Altronic DD-40NTV-O User manual

INSTALLATION INSTRUCTIONS

DIGITAL ANNUNCIATOR

DD-40NTV-O, DD-40NTV-U

DEVIATION FROM THESE INSTRUCTIONS MAY LEAD TO IMPROPER OP-

ERATION OF THE MACHINE WHICH COULD CAUSE PERSONAL INJURY

TO OPERATORS OR OTHER NEARBY PERSONNEL.

WARNING:

www.altronicinc.com

FORM DD-40NTV II 12-09

www.altronicinc.com 1

1.0 OVERVIEW

1.1 The Altronic DD-40NTV digital annunciator is an electronic, 40-

point monitor and shutdown device. The annunciator has a built-

in hourmeter/tachometer, overspeed and underspeed*protection,

and pre-/post-lube control*. Local display and remote communi-

cation (via ModBus RTU) is included for all critical operating pa-

rameters, including the internal battery, supplied DC power, and

CD ignition shutdown lead voltages.

1.2 The DD-40NTV annunciator is suitable for use in Class I, Division 2,

Group C or D hazardous areas and consists of the following items:

•DD-40NTV-O

Annunciator, 40 normally-open points

•DD-40NTV-U

Annunciator, 40 normally-closed or open

points (can be mixed)

•691200-3 Power Supply: 10–30 Vdc, 50 mA max.

or 100–400 volt negative ground CD ignition systems

•693115-1 Cable, DB-25 (2 required for DD-40NTV-U

unit only)

•693116-1 Cable, D:B-9 (for RS-232 serial communications)

1.3 RS-232/RS-485 serial communications are provided for

remote engine monitoring via modem or satellite. Serial

communications require the use of the DC power option.

1.4 For reliable operation, the following instructions must be

adhered to strictly.

DEVIATION FROM THESE INSTRUCTIONS MAY LEAD TO

IMPROPER OPERATION OF THE MACHINE WHICH COULD

CAUSE PERSONAL INJURY TO OPERATORS OR OTHER

NEARBY PERSONNEL.

WARNING:

NOTE: The DD-40NTV annun-

ciator may also be used with

the 691200-1 Power Supply

to emulate the function of

the DD-40NTS system. For

more detail, refer to Form

DD-40NTS II 5-02.

Features designated by an * in these Installation Instructions

are NOT available if using the 691200-1 Power Supply.

FORM DD-40NTV II 12-09

2

DD-40NTV DIGITAL ANNUNCIATOR

NOTE: If possible, keep the

original shipping container.

If future transportation or

storage of the annunciator

is necessary, this container

will provide the optimum

protection.

2.0 MOUNTING

2.1 ANNUNCIATOR UNIT:

Using four #10 screws, mount the Annunciator Unit inside a control

panel or to a suitable at surface so that the display is at a conve-

nient viewing height. A drilling template is provided. The annun-

ciator unit box must be grounded.

2.2 691200-3 POWER SUPPLY:

The Power Supply mounts directly to the back of the Annunciator

Unit using two 8-32 x 5/16" length screws provided.

3.0 WIRING (FIGS. 7 – 20)

3.1 The annunciator unit plugs into the power supply through a DB-9

connector.

3.2 The sensor leads connect to the removable terminal strips on the

back of the annunciator. These terminal strips match those used

with the earlier DD-40NT/DD-20NT systems.

3.3 At the terminal strip of the Annunciator unit, strip the insulation

back 3/8"; twist the exposed wires tightly together. Insert the ex-

posed wire end completely into the terminal strip and securely

tighten the clamping screw. It is suggested that wire 18 AWG (max.)

to 24 AWG (min.) be used for the connections directly to the an-

nunciator terminal strip connector.

3.4 Wires running to the various sensors should be in good condition

or replaced with new wiring. Terminations to the main panel ter-

minal strip (if used) should be made with a suitable terminal and

crimping tool or by soldering. There is no requirement for explo-

sion-proof conduit or Class I enclosures; however, suitable physical

protection should be provided.

NOTE: Avoid mounting with

the LCD display facing direct

sunlight.

The display temperature

range is -40°F. to +175°F.

WARNING: REGARDING OLDER ALTRONIC OVERSPEED DEVICES

IF RETROFITTING INTO AN OLDER PANEL, THE DD-40NTV ANNUNCIATOR WILL NOT

RECOGNIZE THE OUTPUT SIGNAL FROM OLDER ALTRONIC OVERSPEED DEVICES:

DTO-1000, DTO-1010, DTO-2200, DTO-3200

DTHO-2100, DO-3300, PTO-2100, PTHO-2100

THESE DEVICES WILL NOT WORK FOR OVERSPEED PROTECTION IN CONJUNCTION

WITH A DD-40NTV ANNUNCIATOR. FOR SUCH PROTECTION, USE THE OVERSPEED

FEATURE BUILT INTO THE DD-40NTV ANNUNCIATOR (REFER TO SECTION 6.3).

www.altronicinc.com 3

DD-40NTV DIGITAL ANNUNCIATOR

4.0 ANNUNCIATOR CONFIGURATION

4.1 The DD-40NTV series unit MUST be congured prior to use. If re-

placing an older series DD series annunciator, modes 1 and 4 can

be used to directly emulate the older system’s performance. Mode

1 duplicates the operation of the DD-40 series and mode 4 dupli-

cates the DD-20 series units. To congure the unit, press the MENU

key to reach the conguration headings from the normal display

mode. After a selection has been made, press the ENTER key to save

the selection. Press MENU to move to the next step. A flowchart

(REFER TO FIG. 6A or 6B) is provided that shows step-by-step pro-

gression through the annunciator conguration procedure.

CAUTION:

A. SENSOR WIRING: SENSOR WIRES WITHIN THE PANEL ENCLOSURE

MUST BE KEPT AT LEAST TWO (2) INCHES FROM OTHER WIRING. USE A

SEPARATE JUNCTION BOX FOR IGNITION AND FUEL VALVE WIRES. RUN

SENSOR LEADS LEAVING THE PANEL IN A CONDUIT SEPARATE FROM ALL

OTHER WIRING AND KEEP SEPARATE THROUGHOUT THE INSTALLATION.

WIRING TO THE SENSORS MUST HAVE A GRADE OF INSULATION CAPABLE

OF WITHSTANDING AN AC VOLTAGE OF 500 V. RMS. SENSOR LEADS MAY

BE CONNECTED TO ANY PASSIVE DEVICE USING CONTACTS SUCH AS

STANDARD SWITCH GAUGES OR LEVEL SWITCHES. DO NOT CONNECT

SENSOR LEADS TO RELAY CONTACTS OR TO ANY VOLTAGE PRODUCING

ELEMENT.

B. SENSORS WILL BE EXPOSED TO MUCH LOWER VOLTAGES AND CURRENT

THAN WITH THE STANDARD MURPHY TATTLETALE OR SIMILAR TYPE

SYSTEM. IN THE CASE OF A FIELD CONVERSION WHERE SENSORS HAVE

PREVIOUSLY BEEN USED WITH MURPHY TATTLETALES, IT IS RECOM-

MENDED THAT THE SENSORS BE CHECKED FREQUENTLY WHEN THE DD

SYSTEM IS FIRST PUT INTO USE. SENSOR CONTACTS MAY BE BURNED

OR PITTED FROM PAST EXPOSURE TO IGNITION SYSTEM PRIMARY VOLT-

AGE. IT IS ADVISABLE TO REPLACE SUCH SENSORS.

C. IF IT BECOMES NECESSARY TO CHECK SENSOR TO PANEL WIRING WITH

AN OHMMETER OR OTHER CHECKER, FIRST DISCONNECT THE PLUG-IN

TERMINAL STRIPS FROM THE BACK OF THE ANNUNCIATOR UNIT. APPLY-

ING VOLTAGE TO THE ANNUNCIATOR THROUGH THE SENSOR LEADS MAY

DAMAGE THE DEVICE. IN ADDITION, THE AREA SHOULD BE TESTED AS

NON-HAZARDOUS BEFORE SUCH TESTING COMMENCES.

FORM DD-40NTV II 12-09

4

DD-40NTV DIGITAL ANNUNCIATOR

4.2 CONFIGURE MODE:

The mode selection allows the unit to be programmed in one of four

modes as shown. The RESET button must be pressed after a change

in mode number.

MODE TYPE OF POINTS CHANNELS NOTES

1 24 Class A 30-37, 40-47, 50-57 Duplicates operation

16 Class B1 10-17, 20-27 DD-40NT series.

2 24 Class A 30-37, 40-47, 50-57

12 Class B1 10-17, 20-23

4 Class B2 24-27

3 24 Class A 30-37, 40-47, 50-57

10 Class B1 10-17, 20-21

2 Class B2 22-23

4 Class C 24-27

4 12 Class A 20-27, 30-32, 40 Duplicates operation

8 Class B1 10-17 of DD-20NT series.

Class Denitions:

Class A Point is always armed.

Class B1 Point is armed B1 time after power-up or pressing the

RESET key.

Class B2 Point is armed B2 time after power-up or pressing the

RESET key.

Class C Point is armed after it clears.

Use the UP and DOWN keys to select the mode and press the ENTER

key to save the mode.

4.3 PROGRAM RPM 1:

This selects the RPM pre-divide number equal to the pulses per

revolution (PPR). The RPM signal can be from either a CD ignition

shutdown lead or a magnetic pickup. The range is selectable from 0

to 361 PPR. A “0” PPR VALUE is used in applications where a speed

input is not used. Use the UP and DOWN keys to select the proper pre-

divide number and press the ENTER key to save.

4.4 PROGRAM RPM 2:

This selects the RPM overspeed value. The range is selectable from

1 to 2499 RPM. Use the UP and DOWN keys to select the overspeed

value and press the ENTER key to save the selection. To disable the

NOTE: A keypad sequence

(password) is required to

edit values. From the sta-

tus screen press and hold

the ENTER key, then press

the MENU key allow values

to be modied. Otherwise,

selected items may only be

viewed. There is no similar

protection for the TIMER

button (Class B1 and B2

timers) or hourmeter.

www.altronicinc.com 5

DD-40NTV DIGITAL ANNUNCIATOR

overspeed function, enter 2500.

4.5 PROGRAM RPM 12*:

This selects the RPM underspeed value. The range is selectable from

0 to 2500 RPM. Use the UP and DOWN keys to select the underspeed

value and press the ENTER key to save the selection. To disable the

underspeed function, enter 2500.

4.6 PROGRAM PRE-LUBE P1*:

This selects the time delay in seconds for which the LUBE (LUB) out-

put is actuated on start-up. The range is from 1 to 999 seconds. Use

the UP and DOWN keys to select the desired pre-lube time (in sec-

onds) and press the ENTER key to save the selection. Entering a value

of zero (0) as the setpoint disables the pre-lube function.

4.7 PROGRAM POST-LUBE P2*:

This selects the time delay in seconds for which the LUBE (LUB)

output is actuated following a manual STOP or SHUTDOWN. The

range is from 1 to 999 seconds. Use the UP and DOWN keys to select

the desired post-lube time (in seconds) and press the ENTER key to

save the selection. Entering a value of zero (0) as the setpoint dis-

ables the post-lube function.

4.8 PROGRAM TIMER 2:

This selects the time delay in seconds for tripping SDI and OUTPUT

2 after a fault occurs. The range of the delay is from 1 to 60 seconds.

Use the UP and DOWN keys to select the time and press the ENTER key

to save the selection. In typical applications, SW1 is used to turn off

the fuel and either SDI or SW2 is used to turn off the ignition.

4.9 PROGRAM SW1:

This selects the RUN state of output SW1, normally open (N.O.) or

normally closed (N.C.). Use the UP and DOWN keys to select the state

and press ENTER to save.

4.10

PROGRAM SW2:

This selects the RUN state of output SW2, normally open (N.O.) or

normally closed (N.C.). Use the UP and DOWN keys to select the state

and press ENTER to save.

4.11

PROGRAM SERIAL MODE:

This selects the type of communications used by the annunciator.

Selections are provided for NONE (must be used for ignition pow-

ered applications), RS-232 ASCII (A 232), RS-232 Modbus RTU

(232), RS-485 ASCII (A 485), or RS-485 Modbus RTU (485). Use

the UP and DOWN keys to select the state and press ENTER to save.

4.12

PROGRAM BAUD RATE*:

This selects the baud rate for communications. Select either 9600 or

38.4k baud. Use the UP and DOWN keys to select the baud rate and press

the ENTER key to save the selection. This applies only for serial commu-

nications and need not be programmed for non-serial applications.

FORM DD-40NTV II 12-09

6

DD-40NTV DIGITAL ANNUNCIATOR

4.13

PROGRAM NODE NUMBER:

This selects the node number for the annunciator. The range of the

node number is from 01 to 99. Use the UP and DOWN keys to select the

node number and press the ENTER key to save the selection. This ap-

plies only for serial communications and need not be programmed

for non-serial applications.

4.14

PROGRAM HOURS:

This selects the pre-programmed number of hours. The range is

from 00000 to 99999 hours. Press the UP and DOWN arrow keys to

modify the hours, then press the ENTER key to save.

4.15

PROGRAM TYPE:

This selects the type of Power Supply being used with the system;

type.1 for 691200-1 (NTS mode) or type.3 for 691200-3 (NTV mode).

4.16

TIMER KEY:

This selects the B1 and B2 timer delays. The range is from 1 to 999

seconds. Pressing the TIMER key once displays the B1 timer, and

pressing the TIMER key again displays the B2 timer. Use the UP and

DOWN keys to change the respective B timer and press the ENTER key

to save the selection.

4.17

DEFAULT SETTINGS:

As shipped from the factory, the device default settings are as follows:

MODE 1

RPM1 (PPR) 1

RPM2 200 RPM

RPM 12 2500 RPM

P1*0

P2*0

TIMER2 5 seconds

SW1 N.O.

SW2 N.O.

SERIAL MODE None

BAUD RATE*9600

NODE NUMBER 01

HOURS 00000

B1 TIMER 5 seconds

B2 TIMER 10 seconds

TYPE 3

NOTE: Unit must be properly

congured for each applica-

tion prior to use.

www.altronicinc.com 7

DD-40NTV DIGITAL ANNUNCIATOR

5.0 KEYPAD DESCRIPTION/FUNCTION

5.1 MENU:

This key allows the user to view/change the following:

•Mode selection

•Pulses per revolution

•Overspeed value

•Underspeed value*

•Pre-lube on-time*

•Post-lube on-time*

•Output switch 1

•Output switch 2

•Communications

•Baud rate*

•Output timer 2

•Node number

•Programmed hours

•Power Supply Type

5.2 UP ARROW:

This key is used to increment/modify selections and allows the user to

view the current RPM, the hourmeter reading, annunciator status, and

all of the monitored electrical voltages*(back-up battery, external DC

power, and CD ignition power.

5.3 DOWN ARROW:

This key is used to decrement/modify selections and allows the user to

view the current RPM, the hourmeter reading, annunciator status, and

all of the monitored electrical voltages (back-up battery, external DC

power, and CD ignition power.

5.4 ENTER:

This key allows for selected items to be saved. When pre- or post-

lubing, pressing the ENTER key will also cancel lubrication.

5.5 STOP:

This key initiates a shutdown condition and the unit will display a

status of [60]. This has precedence over all other functions.

5.6 RESET:

This key clears any faults and resets the Class B1 and B2 timers. If

the pre-lube function is active, RESET also actuates the LUB output.*

The annunciator displays [00] if one or more points is not armed.

Once all the channels are armed, the display reads [01]. The annun-

ciator will power up in the RESET mode. The unit will not reset the

outputs if any of the Class A points are faulted.

LOOPS TO HOME SCREEN

FROM THE HOME SCREEN

BATTERY VOLTAGE*

EXTERNAL DC POWER VOLTAGE*

CD IGNITION SHUTDOWN LEAD VOLTAGE*

PRESS

I: 1 8 6.2

2 4.3

8:

3.6

6:

01

PRESS

PRESS

PRESS

PRESS

00056

100 3

PRESS

RPM

HOURS

FORM DD-40NTV II 12-09

8

DD-40NTV DIGITAL ANNUNCIATOR

5.7 TEST:

This key provides for battery and operating voltage tests and also

allows inputs to be tested (faulted) without causing a shutdown. The

battery in the Power Supply may be checked when the machine is

down and the display reads [00]; push and hold the TEST key – a read-

ing of [80] indicates satisfactory battery voltage. The operating volt-

age may be checked when the machine is operating and the display

reads [01]; push and hold the TEST key – a reading of [89] indicates

the operating voltage is acceptable. To test the sensor input points,

the annunciator must rst be displaying [01] meaning all points are

armed. Push and release the TEST key, and the display will read [09]

indicating the Test Mode. Faulted points will be displayed but will

not cause the outputs to trip. Testing an additional point requires

the TEST key to be pressed again. The annunciator will remain in test

mode for two minutes before reverting back to the running mode

[01]. Any point not cleared in two minutes (either by pressing the TEST

or RESET key) will cause the outputs to trip.

5.8 TIMER:

This key allows the B1 and B2 delay timers to be viewed or modied.

5.9 KEYPAD SEQUENCE (PASSWORD) PROTECTION:

From the status screen, press and hold the ENTER key, then press the

MENU key to allow values to be modied. Otherwise, the selected

items may only be viewed. There is no keypad sequence protection

for the TIMER key (Class B1 and B2 timers).

5.10

CANCEL TIMERS:

From the status screen, depress the ENTER key. While holding the ENTER

key, also press the DOWN ARROW key.

6.0 OPERATION

See chart on next page.

NOTE: Two fault occurrences

will override the TEST mode:

manual STOP function [60]

and OVERSPEED [70].

www.altronicinc.com 9

DD-40NTV DIGITAL ANNUNCIATOR

NOTE:

a.) TEST cannot be used

until the start-up timer

interval ends – [01] on

the display.

b.) A display reading of [09]

means the system output

will not activate unless the

STOP button is pushed.

c.) Do not leave a sensor

number on the display

after the last test; push

the TEST button to get

[09] on the display; then

wait two minutes until

[01] displays or select

the CANCEL TIMERS

feature.

d.) For a complete system

test, allow the test timer

interval to expire – display

changes from [09] to [01]

– then cause one sensor

to fault and allow the sys-

tem output to activate.

This will test the entire sys-

tem for correct operation

upon a fault with minimal

downtime.

6.1 OPERATING SEQUENCE

MACHINE DISPLAY FUNCTION DESCRIPTION

Down [10-57] Shutdown

Shutdown caused by the fault number

indicated. Number will remain until fault

is corrected and RESET button depressed.

[60]

Shutdown

Shutdown caused by depressing STOP button.

[70]

Shutdown Shutdown caused by overspeed.

[71] Shutdown Shutdown caused by loss of RPM signal.

[72]*Shutdown Shutdown caused by underspeed. This is

a Class C function which is armed when

the setpoint is exceeded by 100 RPM.

[80] Shutdown Push TEST button when down, indicates

battery is OK.

[00] Reset

Before starting machine, momentarily push

the RESET button. A display of [00] indicates

all Class A sensors are ready for start-up.

Any number 10-57 indcates a faulted sensor

that must be cleared before start-up.

[60]

Engine Purge

To purge engine prior to start, depress

the STOP button, roll the engine to

purge, then push the RESET button.

Engine can then be started provided

display reads [00].

[61]

Shutdown

Shutdown caused by DE, a serial stop

command.

Running [00] Start-up Start-up timers have Class B1 and B2

points disarmed. All Class A points are

being monitored. Pushing the RESET

button re-cycles the start-up timers. To

cancel the start-up timers, press the

ENTER key, followed by the DOWN key

while still depressing the ENTER key.

[01] Normal

All points are being monitored. The transi-

tion from [00] to [01] indicates the end of

the last start-up timer interval.

[89] Test From [01] display, press and hold TEST

button; indicates adequate operating

voltage.

[09] Test

Press and release TEST button – a timed test

period is initiated for approximately two

minutes. As a sensor is faulted, its number

is latched on the display (but the output is

not activated). To move to the next point,

rstclearthesensor,thenpushtheTEST

button again. The display reverts to [09] until

the next sensor is faulted. After the last test,

push the TEST button to get [09] on the

display; wait two minutes until [01] displays.

[01] Normal

Test period has ended; all points are being

monitored. DO NOT LEAVE MACHINE UN-

LESS DISPLAY READS [01].

FORM DD-40NTV II 12-09

10

DD-40NTV DIGITAL ANNUNCIATOR

6.2 RPM/HOURMETER:

Press the UP and DOWN keys to view the RPM, hourmeter and volt-

ages*. The RPM screen remains until the operator chooses another

option. The HOURS display will revert to the status screen after two

minutes. In either case, the annunciator will display the fault num-

ber when a shutdown occurs.

6.3 RPM OVERSPEED PROTECTION:

The DD-40NTV annunciator has a built in tachometer to monitor

engine overspeed. When the detected RPM is greater than the RPM

overspeed setpoint, the annunciator will trip the fuel and ignition

outputs. When this occurs, the unit will display [70] and activate

the FAULT indicator. REFER TO FIGS. 7 — 20 for the further details.

6.4 RPM UNDERSPEED PROTECTION*:

The DD-40NTV annunciator has a built in tachometer to monitor

engine underspeed. This point is armed when the underspeed set-

point is exceeded by 100 RPM. Once armed, should the monitored

RPM fall below the setpoint, the annunciator will trip the fuel and

ignition outputs. When this occurs, the unit will display [72] and

activate the FAULT indicator. REFER TO FIGS. 7 — 20 for further details.

6.5 BATTERY:

The Power Supply contains a special long-life lithium battery. When

the monitored equipment is not operating, current draw from the

battery is only microamps (millionths of amps). When the annun-

ciator is powered, there is no drain from the battery. This allows for

a battery life of up to 5 years in normal operation. The battery in the

power supply is replaceable; use ONLY Altronic part no. 601952.

Be sure to observe the proper polarity as marked in the Power Sup-

ply when replacing the battery.

THE DD-40NTV ANNUNCIATOR WILL NOT RECOGNIZE THE

OUTPUT SIGNAL FROM AN ALTRONIC DTO-3200 OR OTHER

OLDER OVERSPEED DEVICES (SEE LISTING ON PAGE 2).

THESE DEVICES WILL NOT WORK FOR OVERSPEED PROTEC-

TION IN CONJUNCTION WITH A DD-40NTV ANNUNCIATOR.

FOR SUCH PROTECTION, USE THE OVERSPEED FEATURE

BUILT INTO THE DD-40NTV ANNUNCIATOR.

WARNING:

www.altronicinc.com 11

DD-40NTV DIGITAL ANNUNCIATOR

7.0 FAULT OUTPUTS

7.1 Two digital outputs, SW1 and SW2 are in the Power Supply. These are

rated 400 volts DC, 0.5 amp maximum.

7.2 Output SW1 will trip immediately upon a fault condition or if the

STOP key is depressed.

7.3 Outputs SDI and SW2 will trip after a pre-programmed time delay

(TIMER PROGM2) from either a fault condition or if the STOP key is

depressed.

7.4 For Power Supplies 691200-1 and 691200-3, the maximum voltage

is 400 volts from a negative ground C.D. ignition with a current

drain of microamps. The maximum current rating is 50 mA when

powered from a DC voltage source of 10 to 30 volts.

FORM DD-40NTV II 12-09

12

DD-40NTV DIGITAL ANNUNCIATOR

8.0 PRE-LUBE/POST-LUBE OUTPUT*

8.1 One (1) digital output LUB is located in the power supply 691200-3*.

It is rated 400 volts DC, 0.5 amp maximum.

8.2 Output LUB will be actuated under two operating conditions:

•Following a RESET (remote or manual), the LUB output will remain actuated

until the pre-lube timer (P1) expires.

•Following a manual STOP or FAULT, the LUB output will remain actuated

until the post-lube timer (P2) expires.

9.0 SERIAL COMMUNICATIONS

9.1 Serial communications may be selected as RS-232 or RS-485 using

ASCII or Modbus RTU protocol.

9.2 MASTER/SLAVE OPERATION:

The RS-485 communication system in the annunciator is designed

as a master/slave system; that is, each unit responds to its own

unique address (node number) only after it is interrogated by the

master (computer). A simple command/response protocol must be

strictly observed.

9.3 NODE NUMBER:

The node number is used in the system to identify the desired slave

unit being polled. The node number can be any numeric value from

1 to 99.

9.4 ASCII COMMUNICATION:

All communication to and from the annunciator is performed using

ASCII characters. This allows the information to be processed with

the “string” functions common to high level computer languages

such as BASIC and C. For computers that support standard serial

port interfaces, no special machine language software drivers are

required. The use of the ASCII format also allows for the connec-

tion of these devices to an auto answer modem for long distance

operation without the need for a local supervisory computer. The

ASCII characters also make system debugging easy using standard

terminal emulation software.

9.5 COMMUNICATIONS PARAMETERS:

•Baud Rate: 9600 or 38.4k*

•Data Bits: 8

•Stop Bits: 1

•Parity: None

NOTE: The letter “L” will ap-

pear in the display when the

LUB output has been actu-

ated. To cancel the pre-lube

or post-lube countdown tim-

ers, press the ENTER key. If

pre-lubing, the annunciator

will immediately initiate the

Class B timer(s).

www.altronicinc.com 13

DD-40NTV DIGITAL ANNUNCIATOR

9.6 COMMAND STRUCTURE:

The annunciator operates with a simple command/response protocol

to monitor all functions. A command must be transmitted to the unit

by the master (computer or PLC) before the slave can respond with use-

ful data. A slave unit can never initiate a communications sequence.

Communication to the annunciator is performed with two character

ASCII command codes. The general format used for the commands is

illustrated below using the READ DATA command as an example. The

hexadecimal values for the characters are shown only as a reference for

those using low level (assembly language) decoding and will not appear

on the communications terminal screen. All of the characters used in

the communications protocol are standard ASCII characters and ap-

pear on the computer keyboard as shown with the exception of the “not

acknowledge” (NAK) which is the industry standard “control U”.

header start node space command end

ASCII > ( 01 R D )

HEX 3Eh 28h 30h 31h 20h 52h 44h 29h

Command Header “>” (3Eh):

Each command must begin with the command header sometimes

referred to as a prompt character. The ASCII character used is the

“>” which means that a command message will be sent from the

master to the slave.

Start of Text “(” (28h):

The command header must be followed by the start of text indicator.

Node Number “01 -99” (30h 31h):

The node number or address of the device being contacted.

Space (20h):

Following the node number is an ASCII space character (not print-

able, value 20h) to act as a delimiter between the node number and

the two character command word.

Command Word “RD” (52h, 44h):

The command words are standard two letter (upper case) com-

mands sent by the master for gathering specic information about

the status of a slave. The commands are listed under STANDARD

COMMANDS below.

End of Text “)” (29h):

The end of text indicator says this is the end of the command.

FORM DD-40NTV II 12-09

14

DD-40NTV DIGITAL ANNUNCIATOR

STANDARD COMMANDS

Information coming from

serial command(s) Command Response Notes

Annunciator status >(01 RD) <(01 XX) (XX - Refer to section 6.0)

Read hourmeter >(01 RH) <(01 XXXXX) (XXXXX = Hours)

Read current RPM >(01 RP) <(01 XXXX) (XXXX = RPM)

Reset the annunciator >(01 RR) <(01 RR)

Stop the annunciator >(01 RS) <(01 RS)

Valid Response:

A command/response sequence is not complete until a valid re-

sponse is received. When a slave unit receives a valid command, it

interprets the command, performs the desired function and then

communicates the response to the master within 20mS. The master

may not initiate a new command until the response from a previous

command is completed.

A valid response can occur in three ways:

•A normal response indicated by a “<” header and “( )” beginning

and end of text.

•An error response indicated by a “§” NAK (not acknowledged).

•A communications time-out error.

An NAK error response will be sent by the annunciator when it has

received a command with an error in the message. All commands

must be of the format above. The header, start-and-end of text char-

acters, a valid node number and spaces must be sent and correct to

receive an NAK; if not, no response will be sent.

9.7 RS-485 COMMUNICATIONS:

•HALF DUPLEX OPERATION:

The RS-485 system employed uses two wires for communica-

tion and cannot send and receive data at the same time over

the same two wires making it a half duplex system. When the

master is in the transmit mode, the slave is in the receive mode

and visa-versa.

•ELECTRICAL OPERATING RANGE:

RS-485 is a communications standard to satisfy the need for

multi-dropped systems that can operate at high speeds over

long distances. RS-485 uses a balanced differential pair of

wires switching from 0 to 5 volts to communicate data. RS-485

drivers can handle common mode voltages from −7 to +12 volts

without loss of data, making them an excellent choice for indus-

trial environments.

www.altronicinc.com 15

DD-40NTV DIGITAL ANNUNCIATOR

•COMMUNICATIONS WIRING:

The RS-485 wiring diagram illustrates the wiring required for

multiple slave unit hookup. Note that every slave unit has a di-

rect connection to the master. This allows any one slave unit

to be removed from service without affecting the operation of

the other units. Every unit must be programmed with a unique

address or node number, but the addition of new units or nodes

can be in any order. To minimize unwanted reections on the

transmission line, the bus should be arranged as a trunk line

going from one module to the next. Random structures of the

transmission line should be avoided. Special care must be taken

with long busses (500 feet or more) to ensure error free opera-

tion. Long busses must be terminated with a 120 ohm resistor

between the terminals marked RS-485 “A” and RS-485 “B” at

the master only. The use of twisted pair shielded cable will en-

hance signal delity and is recommended. To prevent ground

loops the shield should be connected to the shield terminal at

the master only.

•LOADING:

RS-485 uses a balanced differential pair of wires switching

from 0 to 5 volts to communicate data. In situations where

many units (99 max.) are connected together on a long run,

voltage drop on the communications leads becomes a major

problem. Voltage drops on the RS-485 minus lead appear as

a common mode voltage to the receivers. While the receivers

are rated to a maximum voltage difference of ±7 volts, −7V to

+12V, a practical system should not have a voltage difference

exceeding ±3 volts under normal conditions. The wire gauge

used for the connections limits the maximum number of units

or the maximum length of wire between units in each applica-

tion. The following formula can be used as a guideline to select

the appropriate wire gauge.

For 18 AWG wire No. of annunciator units = (4000)/(ft of wire used)

For 20 AWG wire No. of annunciator units = (3600)/(ft of wire used)

For 22 AWG wire No. of annunciator units = (2400)/(ft of wire used)

NOTE: The maximum number

of units that can be connect-

ed in a system is 99.

FORM DD-40NTV II 12-09

16

DD-40NTV DIGITAL ANNUNCIATOR

9.8 RS-232 COMMUNICATIONS:

•For proper operation, the wire length should not exceed 50 feet.

•Use standard DB-9 connector and computer cable Altronic

693 116-x or equivalent.

9.9 MODBUS STRUCTURE:

The annunciator can operate as a Modbus RTU slave. A command must be trans-

mitted to the unit by the master (computer or PLC) before the slave can respond

with useful data. A slave unit can never initiate a communications sequence.

Select the Modbus communications option. SEE SECTION 4.11. Communica-

tion to the annunciator can then be performed using standard Modbus RTU

protocol. Multiple register reads are supported, specify number of registers.

REGISTER MODBUS REGISTER VALUE

40001 RPM (0-2500)

40002 Hourmeter hours (0-65535)

40003 Class B1 timer left to expire (seconds)

40004 Annunciator Status (contains same status as display)

40005 Output Status (bit 0 = SW1, bit 1 = SW2, 1 = tripped, 0 = running)

40006 Input (chan. 10-27; bit 0 = 10, bit 8 = 20, bit 15 = 27)

40007 Input (chan. 30-47; bit 0 = 30, bit 8 = 40, bit 15 = 47)

40008 Input (chan. 50-57; bit 0 = 50, bit 7 = 57, bit 8 = ovrspd,

bit 9 = loss of spd, bit 10 = underspeed)

Input OK = 1, Input Fault = 0; 40006, 40007, 40008

all FF for running OK

40009*Class B2 timer left to expire (seconds)

40010*Test timer left to expire (max. 120 seconds); 0 = not in Test Mode

40011*Time from Fuel Trip (seconds) before Ignition Shutdown

40012*Pre-lube left to expire (seconds); 0 = prelube not being performed

40013*Post-lube left to expire (seconds); 0 = postlube not being performed

40018*Internal Battery Voltage (Example: 36 = 3.6 volts)

40019*DC Power Voltage (Example: 246 = 24.6 volts)

40020*Ignition Voltage (Example: 1847 = 184.7 volts)

40021*B1 Setpoint (seconds)

40022*B2 Setpoint (seconds)

40023*Ignition Delay Setpoint (seconds)

40024*Prelube Setpoint (seconds)

40025*Postlube Setpoint (seconds)

40026*DD-40NTVCongureMode(SEE SECTION 4.2)

40082*Overspeed Setpoint

40083*Underspeed Setpoint

www.altronicinc.com 17

DD-40NTV DIGITAL ANNUNCIATOR

FIG. 1 SPECIFICATIONS AND DIMENSIONS, DD-40NTV-O

MENU

STOP

TEST

ENTER

TIMER

RESET

TEST

TIMER 1 2

RUN

FAULT

MODE

RPM

HOURS

PROGM

6.50

3.50

2.38

.88

6.00

.203 DIA.

(TYP 4)

6.00

6.50

SPECIFICATIONS:

POWER REQUIRED: DC POWERED 12–24 VDC, 5 WATTS TYPICAL OR

CD IGNITION SYSTEM 100 VOLTS MINIMUM.

INPUTS: RPM SIGNAL FROM CD IGNITION OR PICKUP.

40 DISCRETE SWITCH INPUTS NORMALLY OPEN.

4 SELECTABLE OPERATING MODES FOR NUMBER OF

CLASS A, B (TWO TIMERS B1, B2) AND C SENSORS.

MODE A B1 B2 C

1 24 16 0 0

2 24 12 4 0

3 24 10 2 4

4 12 8 0 0

OUTPUTS: 3 DIGITAL OUTPUTS.

AUXILIARY TERMINALS FOR CD IGNITION SHUTDOWN AND

FUEL VALVE TRIP, PROGRAMMABLE DELAY TIME ON OUTPUT SW2.

FEATURES: INTEGRATED UNDERSPEED, OVERSPEED TACHOMETER AND

RUNTIME HOURMETER, PRE-LUBE/POST-LUBE.

DISPLAY CUSTOM 5-DIGIT LCD DISPLAY.

SCAN RATE: SCANS ALL 40 DISCRETE SWITCHES 5 TIMES/SECOND.

OPERATING TEMPERATURE RANGE: – 40° C TO + 80° C (– 40° F TO 176° F)

COMMUNICATIONS: RS–232 OR RS–485, CONNECTION ON POWER SUPPLY

(DC POWER REQUIRED)

HAZARDOUS AREA CLASSIFICATION: CLASS 1, DIV. 2, T4, GROUP C & D.

RS–232

DO NOT CONNECT

IF HAZARDOUS

CONDITION EXISTS

IGN INPUT 100–400V

DC INPUT 10–30VDC

50 mA MAX.

DD–40NTV–O

S/N

CERTIFIED FOR USE IN

CLASS I, DIV. 2, GROUP

C & D AREAS

U.S. Patent 6,738,244

Tx Rx

P/N 691200–3 S/N

GIRARD, OHIO

GIRARD, OHIO

INSTALL PER FORM DD-40NTV II

CERTIFIED CLASS I,

DIV 2, GRP C & D

ANNUNCIATOR POWER SUPPLY

24V

I

G

N

B A

RS485

P

U

R

R

L

U

B

S

W

1

F

V

A

S

W

2

S

D

I

+IG SD S2 FV S1 LB RR PU B A

NOTE: REQUIRES SQUARE

OPENING OF 5.60"

FORM DD-40NTV II 12-09

18

DD-40NTV DIGITAL ANNUNCIATOR

3.50

2.38

.88

4.00

1.85

2.50

6.35

7.00

.50

.190 DIA.

(TYP)

6.00

DB-25 CABLE

P/N 693115

N/O

SWITCH

N/C

SWITCH

UNUSED

OUTPUT

N/O

SWITCH

N/C

SWITCH

UNUSED

OUTPUT

TERMINAL BOARDS

P/N 672169

NON-INCENDIVE

FIELD WIRING ONLY

NON-INCENDIVE

FIELD WIRING ONLY

34 35 36 37 40 41 42 43 44 45 46 47 50 51 52 53 54 55 56 57 C10 11 12 13 14 15 16 17 20 21 22 23 24 25 26 27 30 31 32 33 C

.203 DIA.

(TYP 4)

6.00

RS–232

DO NOT CONNECT

IF HAZARDOUS

CONDITION EXISTS

Tx Rx

P/N 691200–3 S/N

GIRARD, OHIO

INSTALL PER FORM DD-40NTV II

CERTIFIED CLASS I,

DIV 2, GRP C & D

ANNUNCIATOR POWER SUPPLY

24V

I

G

N

B A

RS485

P

U

R

R

L

U

B

S

W

1

F

V

A

S

W

2

S

D

I

+IG SD S2 FV S1 LB RR PU B A

DD–40NTV–U

S/N

GIRARD, OHIO

MENU

STOP

TEST

ENTER

TIMER

RESET

TEST

TIMER1 2

RUN

FAULT

MODE

RPM

HOURS

PROGM

6.50

6.50

SPECI

FICATIONS:

POWER REQUIRED: DC POWERED 12–24 VDC, 5

WATTS TYPICAL OR

CD IGNITION SYSTEM 100 VO

LTS MINIMUM.

INPUTS:

RPM SIGNAL

FROM CD IGNITION OR PICKUP

.

40 DISCRETE SWITCH INPUTS NORMAL

LY OPEN.

4 SELECTABLE OPERATING MODES FOR NUMBER OF

CLASS

A, B (TWO TIMERS B1, B2)

AND C SENSORS.

MODE A B1 B2 C

1 24 16 0 0

2 24 12 4 0

3 24 10 2 4

4 12 8 0 0

OUTPUTS:

2 DIGITAL

OUTPUTS, PROGRAMMABLE, N.O. OR N.C.

AUXILIARY

TERMINALS FOR CD IGNITION SHUTDOWN

AND

FUEL VALVE TRIP, PROGRAMMABLE DELAY TIME ON OUTPUT SW2.

FEA

TURES:

INTEGRAT

ED UNDERSPEED, OVERSPEED T

ACHOMETER AND

RUNTIME HOURMETER, PRE-LUBE/POS

T-LUBE.

DISPLA

Y CUSTOM 5-DIGIT LCD DISPLAY.

SCAN RA

TE: SCANS ALL

40 DISCRETE SWITCHES 5 TIMES/SECOND.

OPER

AT

ING TEMPERA

TURE RANGE: – 40° C TO + 80° C (– 40° F TO 176° F)

COMMUNIC

ATIONS:

RS–232 OR RS–485, CONNECTION ON POWER SUPP

LY

(DC POWER REQUIRED)

HAZARDOUS

AREA CLASSIFICATION: CLASS 1, DIV. 2, T4, GROUP C & D.

U.S. Patent 6,738,

NOTE: REQUIRES SQUARE OPENING OF 5.60"

FIG. 2 SPECIFICATIONS AND DIMENSIONS, DD-40NTV-U

www.altronicinc.com 19

DD-40NTV DIGITAL ANNUNCIATOR

FIG. 3 INSTALLATION DIAGRAM: DD-40NTV-X TO 691200-3 POWER SUPPLY

PIN 1

GIRARD, OHIO

NOTES:

1. PLUG DB–9 CABLE FROM POWER SUPPLY INTO

ANNUNCIATOR UNIT. SECURE WITH SCREWS.

2. SECURE POWER SUPPLY TO ANNUNCIATOR UNIT

WITH 2 EA. B–32 X 5/16" SCREWS PROVIDED.

34 35 36 37 40 41 42 43 44 45 46 47 50 51 52 53 54 55 56 57

10 11 12 13 14 15 16 17 20 21 22 23 24 25 26 27 30 31 32 33

FORM DD-40NTV II 12-09

20

DD-40NTV DIGITAL ANNUNCIATOR

FIG. 4 GENERAL ELECTRICAL HOOK-UP, DD-40NTV-O WITH 691200-3 POWER SUPPLY

IGNITION SHUTDOWN LEAD

SWITCH

IGNITION SHUTDOWN

SWITCH, DC RELAY

SUPPLY FOR CD FUEL VALVE

(BUILT-IN CAPACITOR)

FUEL VALVE SWITCH

(GOES TO GROUND ON FAULT)

PRE-/POST-LUBE OUTPUT*

REMOTE RESET

PICKUP INPUT FOR TACHOMETER

RS485 B COMMUNICATION

RS485 A PORT

CD IGNITION SHUTDOWN

LEAD 100–400 VOLTS

(NEGATIVE GROUND ONLY)

PANEL GROUND

+12–24 VDC

NOTES:

1. ENGINE GROUND AND

PANEL GROUND MUST

BE THE SAME.

2. FOR IGNITION POWER,

USE (IGN) AND ( )

TERMINALS. FOR DC

POWER, USE (+24)

AND ( ) TERMINALS.

3. POWER SUPPLY MINUS

AND SENSOR GROUND

MUST BE AT GROUND.

SERIAL

COMMUNICATION

INDICATORS

RS–232

COMMUNICATION

PORT

NORMALLY OPEN

SENSORS

WARNING:

SENSOR LEADS FROM THE

ANNUNCIATOR MUST NOT

CONTACT ANY EXTERNAL

VOLTAGE SOURCE. DAMAGE

TO THE SYSTEM WILL RESULT

FROM CONNECTION BETWEEN

THE SENSOR LEADS AND THE

IGNITION SYSTEM OR ANY AC

OR DC POWER SOURCE.

This manual suits for next models

1

Table of contents

Other Altronic Control System manuals

Popular Control System manuals by other brands

Simple

Simple XWS7-1001 user manual

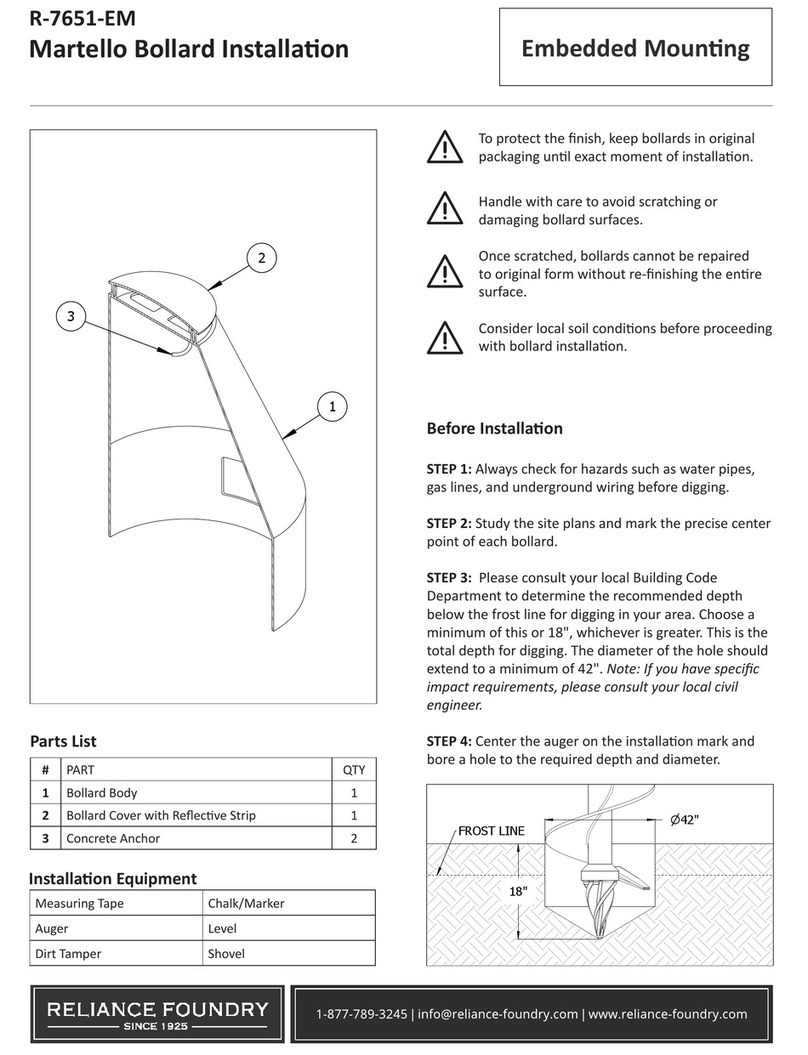

Reliance Foundry

Reliance Foundry R-7651-EM Installation

Norac

Norac UC4+ installation manual

ROTOTILT

ROTOTILT TLEE Instructions for use

Radionics

Radionics D2212 installation manual

Whelen Engineering Company

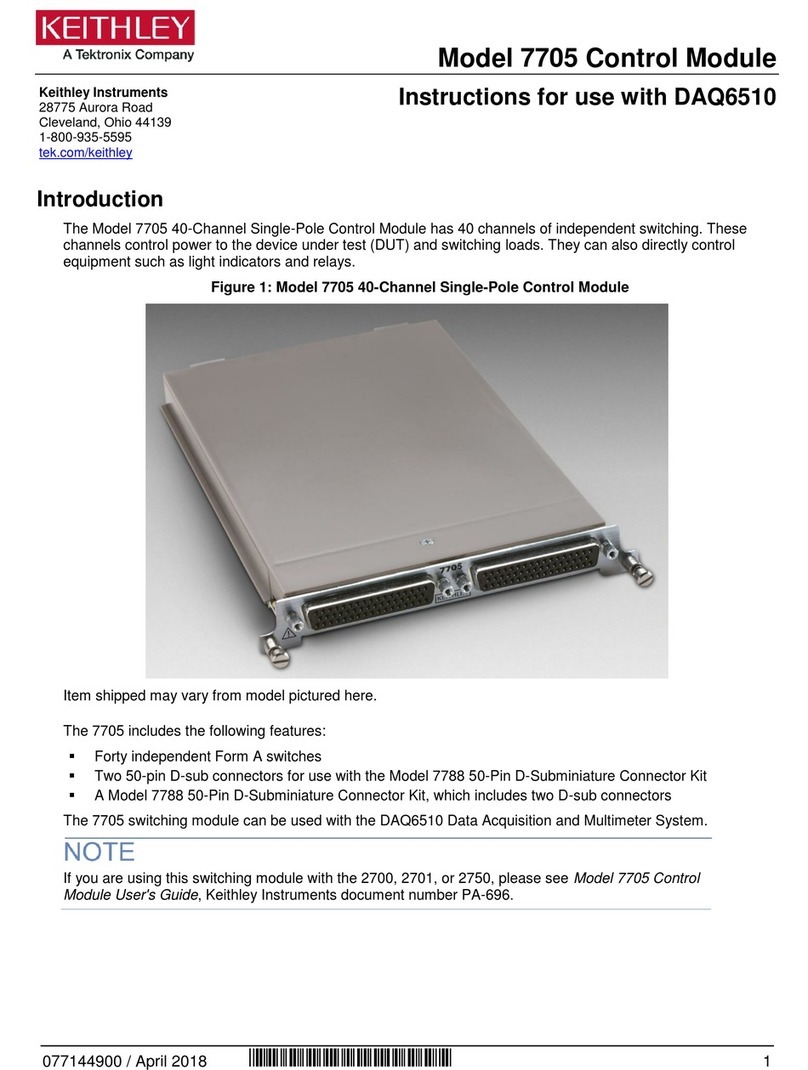

Whelen Engineering Company CanTrol Installation & operating guide