3

www.altrex.com

EN

1. Introduction

Thismanualappliesexclusivelytofoldingandrollingtowercongurations(hereinafter:‘thescaold)asdescribedinthis

assembly&usermanual(hereinafter:‘themanual’).Priortostartingtoassemblethetower,youshouldcarefullyreadthisma-

nual. The required tower should be assembled and used in accordance with this manual.All instructions in this manual have to

befollowedstrictly.Notfollowingtheinstructionscontainedinthismanualcaneasilyresultinseriousaccidents.Altrexcannot

beheldliableforanylossresultingfromtheassemblyoruseofanAltrextowerthatisnotincompliancewiththemanual.The

employer,supervisoranduserareresponsibleforthecorrectuseofthetowerinaccordancewiththismanualandtheymust

ensure that this manual is available at all times when work is being carried out using the tower. Additional copies of the manual

can be ordered from Altrex.

Local legislation and regulations might encompass measures in addition to those stated in this manual.

AltrexBV–Mindenstraat7–8028PKZwolle–T

el.:+31(0)384557733–Email:

[email protected]–Internet:www

.altrex.com

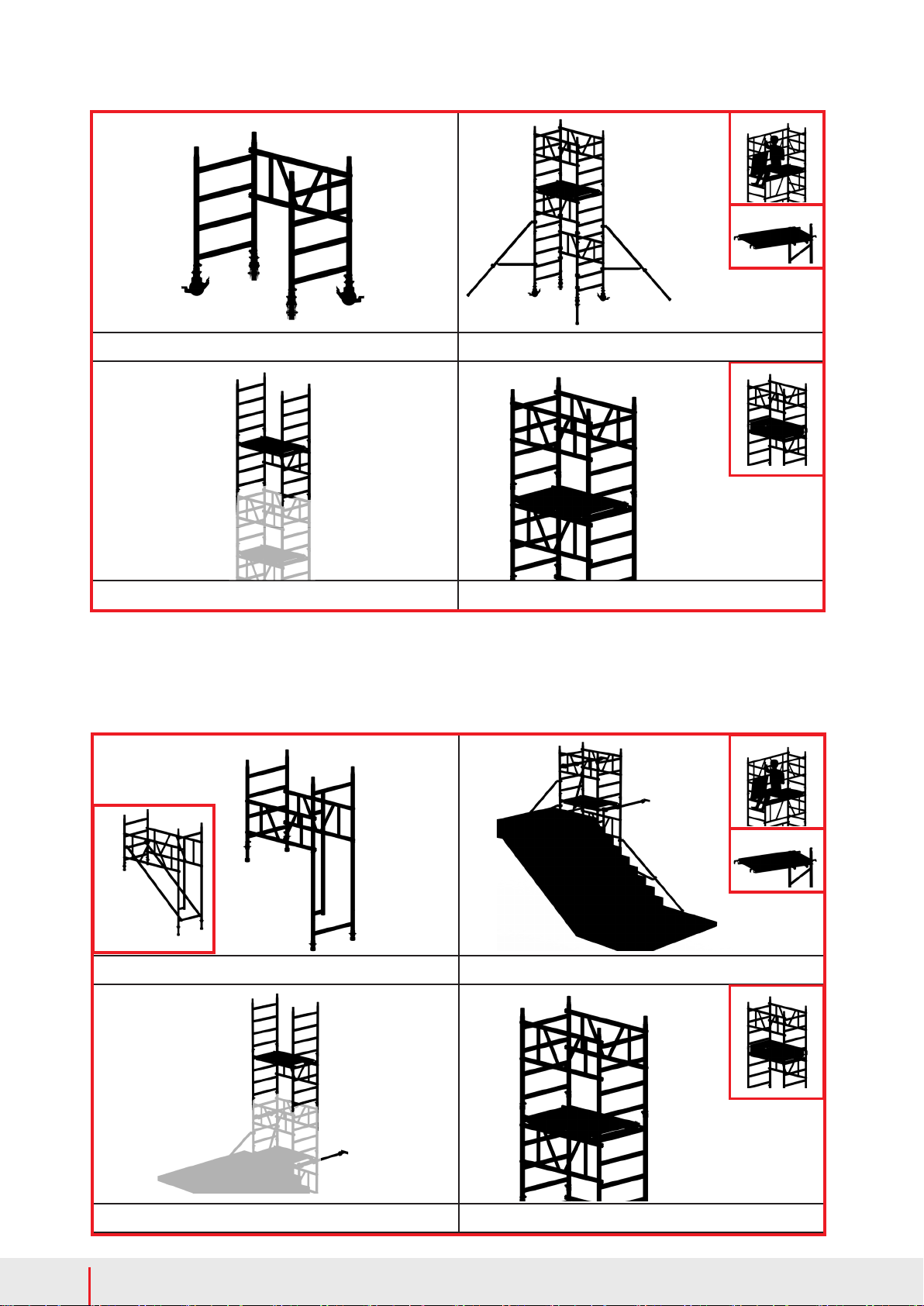

2. Type of rolling tower

MiTOWER MiTOWER+

Norm EN1004 EN1004

Category 3 - H2 3 - H2

Accesscategory XXCD XXCD

Maximum platform height outdoors 4 m 6 m

Maximum platform height indoors 4 m 6 m

Maximum platform load 150 kg 240 kg

Maximum load on rolling tower 750 kg 750 kg

Max number of platforms to be loaded 1 2

Maximum wind load 7,9m/s

(max.4Beaufort*) 7,9m/s

(max.4Beaufort*)

Minimumnumberofassemblypersons 1 1

3. Safety instructions

1. Thelocationoftherollingtowermustbecheckedtopreventaccidentsduringassembly,dismantlingandmovingwithrespectto:

A. Ahorizontal,atandsolidbase;

B. Thelocationmustbefreeofobstacles;

C. Maximum allowed wind speeds.

2. Checkifallrequiredparts,toolsandsafetytools(ropes,etc)forassemblingtherollingtowerareavailable.

3. Therollingtowermustnotbeoutoftheplumbinexcessof1%.Therefore,ataheightof4meters,thedeviationmaynotexceed4cm.

4. Theuseofhoistinggearonorattachedtotherollingtowerisnotpermitted;thiscanseriouslyaectthestabilityofthetower.

Rollingtowerparts,toolsandmaterialsmayonlybebroughtupanddown(toandfromtheworkoor)manuallyusingarope,for

example.

5. Checkallpartsfordamage.Damagedorincorrectpartsmaynotbeused.Mixingrollingtowerpartsofdierentbrands/from

dierentmanufacturersisnotpermitted,becausestrength&stabilitycalculationwasnotcarriedoutforthemixedconguration

concerned.

6. Thestandardcongurationsinthismanualarenotcalculatedontheuseoftarpaulinsand/oradvertisingboards.

7. Neverleavetherollingtowerunsupervised.Iftherollingtowermustbeleftunsupervised,youhavetomakesurethat

unauthorisedindividualscannotaccessit.Anchorthetowerwith2anchoragetubes(309106)ifthereisachangethatwindspeed

mightexceed4Beaufort*duringtheunsupervisedperiodoftime.

8. Particularattentionshouldbepaidtousingrollingtowerswhenthereiswind:

- withaspeedgreaterthan7,9m/s(maximum4onthescaleofBeaufort*);takealsointoaccountsquallsandgusts.

- inareasthatareverysensitivetowinde.g.,inopenconstructionsandatthecornersofabuilding.

Inthesecases,therollingtowermustbedisassembledormovedtoawind-freeplace.

9. Lateralloadsexceeding30kgresultingfromworkactivitiesontherollingtowerarenotpermitted.Intheeventofsignicantly

largerforces,thescaoldshouldbeanchoredtothefaçadeat2pointsevery4metres.

10. Never access the rolling tower on the outside and never stand on the braces.

11. Trianglestabilisersandballastmustalwaysbeattachedaccordingtotheconguration&ballasttable.

12. Hoisting or suspending the tower is not permitted.

13. Itisnotpermittedtoincreasetheheightofaplatforme.g.withladders,stepladders,boxesoranyotherobject.

14. Mobile acces towers are not designed as anchor points for personal fall protection.

Index

1. Introduction

2Typeofrollingtower

3. Safetyinstructions

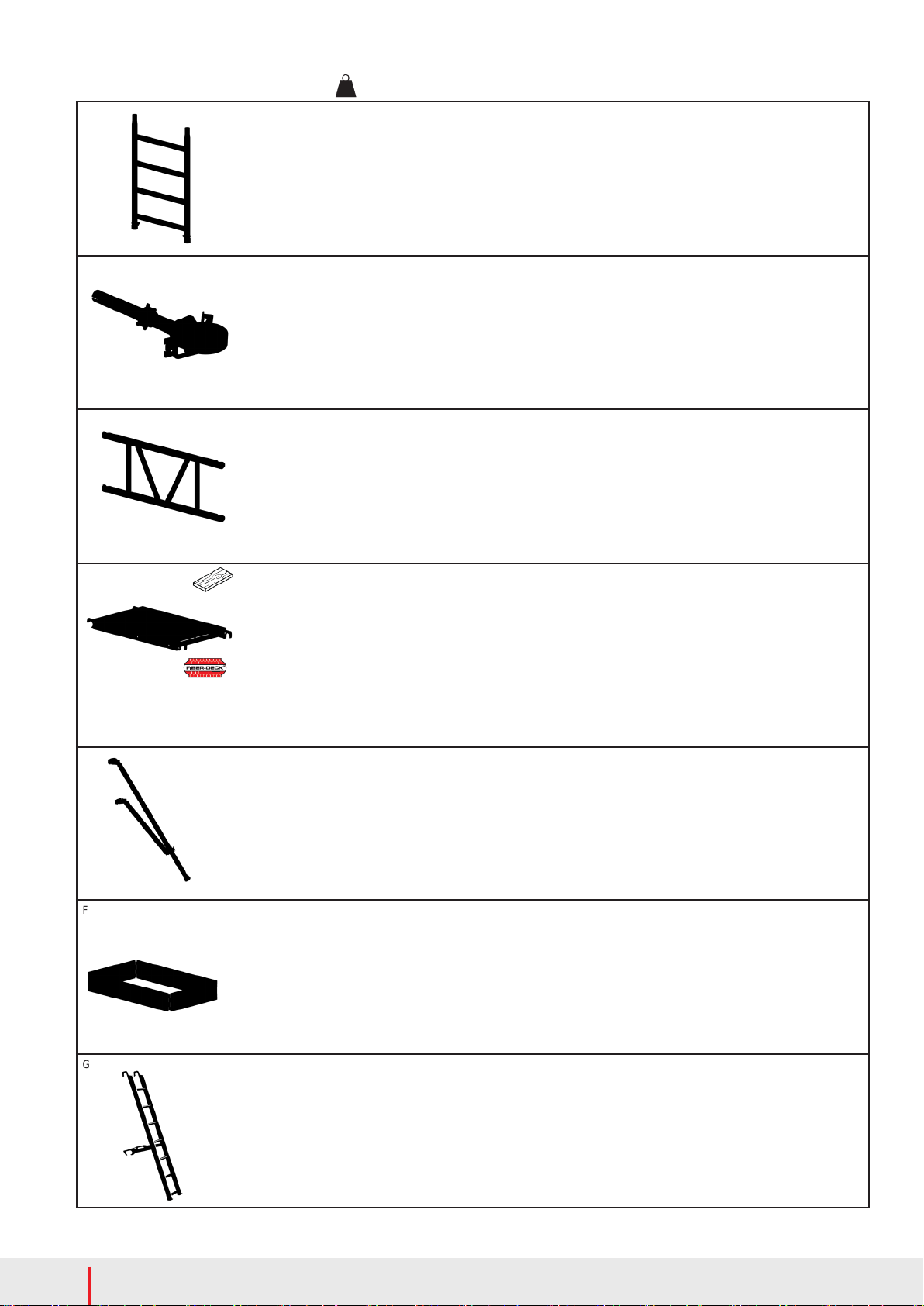

4. Parts

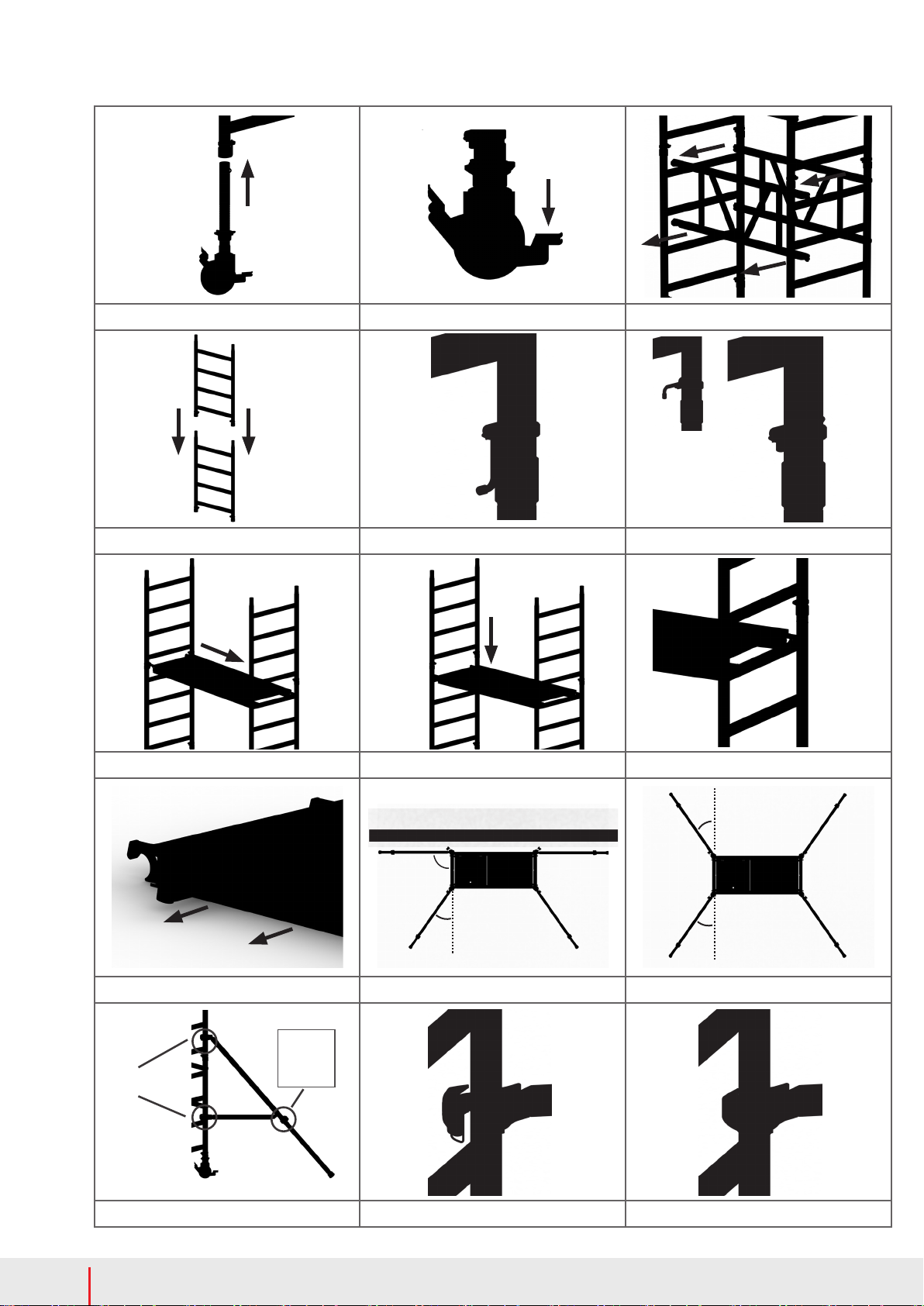

5. Mounting instructions

6. Check before use

7. AssemblingtheMiTOWER/MiTOWER+

8. Assembling the MiTOWER STAIRS

9. Ballast

10. Moving the rolling tower

11. Disassemblyoftherollingtower

12. Inspection,CareandMaintenance

13. Warrantyconditions

14. Abbreviations and logos

Annex

T1. Parts

T2. Mounting instructions

T3.AssemblystepsevenworkingheightsMiTOWER/MiTOWER+

T4.AssemblystepsoddworkingheightsMiTOWER/MiTOWER+

T5.CongurationsMiTOWER

T6.CongurationsMiTOWER+

T7.AssemblystepsMiTOWERSTAIRS

T8.CongurationsMiTOWERSTAIRS

*)4Beaufort:smallbranchesmove,raisesdust

andloosesnow,onalakewavesbecomelonger

withfairlyfrequentwhitehorses.

www.lglt.co.za

Please see Strength & Stability Certificate