Altronic DE-3000 User manual

1

Operating Instructions

DE-3000 Series Configurable Safety Shutdown and Control System

with Graphing Capabilities

Form DE-3000 IOI 7-17

SOME FEATURES IN THIS MANUAL ARE ONLY APPLICABLE TO

DE-3000 FIRMWARE DATED 2014 OR LATER, INCLUDING:

•OEM Engine Control

•Lube No-Flow/Lube Monitoring

•Linear Ramp Control

•Cool-down

•Integrated output timers on digital output channels #5 and #13

•Multi-Start

DE-3000 IOI 7-17

All rights reserved © ALTRONIC, LLC 2017 2

1.0 OVERVIEW

1.1 For help locating subjects in this document, a section index is provided on page 61.

A glossary of technical terms begins on page 58.

1.2 The Altronic DE-3000 controller system is an electronic, microprocessor-based

system designed to sense various analog and digital input points to control and

monitor industrial compressors. The system is field-programmable using a PC

and the supplied terminal program and contains a non-volatile memory to store

the setup. Serial communications provide an interface to PC’s, PLC’s, modems

and satellite uplinks for remote communication. An LCD display shows system

status, programmed engine/motor and compressor parameters and channel la-

bels. A front-mounted keypad serves as the user interface. The DE-3000 pro-

vides for both the safety shutdown functions needed to prevent unnecessary

damage to remotely-operated equipment and the closed-loop automatic control

functions needed to optimize their efficiency of operation. The DE-3000 also

provides for remote data acquisition and supervisory control in a compact, low

cost package for industrial compressor applications. The optimization strate-

gies available for the management of compressor throughput include automatic

prime mover speed setting as well as capacity control. On rotary screw compres-

sors, capacity control can be done via suction throttling, or using an internal

gas bypass technique employing poppet valves, turn valves or slide valves. On

reciprocating compressors, capacity can be controlled using external gas bypass

loops or pressure regulation techniques. A wide range of output options, includ-

ing both analog current loops and digital outputs, are provided to interface with

the large variety of actuation systems currently in use. In addition, automatic

load limiting based upon prime mover power capabilities or other application

specific limitations, such as cooling capacity, are readily implemented. There

are also AUTO START and OEM ENGINE CONTROL options that are enabled

using the terminal program.

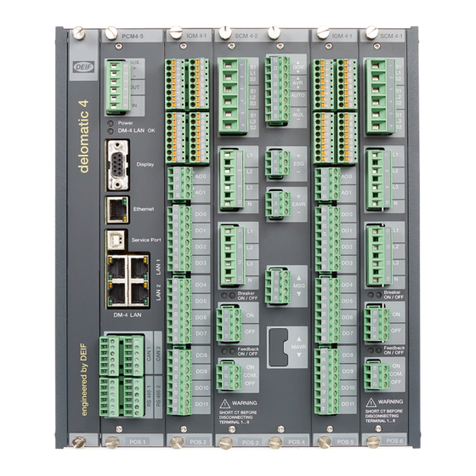

1.3 The system has three main parts: a panel-mounted Display Module (DE-3000),

a Power Supply Module (691122-1), and a Terminal Module (691171-1). These

components are interconnected by means of Cable assembly (693115-1). An

additional terminal board may be added for 30 extra channels (691171-2) or 15

extra channels (691175-2). This increases the channel selections from 1-30 to

1-60 or 1-45 respectively.

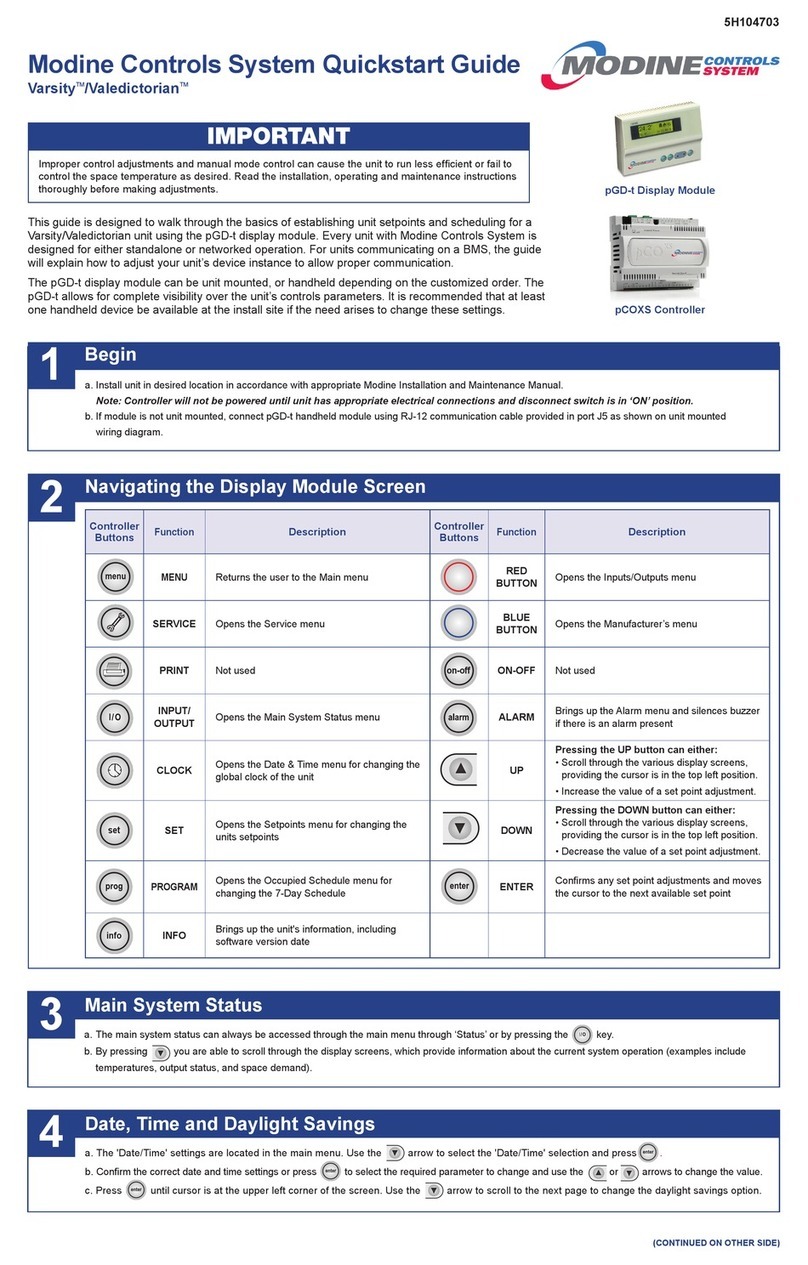

2.0 DISPLAY MODULE

2.1 The Display Module serves as the user interface for the DE-3000 system. It is in

a 6.5" x 6.5" panel-mounted enclosure and consists of an alphanumeric backlit

LCD display, a 16-key front-mounted keypad, DB-25 D-Sub and DB-9 D-Sub

connectors and five pairs of serial port indicators.

Two DE-3000 models are available and their displays are compatible with each

other, although they have a few functional differences. The ‘classic’ display is

4x20 characters, and the “new” display features 128x64 multi-color graph-

ics. The larger display uses the top line to further annunciate the engine status

“RUNNING, TIMERS ACTIVE, FIRST FAULT,” etc. The home screen, typical of

the 4x20 display, appears at the bottom of the larger display. It also incorpo-

rates a graphing capability which replaces the original bargraph feature. Color

backlighting has been added to the new display. The backlight color changes,

e.g., green for RUNNING, yellow for TIMERS ACTIVE and red for STOP/FAULT

condition, to indicate the status of the machine.

2.2 The keypad is a sealed membrane unit that contains the familiar STOP, RESET

and TEST keys as well as other keys used to navigate through channel status and

description, view process screens, and to edit the configuration.

2.3 The LCD displays a HOME SCREEN that displays a status line, the speed, the

suction pressure and the discharge pressure. Pressing the VIEW CHANNEL key

displays the channel number, its timer status, analog value (if applicable) and

the corresponding 20-character user defined label.

NOTE: IF POSSIBLE, KEEP THE ORIGI-

NAL SHIPPING CONTAINER. IF FUTURE

TRANSPORTATION OR STORAGE OF THE

CONTROLLER IS NECESSARY, THIS CON-

TAINER WILL PROVIDE THE OPTIMUM

PROTECTION.

WARNING: THE CONTROLLER SYSTEM

MUST BE CONFIGURED PRIOR TO USE

ON A COMPRESSOR SYSTEM. REFER-

ENCE THE PROGRAMMING INSTRUC-

TIONS (PAGE 53) FOR INSTRUCTIONS

DESCRIBING HOW TO CONFIGURE THE

CONTROLLER FOR THE SPECIFIC AP-

PLICATION. VERIFY THE PROGRAM IN

NONVOLATILE MEMORY (THE EEPROM)

PRIOR TO STARTING THE SYSTEM. RE-

FER TO SECTION 10.0 ON HOW TO VIEW

THE CURRENT CONFIGURATION.

WARNING: DEVIATION FROM THESE

INSTRUCTIONS MAY LEAD TO IMPROP-

ER ENGINE OPERATION WHICH COULD

CAUSE PERSONAL INJURY TO OPERA-

TORS OR OTHER NEARBY PERSONNEL.

DE-3000 IOI 7-17

All rights reserved © ALTRONIC, LLC 2017 3

2.4 The keypad, along with the LCD display, are used to navigate through channel

status and descriptions, view process screens, and to view or edit the system’s

configuration. The ↑UNITS or ↓UNITS or the →TENS or ←TENS keys are used

to access channels by increasing or decreasing the channel numbers by one or

by ten with each key press. Pressing the NEXT key advances the display to the

next screen or item. All menu adjustments are saved in non-volatile EEPROM

memory by pressing the ENTER key. The EEPROM memory retains the current

configuration during normal operation, after compressor shutdown and a system

power-down.

2.5 Five pairs of LED’s are provided on the back of the Display Module for trouble-

shooting purposes, one Receive (RX) and one Transmit (TX) LED for each port.

The TX LED will flash when the Display Module is transmitting serial communi-

cations on the labeled port. The RX LED will flash when the Display Module is

receiving serial communications on the labeled port.

2.6 Ports 4 and 5 are located on the display board.

3.0 POWER SUPPLY MODULE

3.1 The Power Supply Module is made to be rail-mounted and is the interface be-

tween the Terminal and Display Modules and to other systems. It typically plugs

directly into the Terminal Module using the DB-25 connectors and is held to-

gether with screws and screw locks.

3.2 The Power Supply Module accepts up to four industry-standard, commercially-

available 0.6 inch plug-in Output Modules. The Output Modules provide a means

of using the DE-3000 controller safety shutdown system status to interface with

other systems on the engine/motor and compressor. A typical application would

be as a relay or solenoid coil driver. T he Output Modules are optically isolated,

solid-state switches which are isolated from power supply minus and engine

ground. The Output Modules will be in the open (de-energized) condition when

the unit is not powered.

Outputs 1 and 2 can be software-configured for either normally-open (N/O) or

normally-closed (N/C) operation and have an LED indicator associated with them.

Outputs 3 and 4 are pre-programmed normally-open for use with the optional

OEM Engine Control or Auto start feature. If an Output Module is programmed for

normally-closed (energized for run), the LED will be ON in the normal run condi-

tion and OFF for a fault condition. For Normally-open configured modules the LED

will be OFF for normal run condition and turn ON for a fault condition.

The standard Output Module outputs use the top row of the dual 16-position

terminal strip which is marked OUT 1 through OUT 4. Each of these outputs

are fused with a replaceable 6.3 amp slow-blow fuse, Altronic P/N 601653.

In addition to accepting industry-standard Output Modules, a custom Altronic

Output Module P/N 691124 is available for tripping ignition powered CD fuel

valves and shorting CD ignition shutdown leads upon a fault. When making use

of OEM Engine Control, outputs 1 and 2 will not be wired to trip the fuel and ig-

nition valves. When both functions are required, two of these modules are used

as follows: OUT 1 slot must be used to trip the fuel valve, and OUT 2 slot must

be used to short the ignition. If 12-24Vdc is lost to the DE-3000 annunciator

system, the custom Output Modules will trip the fuel valve and short the igni-

tion shutdown lead. This mimics the “fail-safe” operation of a normally-closed

Output Module and therefore the LED will be ON in the normal run condition

and OFF for a fault condition. In programming the system, these modules are

identified by using the IGN/FUEL selection. Terminals IGN+ and IGN− are used

to connect the shutdown lead, and FV1 and FV2 are used for the CD fuel valve.

A capacitor is included in the Power Supply Module to supply the energy to trip

the fuel valve.

3.3 The 12-24Vdc power for the DE-3000 system is applied to the power supply

terminals marked (+) and (−) 12–24Vdc INPUT POWER. A 6.3 amp replaceable

slow-blow fuse protects the system from over-currents, and a power LED lights

when power is applied to the system.

CLASSIC DISPLAY

NEW DISPLAY

DE-3000 IOI 7-17

All rights reserved © ALTRONIC, LLC 2017 4

3.4 The external connection for the two serial RS-485 communication ports is on

the Power Supply Module terminal strips. Port 2 is for RS-485 serial communi-

cation to future Altronic instruments, and port 3 is for RS-485 serial communi-

cation to a PC (personal computer) or a PLC (programmable logic controller) to

perform remote monitoring or control functions if desired.

3.5 Terminals marked IGN IN and PU IN are used by the DE-3000 system to detect

either engine rotation or ignition system firings. This input monitors changing

signals such as those Seen on either the ignition shutdown lead or a magnetic

pickup monitoring an engine mounted gear.

THE MAGNETIC PICKUP INPUT MUST BE USED FOR APPLICATIONS EN-

ABLING THE AUTO START OR OEM ENGINE CONTROL FUNCTION.

•The IGN IN terminal connects to the positive (+) C.D. ignition shutdown lead.

•The PU IN terminal connects to one magnetic pickup input; the other pickup

wire connects to the minus (−) terminal on the Power Supply Module.

4.0 TERMINAL MODULE

4.1 The Terminal Module is made to be rail-mounted and is the point of interface

between the field sensor wiring and the DE-3000 control system. A removable

dual terminal strip is used for the connection of the system to the equipment

mounted discrete sensors which may consist of up to 30 inputs, where any of

the 30 can be used for either a normally-open, normally-closed switch, or analog

inputs including K- or J-type thermocouples. These are listed as channels 01–

30 for the 691171-1 terminal board. They accept industry-standard transducer

signals in the range of 0-5 VDC. Connections from the Terminal Module to the

Display Module are made using the 693115-x series Cable Assembly.

4.2 The DE-3000 is designed to operate with industry-standard voltage or current-

amplified output transducers in the range of 0 to 5Vdc or 0 to 25mA. Four se-

ries of transducers are available from Altronic: pressure transducers 691201-x,

691204-x and temperature transducers 691202/203-300, 691212/213-450.

4.3 Another terminal board assembly may be added to increase the inputs from 30

to either 45 or 60 inputs. Use cable 693133-1 to connect the two boards. The

691175-2 provides an additional 15 inputs, 4 digital outputs, 2 analog outputs

and an extra speed (pickup) input. The 691171-2 provides an additional 30

inputs, 8 digital outputs, 2 analog outputs, and an extra speed (pickup) input.

4.4 PRESSURE TRANSDUCERS

The pressure transducers, Altronic P/N 691201-x and P/N 691204-x, are pack-

aged in a rugged sealed case with a NPT pressure port, a corrosion resistant

media cavity, and a Packard Electric Metri-Pack connector. The ranges available

are 0-100, 300, 500, 1000, 2000, and 5000 PSIG for the 691201-x series

and 0-50,100, 300, 500 PSIA for the 691204-x series, all of which have an

overload rating of 1.5 times full scale without damage. The three wires from the

transducer are: +5 volt excitation, +0.5 to 4.5 volt output, and minus return.

These three wires connect directly to the back of the Terminal Module using

cable assembly P/N 693008-x.

4.5 DIFFERENTIAL MEASUREMENTS

Differential pressures or temperatures may be measured by using two consecu-

tive channels. The transducers used to measure differential values must be of

the exact same type and range. The first channel of the pair will display the

basic parameter it is monitoring and the second channel of the pair will display

the numeric difference in engineering units of its value subtracted from the first

channel’s value. Setpoints for each channel monitor the displayed value of that

channel. The second channel setpoints monitor the differential value.

4.6 TEMPERATURE TRANSDUCER

The temperature transducers, Altronic P/N 691202-300, 691203-300 with a tem-

perature measurement range of +5 to 300°F and the 691212-450, 691213-450

with a temperature range of -40 to +450°F are packaged in a sealed, stainless steel

NOTE: AN INSTALLATION MAY USE ONLY

ONE OF THE TERMINALS IGN IN, PU IN,

OR T+.

691171-1 FOR CHANNELS 01-30

691171-2 FOR CHANNELS 31-60

691175-2 FOR CHANNELS 31-45

DE-3000 IOI 7-17

All rights reserved © ALTRONIC, LLC 2017 5

housing with a 5/8"-18 UNF threaded body, and a Packard Electric Metri-Pack

connector. During configuration the standard calibration for the 691202/203-300

sensor is selected as dEG1 and the standard calibration for the 691212/213-450 is

selected by choosing dEG2. The three wires from the transducer are: +5 volt excita-

tion, temperature output voltage, and minus return. These wires connect directly to

the Terminal Module using cable assembly P/N 693008-x.

4.7 THERMOCOUPLE INPUTS

The Terminal Modules can accept industry-standard type J or K thermocouples

on inputs 01–60. Automatic cold junction compensation is built-in. The units

can be configured to °F or °C. Both a high and low setpoint is associated with

each channel. The monitor can read type J thermocouples between -76°F and

+1382°F (-60°C and +750°C) and type K thermocouples between -76°F and

+1472°F (-60°C and +800°C).

4.8 N/O and N/C INPUTS

The inputs can also accept standard normally-open and normally- closed con-

tacts. For normally-open input, place the wire between the corresponding in-

puts. Ground the connection to cause a fault. Similarly, for normally-open, wire

the sensor in a normally-closed connection and open it to cause a fault.

4.9 4-20mA inputs

The terminal module can accept 4-20mA inputs by selecting the internally-

connected 200-ohm resistors, creating a termination voltage of .8 to 4.0 volts.

The jumper wires between the + and – terminals for that channel must be con-

nected for proper operation.

4.10 For each input, the corresponding CHANNEL SWITCH must be set according

to the input type. Switches are turned ON by moving them toward the ANALOG

OUT labeling.

4.11 Digital outputs 1 through 8 are pilot-duty, and turn on to common ground when

closed. Outputs 1 through 8 are rated at 500mA, 60V. See FIG. 8 for wiring details.

5.0 MOUNTING

5.1 DISPLAY MODULE

Mount the Display Module inside a control panel or to a suitable flat surface so

that the display is at a convenient viewing height. A drilling template and mount-

ing dimensions are provided.

5.2 POWER SUPPLY MODULE

Mount the Power Supply Module in the panel either on the bottom or the side of

the main panel. The Power Supply Module is made to be rail-mounted onto com-

mercially available 32 or 35mm DIN mounting rails. It is also made to plug directly

into the Terminal Module using the DB-25 connectors and is held together with

screws and screw locks. Two end brackets P/N 604199 should be used to keep

the modules from sliding off the ends of the mounting rail.

Alternatively, the Power Supply Module and the Terminal Module can be mount-

ed separate from each other on the DIN mounting rails but in the same panel;

in this case, a DB-25 male/female cable such as P/N 693115-1 is used to elec-

trically connect these modules. The operating temperature range of the Power

Supply Module is −31°F to +176°F (−35°C to +80°C).

5.3 TERMINAL MODULE

Mount the Terminal Module either on the bottom or the side of the main panel.

The Terminal Module and Power Supply Module can be rail-mounted onto com-

mercially available 32 or 35mm DIN mounting rails. The Terminal Module plugs

directly into the Power Supply Module using the DB-25 D-Sub connectors and

is held together with screws and screw locks. Two end brackets P/N 604199

are used to keep the modules from sliding off the ends of the rail. The Terminal

Module and the Display Module are electrically connected with a DB-25 male/

female cable, 693115-x series or equivalent. The operating temperature range

of the Terminal Module is −31°F to +176°F (−35°C to +80°C).

NOTE: AVOID MOUNTING THE UNIT

WITH THE LCD DISPLAY FACING DIRECT

SUNLIGHT. THE DISPLAY OPERATING

TEMPERATURE RANGE IS −13°F TO

+149°F (−25°C TO +65°C).

IMPORTANT: PRESSURE TRANSDUCERS

WILL WITHSTAND OVERLOADS AS HIGH

AS 1.5 TIMES RATED PRESSURE. IF THE

OVERLOAD RATING IS EXCEEDED, FAIL-

URE MAY OCCUR. PRESSURE FLUCTUA-

TIONS OCCUR IN MOST RECIPROCATING

SYSTEMS; PICK THE TRANSDUCER

WITH A RATING HIGH ENOUGH TO PRE-

VENT OVERLOAD BY PEAK PRESSURES

OF PULSATIONS. IT IS RECOMMENDED

THAT A PRESSURE SNUBBER BE USED

WHICH WILL REDUCE THE PEAK PRES-

SURE APPLIED TO THE TRANSDUCER.

THE LIFE OF THE TRANSDUCER WILL BE

EXTENDED WITH THE USE OF A SNUB-

BER OR PULSATION DAMPENER.

DE-3000 IOI 7-17

All rights reserved © ALTRONIC, LLC 2017 6

5.4 PRESSURE TRANSDUCER

Mount the pressure transducer in the panel or in a manifold or tube off of the

engine. Do not expose the pressure transducer to temperatures above 221°F

(105°C). The second terminal module should be placed close to the first and the

wire connecting them should be free of high-powered panel signals.

5.5 TEMPERATURE TRANSDUCER

Mount the temperature transducer in a thermowell on the engine or machine.

The actual sensor is located at the bottom of the transducer body; to ensure

accuracy, the tip of the probe should be surrounded by the measured media.

6.0 WIRING (SEE WIRING DIAGRAMS)

6.1 SYSTEM COMPONENT WIRING

A DB-25 male/female cable, 693115-x series or equivalent, is used to connect

the Terminal Module to the Display Module and secured with the cable lock

screws. If mounted on the same mounting rail, plug the Terminal Module directly

into the Power Supply Module using the DB-25 D-Sub connectors at the ends

of the modules and secure them together with the screws and screw locks cap-

tive to the connectors. If the Power Supply Module and the Terminal Module are

mounted separate from each other (must be mounted in the same panel) a DB-

25 male/female cable such as P/N 693115-1 or equivalent is used to connect

these modules.

6.2 POWER WIRING

Connect the supply power wires to the 12-24Vdc input power terminals on the

power supply, plus to terminal (+) and minus to terminal (−); power requirement

is 12 to 24Vdc (10 watts max.). The DC− terminal must be connected to panel

ground which should be the same as engine ground.

This is the return path for normally-open sensors and MUST be connected for

proper operation. DO NOT ground this device directly to the ignition system

common coil ground.

6.3 SENSOR WIRING DISCRETE INPUTS

The sensor leads connect to the removable terminal strips on the Terminal Mod-

ule. The terminal numbers correspond to the display numbers which also have a

user assigned 20-character label associated with it. The sensor inputs are num-

bered 01-30, 01-45 or 01-60. With AUTO START enabled, the Remote Reset

on the terminal board is wired for a start switch. Sensor inputs 01–60 can be

configured as class A, class B or class C logic. Any discrete sensor point can be

wired for normally-open or normally-closed operation.

•Normally-open (N/O) sensor switches are wired with one wire to the

bottom terminal strip of the respective sensor number and the other to

engine ground which should be the same as power minus (−). A short

jumper from the bottom terminal to the top terminal must be connected

for normally-open sensors. (See wiring diagrams)

•Normally-closed (N/C) sensor switches are wired with one wire to the bot-

tom terminal strip and the other to the top terminal strip of the respective

sensor number. Note that the short jumper wire must be removed.

•Remote stop and remote reset are wired the same as the sensor

switches, and can be used with either normally-open or normally-closed

contacts.

Use a wire size between 16 AWG (max.) and 24 AWG (min.) to connect the sen-

sor switches to the terminal strip connector. Strip the insulation back 3/8"; twist

the exposed wires tightly together. Insert the exposed wire completely into the

terminal strip and securely tighten the clamping screw. Wires running to sensor

switches must be in good condition or replaced with new wires. When running

wires, take care not to damage the insulation and take precautions against later

damage from vibration, abrasion, or liquids in conduits. An explosion-proof con-

duit is not required. However; wires should be protected from damage by run-

IMPORTANT: DO NOT EXCEED THE

ABSOLUTE MAXIMUM RATING OF THE

TRANSDUCERS, 350°F (176°C) FOR THE

691202/203-300 OR 450°F (232°C) FOR

THE 691212/213- 450. CARE SHOULD

BE TAKEN TO PROTECT THE WIRING AND

CONNECTORS FROM CONTACT WITH HOT

SURFACES.

DE-3000 IOI 7-17

All rights reserved © ALTRONIC, LLC 2017 7

ning them in a protective conduit or in sheaths where appropriate. In addition, it

is essential that the following practices be adhered to:

A. Never run sensor wires in the same conduit with ignition wiring or other

high energy wiring such as the AC line power.

B. Keep secondary wires to spark plugs and other high voltage wiring at

least eight inches (200mm) away from sensor and sensor wiring.

C. Sensor switches may be connected to any passive device using contacts

such as standard switch gauges, pressure or level switches. DO NOT con-

nect sensor leads to any voltage producing element.

D. In the case of a field conversion, where sensors have previously been

used with Murphy tattletales, it is recommended that the sensors be

checked frequently when the DE system is first put into use. Sensor

contacts may be burned or pitted from past exposure to ignition system

primary voltage. It is advisable to replace such sensors.

E. If it becomes necessary to check sensor switch to panel wiring with an

ohmmeter or other checker, first DISCONNECT the plug-in terminal strips

from the Terminal Module. Applying voltage to the DE-3000 system

through the sensor leads may damage the device. The area should be

tested as non-hazardous before such testing commences.

ANALOG SENSOR WIRING

For each analog monitored point, inputs 01–60, select a transducer - either an

Altronic pressure or temperature transducer listed above or one that outputs a

signal in the range of 0 to 5 Vdc or 0 to 25 mA. Mount as described above. Use

cable assembly 693008-x or similar to wire transducer to the Terminal Module.

An internal 5 volt sensor supply (500 mA. max.) is available to power the Altronic

transducers; See wiring diagrams. If the 5 volt sensor supply exits the panel, it

must be fused with a 0.5 ampere fuse. If 24Vdc powered sensors are used, the

24 volt supply to them must be fused appropriately. Take care not to damage the

insulation when installing and take precautions against later damage from vibra-

tion, abrasion, or liquids in conduits. In addition, it is essential that the following

practices be adhered to:

A. Never run sensor wires in the same conduit with ignition wiring or other

high energy wiring such as AC line power.

B. Keep secondary wires to spark plugs and other high voltage wiring at

least eight inches (200mm) away from sensor and sensor wiring.

6.4 THERMOCOUPLES AND THERMOCOUPLE EXTENSION WIRE

Grounded or ungrounded type J or K thermocouples may be used. Use thermo-

couple extension wire of the same type as the thermocouple probe to connect to

the terminal module. Use stranded thermocouple wire having a moisture-resis-

tant insulation such as PVC; for higher ambient temperatures, Teflon or B-fibre

insulated thermocouple wire is recommended. To ensure that an accurate signal

is transmitted to the device, avoid any added junctions, splices and contact with

other metals. On unused channels, leave the small jumper wire supplied with the

system in place. Take care not to damage the insulation when installing and take

precautions against later damage from vibration, abrasion, or liquids in conduits.

In addition, it is essential that the following practices be adhered to:

A. Never run sensor wires in the same conduit with ignition wiring or other

high energy wiring such as AC line power.

B. Keep secondary wires to spark plugs and other high voltage wiring at

least eight inches (200mm) away from sensor and sensor wiring.

6.5 LUBE/NO-FLOW SENSOR:

Channels 27 and 28 may be used for a lube/no-flow proximity cycle switch as

an option. Wire the sensor according to section 6.3. The Sensor may be wired

as either a N/O or a N/C with a jumper. The DIP switches on the terminal board

DE-3000 IOI 7-17

All rights reserved © ALTRONIC, LLC 2017 8

must be set as an analog configuration. The lube/no-flow channels generate a

fault when the time between pulses exceeds the programmed run puls time.

6.6 OUTPUT SWITCH WIRING

The Power Supply Module accepts an industry-standard 0.6" Output Module.

The following modules are available from Altronic:

691124 This custom module has two uses: connection to a Murphy fuel valve

and directly grounding a C.D. ignition system.

A. Use in position OUT 1 to connect to a C.D. ignition-type Murphy

fuel valve. Connect terminals 3 and 8 of the fuel valve to the

Power Supply Module terminals marked F1 (FV1) and F2 (FV2).

B. Use in position OUT 2 to directly ground-out (stop) a C.D. ignition

system. Wire the C.D. ignition shutdown lead and ignition ground

to the Power Supply Module terminals marked I+ (IGN+) and I-

(IGN-) observing the proper polarity for the ignition system.

DO NOT connect directly to the ignition system common coil ground.

691125 This module is rated for 5-48 Vdc, 5.0 A. and may be used in any of

the four output slots OUT 1 through OUT 4.

This module may be used to interrupt the DC supply to DC-powered

ignition systems such as Altronic CD1, CPU-90, II-CPU or DISN.

691056 This module is rated for 5-60 Vdc, 2.0 A. and may be used in any of

the four output slots OUT 1 through OUT 4.

691066 This module is rated for 5-200 Vdc, 0.67 A. and may be used in any

of the four output slots OUT 1 through OUT 4.

691065 This module is rated for 24-280 Vac, 2.0 A. and may be used in any

of the four output slots OUT 1 through OUT 4.

6.7 RS-485 COMMUNICATIONS WIRING

There are four RS-485 communication ports available:

•Port 2 is for communication between the display and terminal boards.

•Port 3 is for RS-485 serial communication to a PC or a PLC.

The wiring for port 3 connects to the terminals marked A3, B3 and S3. Connect

to the other communication devices A to A(−) and B to B(+). Connect the shield

wire to the DE-3000 system ONLY.

6.8 SENSE ROTATION INPUT

Terminals marked IGN IN and PU IN on the Power Supply Module are used by

the DE-3000 system to detect either engine rotation or ignition system firings.

On applications using multiple terminal board assemblies, the T+ terminal on the

second terminal board (the one not directly connected to the power supply) can

be used to add a second RPM value. The T+ input is only for use with magnetic

pickups. This input monitors voltage signals such as those seen on either the igni-

tion shutdown lead or a magnetic pickup monitoring an engine-mounted gear.

•The IGN IN terminal connects to the positive (+) C.D. ignition shutdown lead.

•The PU IN terminal connects to one magnetic pickup input; the other pickup

wire connects to the minus (−) terminal on the Power Supply Module.

•The T+ terminal connects to one magnetic pickup input; the other pickup

wire connects to the terminal on the terminal module.

THE MAGNETIC PICKUP INPUT MUST BE USED FOR APPLICATIONS ENABLING

THE OPTIONAL AUTO START OR OEM ENGINE CONTROL FUNCTION.

NOTE: ADDITIONAL CHANNEL SET UP WILL

BE REQUIRED IN THE TERMINAL SOFT-

WARE PROGRAM.

NOTE: AN INSTALLATION MAY USE ONLY

ONE OF THE TERMINALS IGN IN, PU IN,

OR T+.

DE-3000 IOI 7-17

All rights reserved © ALTRONIC, LLC 2017 9

7.0 HAZARDOUS AREA OPERATION

7.1 The DE-3000 system is CSA-certified for CLASS I, DIVISION 2, GROUPS C and

D areas when mounted in a suitable enclosure.

In addition, the following requirements must be met (refer to NFPA standard no. 493):

•The low voltage sensor switch wires within the panel enclosure must

be kept at least two (2) inches away from other wiring. Run the sensor

switch wires leaving the panel in a separate conduit from all other wiring

and keep them separate

•Wiring to the sensors must have a grade of insulation capable of with-

standing an AC voltage of 500 volts RMS.

•Sensor wires must be run in separate conduits and junction boxes from high

voltage wires such as ignition, fuel valve, and other high voltage wiring.

8.0 KEYPAD DESCRIPTION

8.1 The DE-3000 controller Display Module contains a sixteen-key sealed mem-

brane keypad which is used to stop, reset and test the system. The user can also

view process information screens, view channel specifics, cancel timers, and

view and edit pertinent operating parameters.

8.2 STOP key is used for a manual stop condition. By pressing the STOP key, the

controller activates the configured output modules in the power supply.

8.3 RESET key clears all past faulted points and resets all input and output timers

to their preset values.

8.4 TEST key disables the output modules and allows the user to fault or test the input

sensors. Every time the test button is pressed, the test timer resets to its preset value.

8.5 CANCEL TIMERS key cancels all timers.

8.6 VIEW CHAN key allows the user to view the status of any input channel and its

user defined label. Pushing the VIEW CHAN key after a fault will display the

faulted channel and current value.

8.7 NEXT key allows the user to view the CAPACITY CONTROL and RPM SETPOINT

CONTROL screens from the home screen. From the VIEW screen, allows the

user to view the next process information screen. From the MENU screens, the

next value to be edited.

8.8 VIEW key allows the user to view the status of the digital outputs 1 though 8 follow-

ing the first depression. If the digital output is on, the number of that output will be

viewable. Pressing the VIEW key a second time will open the graphing mode.

8.9 ENTER key is used to accept a selection and to save a new value in memory.

8.10 ESC key enables the user to exit any view channels, information or menu screens

at any time and return to the previous screen without changing programmed

values.

8.11 MENU key allows the user to enter the edit menu. The global timers, input class

output assignment, output configuration and the time and date may be viewed

and adjusted using the MENU key.

8.12 ↑UNITS/↓UNITS keys increase or decrease values by one. The →TENS/←TENS

keys increase or decrease values by ten. They are used to increase or decrease

channel numbers, timers and to move the pointer in the menu screen.

8.13 F1 - Function key displays the analog input and output channels.

8.14 F2 - From the RUNNING home screen; used to initiate the cool-down timer.

After a fault, displays the time and date of the 1st fault.

WARNING: SUBSTITUTION OF COMPO-

NENTS MAY IMPAIR INTRINSIC SAFETY

AND/OR SUITABILITY FOR CLASS I, DIV.

2, GROUPS C AND D. DO NOT DISCON-

NECT EQUIPMENT IN DIV. 2 ENVIRON-

MENT UNLESS POWER IS SWITCHED

OFF OR THE AREA IS KNOWN TO BE

NON-HAZARDOUS.

DE-3000 IOI 7-17

All rights reserved © ALTRONIC, LLC 2017 10

9.0 UNDERSTANDING THE HOME SCREENS

9.1 The home screens are a series of screens used to display several of the most

critical operating parameters. All of the home screens provide a status word on

the upper line and, typically, the engine speed on the second line, the suction

pressure on the third line, and the discharge pressure on the fourth line. Other

analog parameters may be programmed for the second, third and fourth lines.

The status line will read one of the following: TIMERS ACTIVE, RUNNING, TEST

XXX SEC, FAULT AL12, MANUAL STOP, AUTO START.

The LCD display always reverts to one of the home screens after a keypad opera-

tion is completed or the operation times out.

9.2 To manually start the engine, press the RESET button. The TIMERS ACTIVE

message will be displayed and remains until all Class B and Class C inputs have

been armed. During the time that the Class B and Class C timers are still active,

manually purge and crank the engine.

TIMERS ACTIVE

STATUS TIMERS ACTIVE

SPEED 330 RPM

SUCTION 102.3 PSIA

DISCHARGE 200 PSIG

9.3 If the AUTO START option is selected when programming the system from the PC,

the display below will appear when the AUTO START sequence begins. The auto

start sequence allows for activation of an electrically controlled pre-lube pump for a

programmed time period prior to cranking. It is recommended that a warning horn or

flashing light be activated by the pre-lube output to inform any personnel which may

be present that a cranking attempt is about to begin. After this user programmed time

delay, cranking will begin. A user-programmable crank disconnect speed switch func-

tion will automatically disable the starter at the selected RPM. If the crank disconnect

RPM is not reached within a user programmed time period, and Multi-Start has not

been enabled, an OVERCRANK FAULT will be generated turning off the fuel and igni-

tion and disabling the starter until a new AUTO START command is received.

AUTO START

STATUS AUTO START

SPEED 130 RPM

SUCTION 102.3 PSIA

DISCHARGE 200 PSIG

If Multi-Start has been enabled, the DE-3000 will automatically attempt an-

other AUTO START sequence if the crank disconnect RPM is not met within the

user-defined time. Once the AUTO START sequence has failed, a delay timer will

begin counting down before the system starts up again. During this delay time,

the display will flash red and yellow and state “RESTART PENDING-XXXs”, with

“XXX” being the time left before restart. Multi-Start can be configured for up to

4 start attempts (or a restart after 3 failed attempts).

STATUS TIMERS ACTIVE

SPEED 330 RPM

SUCTION 102.3 PSIA

DISCHARGE 200 PSIG

STATUS AUTO START

SPEED 130 RPM

SUCTION 102.3 PSIA

DISCHARGE 200 PSIG

DE-3000 IOI 7-17

All rights reserved © ALTRONIC, LLC 2017 11

1ST FAULT

RESTART PENDING- 8s

1st FAULT

OVERCRANK

9.4 If the OEM ENGINE CONTROL option is chosen when programming the DE-

3000, the same AUTO START screen shown in section 9.3 will be displayed

when the sequence is initiated. OEM engine control signals Driven Equipment

Ready (DER), starts the Crank/Multi-Start disconnect timer, and activates a

pre-lube pump when the sequence begins. If the Crank/Multi-Start disconnect

speed is not met within its allotted time, an OVERCRANK FAULT is issued by

the DE. The pre-lube will turn OFF after a programmed disconnect speed is

reached. If the pre-lube disconnect speed is not reached in a given amount of

time, a PRELUBE FAULT will be generated. The start signal and auxiliary mod-

ule will turn ON after a specified amount of time. The start signal will remain

ON between 1-5 seconds, or during the entire running time of the DE. When a

manual stop or fault occurs, the DER signals OFF and the post-lube, start signal

(if still ON) and auxiliary module remain ON for an individually programmed

amount of time before turning OFF.

If Multi-Start has been enabled, the DE-3000 will automatically attempt an-

other OEM ENGINE CONTROL sequence if the Crank/Multi-Start disconnect

RPM is not met within the user-defined time. Just like the Multi-Start for AUTO

START, once the sequence has failed, the display will flash a delay timer will

begin counting down before the system starts up again. Multi-Start can be con-

figured for up to 4 start attempts (or a restart after 3 failed attempts).

9.5 After all Class B and Class C points have timed out and are being monitored,

and if no faults are detected, the home screen will show the RUNNING message.

This is the screen that will remain under normal operation.

RUNNING

STATUS RUNNING

SPEED 1000 RPM

SUCTION 102.3 PSIA

DISCHARGE 300 PSIG

WARNING: WHEN PROGRAMMED FOR

MULTI-START, THE DE-3000 WILL

AUTOMATICALLY ATTEMPT TO START

THE ENGINE AS MANY AS FOUR TIMES.

RESTARTS ARE MADE BETWEEN 30

AND 90 SECONDS FOLLOWING AN

OVERCRANK FAULT. PERSONNEL

AROUND THE ENGINE MUST BE

NOTIFIED TO TAKE THE NECESSARY

SAFETY PRECAUTIONS TO AVOID INJURY

OR MALFUNCTION.

STATUS RUNNING

SPEED 1000 RPM

SUCTION 102.3 PSIA

DISCHARGE 300 PSIG

DE-3000 IOI 7-17

All rights reserved © ALTRONIC, LLC 2017 12

9.6 Whenever a programmed servicemeter interval has expired, a *character will be

displayed at the end of the STATUS word on the top line of the HOME screen.

Digital control output #7 will turn ON when any service meter interval has ex-

pired. This output can be used to trigger a horn or light or to initiate a service

call. The servicemeter will show the hours remaining until a scheduled service

function is required. When a service function is overdue, the hours left will

display 0. To access the servicemeter messages, press the Menu key from the

Home screen, and then select Hourmeter Functions.

F1

PRESS TO

VIEW

MESSAGE RUNNING

HOURMETER/RESET TIME

MESSAGE NUMBER: >00

TOTAL HOURS: 8971

OPERATING HOURS

↑

UNITS

PRESS TO

CHANGE

NUMBER RUNNING

HOURMETER/VIEW/CLEAR

MESSAGE NUMBER: ~00

TOTAL HOURS: 8971

OPERATING HOURS

↑

UNITS

PRESS TO

CHANGE

NUMBER RUNNING

HOURMETER/VIEW/CLEAR

MESSAGE NUMBER: ~01

HOURS LEFT: 100

OIL CHANGE REQUIRED

STATUS* RUNNING

SPEED 1000 RPM

SUCTION 102.3 PSIA

DISCHARGE 300 PSIG

HOURMETER / SERVICE

MESSAGE NUMBER: ~00

TOTAL HOURS: 8971

OPERATING HOURS

HOURMETER / SERVICE

MESSAGE NUMBER: ~01

HOURS LEFT: 100

OIL CHANGE REQUIRED

DE-3000 IOI 7-17

All rights reserved © ALTRONIC, LLC 2017 13

Proceed through the servicemeter messages to find the required service. The

number of hours left until the listed maintenance is due is displayed for each

service message. When the hours left reaches zero the *character is displayed

on the home screen status line.

F2

PRESS TO

RESET HOURS

REMAINING

↑

UNITS

PRESS TO

CHANGE

NUMBER RUNNING

HOURMETER/VIEW/CLEAR

MESSAGE NUMBER: ~02

HOURS LEFT: 0

OIL CHANGE REQUIRED

There are up to eleven user programmable service messages. The desired mes-

sages and service intervals are selected when programming the DE-3000 sys-

tem. The service intervals can only be changed by using the terminal program

and the PC. The servicemeter alert can be reset after the required service is

performed by pressing the F2 key with the desired message displayed. Each

servicemeter message is individually reset.

9.7 CONTROL SCREEN

From the home screen, the CONTROL LOOP #1 screen is accessed by pressing

the NEXT key once. CONTROL LOOP #1 is a closed loop PID controller which

is assigned to the analog value measured by channel 01. This can be virtually

any pressure, temperature, valve position or other equipment parameter which

can be expressed as an analog value from 0 to 5 volts. Some typical controlled

values would be the discharge pressure of a compressor, the intake manifold

pressure of an engine, the temperature of a cooling system or the chemical

composition of a process output. The first line of the display will indicate the

input channel/output channel and the current value of the controlled parameter.

The next line shows the desired value, the setpoint, of the controlled parameter.

The third line shows the current settings of the loop tuning values; the P: 45%

indicates a proportional band setting of 45%, the I:1s indicates an integral term

of 1 second, and the D:450m indicates a derivative value of 450 minutes.

RUNNING

CH01/A01 42.3 PSIG

SETPOINT 42.2 PSIG

P:45% I: 1s D:450m

AUTO 58%

NEXT

PRESS TO

VIEW

The current values of the control loop can be viewed at any time, however, to

change these values, a specific key sequence must be entered first. To unlock

the control loop values, enter the password (see section 27.0). A small arrow will

appear next to the value to be changed. Use the arrow keys to change the value

and the ENTER key to accept the new value. As the ENTER key is pressed, the

controller will begin controlling to that value and the cursor advances to the next

value. To disable the optional automatic control and force the controller output

to a particular value after unlocking the control, press the F1 key. The display

will indicate that the unit is in MANUAL and the current value of the output. Use

the UNITS arrow keys to change the setpoint value.

HOURMETER / SERVICE

MESSAGE NUMBER: ~02

HOURS LEFT: 0

OIL CHANGE REQUIRED

CH01/A01 42.3 PSIG

SETPOINT 42.2 PSIG

P:45% I: 1s D:450m

AUTO 58%

DE-3000 IOI 7-17

All rights reserved © ALTRONIC, LLC 2017 14

RUNNING

CH01/A01 42.3 PSIG

SETPOINT ~ 42.2 PSIG

P:45% I: 1s D:450m

AUTO 58%

↑

UNITS

PRESS TO

CHANGE

VALUE

ENTER

PRESS TO

ACCEPT

NEW

NUMBER

RUNNING

CH01/A01 42.3 PSIG

SETPOINT 42.2 PSIG

P:45% I: 1s D:450m

MANUAL ~ 58%

↑

UNITS

PRESS TO

CHANGE

VALUE

PRESS TO

CHANGE

MODE

F1

The second control loop, CONTROL LOOP #2, is accessed by pressing the NEXT

key twice from the HOME screen. This second loop can be set as a second in-

dependent PID loop (like LOOP #1), a CASCADE RPM controller, or a LINEAR/

RAMP controller. If used for a second PID loop, the control is based on the analog

input of Channel 02. In addition to controlling the 4-20mA output, based upon

the channel 02 analog voltage, a closed loop control of the input frequency being

measured by the RPM input Channel S01 is also possible. The selection of which

channel acts as the control input is made when programming the unit from the

PC Terminal program. In order to change the tuning values for LOOP #2 from the

LOOP #2 screen, the same key sequence as for LOOP #1 is used.

When CONTROL LOOP #2 is used for CASCADE RPM control or LINEAR/RAMP

control, the analog input on Channel 01 is used to drive the output on A02.

CASCADE RPM control enables engine speed to be controlled based on the

control setpoint on LOOP #1. Once LOOP #1 is forcing a maximum output, en-

gine speed will increase up to a maximum RPM in order to achieve the control

setpoint on Channel 01. LINEAR/RAMP control maps Channel 01 setpoints to

defined 4-20 mA states (mapped to RPM values) on A02. This can be set up

for either direct or inverse acting. LINEAR/RAMP control can be initiated either

after a specified warmup time or the time when input on Channel 26 surpasses

its low control setpoint.

For a Linear/Ramp Control example, assume the unit is programmed as follows:

Linear/Ramp Control for suction pressure on Channel 01

Low setpoint = 5.0 PSIG at 6mA

High setpoint = 20.0 PSIG at 18mA

This will then create a graph as follows (page 15):

CH01/A01 42.3 PSIG

SETPOINT ~ 42.2 PSIG

P:45% I: 1s D:450m

AUTO 58%

CH01/A01 42.3 PSIG

SETPOINT 42.2 PSIG

P:45% I: 1s D:450m

MANUAL ~ 58%

DE-3000 IOI 7-17

All rights reserved © ALTRONIC, LLC 2017 15

18mA

6mA

5.0 PSIG 20.0 PSIG

A02 (4–20mA) vs. Suction Pressure

The screens which will appear for LOOP #2, depending upon which program

options are used, are shown below.

RUNNING

CH02/A02 42.3 PSIG

SETPOINT 42.2 PSIG

P:45% I: 1s D:450m

AUTO 58%

PRESS

TWICE TO

VIEW

NEXT

OR

RUNNING

CH02/A02 1199 RPM

SETPOINT 1200 RPM

P: 45% I: 1s D:450m

AUTO 58%

PRESS

TWICE TO

VIEW

NEXT

OR

RUNNING

Calculated 1800 RPM

A02 54

Suction 13.3 PSIA

RPM 1800 RPM

PRESS

TWICE TO

VIEW

NEXT

CH02/A02 42.3 PSIG

SETPOINT 42.2 PSIG

P:45% I: 1s D:450m

AUTO 58%

CH02/A02 1199 RPM

SETPOINT 1200 RPM

P: 45% I: 1s D:450m

AUTO 58%

DE-3000 IOI 7-17

All rights reserved © ALTRONIC, LLC 2017 16

Pressing NEXT again will reveal any further terminal board PID screens following

the same protocol for viewing, modifying and saving PID information. For CAS-

CADE RPM control and LINEAR/RAMP control, the control screens allow the

user to view the input and output values. In order to change the control strategy

for LINEAR/RAMP control, see section 15.6.

9.8 In addition to the two 4-20mA analog control loop outputs, the DE-3000 offers

a pulsed digital output control option on Digital outputs #1 and #2 for use with

solenoid valves or motor valves. This option is referred to as PULSE CONTROL

and allows for closed loop control of the variable measured by the analog voltage

measured by input channel 03. The pulse control is attached to channel 03,

allowing for three independent control loops. When PULSE CONTROL is used,

Digital output #1 is used to open a valve or to increase the output when it is ON.

Digital output #2 is used to close a valve or decrease the output when it is turned

ON. A decision of which output to activate and for how long is made once per

cycle. A maximum ON time limit is selected when programming the unit from

the PC Terminal Program. To change the control variables for PULSE OUTPUTS,

select EDIT CONTROL VALUES from main menu and press the ENTER key. The

edit control values menu is shown. Next, select EDIT CONTROLS. From the EDIT

CONTROLS screen, select EDIT PRIM. CONTROLS and press the ENTER key.

PRESS

TO EDIT

CONTROLS

ENTER

RUNNING

EDIT SETPOINTS

~EDIT CONTROLS

EDIT PID DEADBAND

CALIBRATION

PRESS

TO EDIT

PULSE

CONTROLS

ENTER

RUNNING

LINEAR/RAMP CONTROL

>EDIT PRIM. CONTROLS

PRESS TO

ACCEPT OR

GO TO NEXT

VALUE

ENTER

PRESS TO

CHANGE

VALUE

↑

UNITS

RUNNING

CONTROL 35.0 PSIG

CYCLE TIME ~ 2 s

PROP. BAND 40 %

DEAD BAND 0.5 PSIG

9.9 On some applications, in addition to all of the standard PID control tuning, it

may be desirable to allow for a small controller deadband in order to promote

system stability. To set or edit the PID deadband value, select this function from

the Menu as shown.

EDIT SETPOINTS

~EDIT PRIM. CONTROL

EDIT PID DEADBAND

CALIBRATION

EDIT SETPOINTS

~EDIT PRIM. CONTROL

EDIT PID DEADBAND

CALIBRATION

CONTROL 35.0 PSIG

CYCLE TIME ~ 2 s

PROP. BAND 40 %

DEAD BAND 0.5 PSI

DE-3000 IOI 7-17

All rights reserved © ALTRONIC, LLC 2017 17

PRESS TO

EDIT PID

DEADBAND

ENTER

RUNNING

EDIT SETPOINTS

EDIT CONTROLS

~EDIT PID DEADBAND

CALIBRATION

PRESS TO

ACCEPT OR

GO TO NEXT

VALUE

ENTER

PRESS TO

CHANGE

VALUE

↑

UNITS

RUNNING

PID #1

DEADBAND 1.0 PSIG

PID #2

DEADBAND 0.2 PSIG

9.10 The TEST home screen is entered by pressing the TEST key. The TEST mode

disarms all outputs and may only be entered from the RUNNING mode. The

test time remaining is shown on the top line. See section 13.0 TEST MODE

SCREENS for more information.

PRESS

TO TEST

TEST

TEST MODE

STATUS TEST 600 SEC

SPEED 1000 RPM

SUCTION 102.3 PSIA

DISCHARGE 200 PSIG

9.11 If a fault condition occurs, the FAULT message for the first faulted channel will

appear on the display and will remain there until it is acknowledged. The numbers

one through two, after AL (alarm), shows the output switch that is faulted. To view

the first fault screen again, press the VIEW CHAN key. If all of the faulted sensors

have been cleared and the RESET key is pressed, the class B, C and output timers

will reset and the display will return to the TIMERS ACTIVE home screen.

1ST FAULT

STATUS FAULT AL12

1ST FAULT

CHAN 24

LOW OIL PRESSURE

EDIT SETPOINTS

EDIT PRIM. CONTROL

~EDIT PID DEADBAND

CALIBRATION

PID #1

DEADBAND 1.0 PSIG

PID #2

DEADBAND 0.2 PSIG

STATUS TEST 600 SEC

SPEED 1000 RPM

SUCTION 102.3 PSIA

DISCHARGE 200 PSIG

STATUS FAULT AL12

1ST FAULT

CHAN 24

LOW OIL PRESSURE

NOTE: THE RESET FUNCTION CAN

ALSO BE IMPLEMENTED BY USING

THE EXTERNAL HARDWARE.RESET/

AUTO START INPUT AVAILABLE ON THE

TERMINAL MODULE. THE BEHAVIOR OF

THE CONTROLLER AND DISPLAY WILL BE

DETERMINED BY THE PROGRAMMING

SELECTIONS MADE WHEN CONFIGUR-

ING THE UNIT.

DE-3000 IOI 7-17

All rights reserved © ALTRONIC, LLC 2017 18

RETURNS TO

FAULT HOME

SCREEN

ESC 1ST FAULT

STATUS FAULT AL12

SPEED 0 RPM

SUCTION 102.3 PSIA

DISCHARGE 0 PSIG

PRESS

TO CLEAR

FAULTS,

RESET

TIMERS AND

OUTPUTS

RESET

PRESS TO

RETURN TO

1ST FAULT

SCREEN

VIEW

CHAN

9.12 The MANUAL STOP message will supersede all of the above home screens if the

STOP key is pressed.

PRESS TO

STOP

STOP

MANUAL STOP

STATUS MANUAL STOP

SPEED 0 RPM

SUCTION 102.3 PSIA

DISCHARGE 0 PSIG

10.0

VIEW PROCESS INFORMATION SCREENS

10.1 The VIEW PROCESS screen displays which digital outputs on the terminal board

are on/off. It also displays either a bargraph or graphing, depending on the type

of display being used.

STATUS RUNNING

SPEED 1000 RPM

SUCTION 102.3 PSIA

DISCHARGE 200 PSIG

RUNNING PRESS

VIEW

PRESS

VIEW

TERM. OUTPUT ENABLED

NO OUTPUTS ENABLED

RUNNING

STATUS FAULT AL12

SPEED 0 RPM

SUCTION 102.3 PSIA

DISCHARGE 0 PSIG

STATUS MANUAL STOP

SPEED 0 RPM

SUCTION 102.3 PSIA

DISCHARGE 0 PSIG

NOTE: THE STOP FUNCTION CAN ALSO

BE IMPLEMENTED REMOTELY BY USING

THE EXTERNAL STOP INPUT AVAIL-

ABLE ON THE TERMINAL MODULE. THE

BEHAVIOR OF THE CONTROLLER AND

DISPLAY WILL BE IDENTICAL TO THAT

OBTAINED BY PRESSING THE LOCAL

STOP KEY ON THE DISPLAY MODULE.

TERM. OUTPUT ENABLED

NO OUTPUTS ENABLED

DE-3000 IOI 7-17

All rights reserved © ALTRONIC, LLC 2017 19

This screen indicates which digital outputs on the terminal board(s) are turned

on. In the above example, no outputs are currently turned on.

PRESS

VIEW

TERM. OUTPUT ENABLED

6

RUNNING

The above example shows digital output #6 on the terminal board is turned on.

10.2 Pressing the VIEW key again presents a different screen depending on which dis-

play is being used. The 128x64 multi-color graphics display will show the screen

below. The 4x20 display will show the screen(s) at right.

SELECT CHANNEL FOR

GRAPHING MODE> 01

RUNNING AFTER

SELECTION

PRESS

ENTER

PRESS TO

SELECT

CHANNEL

UNITS

↓

↑

UNITS

Use the UP and DOWN arrow keys to select which channel to graph. Only the analog

input channels may be selected. Press the ENTER key after a selection has been made.

100.0

0

CH02 55.1 PSIA

PRESS TO

SELECT

CHANNEL

UNITS

↓

↑

UNITS

New data is displayed on the left hand side and the oldest data is shown to the

right. New data will occur once per minute and makes the displayed information

‘move’ to the right hand side of the screen. The information is updated once per

minute allowing the user to view 90 minutes of past data on the screen.

Use the UP and DOWN arrow keys to graph other analog channels (including speed).

10.3 CLASSIC DISPLAY ONLY (NOTE: These screens are shown in right margin.)

The process information screens can be accessed from any of the home screens

(except the test home screen) or from the view channel screen by pressing the

VIEW key. There are six process screens: one, three and five each display up to

four user-programmed process variables; screens two, four and six display an

analog bargraph associated with the previous process variable screen. Thus, up to

12 process variables can be displayed both digitally and in bargraph format.

The analog values are monitored by a microprocessor on the terminal board and

are configured by using a PC and the terminal program. The bargraph end points

are set by the low and high setpoints of the safety shutdown function. Unused

channel screens will not be displayed.

TERM. OUTPUT ENABLED

6

NOTE: THE FOLLOWING SCREENS

DISPLAY THE FIRST GROUP OF FOUR

SELECTED ANALOG INPUTS IN DIGITAL

AND BARGRAPH FORM.

NOTE: THE FOLLOWING SCREENS

DISPLAY THE SECOND GROUP OF FOUR

SELECTED ANALOG INPUTS IN DIGITAL

AND BARGRAPH FORM.

TEMP 1 180 °F

TEMP 2 250 °F

TEMP 3 300 °F

TEMP 4 320 °F

PRESS “VIEW” FOR DIGITAL INFORMATION

PRESS “VIEW” FOR BARGRAPH SCREEN

PRESS “VIEW” FOR DIGITAL INFORMATION

SUCTION 22 PSIA

DISCHRG 100 PSIG

FILTR 10 PSIA

BOP 110 PSIG

PRESS “VIEW” FOR BARGRAPH SCREEN

DE-3000 IOI 7-17

All rights reserved © ALTRONIC, LLC 2017 20

11.0

VIEW CHANNEL STATUS SCREENS

11.1 Use the VIEW CHAN key to enter the view channels screens. Once in the VIEW

CHAN mode, the user can view any channel’s details.

•The first line will be the controller system status; TIMERS ACTIVE, RUN-

NING, FAULT AL12, or MANUAL STOP.

•The second line shows whether the input point is “ARMED” or “NOT

ARMED”. Class A points will always be armed; class B points become

armed only after their timers have timed out. Class C points arm when

cleared or when the timer times out.

• The third line shows the channel number and an analog value of that

input; if configured for that channel.

• The fourth line shows the user entered 20 character channel description.

Upon pressing the view channel key, channel 01 will be shown. The UNITS and

TENS keys allow the user to quickly navigate through the controller channels.

Use the ↑UNITS or ↓UNITS keys to increase or decrease the viewed channel by

one. Use the →TENS or ←TENS keys to increase or decrease the viewed chan-

nel by ten. To exit the VIEW CHAN mode, press the ESC key. After five minutes

with no keypad activity, the display will revert to the current home screen.

FROM CURRENT HOME SCREEN

PRESS

VIEW

CHAN

TIMERS ACTIVE

STATUS TIMERS ACTIVE

SPEED 330 RPM

SUCTION 102.3 PSIA

DISCHARGE 200 PSIG

TO SEE CHANNEL 20 FROM CHANNEL 10

PRESS

→

TENS

TIMERS ACTIVE

STATUS TIMERS ACTIVE

NOT ARMED

CHAN 10

ENGINE OIL PRESSURE

TO SEE CHANNEL 21 FROM CHANNEL 20

PRESS

↑

UNITS

TIMERS ACTIVE

STATUS TIMERS ACTIVE

ARMED

CHAN 20

MANIFOLD PRESSURE

STATUS TIMERS ACTIVE

SPEED 330 RPM

SUCTION 102.3 PSIA

DISCHARGE 200 PSIG

STATUS TIMERS ACTIVE

NOT ARMED

CHAN 10

ENGINE OIL PRESSURE

STATUS TIMERS ACTIVE

ARMED

CHAN 20

MANIFOLD PRESSURE

Table of contents

Other Altronic Control System manuals

Popular Control System manuals by other brands

elsner elektronik

elsner elektronik 60121 Installation & operation

Airzone

Airzone VAF BLUEFACE Quick installation guide

PR

PR CASA ROLLO Mounting instructions

Linear Logic

Linear Logic ScanGauge III user manual

Zodiac

Zodiac AquaLink M8 installation manual

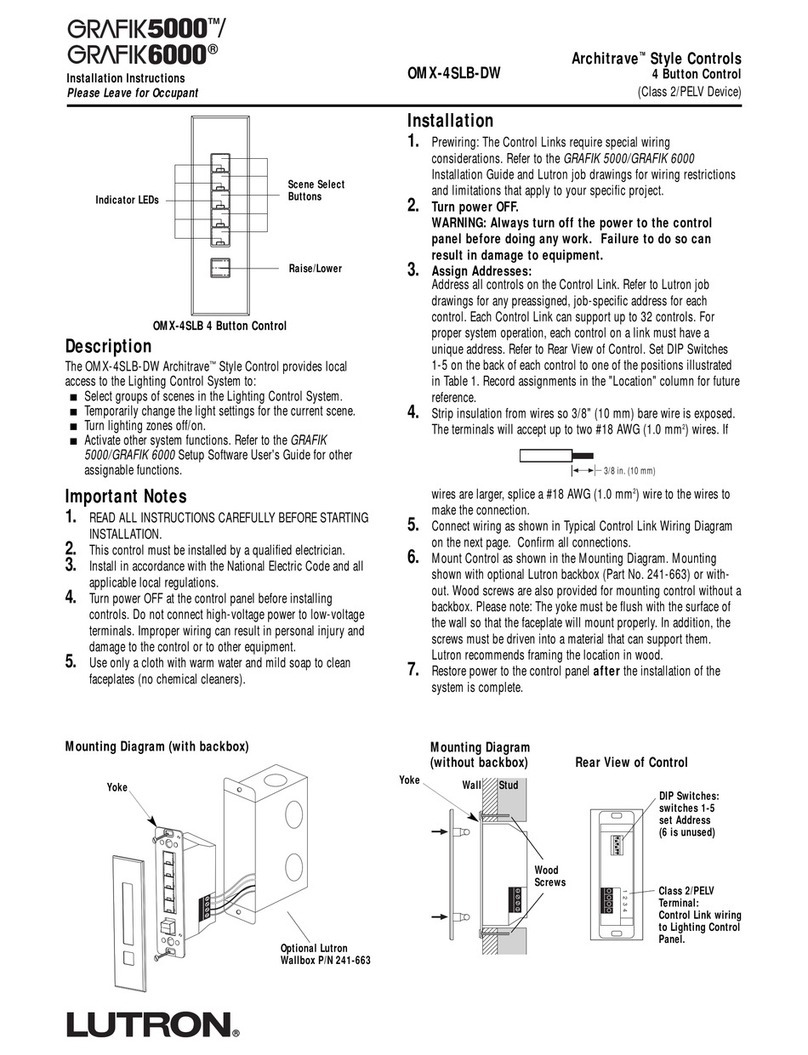

Lutron Electronics

Lutron Electronics Architrave GRAFIK5000 installation instructions