Alpine DP-S Series User manual

Other Alpine CD Player manuals

Alpine

Alpine CRA-1667RF User manual

Alpine

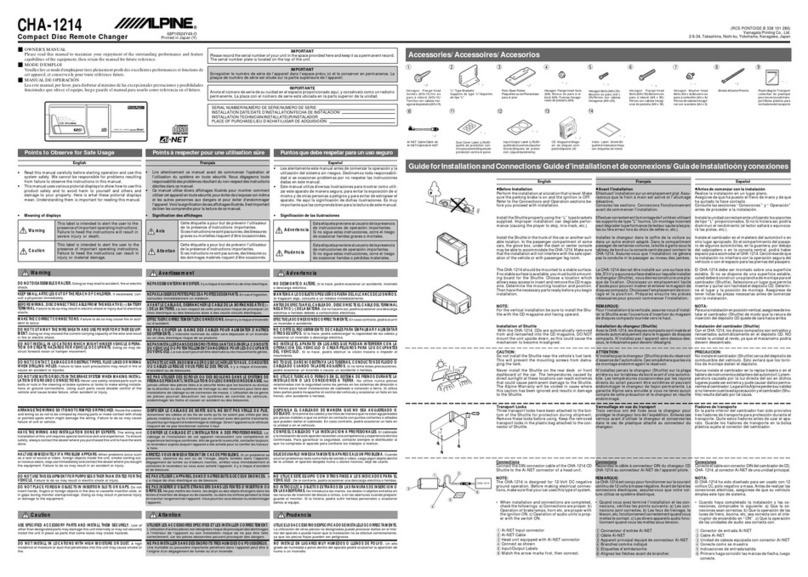

Alpine CHA-1214 User manual

Alpine

Alpine S690 - DHA - DVD Changer User manual

Alpine

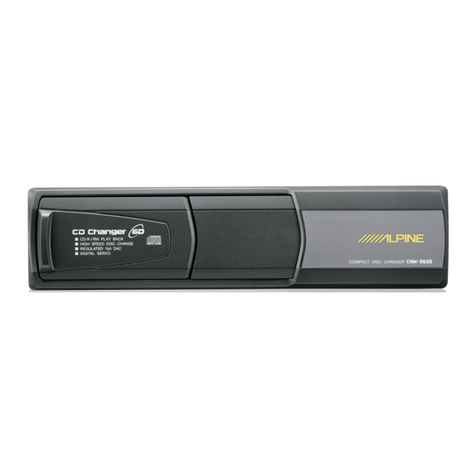

Alpine CHM-S630 User manual

Alpine

Alpine CHM-S630 User manual

Alpine

Alpine CHA-1204 User manual

Alpine

Alpine CDE-136BT User manual

Alpine

Alpine DHA-S680 User manual

Alpine

Alpine S690 - DHA - DVD Changer User manual

Alpine

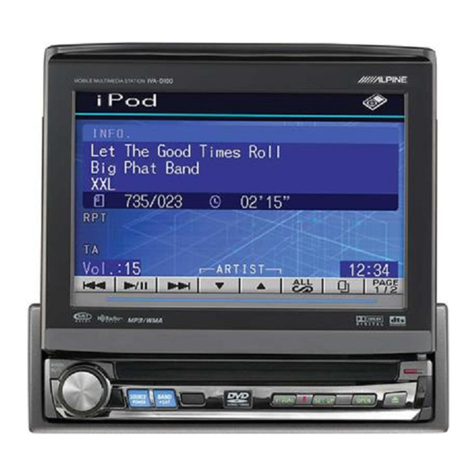

Alpine IVA-D100 User manual

Alpine

Alpine CHM-S653RF User manual

Alpine

Alpine CHM-S655RF User manual

Alpine

Alpine CHA-S614 User manual

Alpine

Alpine 3DA-7987 User manual

Alpine

Alpine S634 - CHA CD / MP3 Changer User manual

Alpine

Alpine CHM-S630 User manual

Alpine

Alpine 7909 User manual

Alpine

Alpine CHA-1214 User manual

Alpine

Alpine 7980M User manual

Alpine

Alpine DVA-5205P User manual