6490009ENLZ / 6790009ENLZ ►2◄

Introduction / Certifi cation Alsipercha System

Apart from the assembly and operating instructions, each chapter

includes a series of safety recommendations. It is important that

these are observed. However, these recommendations are neither

exhaustive nor defi nitive, and should they not coincide with the

indications in the Health and Safety Plan or its equivalent according to

local legislation, the latter shall prevail.

If there are persons who cannot read the documentation or have

diffi culty doing so, they must follow the customer’s instructions and

indications.

Should you have any questions regarding the contents of this manual

or any suggestions as to how it can be improved, please address your

comments to your Alsina Marketing Technician or through our website:

www.alsina.com

Info In order to obtain the best performance from its

formwork systems, Alsina continuously updates the

assembly and operation instructions for its products.

For further information, contact the Alsina Marketing

Technician in your area. The locations of the Alsina Group’s

Sales Network are available at www.alsina.com, or you can

Introduction

Alsina’s instructions for installation, use and safety are intended as

a guide to the procedures required for safe and correct assembly,

disassembly and use of formwork systems under normal conditions, in

line with the standards commonly accepted on work sites. Any specifi c

work circumstance falling outside these standards may require them

to be adapted. When in doubt, do not hesitate to contact one of our

technical departments, anywhere in the world.

The instructions in this document are intended to explain to users

and technicians how the system works; they should ensure correct

preparation and use of the equipment on site. Consequently,

there will be references to general standards that any professional

user should be familiar with. Thus, it is best not to reproduce them in

this manual, since any modifi cations to these standards would lead

to discrepancies between the standards and the manual and could

cause confusion. Users should always refer to the latest version of the

standards in force.

Therefore, the references in this manual in no way annul, replace or

prevail over:

1- Standards and regulations on prevention of risks in the workplace

specifi c to a country or region.

2- The instructions in the specifi c Health and Safety Plan for the works.

3- Safety instructions in the evaluations and plans applying to specifi c

work functions in a company.

4- Technical orders and instructions specifi c to particular stages of

the works, issued by the technical directors, the health and safety

offi cer, the foremen and/or Prevention Resources.

Throughout the project, users shall respect, at all times, the specifi c

laws, standards and regulations of the country or region related to

prevention of risks in the workplace and any other legislation applicable

to each case and, if necessary, supplement the instructions and adapt

to other Work Safety Measures.

It is the customer’s responsibility to prepare, document, implement

and review the risk evaluation for the construction work.

This documentation provides the basis for the evaluation of specifi c

risks in the works, and Alsina’s Instruction Manuals may in no case be

regarded as a substitute.

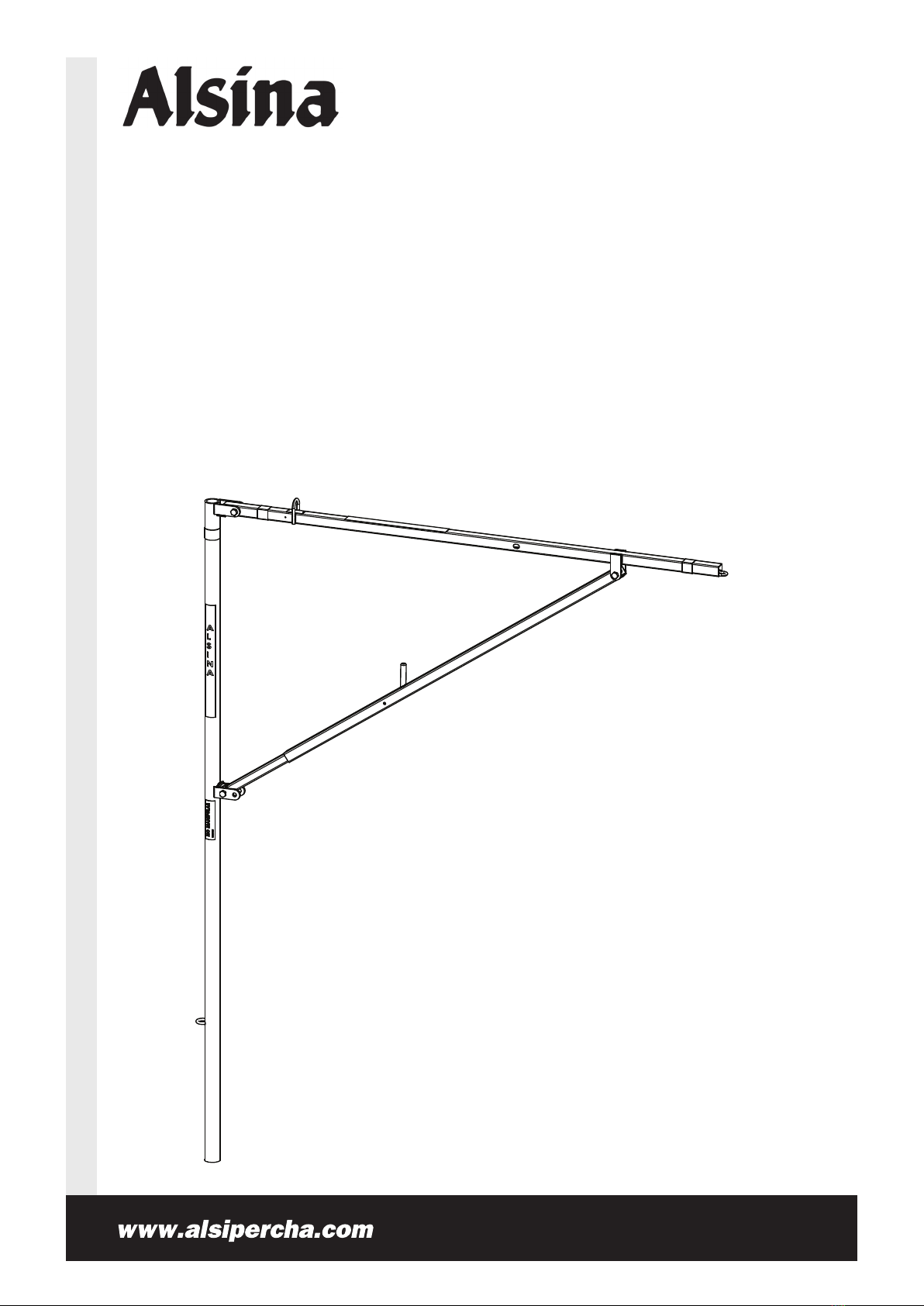

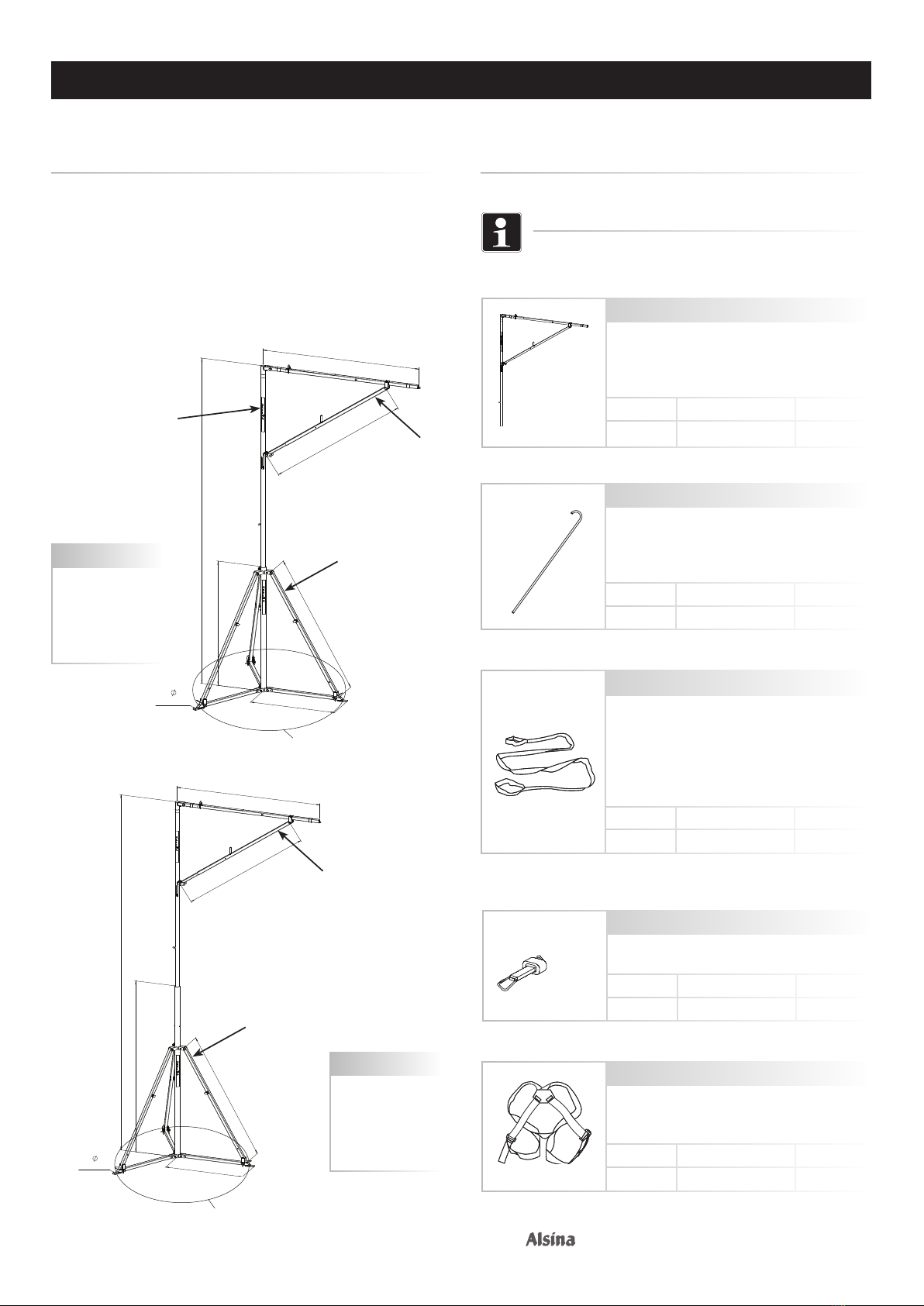

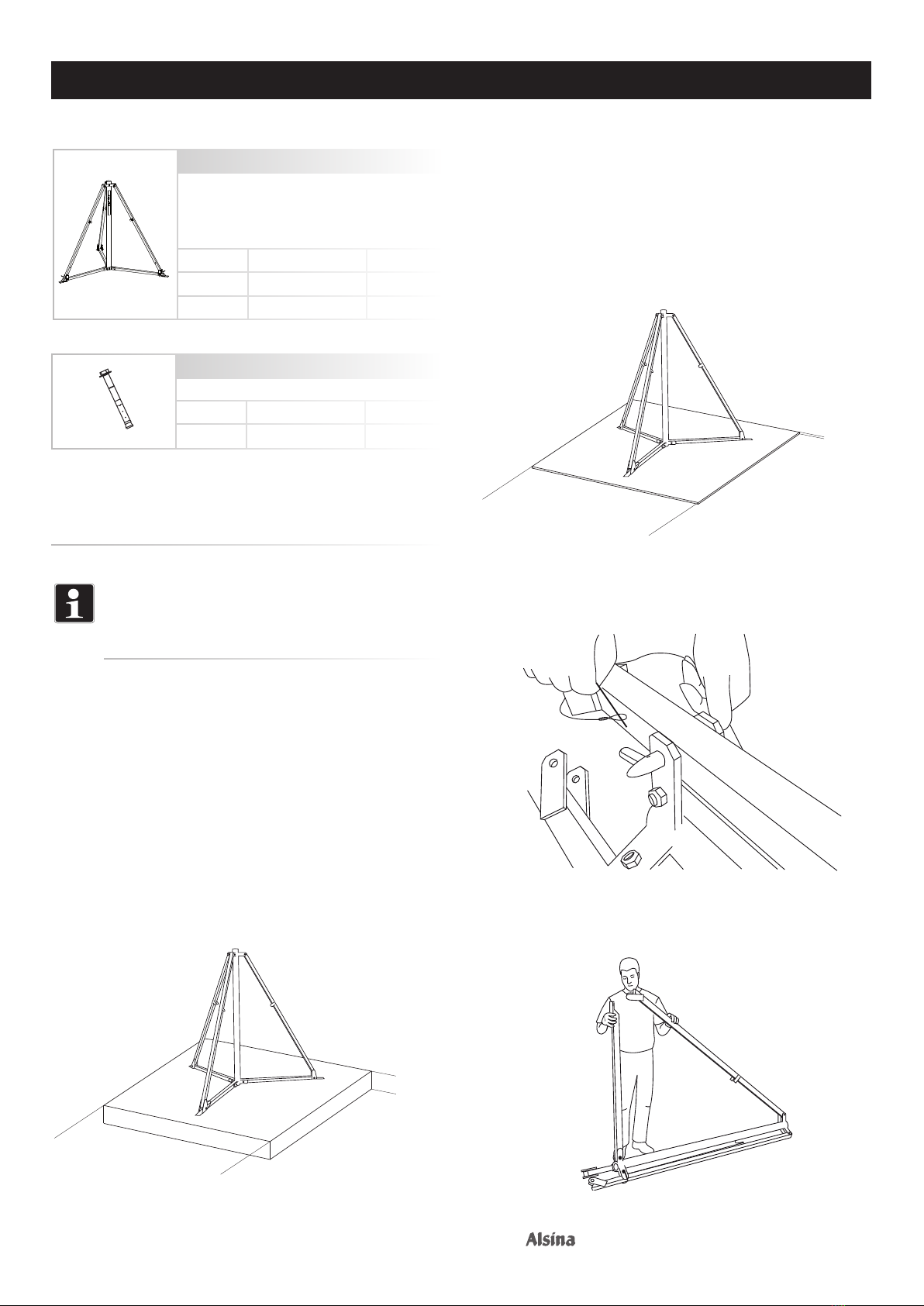

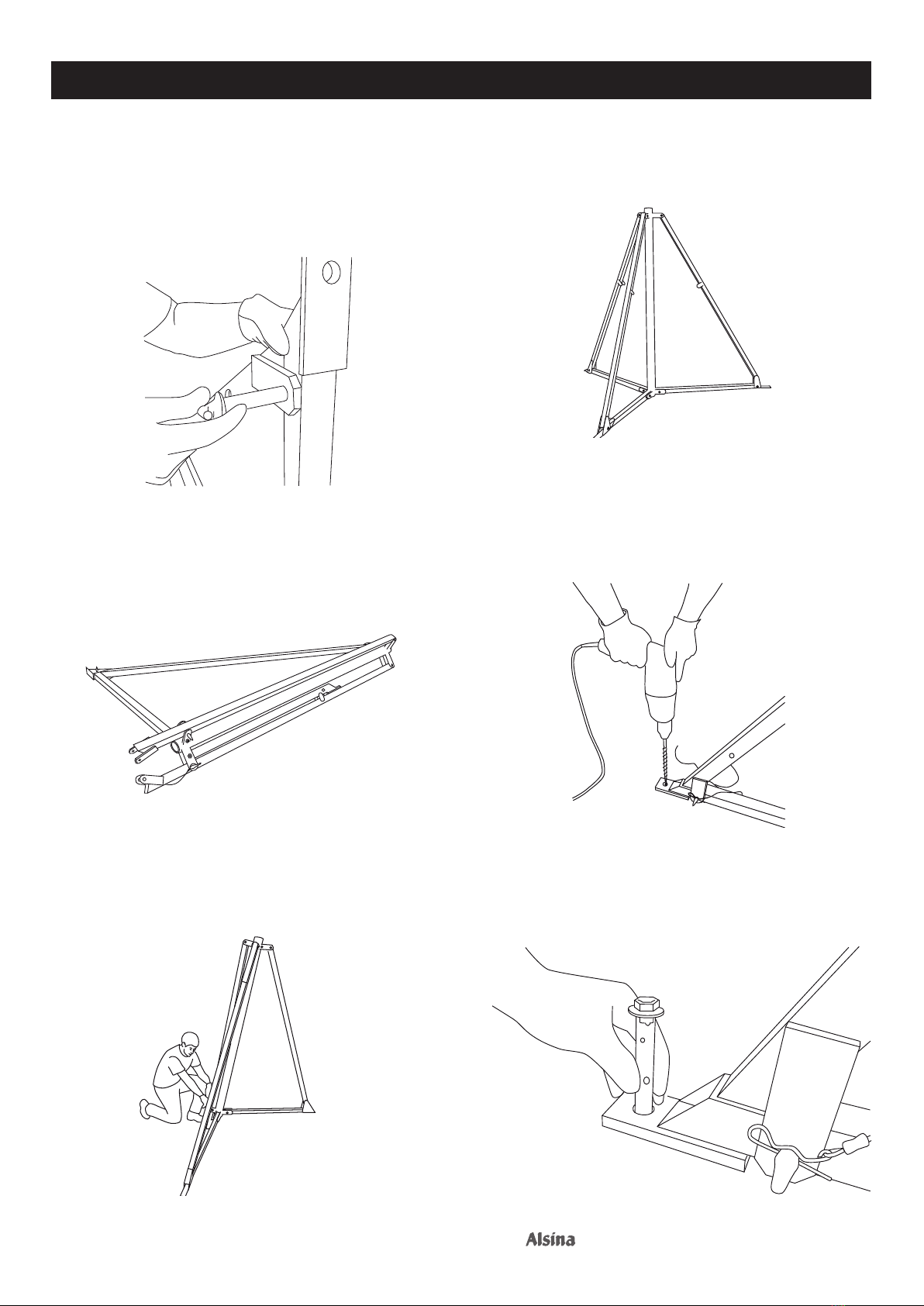

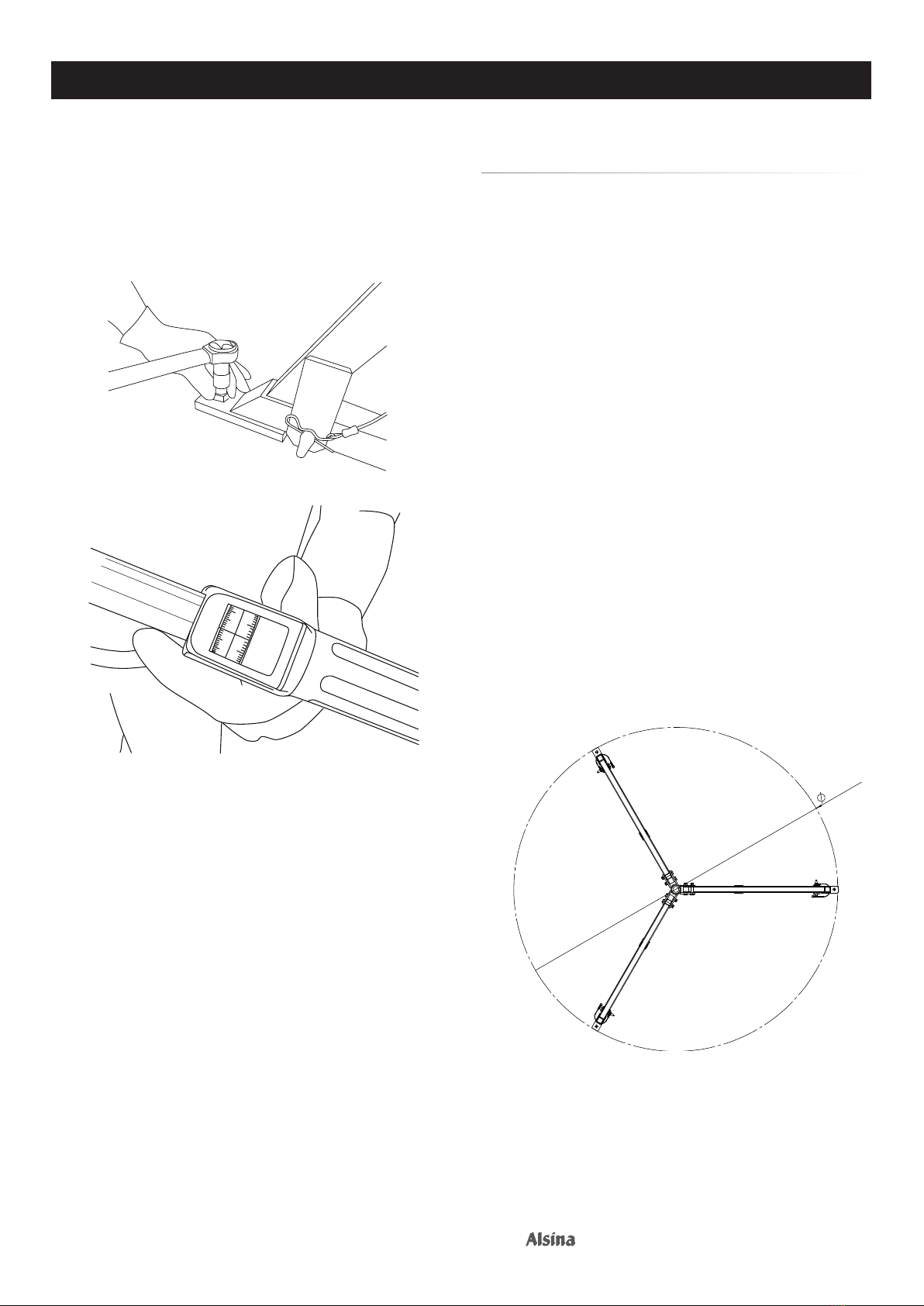

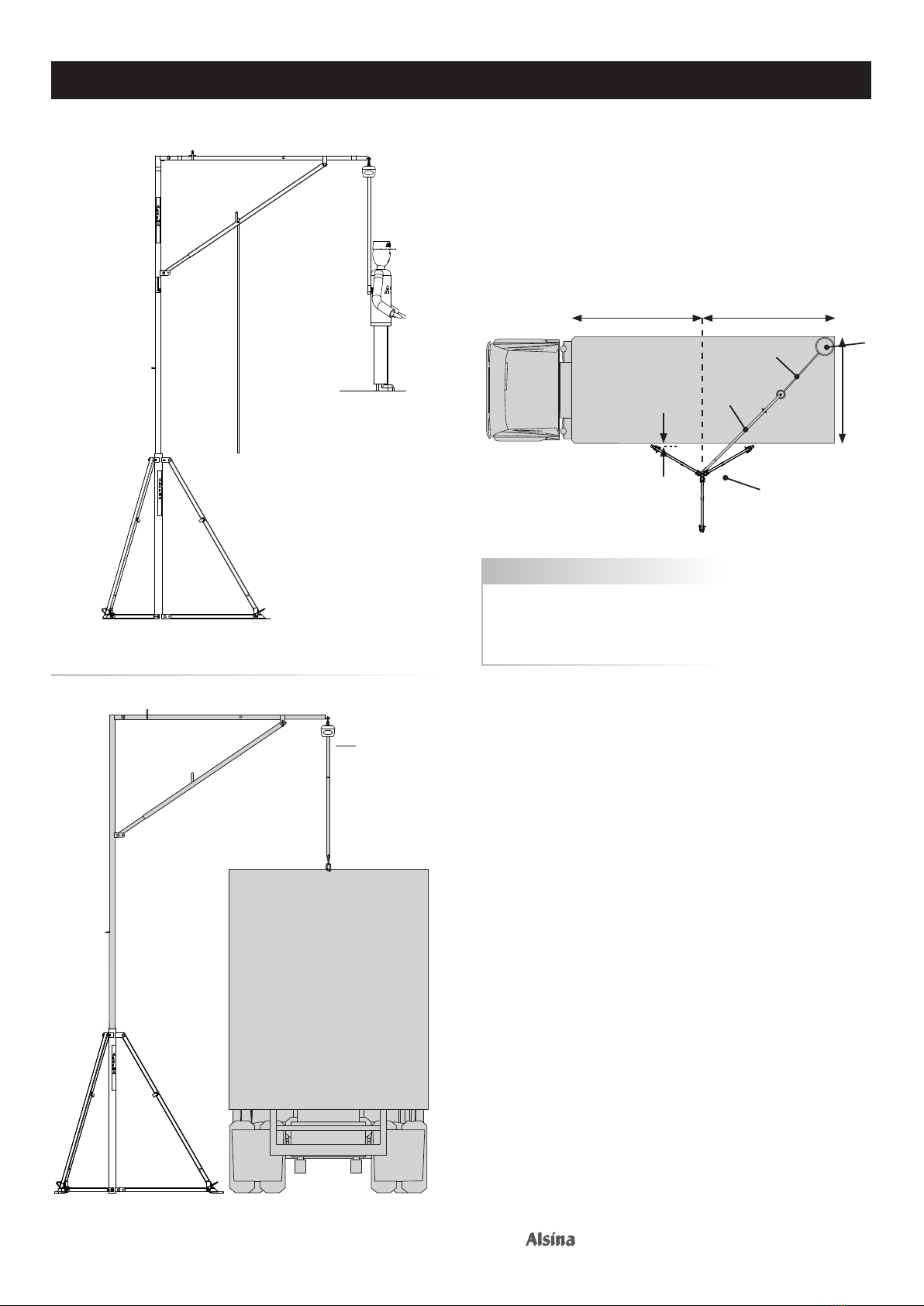

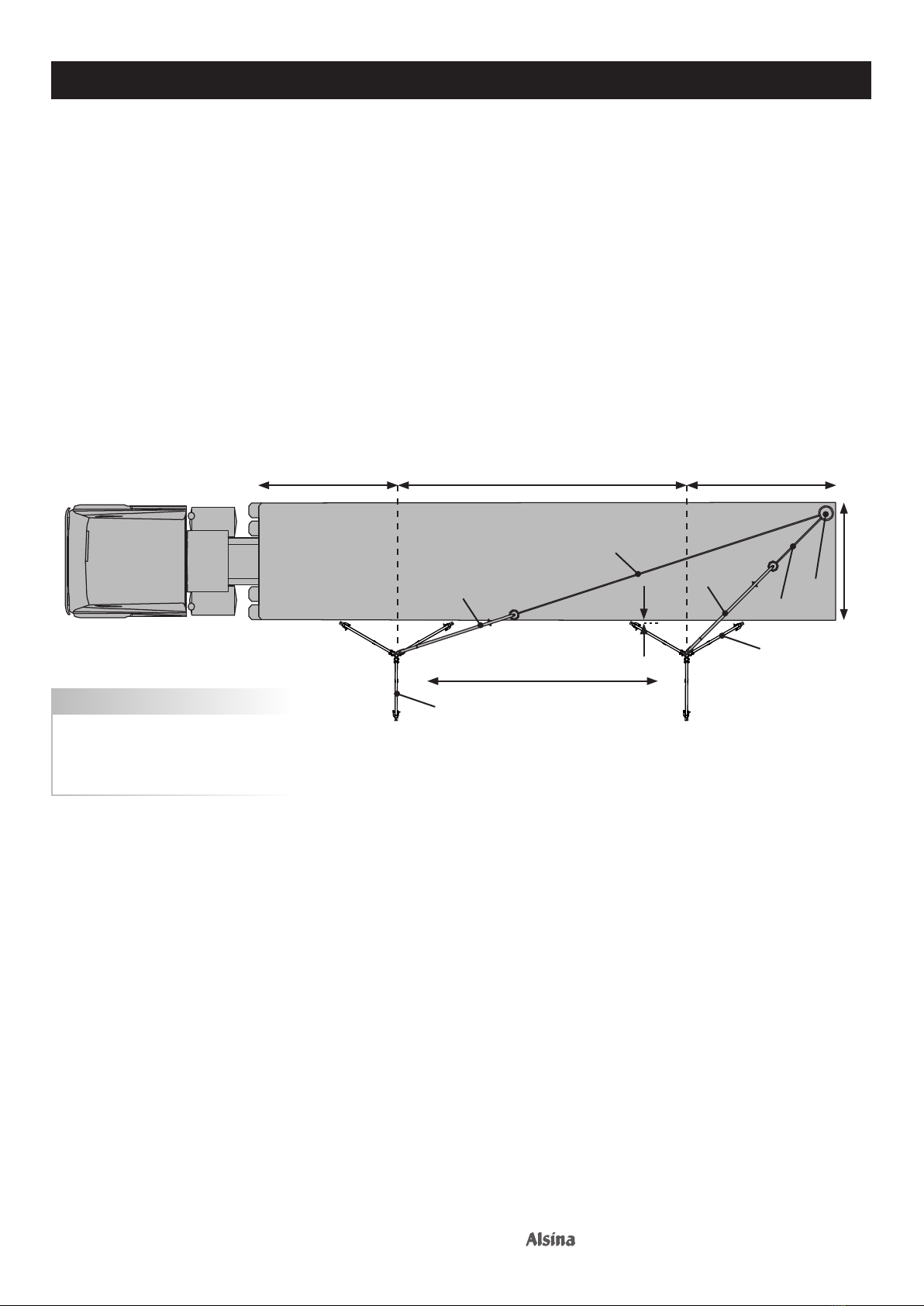

Sets of vertical formwork equipment, as systems, are made up

by joining different components. As far as possible, drawings and

diagrams have been included as an aid to understanding these

instructions. All personnel working with these products should be

familiar with the contents of this document and the safety instructions

therein.

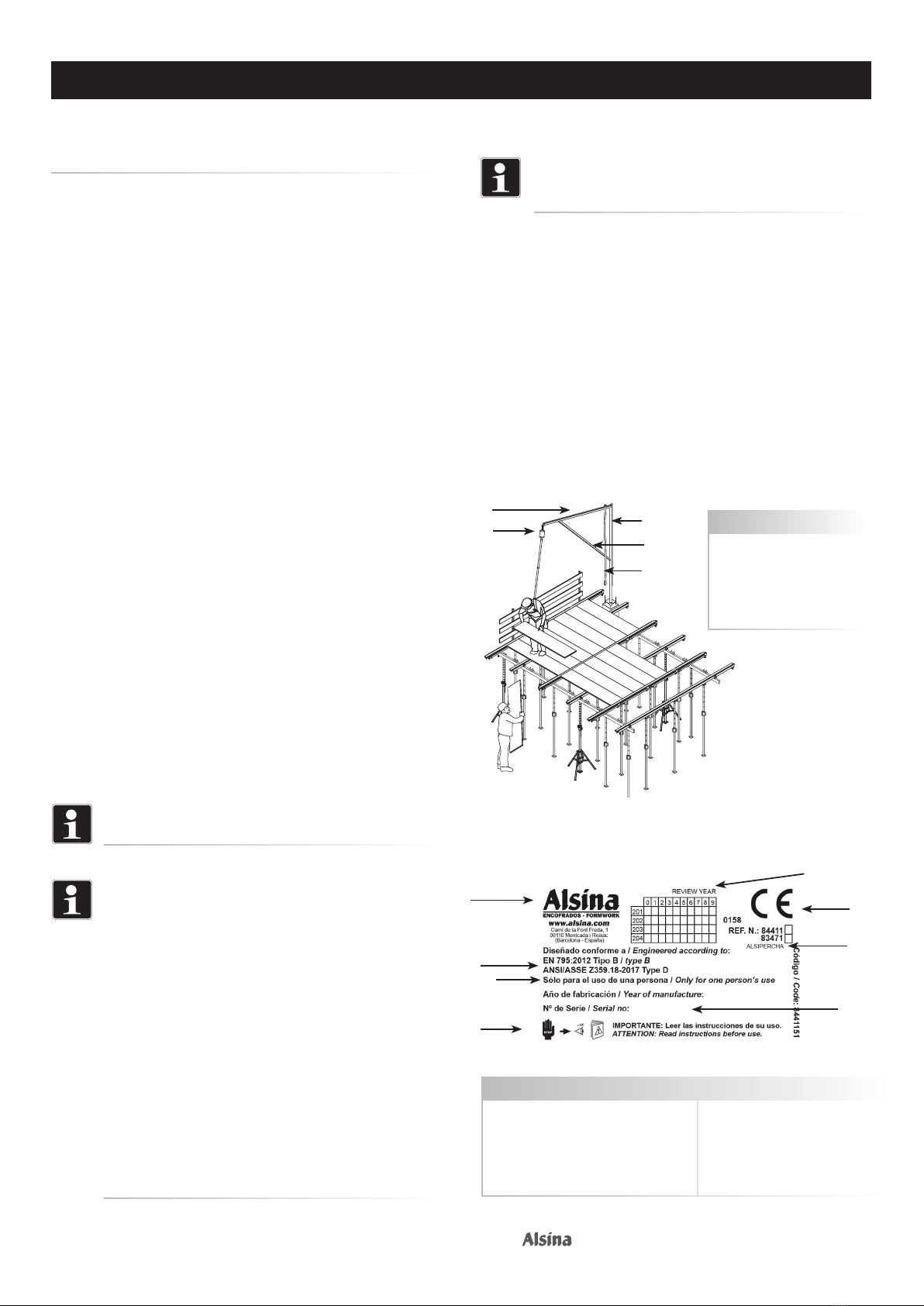

The illustrations in this manual refer, in part, to different phases of the

assembly process. Customers should ensure that they have a copy of

the assembly and operating instructions, supplied by Alsina, and that

these are known to and available to users on site.