Allmand ECLIPSE 2220/SE Series Product manual

1

OPERATOR’S AND PARTS MANUAL

2220/SE SERIES

FLASHING ARROWBOARD

ALLMAND BROS. INC

P.O. BOX 888

HOLDREGE, NE 68949

PHONE: 308/995-4495, 1-800/562-1373

ALLMAND FAX: 308/995-5887

ALLMAND PARTS FAX: 308/995-4883

ECLIPSE 2220/SE

ECLIPSE

For Parts and Updates visit Allmand on the Web at www.allmand.com

2

3

TABLE OF CONTENTS

ALLMAND 2200/SE ECLIPSE

Table of Contents Page 3

Description and Features Page 4

Safety and Precautions Page 5

Set-up/Operating Instructions Page 6

Trailer Alignment (illustration) Page 7

Safety and Warning Decals Page 8

Winch Operating Instructions Page 9

Periodic Maintenance Page 10

Array Maintenance Page 10

Battery Maintenance Page 11

Troubleshooting Page 12

Controller (illustration) Page 13

Controller Features and Operation Page 14

APF Flashing Array Display Sequence Illustrations Page 15

Allmand Eclipse 2220/SE Halogen Lamp Descriptions Page 16

Allmand Eclipse 2220/SE LED Lamp Descriptions Page 16

Wiring Diagrams Page 17

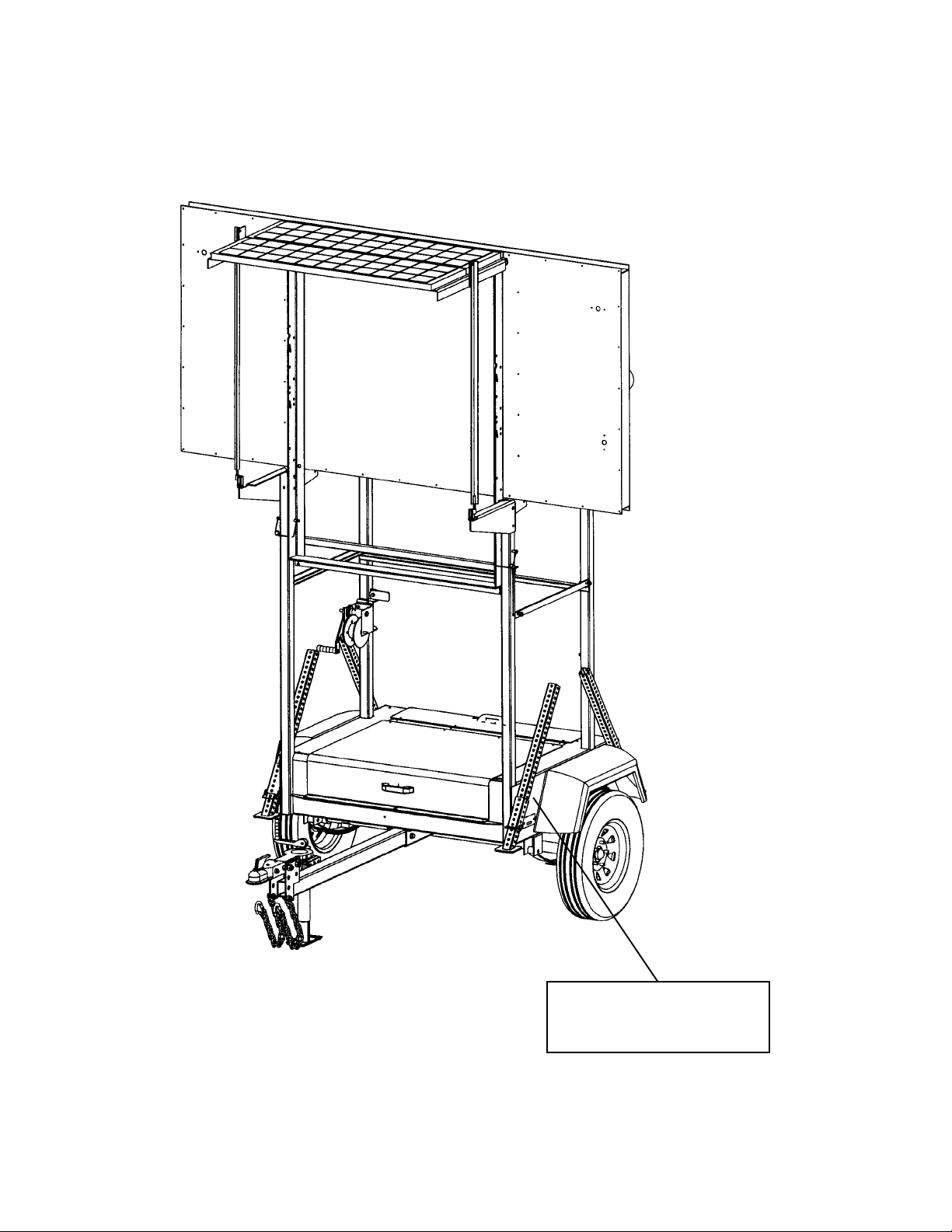

Serial Number Plate Location Page 18

Parts and Accessories Page 19

4

ALLMAND ECLIPSE 2220/SE SERIES SOLAR ASSIST ARROWBOARD

DESCRIPTION AND FEATURES

The ALLMAND ECLIPSE 2220/SE SERIES solar assist arrowboard uses two, three or four

12V DC 8D deep cycle batteries, providing a nominal 12V DC to the operating system. The

battery enclosure is lockable, ventilated and designed to protect the batteries from theft or

vandalism. The location of the enclosure allows for easy maintenance or replacement of the

battery bank. An electronic control system protects the batteries from overcharging and gas-

sing. The Low Voltage Disconnect (LVD) system protects the battery from excessive dis-

charge which can result in premature battery failure.

Solar charging is accomplished by a 50w, 75w, or 100w class 12V DC single crystalline

photovoltaic array located above the sign panel. This provides maximum exposure of the array

to the sun. The array location minimizes vandalism or theft. The array constantly charges the

batteries when exposed to the sun. An optional ALLMAND ECLIPSE battery charger, specifi-

cally designed for this unit, allows the batteries to be recharged using standard 115V AC line

current.

The ALLMAND ECLIPSE 2220/SE SERIES features the Allmand Eclipse LED Lamp con-

sisting of individual ORANGE/AMBER LEDs per lamp. Each LED is situated on a printed

circuit board behind an individual Fresnel lens element. If an individual LED burns out, the

entire lamp does not go out. This results in greater safety as the sign will still show a complete

display even if several individual LEDs in a number of lamps are not functioning. The LED

lamp easily interchanges with halogen lamps, allowing older halogen equipped boards to be

re-fitted with LED lamps. It is not recommended, however, that LED and halogen lamps be

mixed in the same board.

The LED lamp has approximately 1/5 of the power requirement of the ALLMAND halogen

lamp, resulting in much longer run time between recharges. With the LED lamp, the display is

more defined, resulting in greater legibility distances (greater than one mile, which exceeds

MUTCD requirements). The ALLMAND LED lamp carries a 5-year limited warranty from the

manufacturer against defects in materials and workmanship.

Also available is our proven modular PAR-46 high visibility/high efficiency halogen lamp. The

lamp life is over three times that of a standard 4412-A lamp . The lamp housing/reflector and

Lexan lens provide an extremely durable and damage-resistant assembly. This lamp assembly

easily meets or exceeds the MUTCD (Section 6E-9) one mile visibility specification.

The ALLMAND ECLIPSE 2220/SE SERIES CONTROLLER is mounted directly on the sign

panel to minimize electrical connections and exposed wiring. This feature, along with the

lockable cover, also makes malicious mischief or vandalism less likely. This unit is a high-

reliability solid state component featuring state of the art electronics and engineering. Lamp

dimming during night time hours is accomplished via the ALLMAND ECLIPSE SUNTRAK

system which automatically varies the lamp intensity relative to ambient light levels.

5

The trailer consists of a formed 10 GA steel deck with crossmembers and an integral battery

compartment with lockable steel cover. Four steel uprights welded to the deck support the sign

panel for operation and transportation. A positive mechanical lock secures the sign in both

operating and towing positions. The tongue is constructed of 3" tubing and has a heavy-duty

combination 3" diameter pintle ring and 2" ball coupler. A folding screw jack is mounted to the

tongue immediately behind the pintle eye. Four adjustable corner stands (one at each corner of

the trailer) stabilize the trailer when in operation. They are constructed of 1-3/4" Telespar tubing

complete with footpads, locking pins, and clips. The trailer rides on a 1500 lb. tube-type leaf

spring axle with 5-lug hubs and 13" 4-ply rated tires and wheels. Raising and lowering of the sign

panel is accomplished by a ratchet-type hand crank winch and pulley system with safety brake

clutch and a single 3/16" braided steel cable that will raise and lower the sign panel evenly. Flush

mounted stop, turn, and taillights with a 4-contact male end connector on the cable insures

towing safety. Color coding of the wiring is in accordance with SAE practice, (SAE J560A and

SAE J895). The trailer is finished in high-visibility Safety Or-

ange paint.

SAFETY AND PRECAUTIONS

A safe environment around the ALLMAND ECLIPSE 2220/SE

SERIES SOLAR ASSIST AROWBOARD is encouraged. The

following recommendations should be noted since the

ALLMAND ECLIPSE 2220/SE SERIES is typically used in

construction areas with greater traffic congestion, thereby

increasing the risk of accidents or injuries.

The sign panel should always be in travel position (lowered)

and secured using the attached lock pins when towing the

ALLMAND ECLIPSE 2220/SE SERIES at highway

speeds. Make sure that the hitch is properly engaged with

the towing vehicle and that the safety chains are properly

fastened and all jacks and/or jackstands are raised and

secured before towing. Also be certain that the taillights are

connected and working properly before towing the unit.

DESCRIPTION AND FEATURES

A low-voltage disconnect (LVD) system protects the batteries from damage if solar conditions fail

to adequately maintain a sufficient charge. This system features a red warning lamp which signals

low battery voltage and imminent shutdown of the system. This lamp is mounted on the rear of the

sign panel and is easily visible from the jobsite or roadway. If battery voltage becomes danger-

ously low, the sign panel display will revert to a 4-corner warning mode. At this time mainte-

nance personnel will need to either recharge the batteries or replace them with fully

charged units if necessary.

6

The trailer should be properly set up with the jack stabilizers, sand bags, etc. in position before

leaving the ALLMAND ECLIPSE 2220/SE SERIES deployed in the traffic control area. Periodi-

cally inspect the tongue, pins, safety chains, hitch, all nuts, bolts, cable clamps, wiring, etc. for

wear and repair or replace if necessary.

SAFETY NOTE/DISCLAIMER

ALLMAND BROS. INC. has taken precautions to ensure that the ALLMAND ECLIPSE

2220/SE SERIES is safe and reliable. ALLMAND BROS. INC., however, is not responsible

for any injuries, accidents or other mishaps as a result of the use or misuse of this or any other

ALLMAND product. It is the user’s responsibility to ensure that the manner in which the

ALLMAND ECLIPSE 2220/SE SERIES is used is consistent with safe practices and the user

is to understand that he/she is the only liable party.

SET-UP/OPERATING INSTRUCTIONS

The following is a step-by-step procedure for set-up and operation of the ALLMAND ECLIPSE

2220/SE SERIES SOLAR ASSIST ARROWBOARD.

NOTE: Before transporting the trailer to the jobsite, be certain that the batteries are fully charged

using the optional ALLMAND ECLIPSE charger or any commercially available minimum 50

amp battery charger designed to charge a deep-cycle battery bank of this size. Be certain that

the battery bank is charged completely, allowing the unit to operate as long as possible before

low-voltage shutdown occurs.

1. Block the wheels of the trailer first, then remove the trailer from the towing vehicle.

2. With the sign panel directed toward the traffic, level unit off the tires using the jacks and /or

jackstands.

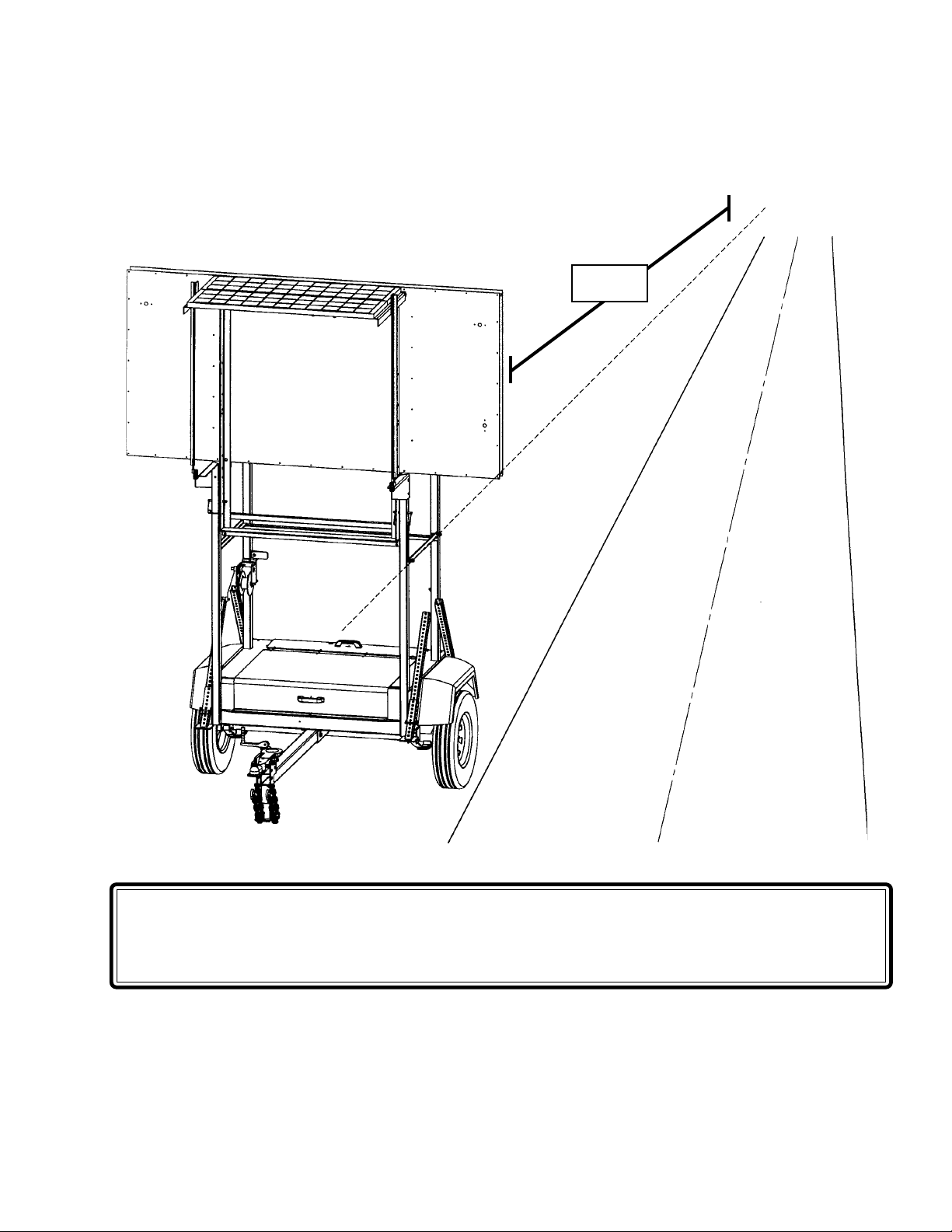

CAUTION: For safe operation and maximum visibility, sight through the eyelets midway up the

right frame uprights to align the unit relative to the roadway and the horizon as illustrated on the

following page. Observe the operation of the machine from varying vantage points down the

roadway to ensure that maximum visibility is maintained throughout the controlled area.

Lift the controller cover and turn mode switch to desired mode. Turn power switch on and deter-

mine that the display that has been selected is the desired mode and that it is operating properly.

CAUTION: Always check for overhead obstructions before raising sign panel.

3. Remove sign panel spring pins and erect sign panel by cranking braking winch. See WINCH

OPERATING INSTRUCTIONS on page 8.

4. Insert spring pins into the trailer uprights to stabilize the sign.

5. Ensure that the display is operating correctly and is readable from an adequate distance

before leaving the worksite.

7

TRAILER ALIGNMENT ILLUSTRATION

CAUTION: For safe operation and maximum visibility, sight through the eyelets midway up the

right frame uprights to align the unit relative to the roadway and the horizon as illustrated above.

Observe the operation of the machine from varying vantage points down the roadway to ensure

that maximum visibility is maintained throughout the controlled area.

1 MILE

8

SAFETY AND WARNING DECALS

ALWAYS REPLACE ANY SAFETY AND INSTRUCTIONS DECALS THAT BECOME

DAMAGED, PAINTED OVER, OR OTHERWISE ILLEGIBLE!

Refer to the following representations of the safety warning decals used on the ALLMAND

ECLIPSE 2220/SE Series trailer to insure correct ordering if replacement becomes neces-

sary.

9

WINCH OPERATING INSTRUCTIONS

The winch is designed to lift load (“reel in”) when the crank is turned in a clockwise direction.

This action will produce a clicking sound. To lock load at any desired position, simply release

the hand crank. To lower load (“reel out”), turn the hand crank in a counter-clockwise direction.

To lock load in any desired position, turn handle crank clockwise until at least two clicks are

heard before releasing handle.

WARNING: Never exceed rated winch load. Excess load may cause premature failure and

could result in serious personal injury. This winch is rated at 1200 pounds with one layer of

cable on a 2-1/2" hub. Using more layers of cable increases the load on the winch.

CAUTION: Never apply load to winch with cable fully extended. Keep at least three full turns of

cable on the reel.

IMPORTANT: Sufficient load must be applied to the cable to overcome internal resistance

and operate brake properly. Otherwise, turning the hand crank counter-clockwise will only

remove the crank from the shaft as the reel will not turn. Minimum operating load requirement

for the DLB-1200 winch is 75 pounds.

NOT FOR MOVEMENT OF HUMAN BEINGS

WINCH LUBRICATION: This winch has been fully lubricated at the factory, but for continued

smooth performance and increased life, occasionally grease gears, reel shaft and handle

threads. An occasional drop of oil on drive shaft bearings is also recommended.

CAUTION: DO NOT OIL OR GREASE BRAKE MECHANISM

10

PERIODIC MAINTENANCE

The ALLMAND ECLIPSE 2220/SE SERIES SOLAR ASSIST ARROWBOARD has been

designed to minimize maintenance. However it will be necessary to inspect or test the follow-

ing areas on a periodic basis.

ARRAY MAINTENANCE

1. Clean solar panels.

2. Check solar panels and wiring.

3. Check wiring to ensure that there is no damage caused by normal use, wear and tear, road

vibration, etc.

BATTERY MAINTENANCE

4. Check water level on each cell of the batteries. Top off when necessary using only distilled

water.

5. Check battery condition . Charge when necessary or when not in use.

GENERAL MAINTENANCE

6. Check taillights to ensure proper operation. Also check tongue, safety chains and pins.

7. Check sign panel for proper lamp operation. Replace lamps when needed.

8. Check tires and wheel bearings.

9. Check all nuts and bolts for tightness.

ARRAYMAINTENANCE

Examine the entire array for the following:

Examine the top (photosensitive) surface of each module for cleanliness. Any visible accumu-

lation of dirt can impair energy production and should be removed. Use a soft cloth and either

plain water or a solution of mild detergent (such as dishwashing detergent) followed by a rinse

with plain water. Do not spray or direct a solid stream of water at the modules. No abrasive

material should be used in cleaning the modules. It is very important to note that water can

increase the chance of electrical shocks and burning. Care should be taken to use properly

insulated tools and rubber gloves when cleaning the modules.

Examine all electrical cabling. Make certain that connections are tight at the module junction

boxes, the controller, and the battery bank. Look for any signs of cable breaks and also for

damaged or missing insulation. If any worn or damaged wiring appears likely to interfere with

proper operation now or later, replace the damaged wire.

11

ARRAYMAINTENANCE (cont)

The array may be tested by using a voltmeter to check the voltage across the array (+) terminal

and array (-) terminal of the sign connector. Expose array to full sunlight. Using a voltmeter, check

open circuit voltage across the leads. The meter should indicate a voltage reading of 16-20V

DC.

Check all bolts and nuts. Tighten as needed.

BATTERYMAINTENANCE

Check the level of electrolyte in each battery cell. If necessary, add DISTILLED water to bring the

electrolyte up to the required level. A hydrometer may be used to test the condition of each

individual cell or a voltmeter may be used to test the condition of each individual battery.

Examine all battery terminals for signs of corrosion. If any terminal is corroded, disconnect the

battery cable. Clean the battery terminal and the connector on the cable with appropriate wire

brushes. Reconnect the cable to the battery terminal.

NOTE: Batteries must be recharged periodically using an AC battery charger to avoid over-

sulfating plates and impairment of battery performance.

If ALLMAND ECLIPSE 2220/SE Series supplied BATTERY CHARGER is not used, a charge

current of at least 50 amps must be provided to sufficiently charge batteries. Use extreme cau-

tion when using other than ALLMAND ECLIPSE 2220/SE Seriescharger to observe correct

battery polarity and also to avoid over-charging (“boiling”) of batteries.

CAUTION! Any battery is an infinite current source when the battery terminals are mo-

mentarily shorted which can lead to serious bodily injury or fire. Goggles and other

protective equipment should be worn to shield skin and eyes from battery acid.

12

TROUBLESHOOTING

The ALLMAND ECLIPSE 2220/SE SERIES SOLAR ASSIST ARROWBOARD is a highly reliable

and trouble free piece of equipment. However, should a rare problem occur, the following list of trouble-

shooting procedures will assist the operator in locating and correcting the source of the problem.

PROBLEM PROCEDURE

Display not functioning properly Check wiring, lamps and

or not functioning at all. connections. Replace lamp

elements or controller if necessary

Check batteries, re-charge or

replace if necessary.

No power to system. Check circuit breakers on

controller. Allow to automatically

reset if tripped. Check wiring.

Replace controller.

Operational time is less than desired. Check battery condition. Charge

batteries with heavy-duty AC charger. Use

hydrometer to ensure that batteries are

fully charged before putting unit into

service. (See BATTERY MAINTENANCE

section). Check solar panels. (See

ARRAY MAINTENANCE section.)

LVD lamp illuminated or system shut down. Charge batteries using properly sized AC

charger until voltmeter or hydrometer

indicates batteries are fully charged.

Batteries will not fully charge. Check battery condition. (See BATTERY

MAINTENANCE section.) Replace if

necessary.

NOTE: If it has been determined that the controller is defective it may be returned freight

prepaid to:

ECLIPSE ELECTRONIC REPAIR CENTER

1903 BARRETT DRIVE

TROY, MI 48084

PHONE: (248) 362-0544

Repair (or replacement at our option) and return will be done on a timely basis to minimize downtime.

Out-of-warranty units will be repaired on a time and materials basis, usually within two working days of

receipt. Be certain to specify the problem and include complete return information (including zip code,

phone/FAX numbers, contact person, purchase order number, etc.) with the failed unit.

13

CONTROLLER ILLUSTRATION

ALLMAND BROS., INC.

MODEL 2220/SE

14

CONTROLLER FEATURES AND OPERATION

1. MODE SWITCH: Selects display mode. Rotate switch to select desired display. 15 lamp

ALT display choices include:

LEFT ALTERNATING ARROW

LEFT SEQUENTIAL ARROW

RIGHT ALTERNATING ARROW

RIGHT SEQUENTIAL ARROW

LEFT/RIGHT ALTERNATING ARROW

LEFT/RIGHT SEQUENTIAL ARROW

ALTERNATING CAUTION BAR

4-CORNER WARNING

The optional 25 lamp APF display offers the following display choices in addition to the above:

LEFT SEQUENTIAL CHEVRON

RIGHT SEQUENTIAL CHEVRON

DOUBLE DIAMOND WARNING

SEQUENTIAL CAUTION BAR

2. ON-OFF SWITCH: Turns display on or off.

**CIRCUIT BREAKER: 6 amp auto-reset breaker protects controller from shorts in wiring or

lamps.

** PHOTOCELL: Located inside bottom frame channel of sign panel directly below controller.

ALLMAND ECLIPSE SUNTRAK system automatically varies lamp intensity relative to

ambient sunlight. Photocell location prevents false brightening of lamps by oncoming

vehicle lights.

** LOW VOLTAGE DISCONNECT WARNING LAMP (Not Shown):Located on sign panel

directly behind controller, flashes intermittently if battery voltage drops below 11.5 volts. At

this time maintenance personnel must take corrective action, as machine shut-down is

imminent. See TROUBLE SHOOTING and MAINTENANCE sections. (NOTE: Sign

panel will default to a 4-corner warning display if battery voltage falls below 10.5

volts.)

** POLARITY PROTECTION (Not Shown):Fuse located on P.C. board behind face panel

protects against damage to controller from reversed battery polarity.

15

APF FLASHING ARROW DISPLAYSEQUENCES

LEFT SEQUENTIAL CHEVRON

RIGHT FLASHING ARROW LEFT FLASHING ARROW

DOUBLE FLASHING ARROW RIGHT SEQUENTIAL ARROW

LEFT SEQUENTIAL ARROW FLASHING WARNING BAR

DOUBLE SEQUENTIAL ARROW DOUBLE DIAMOND WARNING

SEQUENTIAL WARNING BAR 4-CORNER WARNING DISPLAY

RIGHT SEQUENTIAL CHEVRON

16

ALLMAND ECLIPSE LAMPS

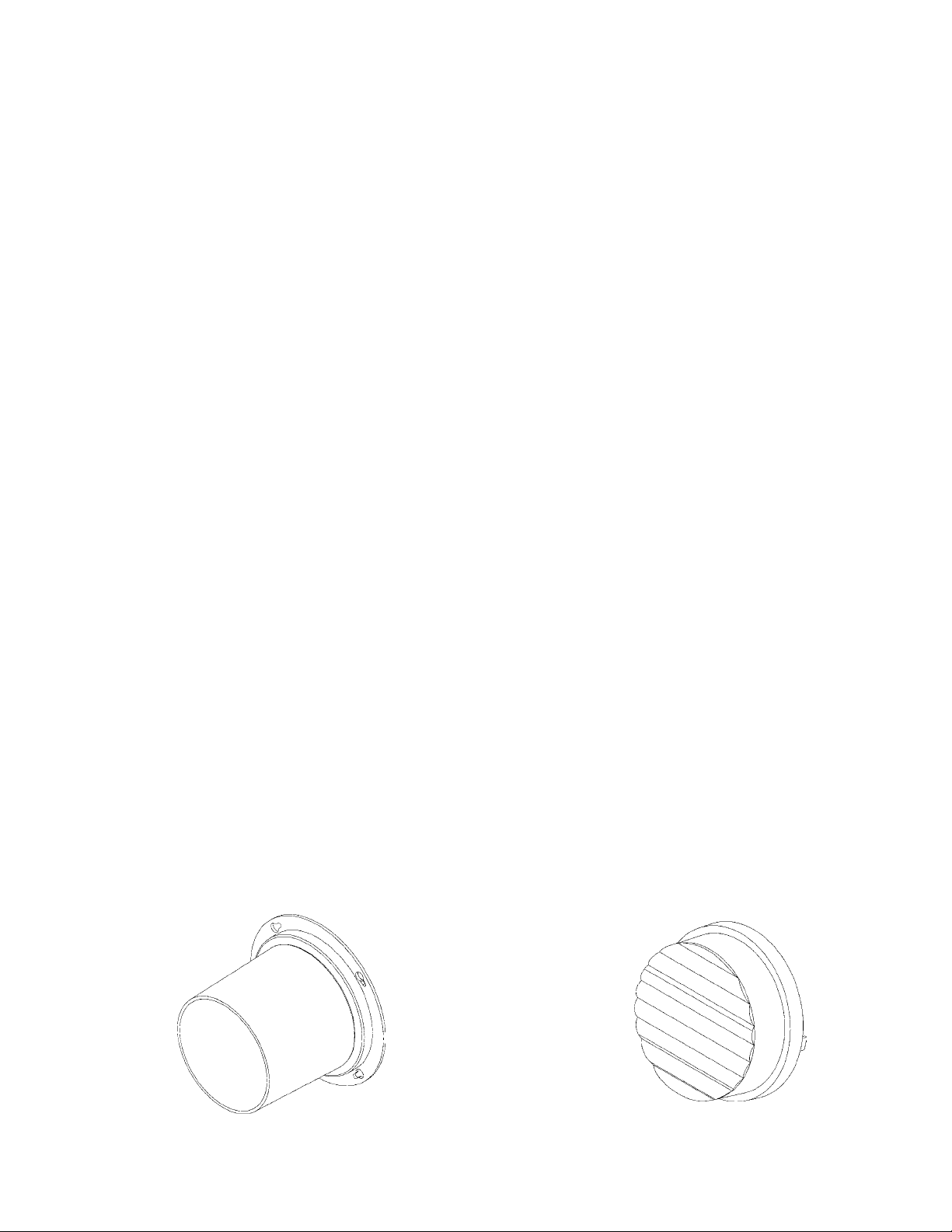

ALLMAND ECLIPSE 2220/SE SERIES LED LAMP ASSEMBLY

ALLMAND ECLIPSE LED LAMP DESCRIPTION AND FEATURES

•Each lamp has individual orange/amber LEDs, with each LED situated on a printed circuit

board behind an individual Fresnel lens element.

•The orange/amber color of the lamp display is more consistent with the color of the standard lamps

used in older diesel boards.

•If an individual LED burns out, the entire lamp does not go out. This results in greater safety as the

sign will still show a complete display, even if several individual LEDs in a number of lamps are not

functioning.

•The LED lamp easily interchanges with halogen lamps, allowing older halogen equipped boards to

be re-fitted with LED lamps. (However, it is not recommended that LED and Halogen lamps be

mixed in the same board.)

•The LED lamp has approximately 20% of the power requirement of the Eclipse halogen lamp, result

ing in much longer run time between recharges.

•LED lamp display is more defined, resulting in greater legibility distances (greater than ONE MILE,

which exceeds MUTCD requirements.)

•The LED lamp carries a 5-year limited warranty from the manufacturer against defects in materials

and workmanship.

LAMP VISOR ALLMAND LED LAMP

ALLMAND ECLIPSE HALOGEN LAMP DESCRIPTION AND FEATURES

1. LENS: Amber Lexan lens provides maximum durability and light transmittal.

2. HOUSING / REFLECTOR: Lexan housing provides greater durability than glass lamps.

Highly polished reflective surface features a 30° horizontal and 8° vertical beamspread for

maximum brightness and off-axis visibility.

3. LAMP ELEMENT: 12V DC 5W tungsten-halogen lamp element has three times the life

expectancy of a standard 4412A arrowboard replacement lamp.

17

ALLMAND ECLIPSE 2220/SE SERIES ARROWBOARD

SIGN PANEL WIRING DIAGRAM

APF (25-LAMP) SIGN ASSEMBLY

MOLEX CONNECTOR #1 MOLEX CONNECTOR #2

PIN# WIRE COLOR LAMP# PIN# WIRE COLOR LAMP#

1 BROWN 16 1 YELLOW 4

2 BLACK 9 2 PURPLE 10

3 RED 7 3 GRAY 3

4 YELLOW 12 4 BLUE 8

9 GREEN 6 8 BLACK 17*

10 BLUE 13 9 GREEN 2

11 GRAY 5 10 BLACK is

12 PURPLE 11 11 RED 1

12 BROWN 14

ALT (15-LAMP) SIGN ASSEMBLY

MOLEX CONNECTOR

PIN# WIRE COLOR LAMP #

1 YELLOW 14

2 GRAY 8

3 BLACK 2

4 RED 3,4

5 PURPLE 1

6 GREEN 5

7 BLUE 6

8 ORANGE 16

9 BROWN 13

10 PINK 7

SIGN PANEL LAMP NUMBERING CHART

(*) NOTE: LAMP #17 IS THE LOW VOLTAGE WARNING LAMP located on sign

behind controller.

18 ALLMAND ECLIPSE 2220/SE SERIES P ARTS REFERENCE

MODEL SERIAL NUMBER PLATE LOCATION

ALLMAND

SERIAL NUMBER PLATE

LOCATED HERE

ALLMAND ECLIPSE 2220/SE SERIES PARTS REFERENCE 19

PARTS MANUAL

2220/SE SERIES

FLASHING ARROWBOARD

For Serial Number 0458AB02 and up

ALLMAND BROS. INC

P.O. BOX 888

HOLDREGE, NE 68949

PHONE: 308/995-4495, 1-800/562-1373

ALLMAND FAX: 308/995-5887

ALLMAND PARTS FAX: 308/995-4883

ECLIPSE 2220/SE

ECLIPSE

20 ALLMAND ECLIPSE 2220/SE SERIES P ARTS REFERENCE

Other manuals for ECLIPSE 2220/SE Series

1

Table of contents

Popular Safety Equipment manuals by other brands

Lanex

Lanex PB-20 instruction manual

SKYLOTEC

SKYLOTEC ANCHOR ROPES Instructions for use

Besto

Besto Buoyancy Aid 50N Instructions for use

TEUFELBERGER

TEUFELBERGER NODUS Manufacturer's information and instructions for use

Troy Lee Designs

Troy Lee Designs Tbone Product owners manual

Innova

Innova Xtirpa Instruction and safety manual

bolle SAFETY

bolle SAFETY B810 quick start guide

SHENZHEN FANHAI SANJIANG ELECTRONICS

SHENZHEN FANHAI SANJIANG ELECTRONICS A9060T instruction manual

Hiltron security

Hiltron security POWER8E Installation and use manual

Salewa

Salewa MTN SPIKE user manual

Hatco

Hatco B-950P installation guide

Sitec

Sitec TX MATIC operating manual