9

3. Technical Data

3.1. Technical Values

Operating data

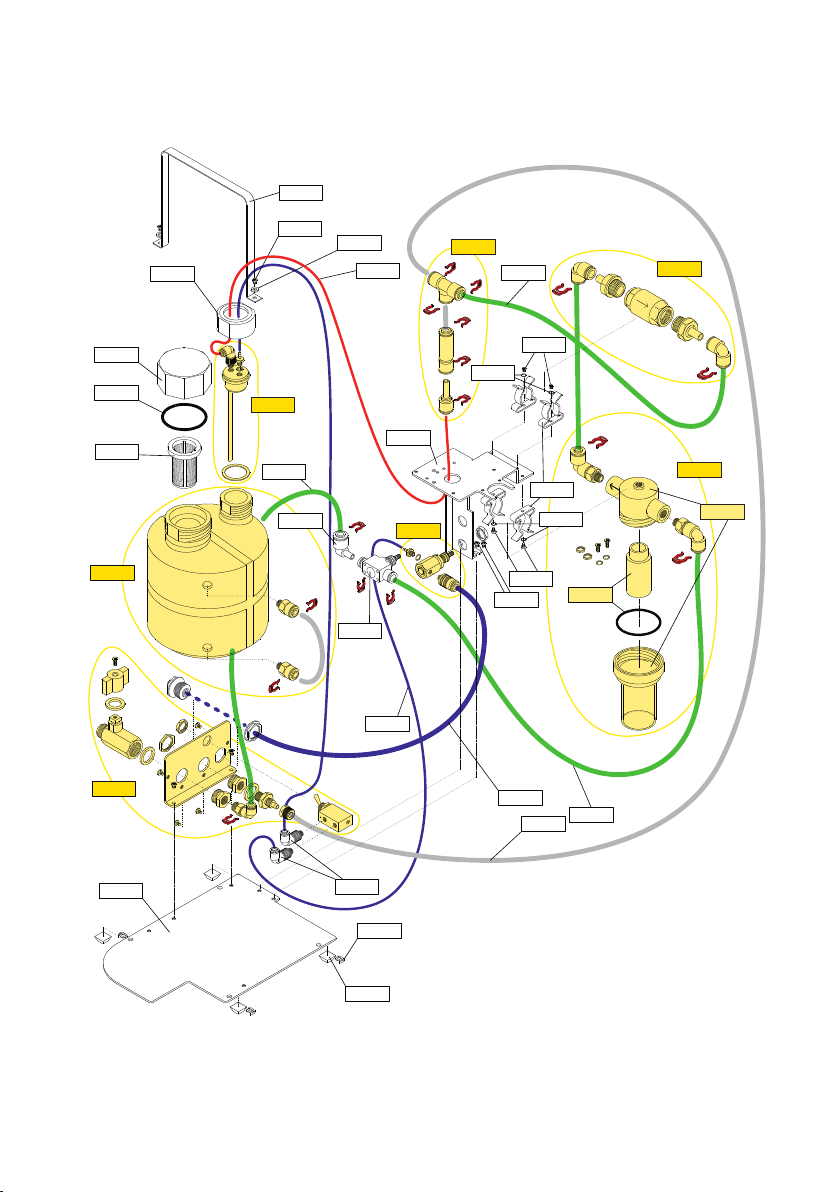

Filling amount: Min: 200 ml, Max: 900 ml

Microlter: 80µm(FilterF2)

Connection data

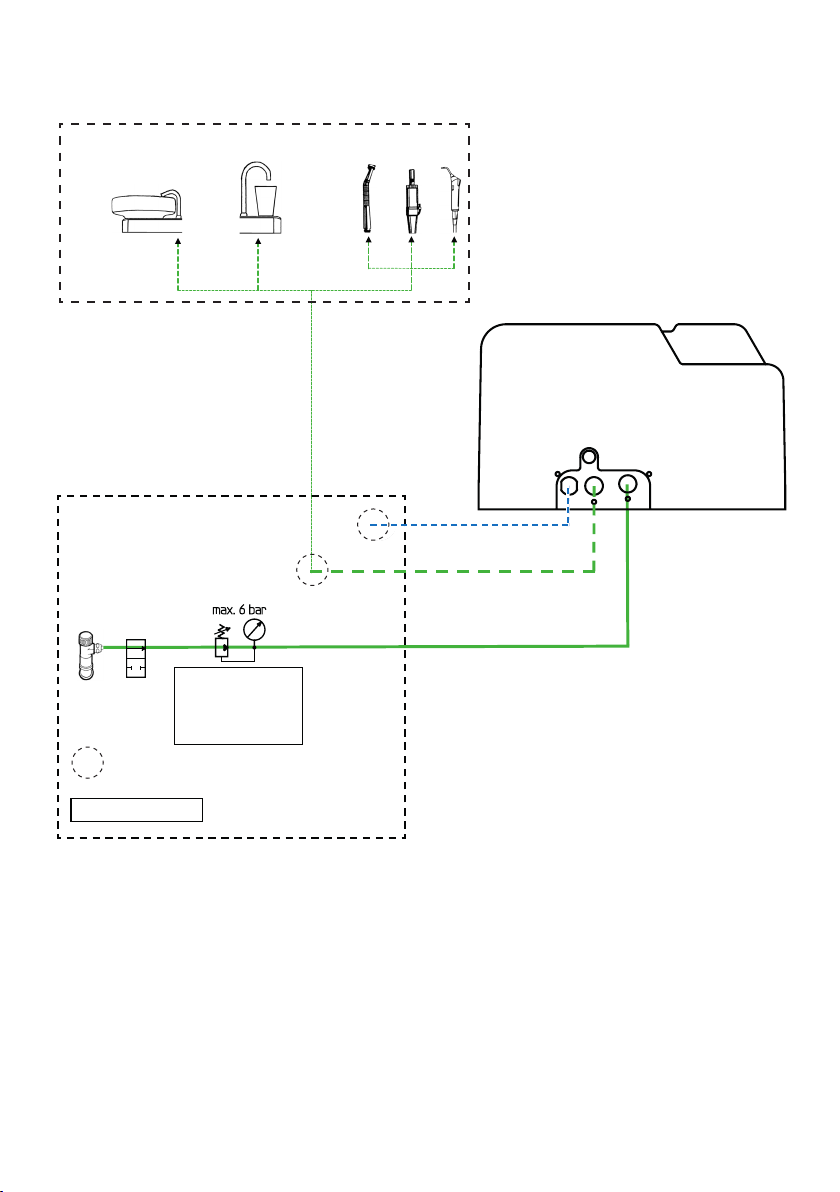

Media: Compressedair:withoutoil,drainedandltered

Water: ltered(80µm)

Maximum admissible pressures: Air pressure in incoming pipes: max. 8 bar

Air pressure in the tank: 2 bar

Pressure of incoming water: max. 6 bar

Connection lines: Incoming air pipe: blue PE-/PA-tube

Measures and weight

Measurements

(without tubes): width x length x height: 20 cm x 29 cm x 18.5 cm

Weight (empty): approx. 2.5 kg

Material

Chassis: sheet steel, galvanized

Casing: acrylonitrile butadiene styrene copolymer (ABS)

Tank: high-density polyethylene (HDPE)

Screwes connections: Polyoxymethylene (POM), brass

Tubes: polyamide, polyethylene, high-grade steel

ALPRO-BCS*

Weekend-System II*

SN XXXXXX

Gerätepass und Übergabeprotokoll

Entwurf_Gerätepass_210930_DE Seite / page 2/2

REF 80300357_01_20211012_DE

Bitte beachten:

Installation (ISO13485:2016 – Pkt. 7.5.3) und Wartung (ISO13485:2016 – Pkt. 7.5.4) des Geräts hat

ausschließlich durch von ALPRO autorisierte S ervice-Technikerzu er folgen, ansonsten erlischt die

Gewährleistung.

Hinweis betrifft nur Weekend-System II:

Zwischen Wasseranschluss/ Behandlungseinheit und dem Weekend-System II muss unbedingt ein

Wasser-Feinfilter z.B. Praxis-Eingangsfilter (Maschenweite max. 80 µm) installiert sein! Andernfalls

können wir keine Gewährleistung übernehmen, wenn das Gerät aufgrund Verschmutzung in den

Leitungen ausfällt (nähere Informationen, siehe Handbuch)

ALPRO MEDICAL GMBH

Mooswiesenstr. 9

D-78112 St. Georgen/ Schwarzwald

Tel.: 0 77 25/93 92-0, Fax: 0 77 25/93 92 91

E-mail: alpro@alpro-medical.de

Internet: www.alpro-medical.de

ALPRO MEDICAL GmbH

______________ _________________

Datum Unterschrift

*zutreffendes Gerät bitte ankreuzen

ALPRO-BCS*

Weekend-System II*

SN XXXXXX

Gerätepass und Übergabeprotokoll

Entwurf_Gerätepass_210930_DE Seite / page 1/2

REF 80300357_01_20211012_DE

Prüfprotokoll : _______________

Funktionsprüfungen:

i. O.

Dichtigkeitsprüfungen:

i. O.

Montage-/Prüftermin :

Hiermit wird bestätigt, dass das

ALPRO-BCS*

Weekend-System II*

in der Praxis installiert wurde.

(Anschrift Zahnarztpraxis)

Am______________ an der Behandlungseinheit ______________________________________

(Datum)

(Marke / Standort / Zimmer)

Hersteller-konform angeschlossen und übergeben wurde. Das Personal, namentlich Frau /Herr

___________________ wurde in die Funktionen des Gerätes, siehe Bedienungsanleitung,

von der Fa.__________________________________________________________ eingewiesen.

(Fachhandel / Techn. Service)

Gekauft am:

_______________________________________ ________________________________

(Unterschrift / Stempel Fachhandel / Techn. Service) (Unterschrift / Stempel Zahnarztpraxis)

Aus Gründen der Gewährleistung und des Qualitätswesens gem. ISO

13485:2016 – Pkt. 7.5.3, bitten wir Sie, den Pass mit Protokoll

auszufüllen und eine Kopie an uns zurückzusenden. Vielen Dank!

*zutreffendes Gerät bitte ankreuzen

For warranty and quality reasons

according to ISO 13485:2016 - 7.5.3,

we kindly ask you to ll in the device

passport including the protocol and

return a copy to us as the manufacturer.

Thank you very much!