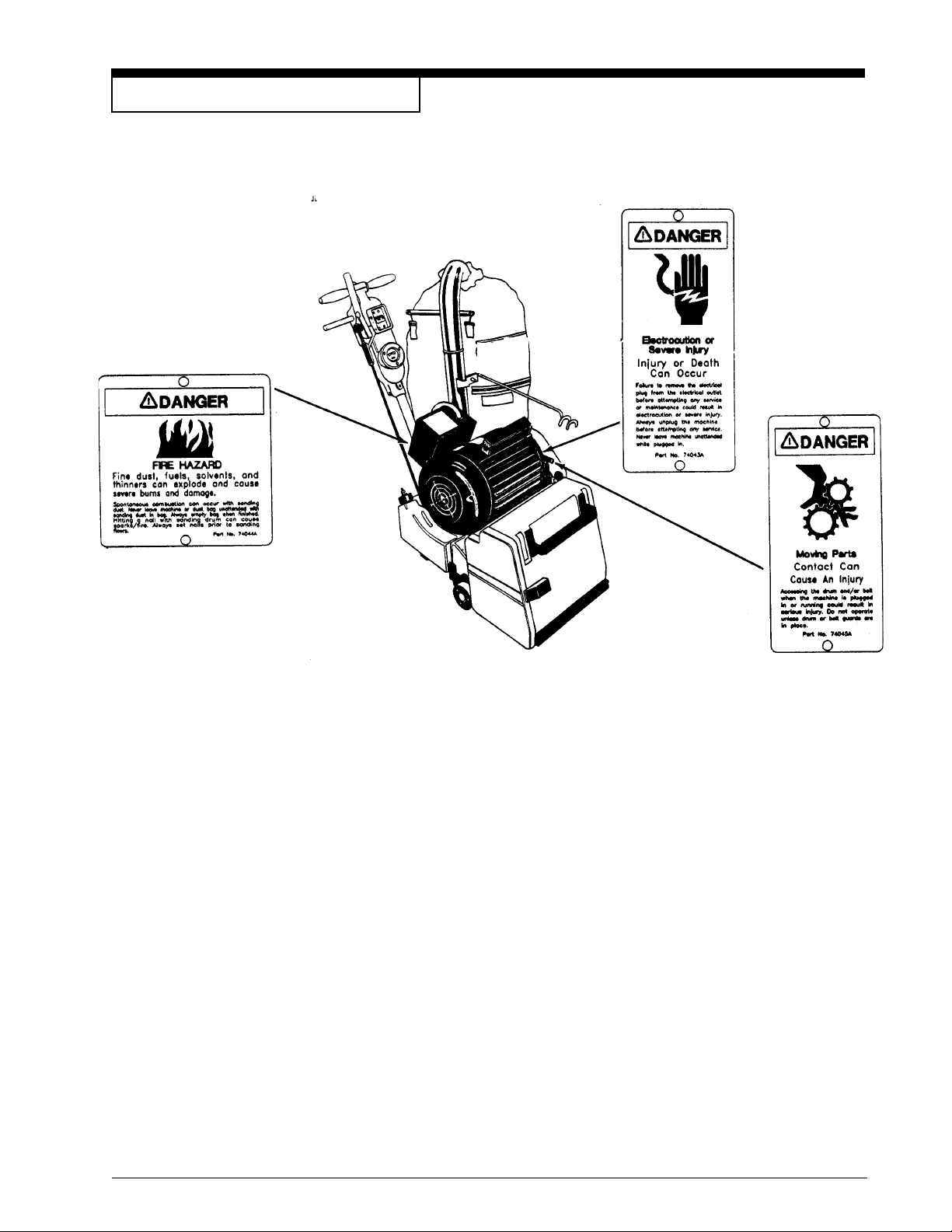

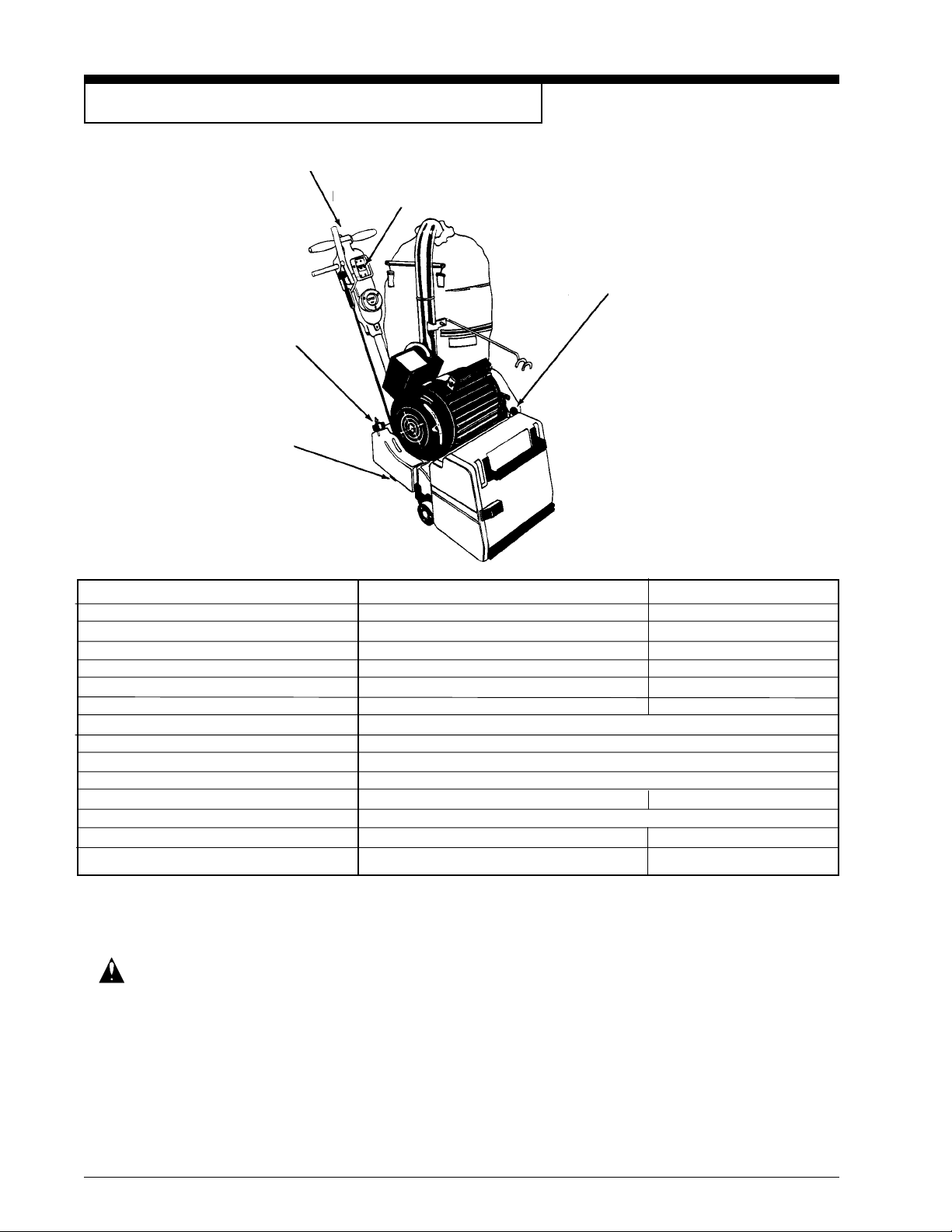

Page 4 AMERICAN SANDERS TECHNOLOGY Classic 12 Belt Sander Operator's Manual

DANGER: Electrocutioncouldoccurifmaintenanceandrepairsareperformedonaunitthatisnotproperly

disconnected from the power source. Disconnect the power supply before attempting any

maintenanceorservice.

DANGER: Electrocution could occur if machine is used on ungrounded electrical circuit. Never remove

or disable the grounding supply conductor on the electrical cord. Consult an electrician if the

grounding conductor is missing or if you suspect your circuit is not grounded properly.

DANGER: Use of this machine with a damaged power cord could result in an electrical shock. Do not

use the machine if the power cord is damaged. Do not use the electrical cord to move the

machine.

DANGER: Electrocution or injury could occur if the power cord is run over or damaged by the sander.

Keep the cord free from under the machine to avoid contact with the sandpaper. Always lift

the power cord over the machine.

DANGER: Moving parts of this machine can cause serious injury and/or damage. Keep hands, feet and

loose clothing away from all moving parts of the sander.

DANGER: Operating a sander without all guards, doors or covers in place can cause an injury or damage.

Always check to make sure that all of the guards, doors and covers are secure and in place.

DANGER: Injury to the operator or bystanders could occur if the machine's power is on while performing

maintenance, changing or adjusting the belt, or changing the dust bag.

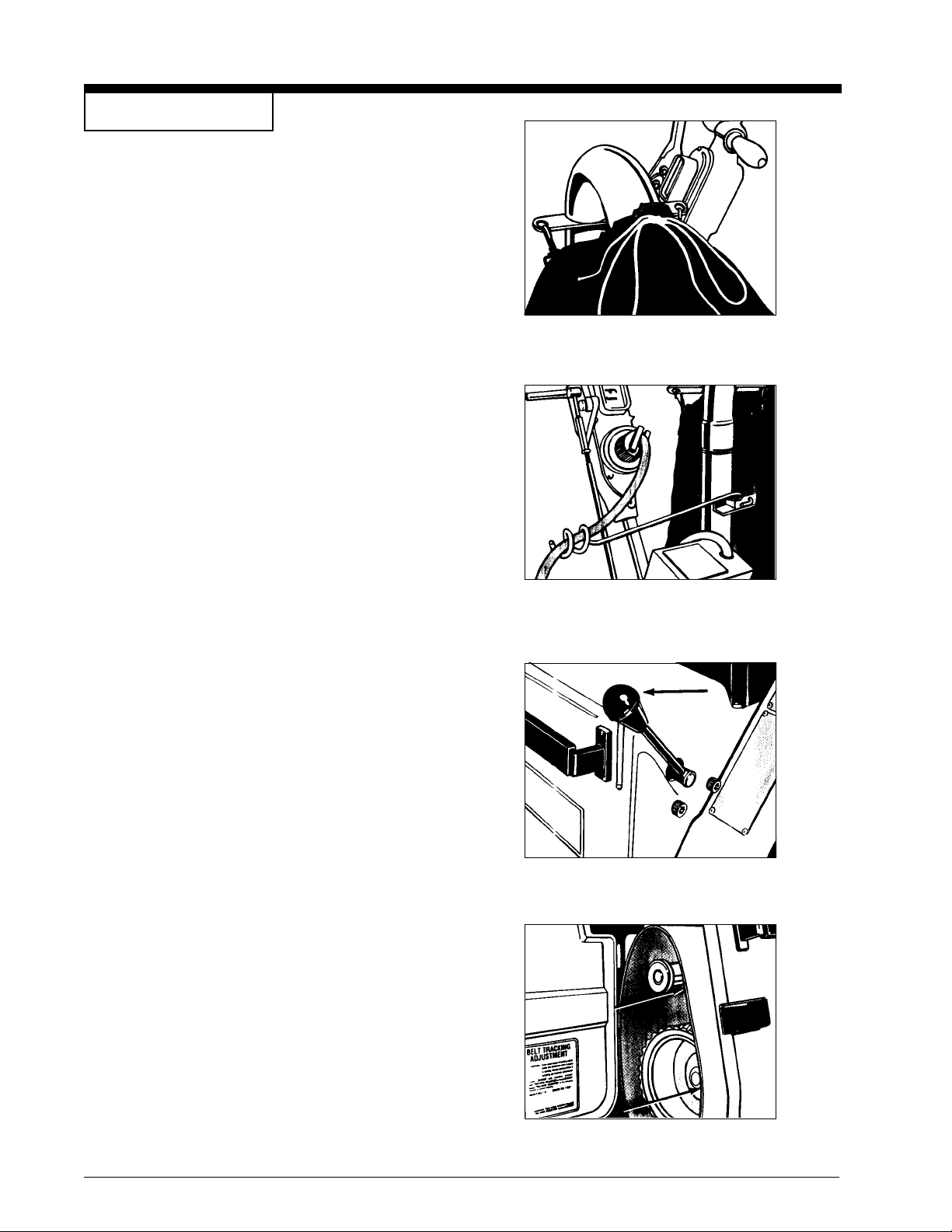

DANGER: Attempting to adjust the belt tracking while the machine is on can cause injury and/or damage.

Do not perform belt tracking adjustments while the machine is running.

WARNING: Failure to read and observe all safety statements found on your machine or in this Owner's

Manual can result in serious injury or damage. Read and observe all safety statements. Make

sure that all labels, decals, warnings, cautions, and instructions are fastened to the machine.

GetnewlabelsfromyourauthorizedAmericanSandersTechnologydistributor.

WARNING: Sanding dust can be airborne and can be breathed in while operating a sander. Always wear

a dust mask while operating sanding equipment.

WARNING: Injury to the eyes and/or body can occur if protective clothing and/or equipment is not worn

while sanding. Always wear safety goggles, protective clothing, and a dust mask while

performing any sanding operation.

WARNING: Bodily injury could occur if power is applied to the machine with the power switch already in

the "ON" position. Always check to assure that the power switch is in the "OFF" position

before applying power to the power cable.

CAUTION: Maintenance and repairs performed by unauthorized personnel could result in damage or

injury. Maintenance and repairs performed by unauthorized personnel will void your warranty.

Servicing of this unit must always be referred to an authorized American Sanders Technology

distributor.

CAUTION: Use of this machine to move other objects or to climb on could result in injury or damage. Do

not use this machine as a step or furniture. Do not ride on this machine.

CAUTION: Damage could occur to the machine if not properly kept in a dry building for storage. Store

the machine in a dry building.

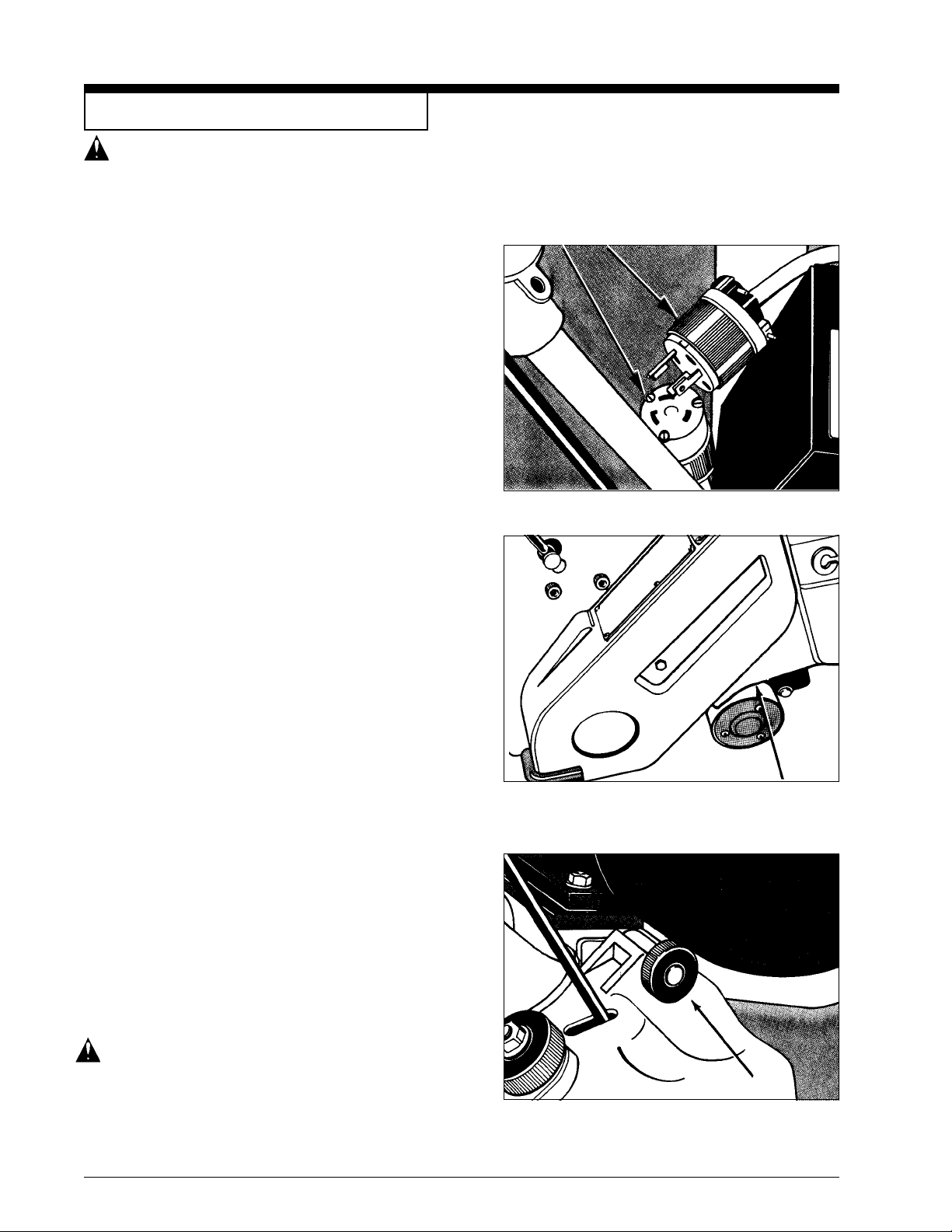

CAUTION: The machine is heavy. When transporting the machine, remove the motor. Get help to lift

the machine and motor.

CAUTION: Serious damage to the floor can occur if the machine is left running in one spot while the

sandingdrumisin contact withthefloor. To avoid damage tothefloor, feather cutinat a normal

sanding rate. Do not dwell while lowering or raising the contact wheel. Always sand at a

constant rate.