Altronic GTI Bi-Fuel User manual

Operating Manual

IN-LINE ENGINE CONTROL SYSTEM

Form GPN1000 OM 11-12

GPN1000 OM 11-12 GTI Operating Manual for In-line Engines

All rights reserved © ALTRONIC, LLC 2011

2

1.0 OVERVIEW

1.1 This manual applies to GPN1000 and GPN1000-12 panels used with Series

25-A, 50-A, 65-A, and 65-B (formerly Series A-A, I-A, II, and III-A) kits used

on in-line or small V-engines. For help locating subjects in this document see

p a g e 17.

1.2 The control system panel GPN1000 consists of two main parts packaged in

an industrial enclosure: Display Module DE-1510 and Power/Terminal Module

691142-2. Interconnecting cable 693115-1 connects Module DE-1510 to

Module 691142-2. The GPN1000 is for 24V systems, and the GPN1000-12 is

for 12V systems.

1.3 The Altronic DE-1510 controller system is a dedicated electronic microprocessor-

based system designed to sense specific analog and digital input points to

control and monitor the GTI Bi-Fuel® natural gas fumigation system for diesel

engines. The system is configurable for various applications using a PC (personal

computer) and the supplied DE-1510 terminal program and contains a non-volatile

memory to store the setup. Serial communications provide an interface to PC’s,

PLC’s, modems and satellite uplinks for remote communication if desired. A

backlit 4x20 LCD character display shows system status, programmed controller

parameters and channel labels. A front mounted keypad serves as the user

interface. The DE-1510 provides for the natural gas fueling off/on control function

and for an optional closed loop automatic control function to optimize the amount

of natural gas substitution of diesel fuel under varying modes of operation.

Additionally, the DE-1510 provides for remote data acquisition and supervisory

control in a compact, low cost package dedicated to natural gas fuel substitution

on industrial diesel engine applications.

2.0 DE-1510 DISPLAY MODULE

2.1 The Display Module serves as the user interface for the DE-1510 system.

Packaged in a 6.5" x 6.5" panel mounted enclosure, it consists of an

alphanumeric 20-character x 4-line backlit LCD display, a 16-key front-mounted

keypad, DB-25 D-Sub and DB-9 D-Sub connectors and three pairs of serial port

indicators.

2.2 The keypad is a sealed membrane unit containing the STOP and RESET keys

and other keys used to navigate through channel status, description, view

screens, and to edit the setpoints.

2.3 The LCD has a home screen that displays a status line, BI-FUEL OFF or ON,

gas supply pressure (GSP), manifold air pressure (MAP1) and manifold air

temperature (MAT1). Pressing the VIEW CHANNEL key displays the channel

number, its timer status, analog value (if applicable) and the user label.

2.4 The keypad, along with the LCD display, are used to navigate through channel

status and descriptions, view screens, and to view or edit the system’s

configuration. The ↑UNITS or ↓UNITS or the →TENS or ←TENS keys are used

to access channels by increasing or decreasing the channel numbers by one or

by ten with each key press. Pressing the NEXT key advances the display to the

next screen or item. All menu adjustments are saved in non-volatile EEPROM

memory by pressing the ENTER key. The EEPROM memory retains the current

configuration during normal operation, after engine shutdown and at system

power-down.

2.5 Three pairs of LED’s are provided on the back of the Display Module for

troubleshooting purposes, one Receive (RX) and one Transmit (TX) LED for

each port. The TX LED will flash when the Display Module is transmitting serial

communications on the labeled port. The RX LED will flash when the Display

Module is receiving serial communications on the labeled port.

WARNING: DEVIATION FROM THESE

INSTRUCTIONS MAY LEAD TO

IMPROPER ENGINE OPERATION WHICH

COULD CAUSE PERSONAL INJURY

TO OPERATORS OR OTHER NEARBY

PERSONNEL.

NOTE: If possible, keep the original

shipping container. If future

transportation or storage of the

controller is necessary, this container

will provide the optimum protection.

GPN1000 OM 11-12 GTI Operating Manual for In-line Engines

All rights reserved © ALTRONIC, LLC 2011

3

3.0 POWER/TERMINAL MODULE

3.1 The Power/Terminal Module is rail mounted and is the interface to the DE-

1510 Display Module and to other systems. It also is the point of interface

between the field sensor wiring terminal strip and the DE-1510 control system.

A removable dual terminal strip is used for the connection of the system. The

equipment mounted discrete sensors may consist of up to 4 normally-open or

normally-closed switches as well as 8 analog transducers. The 4 discrete sensor

inputs are numbered 10-13. The 8 analog inputs are numbered 20-27.

3.2 The Power/Terminal Module has six solid state output switches. The output

switches provide a means of using the DE-1510 controller system status to

operate relays and the fuel solenoid valve. The output switches will be in the

open (de-energized) condition when the unit is unpowered. If 24 Vdc is lost

to the DE-1510 system, the output switches will go to an open state. Output

switches 3 and 4 function as normally-closed contacts to permit the Bi-Fuel

solenoid valve to turn on. If supply voltage is lost, the LED’s will be ON in the

normal Bi-Fuel ON condition and OFF for a Bi-Fuel OFF or fault condition.

Output 5 functions as a driver for the FAULT LED on the front of the panel and

will normally be off.

3.3 The input power of the DE-1510 system is applied to the power supply terminals

marked (+) and (–) PWR. A 6.3 amp, replaceable slow-blow fuse protects the

system from over currents, and a power LED lights when power is applied to the

system.

4.0 MOUNTING THE PANEL (FIG. 1)

4.1 Mount the control panel(s) to a post or to a suitable flat surface so that the

display is at a convenient viewing height.

5.0 WIRING (SEE WIRING DIAGRAMS: FIGS. 2, 3 & 4)

5.1 SYSTEM COMPONENT WIRING (FIG. 2)

Three individual wiring harnesses are provided in the system kits. Each wiring

harness, or bundle, consists of functionally-grouped connections to sensors

or actuators, which would normally be located in the same general area. Each

bundle is marked as Engine Harness, Fuel Harness, or Power Harness. The

wiring is protected by a flexible plastic tubing. Each wiring bundle is provided

with a bulkhead fitting installed. Mount the bulkhead fittings into the holes

provided in the bottom of the panel. When routing the wiring, it is essential that

the following practices be adhered to:

Never run sensor wires in the same conduit with high energy

wiring such as the AC line power.

Keep high voltage wiring at least eight inches (200mm) away from

sensor and sensor wiring.

If it becomes necessary to check sensor to panel wiring with an

ohmmeter or other powered means, first DISCONNECT the plug-in

terminal strips from the Terminal Module. Applying voltage to the DE-

1510 system through the sensor leads may damage the device.

5.2 ENGINE (ORANGE) HARNESS WIRING (FIG. 3)

A. Mount the pressure sensors provided in the accessory kit to the engine

in a manifold or tube from the engine. Depending upon the specific

application, there may be unused wires in the bundle. Plug in the mating

connectors; VAC1 is the air cleaner vacuum and MAP1 is the MANIFOLD

AIR PRESSURE.

NOTE: Avoid mounting the GPN1000

panel with the LCD display facing

direct sunlight. The display operating

temperature range is −31°F to +176°F

(−35°C to +80°C). The panel should

be mounted within 10 ft. (GPA0005-

10), 20 ft. (GPA0005-20), or 30 ft.

(GPA0001-30) of the engine, the

fuel solenoid valve and fuel pressure

regulator.

NOTE: All furnished drawings and

instructions assume (–) ground DC

system. In the case of a floating

ground, or (+) ground DC system,

please contact Altronic Factory for

support.

NOTE: Do not expose the pressure

transducer to temperatures above

221°F. (105°C).

GPN1000 OM 11-12 GTI Operating Manual for In-line Engines

All rights reserved © ALTRONIC, LLC 2011

4

B. Mount the thermocouples to the engine, routing the thermocouple wires as

required. To accommodate the differences in location of the sensors, remove

the individual wires from the plastic tubing, as required, and tape the tubing

closed after proper length to reach the sensor location is known. MAT1

is the MANIFOLD AIR TEMPERATURE and EGT1 is the EXHAUST GAS

TEMPERATURE.

C. If the optional vibration sensor is used, mount as indicated and connect to

the wires marked VIB+ and VIB1 (signal to panel).

D. At the panel end, adjust the length of the bundle, if required, and mount the

bulkhead fitting through the far left hole, viewing the panel from the front.

Terminate the wires to the customer connection terminal strip. Each wire is

marked with the same identifier as the terminal strip; connect these to match.

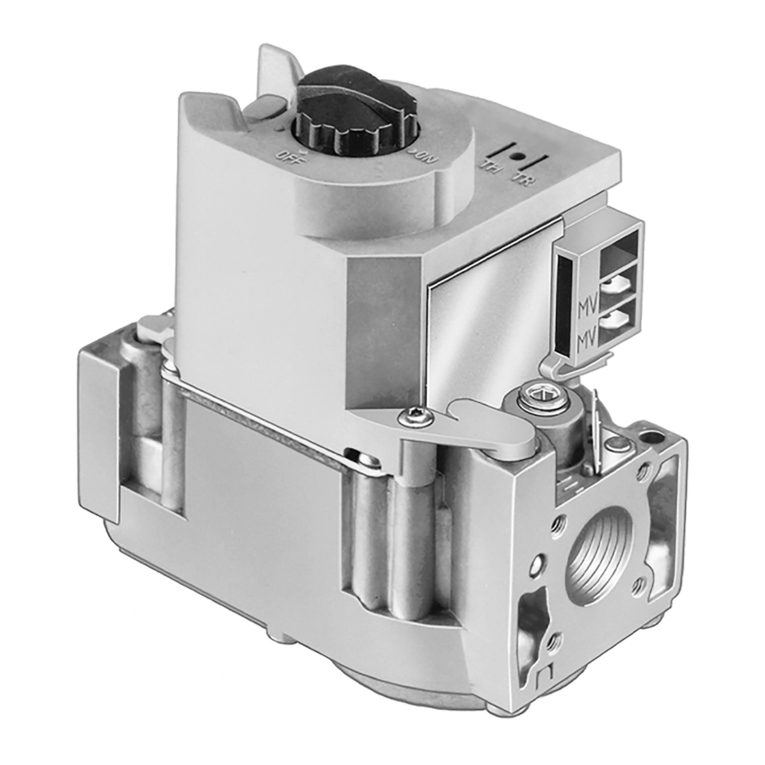

5.3 FUEL (BLUE) HARNESS WIRING (FIG. 3)

The FUEL HARNESS contains the wiring to the fuel supply and pressure

regulator and is not to be routed to the engine.

A. After mounting the FUEL GAS SOLENOID VALVE, connect the SOL+ and

SOL- wires to the solenoid coil.

B. Connect the ROP wires to the REGULATOR OUTPUT PRESSURE switch

terminals. Do not connect the shield wire, as it is terminated at the panel

end only.

Note: The GPN1000-12 panel does not utilize the ROP input.

C. Mount the GAS SUPPLY pressure transducer GSP and plug in the connector.

D. At the panel end, adjust the length of the bundle, if required, and mount the

bulkhead fitting through the third from the left hole viewing the panel from

the front. Terminate the wires to the customer connection terminal strip.

Each wire is marked with the same identifier as the terminal strip; connect

these to match.

5.4 POWER (RED) HARNESS WIRING (FIG. 3)

The POWER HARNESS contains the power wiring for the panel.

A. GPN1000

Connect the supply power wires to the 24 Vdc input power terminals on

the power supply, plus to terminal (+) and minus to terminal (−); power

requirement is 24 Vdc, 120 watts max. The DC− terminal will be connected

to the panel ground which must be the same as engine chassis ground.

GPN1000-12

Connect the supply power wires to the 12 Vdc input power terminals on

the power supply, plus to terminal (+) and minus to terminal (−); power

requirement is 12 Vdc, 180 watts max. The DC− terminal will be connected

to the panel ground which must be the same as engine chassis ground.

B. At the panel end adjust the length of the bundle, if required, and mount the

bulkhead fitting through the far right hole viewing the panel from the front.

Terminate the wires to the customer connection terminal strip. Each wire is

marked with the same identifier as the terminal strip; connect these to match.

NOTE: This is the return path for

normally-open sensors and must be

connected to the engine block or

chassis ground for proper operation.

GPN1000 OM 11-12 GTI Operating Manual for In-line Engines

All rights reserved © ALTRONIC, LLC 2011

5

6.0 KEYPAD DESCRIPTION

6.1 The DE-1510 controller Display Module contains a 16-key sealed membrane

keypad which is used to adjust, stop and reset the system.

6.2 STOP

Used for a manual stop condition. By pressing the STOP key, the controller

activates the configured outputs.

6.3 RESET

Clears all past faulted points and resets all input and output timers to their

preset values. This can also be accomplished remotely by interrupting the DC

power to the panel for 5 seconds.

6.4 CANCEL TIMERS

Cancels all timers.

6.5 VIEW CHAN

Allows the user to view the status of any input channel and its user defined

label.

6.6 NEXT

Shows optional settings.

6.7 ENTER

Used to accept a selection and to save a new value in memory.

6.8 ESC

Enables the user to exit any view channels, information or menu screens at any

time and return to the previous screen without changing programmed values.

6.9 MENU

Allows the user to enter the edit menu. Control setpoints may be viewed and

adjusted using the MENU key.

6.10 UNITS/TENS

Increase or decrease values by one. The →TENS/←TENS keys increase or

decrease values by ten. These keys are used to increase or decrease channel

numbers, timers and to move the pointer in the menu screen.

6.11 F1

From Home screen, function key F1 displays the hourmeter. From control screen

F1 switches between auto and manual modes.

6.12 F2

Displays the time and date of the first fault.

GPN1000 OM 11-12 GTI Operating Manual for In-line Engines

All rights reserved © ALTRONIC, LLC 2011

6

7.0 UNDERSTANDING THE HOME SCREENS

7.1 The “home screens” are described as a series of screens used to display several

of the most critical operating parameters on one screen. All of the home screens

provide a status word on the upper line.

The status line will read one of the following:

BI-FUEL ON

BI-FUEL OFF

BI-FUEL INHIB

TIMERS ACTIVE

CHECKING INPUTS

FAULT AL1

MANUAL STOP

The LCD display always reverts to one of the home screens after a keypad

operation is completed or the operation times out.

7.2 To activate the Bi-Fuel system, turn on the power; the unit automatically resets.

If no system faults are detected during the CHECKING INPUTS scan, the home

screen will display the TIMERS ACTIVE message until the programmed fuel

delay timer expires. After the time delay is completed, the home screen will

display either the BI-FUEL ON or BI-FUEL OFF status according to the current

conditions and the programmed control values. The RESETTING message will

be displayed momentarily followed by TIMERS ACTIVE, and the home screen

will then re-appear.

APPEARS IMMEDIATELY

AFTER POWER-UP OR A USER

RESET COMMAND FOR ABOUT

1 SECOND

RESETTING

APPEARS AFTER RESET AS

UNIT SCANS INPUTS FOR

PRE-EXISTING FAULT

CONDITIONS

CHECKING INPUTS

GSP1 9.0 PSIG

MAP1 12.0 PSIG

MAT162°F

APPEARS AFTER RESET OR

BI-FUEL OFF CONDITION

WHEN NO FAULTS ARE

DETECTED AND THE

BI-FUEL DELAY TIMER IS

ACTIVE

STATUS TIMERS ACTIVE

GSP1 9.0 PSIG

MAP1 12.0 PSIG

MAT162°F

APPEARS WHEN ALL TIMERS

ARE EXPIRED, ALL FAULTS ARE

CLEAR AND ALL CONTROL

SETTINGS ARE PERMITTING

THE BI-FUEL GAS VALVE TO

BE ON

STATUSBI-FUELON

GSP1 9.0 PSIG

MAP1 12.0 PSIG

MAT162°F

GPN1000 OM 11-12 GTI Operating Manual for In-line Engines

All rights reserved © ALTRONIC, LLC 2011

7

APPEARS WHEN ALL TIMERS

ARE EXPIRED, ALL FAULTS ARE

CLEAR AND ONE OR MORE

CONTROL SETTINGS IS

KEEPING THE BI-FUEL GAS

GAS VALVE IN THE OFF

POSITION UNTIL CONDITIONS

CHANGE

STATUSBI-FUELOFF

GSP1 9.0 PSIG

MAP1 12.0 PSIG

MAT162°F

7.3 The DE-1510 controller continuously monitors the system for two different levels

of setpoints. The first group are called control setpoints and, when violated, they

cause the Bi-Fuel function to be temporarily suspended (engine reverts to 100%

diesel operation) until conditions change. The violation of these setpoints may

occur readily in normal operation of the engine and the system does not require

any USER intervention to begin re-supplying natural gas when these clear, after

the bi-fuel delay expires.

APPEARS WHEN ALL TIMERS

ARE EXPIRED, ALL FAULTS ARE

CLEAR AND ONE OR MORE

CONTROL SETTINGS IS

KEEPING THE BI-FUEL GAS

GAS VALVE IN THE OFF

POSITION UNTIL CONDITIONS

CHANGE

STATUSBI-FUELOFF

GSP1 9.0 PSIG

MAP1 12.0 PSIG

MAT162°F

APPEARS WHEN CHANNEL 13

HAS BEEN ACTUATED

STATUSBI-FUELOFF

GSP1 9.0 PSIG

MAP1 12.0 PSIG

MAT162°F

A temporary Bi-Fuel Inhibit can be implemented when desired, by opening the

jumper connection between the terminals for input 13. This input prevents

output #4 from turning on, which prevents Bi-Fuel operation. Bi-Fuel operation

may begin after input 13 is no longer actuated.

7.4 The safety shutdowns are the second level of monitored setpoints. When any of

these setpoints are violated even momentarily, the Bi-Fuel will stop supplying

natural gas (engine reverts to 100% diesel operation) and will NOT begin re-

supplying gas, until a USER initiated RESET is received. When one of the safety

shutdown setpoints has been violated, the gas solenoid valve is closed, and the

FAULT message for the first faulted channel will appear on the display and will

remain until it is acknowledged by a RESET. The number 1, after AL (alarm),

shows the output switch that is faulted. If all of the faulted sensors have been

cleared and the RESET key is pressed, the class B and output timers will reset

and the display will repeat the sequence of section 7.2.

STATUSFAULTAL3

1STFAULT

CHAN 12

ROPREG.OUT.PRESS

RETURNS

TO FAULT

HOME

SCREEN

ESC

GPN1000 OM 11-12 GTI Operating Manual for In-line Engines

All rights reserved © ALTRONIC, LLC 2011

8

STATUSFAULTAL3

GSP 9.0 PSIG

MAP1 12.0 PSIG

MAT162°F

PRESS TO

RETURN TO

1ST FAULT

SCREEN

VIEW

CHAN

TO CLEAR

FAULTS, RESET

TIMERS &

OUTPUTS

RESET

When a fault occurs on analog channel,20-27, a HIGH or LOW indication will

also be displayed as to whether the point faulted on a high or low setpoint.

A HIGH SETPOINT FAULTED ON

AN ANALOG INPUT. THE

CURRENT ANALOG VALUE AND

HIGH ARE DISPLAYED

STATUSFAULTAL3

1stFAULTHIGH

CHAN2318PSIG

MAP1 ENG MAN PRESS 1

The DE-1510 controller system “stamps” the time and date of the first fault. To

view the time and date of the first fault, press the F2 key after a fault occurs

but before reset is initiated. If no key is pressed for 10 seconds, the display will

revert to the first fault screen.

TIMEANDDATEOF

THEFIRSTFAULT.

TIME:3:10PM

DATE:03-25-2011

VIEW TIME

AND DATE

OF FIRST

FAULT

F2

7.5 From the home screen, any control fault condition can be viewed by pressing

the NEXT key once. The screen holds a host of information for optional

equipment, but also has the ability to scroll through any outstanding channels

with a CONTROL set point violated. As long as the first line is holding the Gas

Valve in AUTO mode, the second line will contain the violated channels, scrolled

one at a time. If the Gas Valve is in MANUAL mode, or there are no control set

points violated, then the second line will contain the HOLD POSITION value.

To alternate between MANUAL and AUTO mode press the F1 key.

7.6 The MANUAL STOP message will supersede all of the above home screens if

the STOP key is pressed. The fuel solenoid valve will close and remain closed

until RESET.

STATUSMANUALSTOP

GSP1 9.0 PSIG

MAP1 12.0 PSIG

MAT162°F

PRESS TO

STOP

STOP

GPN1000 OM 11-12 GTI Operating Manual for In-line Engines

All rights reserved © ALTRONIC, LLC 2011

9

8.0 VIEW CHANNEL STATUS SCREENS

8.1 Use the VIEW CHAN key to enter the view channels screens. Once in the VIEW

CHAN mode, the user can view any channel’s details. The UNITS and TENS

keys allow the user to quickly navigate through the controller channels. Use the

↑UNITS or ↓UNITS keys to increase or decrease the viewed channel by one.

Use the →TENS or ←TENS keys to increase or decrease the viewed channel

by ten. To exit the VIEW CHAN mode, press the ESC key. After two minutes with

no keypad activity, the display will revert to the current home screen.

9.0 VIEWING OR EDITING THE SETPOINT VALUES USING

THE MENU MODE

9.1 The menu screens can be accessed from any home screen by pressing the

MENU key. The menu screens allow the user to view or edit values and the time

and date. The controller must be initially configured using the terminal program

running on a PC connected to the RS-232 port on the back of the controller.

Reference the programming instructions section 12.0 for details on how to

configure the controller system for a specific application. The menu screens are

intended to view or edit the already programmed values in the field. Changes

made in the menu are stored in permanent memory and remain fixed until

changed again.

9.2 To view the controller configuration, from the home screen press the MENU

key. Use the NEXT key to select the group to be viewed and press ENTER. To

edit the controller configuration, the controller system requires a password key

sequence.

The password procedure is: From the home screen, press the MENU key. Then

press the F2 key followed by the F1 key. Upon pressing this sequence, changes

can be made to the configuration.

9.3 The menu screens have two levels. The first level lists the headings of the items

to be viewed or edited. Upon selecting one of the headings, the second level

is displayed. Press the MENU key to enter the first level of the menu screens.

The arrow points to the first selection to be viewed or edited. Three keys can

be used to navigate the first level of menu selections: NEXT or ↑UNITS or

↓UNITS keys. The NEXT key will move the arrow down one selection. The ↑

UNITS or ↓UNITS keys will move the selector arrow up or down one selection.

Once the arrow is pointing to the selection group to be edited, press the ENTER key.

The display will advance to the second level to view or allow changes to the values.

9.4 To edit the setpoint values, point to EDIT CONTROL VALUES and press the

ENTER key. The edit control values menu is shown. The arrow points to the

EDIT SETPOINTS. The example shows how to change the LO setpoint of CHAN

23. Use arrow keys as shown to select desired channels. Use ENTER key as

shown to select LO or HI setpoint.

9.5 To edit the setpoint values, point to EDIT CONTROL VALUES and press the

ENTER key. The edit control values menu is shown. The arrow points to the

EDIT SETPOINTS. The example shows how to change the LO setpoint of Chan

23a. Use arrow keys to select desired channels. Use ENTER key to select LO or

HI setpoint.

FIRST GROUP OF

MENU SCREENS

~EDITCONTROLVALUES

EDITSAFETYSHUTDWN

CALIBRATION

MOREMENUS

NOTE: To edit any value, the password

combination must be entered from first

level menu. Press the F2 key followed

by the F1 key. Upon pressing this

sequence, changes can be made to the

configuration.

GPN1000 OM 11-12 GTI Operating Manual for In-line Engines

All rights reserved © ALTRONIC, LLC 2011

10

~EDITSETPOINTS

EDITDYNAMICVALUES

PRESS TO

EDIT

SETPOINTS

ENTER

CHAN ~20

LOSP20.0%

HISP110.0%

DIESELFUELPERCENT

TO SELECT

CHAN 23

PRESS 3

TIMES

↑

UNITS

CHAN~23

LOSP2.0PSIG

HISP15.0PSIG

MAP1 ENG MAN PRESS 1

PRESS TO

EDIT LO

SETPOINT

ENTER

CHAN23

LOSP~2.0PSIG

HISP15.0PSIG

MAP1 ENG MAN PRESS 1

PRESS TO

CHANGE

LO VALUE

↑

UNITS

ACCEPT

AND GO TO

HI VALUE

ENTER

9.6 To edit hysteresis values, select EDIT HYSTERESIS and press the ENTER key.

EDITSETPOINTS

EDITDYNAMICVALUES

~EDITHYSTERESIS

EDITHYSTERESIS

MAP1 ~ 0.0

KW%0.0

There is a programmable hysteresis value for both the MAP1 and the KW%

sensor which prevents the gas from turning on and off as these channels dither

around the high and low control setpoints.

PRESS

TO EDIT

HYSTERESIS

ENTER

UNITS

↓

PRESS TO

CHANGE

VALUE

↑

UNITS

PRESS TO

ACCEPT

OR GO

TO NEXT

VALUE

ENTER

GPN1000 OM 11-12 GTI Operating Manual for In-line Engines

All rights reserved © ALTRONIC, LLC 2011

11

9.7 To view or edit safety shutdown values, choose EDIT SAFETY SHUTDWN from

the main menu. To edit or view setpoints, choose EDIT SETPOINTS.

FIRST GROUP OF MENU SCREENS

EDITCONTROLVALUES

~EDITSAFETYSHUTDWN

CALIBRATION

MOREMENUS

SECOND GROUP OF MENU SCREENS

~EDITSETPOINTS

VIEWINPUTCLASS

CHAN ~20

LOSP20.0%

HISP110.0%

DIESELFUELPERCENT

PRESS TO

GO TO LO

SETPOINT

ENTER

9.8 To view or edit the sensor calibration, select CALIBRATION from the main

menu. Use the arrow keys to select the desired channel for calibration. Use

the enter key to select either zero or span calibration for the selected channel.

Watching the bottom line of the display use the arrow keys to display the desired

value. For example, in order to calibrate the zero value of the transducer, apply

the zero value to the input and follow the steps below. If the full scale value also

requires calibration apply the full scale input to the channel and adjust the span

to obtain the desired reading on the bottom line of the display as shown.

FIRST GROUP OF MENU SCREENS

EDITCONTROLVALUES

EDITSAFETYSHUTDWN

~CALIBRATION

MOREMENUS

CHAN ~20

ZEROCALIBRATION

SPANCALIBRATION

0.3%

ARROW

KEYS TO

CHANGE

CHANNEL

↑

UNITS

PRESS TO

SELECT

ZERO CAL.

ENTER

PRESS TO

GO TO

NEXT

MENU

ENTER

PRESS TO

GO TO

NEXT

SCREEN

ENTER

PRESS TO

GO TO

NEXT

MENU

ENTER

GPN1000 OM 11-12 GTI Operating Manual for In-line Engines

All rights reserved © ALTRONIC, LLC 2011

12

CHAN 20

~ZEROCALIBRATION

SPANCALIBRATION

0.0%

ARROW

KEYS TO

CHANGE

UNITS

↓

PRESS TO

SELECT

SPAN CAL.

ENTER

9.9 Select MORE MENUS from menu.

EDITCONTROLVALUES

EDITSAFETYSHUTDWN

CALIBRATION

~MOREMENUS

FIRST

GROUP

OF MENU

SCREENS

PRESS TO

GO TO

NEXT

MENU

ENTER

9.10 The display shows the current Engineering units selection English or Metric. Use

the up arrow key to change and then press Enter to accept the new selection

and move to Edit Time and Date.

ENGR.UNITS~ENGLISH

EDIT TIME AND DATE

HOURMETERFUNCTIONS

MOREITEMS

PRESS TO

CHANGE

UNITS

↑

UNITS

PRESS TO

ACCEPT

ENTER

Selection arrow now points to time and date.

ENGR.UNITSENGLISH

~EDIT TIME AND DATE

HOURMETERFUNCTIONS

MOREITEMS

PRESS

TO GO

TO NEXT

SCREEN

ENTER

The time and date will be displayed with the selection arrow pointing to the

time. The hours and minutes can be edited separately; AM and PM follow

the hours. With the selection arrow pointing to the hours, use the ↑UNITS

or ↓UNITS keys to increase or decrease the hours. Press ENTER to save the

new hour setting; the selection arrow will point to the minutes. Use the same

procedure to edit the minutes. Use the NEXT key to move through the time and

date screen without making a permanent change in memory.

TIME:~11:30AM

DATE:09-03-2011

PRESS TO

CHANGE

VALUE

↑

UNITS

PRESS TO

ACCEPT

ENTER

The date is shown as month-day-year. The month, day and year can be edited

separately. With the selection arrow pointing to the month, use the ↑UNITS or

↓UNITS keys to increase or decrease the month. Press ENTER to save the new

month setting; the selection arrow will point to the day. Use the same procedure

to edit the day and the year.

GPN1000 OM 11-12 GTI Operating Manual for In-line Engines

All rights reserved © ALTRONIC, LLC 2011

13

TIME:11:30AM

DATE:~09-03-2011

PRESS TO

CHANGE

VALUE

↑

UNITS

PRESS TO

ACCEPT

ENTER

9.11 To view the Hourmeter message, select HOURMETER FUNCTIONS from the

main menu and press ENTER.

ENGR.UNITSENGLISH

EDIT TIME AND DATE

~HOURMETERFUNCTIONS

MOREITEMS

PRESS TO

GO TO SET

HOURMETER

ENTER

HOURMETER/SERVICE

MESSAGE NUMBER: 00

TOTALHOURS:~1500

RUNTIMEHOURS

PRESS TO

CHANGE

VALUE

↑

UNITS

PRESS TO

ACCEPT

ENTER

9.12 To view or edit the values for VIBRATION TIMER, BI-FUEL DELAY TIMER,

COMMUNICATION SETTINGS and to view the FIRMWARE REVISION level,

select MORE ITEMS. The Vibration Timer is the length of time in seconds that

a vibration level must be detected for to cause a fault. The Bi-Fuel Delay Timer

is the amount of time in seconds before Bi-fuel will be allowed to turn on after

a power loss, reset, or controlled off condition, if no faults exist.

ENGR.UNITSENGLISH

EDIT TIME AND DATE

HOURMETERFUNCTIONS

~MOREITEMS

PRESS TO

GO TO MORE

ITEMS

ENTER

VIBRATIONTIMER~0s

BI-FUELDELAY100s

COMMUNICATIONS

VIEWFIRMWAREREV.

PRESS TO

CHANGE

VALUE

↑

UNITS

PRESS

TO GO TO

BI-FUEL

DELAY

ENTER

VIBRATIONTIMER0s

BI-FUELDELAY~100s

COMMUNICATIONS

VIEWFIRMWAREREV.

PRESS TO

CHANGE

VALUE

↑

UNITS

PRESS

TO GO TO

COMM

MENU

ENTER

GPN1000 OM 11-12 GTI Operating Manual for In-line Engines

All rights reserved © ALTRONIC, LLC 2011

14

VIBRATIONTIMER0s

BI-FUELDELAY100s

~COMMUNICATIONS

VIEWFIRMWAREREV.

PRESS

TO EDIT

SETTINGS

ENTER

PRESS TO

CHANGE

VALUE

↑

UNITS

VIBRATIONTIMER0s

BI-FUELDELAY100s

COMMUNICATIONS

~VIEWFIRMWAREREV.

PRESS

TO VIEW

FIRMWARE

REVISION

ENTER

10.0 CONTRAST RATIO ADJUSTMENT

10.1 The LCD contrast ratio is adjusted for optimum contrast over a large temperature

range at the factory. It may be necessary to make slight adjustments to the LCD

contrast ratio because of aging and or extreme temperature changes. The contrast

ratio potentiometer (TP1) is located on the back of the Display Module. Use an

adjusting tool and turn the potentiometer clockwise to lighten the contrast ratio or

counterclockwise to darken the contrast ratio.

To set the potentiometer back to the factory setting: with the Display Module

at an ambient temperature of approximately 65°F to 77°F (18°C to 25°C), turn

the potentiometer clockwise until the display contrast ratio is almost too light

to read. Turn the potentiometer counterclockwise 3 to 3-½ turns. The display

should then be at a desirable contrast ratio.

11.0 DATA LOGGING AND COMMUNICATION OPTIONS

11.1 The DE-1510 controller system contains a data logging feature. Data logging

collects information from the system and keeps track of, or logs, that

information over a period of time. That data is then available through a PC or

PLC at port 1 (the RS-232 port) or port 3 (the RS-485 port).

11.2 NODE NUMBER

The node number is the address of the controller being contacted. This number

is programmed by the terminal program and can be viewed or edited in the

menu screen. A two digit number from 01 to 99 can be used.

11.3 COMMUNICATIONS PARAMETERS

The following must be set in the PC or PLC to communicate with the controller

system:

Baud Rate: 9600

Data Bits: 8

Stop Bits: 1

Parity: None

11.4 The data logging memory can retain a total of 100 records before writing over

the oldest information. The most current data is always record number one; the

next most current is number two, etc. The oldest information, record 100, is

lost when a new record is written. The logging period is set for 1 minute.

A new record is also written when a first fault occurs. If the first fault occurs

between the logging period, the first fault record will be record number one and

the next scheduled record will be number two.

GPN1000 OM 11-12 GTI Operating Manual for In-line Engines

All rights reserved © ALTRONIC, LLC 2011

15

11.5 Refer to files on the DE-1510 CD-ROM for more information on serial

communication specifications. This document contains in depth information on

MODBUS, ASCII, ROI (Remote Operator Interface), data logging, and dial in/out

features.

12.0 PROGRAMMING THE DE-1510

12.1 The DE-1510 terminal program operates from a standard PC and permits the

operator to configure the system. There is a monitor mode that the operator can

use to monitor an existing installation and access system data. This data can be

accessed locally or remotely via a modem.

The following user-supplied hardware is required:

Computer: IBM-compatible PC, Windows 95/98/ME/XP, hard drive (10 MB of

free disk space required), CD-ROM drive, SVGA graphics (800X600 or greater

preferred) with color monitor.

Serial Port: RS-232 port for programming.

Modem: 9600 baud (or greater) modem required.

12.2 The terminal program installs from a CD-ROM drive. A minimum of 10MB of

free disk space is required. Additional disk space will be required if the remote

data log database function is used. The space required will be dependent on the

size of the working database.

Insert the CD-ROM disk into the CD-ROM drive and run the setup.exe file. If you

have the autorun selection enabled on your CD-ROM drive, the install program

will run automatically. The install program will prompt you for a destination

folder where the program will be installed. After the install completes, you can

run the program from the Windows Start button, Programs Menu, Altronic DE-

1510 system. Select the DE-1510 menu selection.

12.3 Connect the computer cable from the computer to the DB9 connector Port #1

on the back of the DE-1510 display.

12.4 CONFIGURE KEY

The DE-1510 needs to be initially programmed using the DE-1510 Terminal

program. Select the items for download which best fit the intended application.

12.5 EDIT SETPOINTS KEY

The setpoints of the DE-1510 may be changed from the computer by selecting

this key.

12.6 MONITOR KEY

This feature allows the user to retrieve data logged messages which are typically

used for PC monitoring or SCADA/PLC systems. The connections can use either

a modem or connected directly into the comm. Port. Data logs may be retrieved

into a standard EXCEL file format.

The following keys are applicable during the monitor function:

CONNECT KEY

This feature selects how the PC is going to connect to the DE-1510. Select

either a comm port or a telephone number for a modem.

HANGUP KEY

This disconnects the PC from the port or the modem.

DATALOGS KEY

This feature allows for retrieval of data logged messages in the PC. Data logs

may be retrieved into a standard EXCEL file format.

GPN1000 OM 11-12 GTI Operating Manual for In-line Engines

All rights reserved © ALTRONIC, LLC 2011

16

AUTO START KEY

This feature allows for serial communications to STOP Bi-Fuel operation or

RESET Bi-Fuel operation.

VIEW DATABASE / CHART DATABASE KEY

These powerful tools allow users to display and chart the data logged

information.

12.7 CALIBRATE KEY

This allows the user to calibrate analog sensor channels. Press this button and

select the channel to be calibrated. The sensor selection box will show the

default values or the last values calibrated. The CURRENT DATA box shows

the value being displayed by the DE-1510. On the terminals of the channel

being calibrated, connect a voltmeter between the input (+ and –) to measure

the output voltage of the transducer. Apply the desired minimum pressure,

temperature, vibration, position or KW input to the transducer being calibrated.

Now measure the voltage using the voltmeter on the terminal strip. Enter

this voltage into the LOW SENSOR VOLTAGE box on the PC screen. Click the

ACCEPT button to make this the new calibration value. The CURRENT DATA box

will now read the desired minimum value. If the span is to be adjusted, increase

the input to the transducer to the desired high value. Measure the voltage at

the terminal strip using the voltmeter and enter the measured voltage in the

HIGH SENSOR VOLTAGE box and hit the ACCEPT button. The calibration of the

channel is now complete.

12.8 EXIT KEY

Exits the DE-1510 PC Terminal program.

GPN1000 OM 11-12 GTI Operating Manual for In-line Engines

All rights reserved © ALTRONIC, LLC 2011

17

INDEX BY SECTION:

1.0 OVERVIEW

2.0 DISPLAY MODULE

3.0 POWER/TERMINAL MODULE

4.0 MOUNTING

5.0 WIRING

6.0 KEYPAD DESCRIPTION

7.0 UNDERSTANDING THE HOME SCREENS

8.0 VIEW CHANNEL STATUS SCREENS

9.0 VIEWING OR EDITING THE PROGRAMMED VALUES USING THE MENU MODE

10.0 CONTRAST RATIO ADJUSTMENT

11.0 COMMUNICATIONS

12.0 PROGRAMMING

GPN1000 OM 11-12 GTI Operating Manual for In-line Engines

All rights reserved © ALTRONIC, LLC 2011

18

DE-1510 CHANNEL DESCRIPTION CHART:

CHANNEL DESCRIPTION DISPLAYED UNITS

(Default: English)

DISPLAYED

UNITS

(Metric)

DEFAULT

CONTROL SETPOINTS

DEFAULT

SAFETY SETPOINTS

LOW HIGH LOW HIGH

11 GAS DETECTION (optional) — — — — — —

12* ROP REG. OUT. PRESS. — — — — — —

13 BI-FUEL INHIB. — — — — — —

20 DIESEL FUEL PERCENT % % – 25 125 – 25 125

21 GSP GAS SUPPLY PRESS PSIG Kpa – 12.5 62.5 – 12.5 62.5

22 VAC1 AIR FILTER 1 PSIG Kpa – 12.5 62.5 – 12.5 62.5

23 MAP1 ENG MAN PRESS

1

PSIG Kpa 20 62.5 20 62.5

24 MAT1 ENG MAN TEMP1 °F °C 01472 01472

25 EGT1 ENG EXH TEMP 1 °F °C 01472 01472

26 VIB1 ENG VIBRATION 1 IPS MPS – 0.5 2.50 – 0.5 2.50

27 KW PERCENT % % – 25 125 – 25 125

* ROP not used with GPN1000-12

DE Terminal Program Configuration Defaults

Device/Units: DE-1510 Controller (English)

No. of Vibration Sensors: 1

With Dynamic Control System: Yes

GPN1000 OM 11-12 GTI Operating Manual for In-line Engines

All rights reserved © ALTRONIC, LLC 2011

19

PANEL APPLICATION CHART: SERIES 25-A, 50-A, 65-A, 65-B:

SERIES 25-A 50-A, 65-A 65-B

Panel GPN1000-12 GPN1000 GPN1000

Panel Accessory Kit GPA0005-10 GPA0005-20 GPA0001-30

PANEL ACCESSORY KIT: SERIES 25-A, 50-A, 65-A, 65-B:

PANEL ACCESSORY KIT GPA0005-10 GPA0005-20 GPA0001-30

Engine Harness PART NO. 693128-1 693140-1 6 9 3119 -1

FUNCTIONS MAP1 MAP1 MAP1

VAC1 VAC1 VAC1

EGT1 EGT1 EGT1

MAT1 MAT1 MAT1

VIB+, VIB1 VIB+, VIB1 VIB+, VIB1

KW KW KW

Fuel Harness Assembly PART NO. 693126-1 693139-1 69 3124-1

FUNCTIONS GSP GSP GSP

ROP* ROP* ROP*

SOL+, SOL− SOL+, SOL− SOL+, SOL−

Power Harness Assembly PART NO. 693127-1 693138-1 693125 -1

FUNCTIONS +, −, GND +, −, GND +, −, GND

691201-15 Transducer 1 - GSP 1 - GSP 1 - GSP

691201-50 Transducer 1 - MAP1 1 - MAP1 1 - MAP1

691206-50 Transducer 1 - VAC1 1 - VAC1 1 - VAC1

Vibration Monitoring Kit — — GPA0006-1

Filter Transducer Adapter 610879 610879 610879

1/4” Gasket 610880 610880 610880

Bushing, Strain Relief 610756 610756 610756

* ROP not used with GPN1000-12

GPN1000 OM 11-12 GTI Operating Manual for In-line Engines

All rights reserved © ALTRONIC, LLC 2011

20

FIG. 1 MOUNTING DIMENSIONS – GPN1000/GPN1000-12

GPN1000

Other manuals for GTI Bi-Fuel

1

Table of contents

Other Altronic Control System manuals