the discharge temperature to rise to the target

temperature.

8. Continue to monitor engine and heater information

throughout unit operation. Adjust as needed.

9. In the event of an emergency, engage the emergency

stop. See ‘Emergency Stop’.

A B

Figure 21

-

+

To shut down the heater unit

1. Adjust the thermostat to the lowest temperature setting

(50° F (10°C)).

2. Decrease engine RPMs to 1200.

3. Allow 5-10 minutes for the heater unit to cool down.

4. Decrease engine RPMs to 1000.

NOTE: At engine speeds lower than 1200 RPMs, the

generator ceases to produce electricity.

5. Shut down the engine. See ‘Operating the Engine’.

Shutting Down The Heater Trailer

1. Shut down the heater unit. See ‘Operating the Heater

Unit’.

2. Shut down the engine. See Operating the Engine.

3. Remove heater ducting. See ‘Heater Ducting’.

4. Replace canvas covers onto heater ducts. See

‘Preparing to Operate the Heater Trailer’.

5. Close and latch compartment doors.

Table of contents

Languages:

Other Allmand Heater manuals

Popular Heater manuals by other brands

Kambrook

Kambrook SNUGASABUG FAN HEATER KFH20 user manual

Emerson

Emerson Fisher Yarway AT-25 instruction manual

Harvia

Harvia PO11 Instructions for installation and use

Euromatic

Euromatic ERC24B instruction manual

Frost Fighter

Frost Fighter IDHQR Series Installation - Operation/Maintenance Instructions and Parts List

Royal Sovereign

Royal Sovereign HFN-02 user manual