Altronic DE-4000 User manual

Installation Instructions

DE-4000 Configurable Safety Shutdown and Control System

Form DE-4000 II 1-19

This manual contains information on installing, wiring, and connecting to a DE-4000

Safety Shutdown and Control System in a hazardous or non-hazardous area. This manual

supplements the DE-4000 Safety Shutdown and Control System Operation and Configu-

ration manual form DE-4000 OCM.

DE-4000 II

All rights reserved © ALTRONIC, LLC 2019 2

THIS PAGE INTENTIONALLY BLANK

DE-4000 II

All rights reserved © ALTRONIC, LLC 2019 3

TABLE OF CONTENTS

1.0 GENERAL SAFETY AND WIRING PRECAUTIONS .........................................................4

2.0 OVERVIEW................................................................................................................5

3.0 HMI DISPLAY MODULE (691766-1) ...........................................................................6

4.0 CONTROLLER MODULE (691759-1) ..........................................................................7

5.0 TERMINAL MODULE (691760-1) ...............................................................................8

6.0 MOUNTING.............................................................................................................12

7.0 WIRING ..................................................................................................................13

8.0 HAZARDOUS AREA OPERATION...............................................................................17

9.0 CONNECTING VIA ETHERNET TO CONFIGURE THE DE-4000 ....................................18

10.0 LIST OF FIGURES ...................................................................................................19

DE-4000 II

All rights reserved © ALTRONIC, LLC 2019 4

1.0 GENERAL SAFETY AND WIRING PRECAUTIONS

Review the following safety precautions to avoid injury and prevent damage to

the DE-4000 System or any devices connected to it.

#USE ONLY AS SPECIFIED

To avoid potential hazards, install and use this system only as specified.

Only qualified personnel should perform installation, wiring, and configura-

tion procedures.

#CONNECT AND DISCONNECT PROPERLY

Caution – Do not connect or disconnect equipment, connectors, plugs, etc.,

unless power has been verified to be off.

#PROPERLY GROUND THE SYSTEM

The ground terminal on the Input Power connector of each module must be

connected to panel ground, which should be the same as engine ground. DO

NOT connect directly to common coil ground.

#SINGLE POINT SYSTEM GROUND

The power supply minus (-) terminal and the ground (GND) terminal are

common. GND must be connected to panel ground. Minus(-) must be con-

nected to power supply minus. Common point is the panel ground which

must be the same as engine ground.

#OBSERVE ALL TERMINAL RATINGS

To avoid damage to the system and personnel, observe all ratings and mark-

ings on the modules. Consult the individual sections of this manual for

further ratings information before making connections to the modules.

#MOUNTING/ENCLOSURE

The DE-4000 System must be mounted in a suitable enclosure.

#POWER AND POWER DISCONNECT

a) Power must be from a Class 2 power source with transient protection or

from a 24-volt battery system.

b) The power to the DE-4000 System must be installed in accordance with

the requirements of the National Electrical Code (US) and the Canadian

Electrical Code (Canada)

c) Over-current power protection is required for the DE-4000 System.

d) A separate disconnect for the DE-4000 System is required. An Altronic

Power Management Module (PMM), a fuse block, or circuit breaker,

must be used from the source power to the DE-4000 in the panel.

e) The power disconnect must be marked as the over-current and discon-

nect for the DE-4000 System.

DE-4000 II

All rights reserved © ALTRONIC, LLC 2019 5

2.0 OVERVIEW

2.1 The DE-4000 is a Control and Safety Shutdown system specifically designed

to protect, monitor and control critical rotating machinery such as engines or

motor-driven compressors, pumps and generators operating in normal, harsh,

and/or hazardous environments.

2.2 The system uses state-of-the-art microcontrollers and has a multi-level software

architecture. The Controller Module and Terminal Module run a real-time oper-

ating system to ensure that safety and control functions are reliable and deter-

ministic. The Controller Module also contains a System-On-Module (SOM) that

has an embedded web server and also a key-value datastore. The SOM module

offloads the user interface functionality and also the Modbus communication

to enable the Controller Module and Terminal Module to run real-time without

being affected by connected clients. The system is fully scalable/expandable,

allowing users to incorporate a single control system technology across a wide

range of applications — low, medium, and high-spec.

2.3 The base DE-4000 configuration offers 32 inputs that can be individually con-

figured for use with switch contacts, thermocouples or analog transducers. The

base system also contains 12 digital and 4 analog (4-20mA) outputs. A maxi-

mized DE-4000 system provides 160 configurable inputs, 44 digital and 20

analog outputs.

2.4 The Hardware Safety Connection (HSC) is available as a backup safety shut-

down channel to the communications shutdown. The HSC connects the Terminal

Modules to the Controller Module. It is independent hardware that is used as an

independent shutdown signal from any of the terminal modules. When activated

it triggers Discrete Output #1 (typically used as the fuel shutdown) on the Con-

troller Module, independent of the Controller Module’s microcontroller.

2.5 The system is Ethernet-based, including on-board web pages for system con-

figuration (eliminating the need for a separate terminal program), operation,

control applications, and remote monitoring. The intuitive system configuration

web page operates on a “fill-in-the-blanks” basis whereby the application is not

programmed, but configured. The operator selects the appropriate operating

parameters and setpoints for each input channel, defines the operation of the

digital and analog control outputs, configures the service meters, and estab-

lishes the frequency of system datalog sampling and recording.

2.6 A Human Machine Interface (HMI) Display Module is the user interface. The

system being Ethernet-based allows for several Ethernet-based electronic de-

vices to monitor and display information simultaneously. System data can simul-

taneously be displayed on a panel-mounted HMI, a laptop, a handheld display

such as a mobile phone or tablet, as well as remotely.

2.7 System Configuration files can be created via a laptop or the HMI Display Module,

saved and downloaded, as well as uploaded, to other DE-4000 Systems. This al-

lows for configuration portability for users operating several similar systems.

2.8 Data logs are taken at user-defined intervals and are a compilation of the ana-

log values being monitored by the DE, plus unit speed, status, and complete

information on the first fault that caused a system shutdown (identity, value,

date, time). Data log information is stored on a removable microSD card. Data

log information can be retrieved locally or remotely. An integral data analysis/

trending package that is included with the web interface can display and graph

this data for inspection and analysis.

2.9 The system has three main parts:

#HMI Display (Panel Mounted) (691766-1)

#Controller Module (691759-1)

#Terminal Module, 32 channel (691760-1)

These components are interconnected with CAT5e Ethernet cable assemblies

terminated on both ends with an RJ45 connector.

WARNING: Deviation from these

instructions may lead to improper

engine operation which could cause

personal injury to operators or other

nearby personnel.

WARNING: The control and safety

shutdown system must be configured

prior to use on the machine.

Reference the configuration manual

DE-4000 OCM for instructions

describing how to configure the

controller for the specific application.

Verify the configuration prior to

commisioning the machine.

DE-4000 II

All rights reserved © ALTRONIC, LLC 2019 6

Ethernet Cable, CAT5 0.3m (12") (693221-1)

Ethernet Cable, CAT5 1.0m (39") (693221-2)

Ethernet Cable, CAT5 2.0m (79") (693221-3)

2.10 System power requirement is 10-32VDC, 5 amps max.

2.11 Ambient temperature range:

Controller Module and Terminal Module: –40°C to +85°C (–40°F to +185°F)

HMI Display Module: –30°C to +80°C (–22°F to +176°F).

2.12 The DE-4000 System is CSA- and UL-certified for use in Class I, Division 2,

Groups C and D hazardous locations.

3.0 HMI DISPLAY MODULE (691766-1)

3.1 The HMI Display serves as the user interface for the DE-4000 System. It is a

panel-mounted 8" (diagonal), 1024 x 768 XGA, anti-glare/anti-reflective, 4:3

ratio, TFT LCD with PCAP (capacitive-touch) screen and LED backlight. The

front of the display is sealed to IP67 for tough outdoor environments. The dis-

play has a 1000nit max LED intensity with auto or manual backlight dimming.

3.2 The touchscreen HMI Display is web-based and serves as the “Interface” for

configuring the system, as well as the on-sight user display. The HMI commu-

nicates with the Controller Module via a standard CAT5e Ethernet patch cable.

The required Ethernet cable is terminated with an RJ45 connector on each end.

Industrial Ethernet cable assemblies are available from Altronic reference part

numbers 693221-x, “x” represents the length.

3.3 The Ethernet port on the HMI contains two LED indicators; yellow indicates Eth-

ernet activity, green indicates that a communication “link” has been established.

3.4 A 5-key front-mounted, sealed membrane keypad allows for standard, often-

used keys (STOP, RESET, START). The membrane keypad allows these common

keys to be accessible regardless if the screen is viewable. The STOP, RESET,

and START keys are hard-wired to the back of the Display Module. During in-

stallation, these keys are wired to the Controller Module. These connections,

external to the communications cable, allow for reliable hardware connections

independent of the Display Module operation. The remaining two keys are F1

and F2. These keys can be assigned to frequently used functions.

3.5 The HMI Display displays the DE-4000 System configuration and real-time sta-

tus. No programming or configuration data is stored in the HMI Display. All of

the data is communicated to and from—and stored in—non-volatile memory

on the Controller Module. The Controller Module memory retains the current

configuration during normal operation, after compressor shutdown and a system

power-down.

3.6 Front panel dimensions are 9" x 9". Screw mounting dimensions are 6" x 6". The

mounting hardware is 10-24 studs and nuts. The HMI Display is designed to be

mounted into the current Altronic DE Annunciator cutout. This allows for com-

patibility and ease of mounting to previous Altronic systems without the need to

enlarge the panel cutout. Please note, however, that, when retrofitting an older

DE-xxxx System Panel Mounted Display Module with the DE-4000 HMI Display

Module, an additional 2" on each side of the original cutout is required.

3.7 The backlight intensity on the HMI is auto-adjusted using a light sensor mount-

ed on the front of the HMI.

3.8 The front glass is made from high quality, damage resistant Gorilla Glass. The Go-

rilla Glass enables the HMI front to be exceptionally tough and damage resistant.

3.9 Input Power requirement to the HMI is 10-32 VDC, 0.8 amp typ. 2 amp max.

3.10 Operating temperature range is -30°C to +80°C (-22°F to 176°F)

3.11 The HMI also contains the following communication ports: RS485, CAN, USB

Host, and USB OTG. These ports are not currently used on the DE-4000 System.

DE-4000 II

All rights reserved © ALTRONIC, LLC 2019 7

4.0 CONTROLLER MODULE (691759-1)

4.1 The Controller Module is the hub of the system. It is the main controller interfacing

with up to five Terminal Modules, the HMI Display Module, and other systems. The

scalable and expandable nature of the DE-4000 allows it to be used on the simplest

safety-shutdown-oriented applications, on mid-range applications with minimal or

moderate auto-start or capacity control requirements, and on highly-complex units

where a significant number of points must be monitored and functions controlled

simultaneously. The Controller Module is designed to be rail mounted.

4.2 The system's communication protocol is Ethernet. The Controller Module con-

nects to the other modules via a standard CAT5e Ethernet patch cable. The

required Ethernet cable is terminated with a RJ45 connector on each end. In-

dustrial Ethernet Cable assemblies are available from Altronic reference part

numbers 693221-x, “x” represents the length. Available Ethernet ports are as

follows:

#5 – Ethernet ports reserved to connect up to 5 Terminal Modules

#1 – Ethernet port reserved to connect to the HMI Display

#1 – Ethernet port reserved to connect to an outside network

4.3 DISCRETE OUTPUTS

The Controller Module has four discrete outputs rated 52VDC, 1.2 amp max.

The discrete outputs provide a means of using the DE-4000 controller to in-

terface with other systems on the engine/motor and compressor. The discrete

outputs are typically used for on/off control of on-engine processes. Typical

applications are: Fuel Valve, Ignition Shutdown, Purge, and Crank Disconnect.

The discrete outputs can be configured for either shelf state (normally-open)

or failsafe (normally-closed) operation and have an LED indicator associated

with them. If a discrete output is configured for failsafe (energized for run), the

LED will be ON in the normal run condition and OFF for a fault condition. For

outputs that are configured for shelf state, the LED will be OFF for normal run

condition and turn ON for a fault condition. The four discrete outputs are opti-

cally isolated, bipolar solid-state switches which are isolated from power supply

minus and engine ground. These outputs can be wired as high-side or low-side

configurations. The Output Modules are in the open (de-energized) condition

when the unit is not powered.

4.4 DISCRETE INPUTS

There are three discrete inputs; STOP, RESET, START. These inputs can be con-

nected to the hardware keypad on the Altronic HMI Display Module. They also

can be connected to panel-mounted dry contact switches.

4.5 STATE INDICATING LEDS

There are four state-indicating LEDs: RUN state (green), TIMERS ACTIVE state

(yellow), ALARM state (orange), and STOP state (red).

4.6 RS485 PORTS

There are two RS485 serial ports. The RS485 1 port is used for Modbus slave

data, and the RS485 2 port is used for Modbus master data.

4.7 CAN PORT

One CAN port is available and it is marked CANH, and CANL

4.8 USB PORTS

The USB connectors are not to be used in a hazardous area. Assure area is safe

before connecting or disconnecting to the USB connectors.

4.9 INPUT POWER

Input power requirement is 10-32VDC, 0.8 amp typical, 2 amps max. Over-

current protection is provided with an easy to replace 5 amp automotive blade

fuse. The 12-24VDC power for the Controller Module is to be connected to the

INPUT POWER terminals marked (PWR+) and (PWR−); GND is to be grounded

to panel ground. A dual-color green/red diagnostic LED indicates the system

power status. Green indicates that input power is within the systems operating

voltage range. Red indicates that input power is out of the proper operating

range. Off indicates no—or very low—power.

DE-4000 II

All rights reserved © ALTRONIC, LLC 2019 8

4.10 OPERATING TEMPERATURE RANGE

The Controller Module has an operating temperature range of -40°C to +85°C

(-40°F to 185°F)

4.11 WiFi ANTENNA

Antenna cable connection

The WiFi antenna connector on the Controller Module is a 6.35 mm, 50 ohm,

jack style, threaded SMA type RF connector.

Qualified antenna types

The Wi-FI radio on the DE-4000 is designed to operate with a dipole-type an-

tenna having a maximum gain of 2.14 dBi. Antennas having a gain greater than

2.14 dBi are strictly prohibited for use with the Wi-Fi radio on the Controller.

The required antenna impedance is 50 ohms. Any antenna that is of the same

type and of equal or less directional gain as listed above can be used. To reduce

potential radio interference to other users, the antenna type and its gain should

be so chosen that the equivalent isotropically radiated power (e.i.r.p.) is not

more than that permitted for successful communication. Using an antenna of a

different type or gain more than 2.14 dBi is prohibited.

5.0 TERMINAL MODULE (691760-1)

5.1 The Terminal Module is the point of interface between the field sensor wiring

and the DE-4000 control system. All sensors enter the system through the

Terminal Module. Control outputs, both analog and digital, are driven from the

Terminal Module. The heart of the Terminal Module is a 32-bit microcontroller.

The operating system runs in real-time to ensure that safety and control func-

tions are reliable and deterministic.The interface to the Control Module is via the

Ethernet cable. A DE-4000 System can contain one, or up to five each, Terminal

Modules. Each Terminal Module has the following I/O:

#32 – input channels (individually configurable for use as NO/NC discrete

inputs, J or K thermocouple inputs, or as analog inputs (0-5V or 4-20mA)

#2 – speed inputs (0-10KHz)

#4 – analog outputs (4-20mA)

#8 – high-side or low-side discrete outputs (45V, 2 amp max)

#8 – 5V, 100mA supplies available to power field sensors

The DE-4000 operates with industry-standard voltage or current-amplified out-

put transducers in the range of 0 to 5VDC or 0 to 25mA

5.2 TERMINAL MODULE I/O POINT IDENTIFICATION

Up to five Terminal Boards can be used in a DE-4000 System. The system uses

a simple Terminal Module/Channel number assignment method that identifies

the Terminal Module and I/O point.

Each Terminal Module is assigned a number from 1 to 5 via the Board ID switch.

Inputs and Outputs for each Terminal Module follow the acronym for each chan-

nel shown on the Terminal Module label. The format is: Terminal Module Num-

ber, a colon, then the I/O point acronym.

Examples:

T2:IN7 = Terminal Module 2, Input 7

T1:AO2 = Terminal Module 1, Analog Output number 2

5.3 BOARD ID SWITCH

The Terminal Modules contain a rotary BOARD ID switch. The BOARD ID switch

is used to identify each Terminal Module connected to the DE-4000 System.

Since each Terminal Module operates identically to each other in the system,

the Board ID switch is used to differentiate each Terminal Module from the oth-

ers. Terminal Module 1 must be set to BOARD ID “1”. Terminal Module 2 must

be set to BOARD ID “2”, etc. Terminal Modules must be assigned in numerical

order starting at BOARD ID 1 to 5. Upon power-up the Controller Module sends

out a signal to “look” to see how many Terminal Modules are connected to the

system and that they each contain a unique ID.

DE-4000 II

All rights reserved © ALTRONIC, LLC 2019 9

Once each terminal module is assigned a “T” number using the board ID switch,

the assigned number can be written with a “Sharpie” marker on each Terminal

Module for identification reference. A white box near the board ID switch is

made available as shown at right.

5.4 INPUT CHANNELS

Each input can individually be configured for use as NO/NC discrete inputs, J

or K thermocouple inputs, or as analog inputs (0-5V or 4-20mA). Each input

contains a corresponding 4-position channel switch that must be set accordingly

for proper operation. Switches are turned ON by moving them to the “ON” posi-

tion (toward the connectors). Please see below for proper switch settings. For

reference, the black part of the switch indicates the "on" position. The analog

switch setting is OFF, OFF, OFF, ON.

The input channels contain overvoltage protection that helps prevent damage

from inadvertent field mis-wires. They also contain channel to channel isolation

to prevent one mis-wired channel from affecting other channels.

For analog sensors that require a +5 volt source, the Terminal Module can sup-

ply up to eight +5V sources of current up to 100mA each.

Please refer to figure 8 for Terminal Module Input Sensor wiring diagrams

N/O and N/C DISCRETE INPUTS

The Terminal Board inputs can accept standard normally-open and normally-

closed dry contacts. The wetting current for sensor detection is supplied inter-

nally by the Terminal Module.

#For a normally-open sensor input, place a shunt jumper between INx+ and

INx- and connect the wire from the sensor to the INx+ input. The other wire

from the N/O sensor is grounded to cause a fault.

#For a normally-closed sensor input, connect one wire from the sensor to

INx+, the other on INx-. The sensor is closed for normal operation and opens

upon a fault.

5.5 J or K THERMOCOUPLE INPUTS

Each Terminal Module can accept industry-standard type J or K thermocouples

on inputs 01–32. Automatic cold junction compensation and linearity correc-

tion are built-in. The units can be configured for °F, °C, or °K. Both high and

low setpoints are associated with each channel. The system can read type J

thermocouples between -76°F and +1382°F (-60°C and +750°C) and type K

thermocouples between -76°F and +1472°F (-60°C and +800°C). For both J and

K type thermocouples the red insulation color is (-), the other color is the (+).

5.6 INPUTS – PRESSURE TRANSDUCERS

The pressure transducers, Altronic P/N 691201-x and P/N 691204-x, are pack-

aged in a rugged sealed case with an NPT pressure port, a corrosion resistant

media cavity, and a Packard Electric Metri-Pack connector. The ranges available

are 0-100, 300, 500, 1000, 2000, and 5000 PSIG for the 691201-x series

and 0-50,100, 300, 500 PSIA for the 691204-x series, all of which have an

overload rating of 1.5 times full scale without damage. The three wires from the

transducer are: +5 volt excitation, +0.5 to 4.5 volt output, and minus return.

These three wires connect directly to the Terminal Module using cable assembly

P/N 693008-x.

IN1+

IN1-

IN2+

IN2-

IN3+

IN3-

IN4+

IN4-

IN5+

IN5-

IN6+

IN6-

IN7+

IN7-

IN8+

IN8-

IN9+

IN9-

IN10+

IN10-

IN11+

IN11-

IN12+

IN12-

IN13+

IN13-

IN14+

IN14-

IN15+

IN15-

IN16+

IN16-

IN17+

IN17-

IN18+

IN18-

IN19+

IN19-

IN20+

IN20-

IN21+

IN21-

IN22+

IN22-

IN23+

IN23-

IN24+

IN24-

IN25+

IN25-

IN26+

IN26-

IN27+

IN27-

IN28+

IN28-

IN29+

IN29-

IN30+

IN30-

IN31+

IN31-

IN32+

IN32-

CONFIGURABLE INPUTS

+5V

+5V

+5V

+5V

+5V

+5V

+5V

+5V

AO1+

AO1-

AO2+

AO2-

AO3+

AO3-

AO4+

AO4-

XDUCER SUPPLY

400mA MAX TOTAL

4-20mA ANALOG

OUTPUTS

DO1+

DO1-

DO2+

DO2-

DO3+

DO3-

DO4+

DO4-

DO5+

DO5-

DO6+

DO6-

DO7+

DO7-

DO8+

DO8-

40VDC 2.0 A

MAX.EACH

RPM2+

RPM2-

CANH

CANL

NC

HSC

RPM1+

RPM1-

RS485A

RS485B

SHIELD

RX

PWR+

PWR-

GND

INPUT

POWER

10-32VDC

2 A MAX.

CLASS 2

FUSE (5A)

LINK/ACT

100

P/N 691760 S/N

MUST BE INSTALLED PER FORM DE-4000 II

INSTALLE CONFORMEMENT FORM DE-4000 II

INPUTS ARE NONINCENDIVE WHEN INSTALLED

PER FORM DE-4000 II

OPERATING TEMP RANGE -40°C TO 85°C

DE-4000 TERMINAL MODULE

ANALOG

DEG 1, 2 DIGITAL

NO/NC 4-20MA

THERMO

J OR K

EACH SWITCH MUST BE SET

FOR PROPER OPERATION

TX HSC

BOARD ID

CERTIFIED

CLASS I, DIV.2

GROUPS C&D,T3C T:

WARNING - EXPLOSION HAZARD - DO NOT REPLACE FUSE OR

DISCONNECT CONNECTORS UNLESS POWER HAS BEEN SWITCHED

OFF OR THE AREA IS KNOWN TO BE NON-HAZARDOUS.

AVERTISSEMENT - RISQUE D’EXPLOSION - COUPER LE COURANT OU

S’ASSURER QUE L’EMPLACEMENT EST DÉSIGNÉ NON DANGEREUX AVANT

DE REPLACER CONNECTEURS DE FUSIBLE OU DE DECONNEXION.

IN1+

IN1-

IN2+

IN2-

IN3+

IN3-

IN4+

IN4-

IN5+

IN5-

IN6+

IN6-

IN7+

IN7-

IN8+

IN8-

IN9+

IN9-

IN10+

IN10-

IN11+

IN11-

IN12+

IN12-

IN13+

IN13-

IN14+

IN14-

IN15+

IN15-

IN16+

IN16-

IN17+

IN17-

IN18+

IN18-

IN19+

IN19-

IN20+

IN20-

IN21+

IN21-

IN22+

IN22-

IN23+

IN23-

IN24+

IN24-

IN25+

IN25-

IN26+

IN26-

IN27+

IN27-

IN28+

IN28-

IN29+

IN29-

IN30+

IN30-

IN31+

IN31-

IN32+

IN32-

CONFIGURABLE INPUTS

+5V

+5V

+5V

+5V

+5V

+5V

+5V

+5V

AO1+

AO1-

AO2+

AO2-

AO3+

AO3-

AO4+

AO4-

XDUCER SUPPLY

400mA MAX TOTAL

4-20mA ANALOG

OUTPUTS

DO1+

DO1-

DO2+

DO2-

DO3+

DO3-

DO4+

DO4-

DO5+

DO5-

DO6+

DO6-

DO7+

DO7-

DO8+

DO8-

40VDC 2.0 A

MAX.EACH

RPM2+

RPM2-

CANH

CANL

NC

HSC

RPM1+

RPM1-

RS485A

RS485B

SHIELD

RX

PWR+

PWR-

GND

INPUT

POWER

10-32VDC

2 A MAX.

CLASS 2

FUSE (5A)

LINK/ACT

100

P/N 691760 S/N

MUST BE INSTALLED PER FORM DE-4000 II

INSTALLE CONFORMEMENT FORM DE-4000 II

INPUTS ARE NONINCENDIVE WHEN INSTALLED

PER FORM DE-4000 II

OPERATING TEMP RANGE -40°C TO 85°C

DE-4000 TERMINAL MODULE

ANALOG

DEG 1, 2 DIGITAL

NO/NC 4-20MA

THERMO

J OR K

EACH SWITCH MUST BE SET

FOR PROPER OPERATION

TX HSC

BOARD ID

CERTIFIED

CLASS I, DIV.2

GROUPS C&D,T3C T:

WARNING - EXPLOSION HAZARD - DO NOT REPLACE FUSE OR

DISCONNECT CONNECTORS UNLESS POWER HAS BEEN SWITCHED

OFF OR THE AREA IS KNOWN TO BE NON-HAZARDOUS.

AVERTISSEMENT - RISQUE D’EXPLOSION - COUPER LE COURANT OU

S’ASSURER QUE L’EMPLACEMENT EST DÉSIGNÉ NON DANGEREUX AVANT

DE REPLACER CONNECTEURS DE FUSIBLE OU DE DECONNEXION.

DE-4000 II

All rights reserved © ALTRONIC, LLC 2019 10

5.7 TEMPERATURE TRANSDUCER

Temperature transducers, Altronic P/N 691202-300, 691203-300, and

691212-450, 691212-450 are packaged in a sealed, stainless steel housing

with a 5/8"-18 UNF threaded body and a Packard Electric Metri-Pack connector.

Temperature transducers 691203/202-300 have a temperature measurement

range of +5 to 300°F. Temperature transducers 691212/213-450 have a tem-

perature range of -40 to +450°F. During configuration, the 691202/203-300

transducers are selected as Deg1 Type; the 691212/213-450 transducers are

selected by choosing Deg2 Type. The three wires from the transducers are: +5

volt excitation, temperature output voltage, and minus return. These wires con-

nect directly to the Terminal Module using cable assembly P/N 693008-x.

5.8 INPUTS – DIFFERENTIAL MEASUREMENTS

Differential pressures or temperatures may be measured by using two consecu-

tive channels. The transducers used to measure differential values must be

of the exact same type and range. The first channel of the pair displays the

basic parameter it is monitoring and the second channel of the pair displays

the numeric difference in engineering units of its value subtracted from the first

channel’s value. Setpoints for each channel monitor the displayed value of that

channel. The second channel setpoints monitor the differential value.

5.9 4-20mA INPUTS

The Terminal Module can accept 4-20mA inputs by selecting the internally-con-

nected 200-ohm resistors (via the channel DIP switch), creating a termination

voltage of 0.8 to 4.0 volts. The shunt jumper wire between the + and – terminals

for that channel must be connected for proper 4-20mA operation.

5.10 +5V TRANSDUCER SUPPLY

For convenience there are eight total 5V supplies rated at 100mA each for the

purpose of supplying 5 volts DC to transducers. The 5V supplies are protected

from shorts and reverse connection. The 5V supply contains a unique low for-

ward voltage transistor that allows the output to be a tighter tolerance and to

survive shorts and field mis-wires.

5.11 SPEED INPUTS

Each Terminal Module contains two speed inputs. Each speed input can be

configured independently from the other. Examples of monitored speed inputs

are engine RPM and turbo speed RPM.

Typical speed signals can come from magnetic pickups or Hall effect pickups

monitoring the engine flywheel or other rotating gears. The monitored gear can

be of some ratio to the speed of interest (the speed configuration page is used

to select a ratio of gear teeth to speed of interest). The frequency range of the

speed input is 0 to 100KHz. Nominal input voltage levels are 5 to 24 volts. Each

speed input is protected from mis-wires of up to 200 volts max.

The RPMx- terminals are common to DC-. Connect the speed input to the ter-

minals marked RPMx+ and RPMx-. Altronic magnetic pickups or Hall effect

pickups are typical sources for RPM measurement.

#MAGNETIC PICKUP — Connect the two wires from the 691118 series or

similar magnetic pickup to the Module at terminals RPMx+ and RPMx- using

cable assembly 693104 series.

#HALL EFFECT PICKUP — Connect the three wires from the 791050 series

Hall effect pickup to the module at terminals RPMx+, RPMx-, and a +5 volt

source using cable assembly 593050 series. Connect pickup cable wire B to

a +5V supply, wire A to terminal RPMx+ (plus), and wire C to terminal RPMx-

(minus). In addition, a 10,000-ohm pull-up resistor must be placed across

the +5V supply to GT of the monitor. Refer to the wiring diagrams for hookup

details.

5.12 ANALOG OUTPUTS

Each Terminal Module provides four 4-20mA analog outputs. The analog out-

puts can be used for interfacing to actuators, I/P Transducers, governors, and

other control hardware. These 4-20mA outputs are typically used to implement

control strategies. For further information on typical control strategies, refer to

DE-4000 II

All rights reserved © ALTRONIC, LLC 2019 11

the DE-4000 Operation and Configuration Manual. Connect terminal AOx+ ter-

minal to the plus (+) input, and the AOx- terminal to the (-) input of the device

being controlled.

5.13 DISCRETE OUTPUTS

Each Terminal Module provides eight discrete outputs. DO1 through DO8 are

fault protected, ground isolated, solid state switches that turn on from DOx+ to

DOx-. Each discrete output is rated at 60V, 2A max. They are solid state smart

switches with diagnostics (over current, over temp protection) and can be wired

for high- or low-side operation. Dual LED indicators, one for each output, green

indicates the output is energized, red indicates a fault condition. If an overload

occurs, the red LED will illuminate indicating a fault condition. When the fault

condition is removed, the switch will return to its normal operating condition.

5.14 HARDWARE SAFETY CONNECTION

The Hardware Safety Connection on the Terminal Module, when connected to

the Controller Module, acts as an independent shutdown signal from any terminal

module to the Controller Module. The DE-4000 System relies heavily on Commu-

nications over Ethernet for proper operation. If communications are interrupted,

the Hardware Safety Connection provides the system a parallel path for shutdown.

The Hardware Safety Connection is a separate independent connection to activate

output DS1 on the Control Module, typically the fuel valve shutdown. If there is

an interruption in communication, and the Terminal Module determines that a

shutdown needs to take place, the fuel valve output located on the Controller

Module, DS1, will activate, removing fuel to the engine and thus shutting it down

independent of the normal operation of the Controller Module.

5.15 RS485 PORT

The RS485 serial port on the Terminal Module is marked RS485 A, RS485B,

and SHIELD and is unused at this time.

5.16 CAN PORT

The CAN port on the Terminal Module is marked CANH, and CANL, and SHIELD

and is unused at this time.

5.17 INPUT POWER REQUIREMENT

Input power requirement is 10-32VDC, 0.8 amp typical, 2 amps max. Over-cur-

rent protection is provided with an easy-to-replace 5 amp automotive blade fuse.

The 12-24VDC power for the Controller Module is connected to the INPUT POW-

ER terminals marked (PWR+) and (PWR−); GND is grounded to panel ground.

A LED lights green when proper power is applied to the Terminal Module. A red

power LED indicates that the applied supply voltage is out of tolerance.

5.18 OPERATING TEMPERATURE RANGE

The Terminal Module has an operating temperature range of -40°C to +85°C

(-40°F to 185°F)

DE-4000 II

All rights reserved © ALTRONIC, LLC 2019 12

6.0 MOUNTING

6.1 When the DE-4000 System is installed in a Class I, Division 2 hazardous area,

it must be mounted in a suitable enclosure.

6.2 HMI DISPLAY MODULE

The HMI Display Module is designed to be mounted on the front insert of the

Control Panel. In retrofit applications, the HMI Display Module can be inserted

in the current Altronic DE Annunciator cutout without modifications. This allows

for compatibility and ease of mounting in place of previous Altronic systems

without the need to enlarge the panel cutout. Please note, however, that, when

retrofitting an older DE-xxxx System panel-mounted Display Module with the

DE-4000 HMI Display Module, an additional 2" on each side of the original

cutout is required. Front panel dimensions are 9" x 9". Screw mounting dimen-

sions are 6" x 6". The mounting hardware is M5 x 0.8 threads. Mount the Display

Module inside a control panel or to a suitable flat surface so that the display is

at a convenient viewing height. A drilling template and mounting dimensions are

provided.

6.3 CONTROLLER MODULE

Mount the Controller Module on the inner panel plate or to the side of the main

panel. The Controller Module is designed to be rail-mounted onto commercially-

available 32 or 35mm DIN mounting rails. Two end brackets, P/N 604199,

should be used to keep the module from sliding off the ends of the mounting

rail. Controller Module dimensions are 10" x 5" x 2.37".

6.4 TERMINAL MODULE

Mount the Terminal Module on the inner panel plate or to the side of the main

panel. The Terminal Module is designed to be rail-mounted onto commercially

available 32 or 35mm DIN mounting rails. Two end brackets, P/N 604199,

should be used to keep the module from sliding off the ends of the mounting

rail. Terminal Module dimensions are 10" x 5" x 2.37". Terminal Modules can

be mounted in a separate enclosure as long as the enclosure meets the require-

ments of the area.

6.5 PRESSURE TRANSDUCER

Mount the pressure transducer in the panel or in a manifold or tube off of the

engine. Do not expose the pressure transducer to temperatures above 221°F

(105°C).

6.6 TEMPERATURE TRANSDUCER

Mount the temperature transducer in a thermowell on the engine or machine.

The actual sensor is located at the bottom of the transducer body. To ensure

accuracy, the tip of the probe should be surrounded by the measured media.

6.7 WiFi ANTENNA

Mount the WiFi antenna outside of the enclosure. Attach the coax cable to the

SMA connector.

NOTE: Avoid mounting the HMI

Display Module with the LCD display

facing direct sunlight. The display

operating temperature range is

−30°C to +80°C (−22°F to +176°F).

IMPORTANT: Pressure transducers

will withstand overloads as high

as 1.5 times rated pressure. If the

overload rating is exceeded, failure

may occur. Pressure fluctuations

occur in most reciprocating systems;

pick the transducer with a rating

high enough to prevent overload

by peak pressures of pulsations. It

is recommended that a pressure

snubber be used which will reduce

the peak pressure applied to the

transducer. The life of the transducer

will be extended with the use of a

snubber or pulsation dampener.

IMPORTANT: Do not exceed the

absolute maximum rating of the

transducers, 350°F (176°C) for the

691202/203-300 or 450°F (232°C)

for the 691212/213-450. Care

should be taken to protect the wiring

and connectors from contact with

hot surfaces.

DE-4000 II

All rights reserved © ALTRONIC, LLC 2019 13

7.0 WIRING (See wiring diagrams)

7.1 SYSTEM MODULE CONNECTIONS

The Controller Module is the hub of the system. Ethernet cables connect the

Controller Module to the other modules via standard industrial-type CAT5e

Ethernet patch cables. The required Ethernet cable is terminated with a RJ45

connector on each end. Industrial Ethernet Cable assemblies are available

from Altronic, reference part numbers 693221-x, “x” represents the length.

Ethernet Cable assemblies, terminated both end with RJ45 jacks.

#693221-1 Ethernet Cable, CAT5 0.3m (12")

#693221-2 Ethernet Cable, CAT5 1.0m (39")

#693221-3 Ethernet Cable, CAT5 2m (79")

Available Ethernet ports are as follows:

#5 – Ethernet ports reserved to connect to up to 5 Terminal Modules

#1 – Ethernet port reserved to connect to the HMI Display

#1 – Ethernet port reserved to connect to an outside network

7.2 TERMINAL BLOCK WIRING

Pluggable Connectors with push-in spring-cage (PIT) connections are used

for the input/output wiring on each module. The terminating wire, or wire with

ferrule, can be inserted into the connector without the need of a tool. Fine

gauge wire can also be used without a ferrule but will require using the push-in

opening lever on the connector. To remove the wire, use a tool and press the

opening lever “in” to release the wire.

7.3 POWER WIRING

The DE-4000 System uses distributed wiring. Each module has its own power

input terminals. Using a fuse block in series with the source power, connect

the wires to the 10-32VDC INPUT POWER terminals on each module, positive

to terminal (PWR+) and negative to terminal (PWR-); system power require-

ment is nominal 12 to 24VDC (5 amps max.). The GND terminal must be con-

nected to panel ground which should be the same as engine ground. PWR- and

GND are internally tied.

Normally-open sensors most often use the engine ground as the minus return

path. For normally-open sensors to operate properly, engine ground, panel

ground, and power supply minus MUST be at the same potential as PWR- and

GND wires on the Terminal Module.

DO NOT ground this device directly to the ignition system common coil ground.

7.4 Hardware Safety Connection (HSC)

The Hardware Safety Connection on the Terminal Module, when connected

to the Controller Module, acts as an independent shutdown signal from any

terminal module to the Controller Module.

Connect the Hardware Safety Connection (HSC) from each Terminal Modules’

(HSC) terminal to the Controller Module HDW SAFETY (HSC) terminal. This is

a low voltage 5VDC signal.

7.5 INPUT SENSOR WIRING

Each Terminal Module contains up to 32 sensor inputs. The sensor wire leads

connect to the pluggable terminal blocks on the Terminal Module. The input

terminal numbers correspond to the HMI display channel numbers, which also

have a user assigned 30-character label associated with them. The sensor

inputs are numbered (IN1+, IN1-) to (IN32+, IN32-). When configuring the I/O

for multiple Terminal Modules, the board number is shown first, then the chan-

nel number separated by a colon. For example, channel 15 on terminal board

1 is shown as: T1:IN15.

All unused inputs on the Terminal Module must have a shunt jumper in place.

Each input has a 4-position mechanical switch located on the Terminal Module

that must be switched to the proper position for the sensor type being used.

NOTE: The power pluggable

connector accepts wire in the range

of 24 to 12 AWG. A ferrule with a

nominal length of 12mm (0.47")

is recommended. Each connector

point contains a built-in test point

of 1mm (.04") diameter or 1.2 mm

(.047") diameter for troubleshooting

purposes.

NOTE: The signal connectors

accept solid or fine-stranded wire

(with ferrule) in the range of 24

to 16 AWG. Recommended strip

length of the remaining bare wire

is 9mm (.35"). A ferrule with a

nominal length of 12mm (0.47") is

recommended. Each connector

point contains a built-in test point

of 1mm (.04") diameter or 1.2 mm

(.047") diameter for troubleshooting

purposes.

DE-4000 II

All rights reserved © ALTRONIC, LLC 2019 14

7.5.1 DISCRETE SENSOR INPUT WIRING

#Normally-open (N/O) sensor switches are wired with one wire to the IN+

terminal of the respective sensor number and the other to engine ground

which should be the same as power minus (−). A shunt jumper must be

connected from the (INx+) terminal to the (INx-) terminal for normally-open

sensors. (See wiring diagrams).

#Normally-closed (N/C) sensor switches are wired with one wire to the (INx+)

terminal and the other to the (IN-) terminal of the respective sensor num-

ber. Note that the shunt jumper must be removed.

Use a wire size between 16 AWG (max.) and 24 AWG (min.) to connect

the sensor switches to the terminal strip connector. Strip the insulation

back 3/8"; twist the exposed wires tightly together. Insert the exposed wire

completely into the terminal strip. For wires that are fine and flexible, crimp

on a ferrule. Wires running to sensor switches must be in good condition

or replaced with new wires. When running wires, take care not to damage

the insulation and take precautions against later damage from vibration,

abrasion, or liquids in conduits. An explosion-proof conduit is not required,

however, wires should be protected from damage by running them in a pro-

tective conduit or in sheaths where appropriate. In addition, it is essential

that the following practices be adhered to:

A. Never run sensor wires in the same conduit with ignition wiring or

other high energy wiring such as the AC line power.

B. Keep secondary wires to spark plugs and other high voltage wiring at

least eight inches (200mm) away from sensor and sensor wiring.

C. Sensor switches may be connected to any passive device using con-

tacts such as standard switch gauges, pressure or level switches. DO

NOT connect sensor leads to any voltage producing element.

D. In the case of a field conversion, where sensors have previously been

used with Murphy tattletales, it is recommended that the sensors be

checked frequently when the DE System is first put into use. Sensor

contacts may be burned or pitted from past exposure to ignition

system primary voltage. It is advisable to replace such sensors.

E. If it becomes necessary to check sensor switch to panel wiring with

an ohmmeter or other checker, first DISCONNECT the plug-in terminal

strips from the Terminal Module. Applying voltage to the DE-4000

System through the sensor leads may damage the device. The area

should be tested as non-hazardous before such testing commences.

7.5.2 ANALOG SENSOR WIRING

For each analog monitored point, inputs 01–32 on each Terminal Module, se-

lect a transducer, either an Altronic pressure or temperature transducer listed

above, or one that outputs a signal in the range of 0 to 5 VDC or 0 to 25 mA.

Mount as described above. Use cable assembly 693008-x or similar to wire

transducer to the Terminal Module. The Terminal Module provides eight each

connector terminals to power the Altronic transducers. Max combined current

is 400 mA. See wiring diagrams. If the 5 volt sensor supply exits the panel, it

must be fused with a 0.5 ampere fuse. If 24VDC powered sensors are used,

the 24 volt supply to them must be fused appropriately. Take care not to dam-

age the insulation when installing and take precautions against later damage

from vibration, abrasion, or liquids in conduits. In addition, it is essential that

the following practices be adhered to:

A. Never run sensor wires in the same conduit with ignition wiring or

other high energy wiring such as AC line power.

B. Keep secondary wires to spark plugs and other high voltage wiring at

least eight inches (200mm) away from sensor and sensor wiring.

7.5.3 THERMOCOUPLES AND THERMOCOUPLE EXTENSION WIRE

Grounded or ungrounded type J or K thermocouples may be used. Use

thermocouple extension wire of the same type as the thermocouple probe to

connect to the terminal module. Use stranded thermocouple wire having a

moisture-resistant insulation such as PVC. For higher ambient temperatures,

DE-4000 II

All rights reserved © ALTRONIC, LLC 2019 15

Teflon or B-fibre insulated thermocouple wire is recommended. To ensure that

an accurate signal is transmitted to the device, avoid any added junctions,

splices and contact with other metals. On unused channels, leave the shunt

jumper supplied with the system in place. Take care not to damage the insula-

tion when installing and take precautions against later damage from vibration,

abrasion, or liquids in conduits. In addition, it is essential that the following

practices be adhered to:

A. Never run sensor wires in the same conduit with ignition wiring or

other high energy wiring such as AC line power.

B. Keep secondary wires to spark plugs and other high voltage wiring at

least eight inches (200mm) away from sensor and sensor wiring.

7.6 LUBE/NO-FLOW SENSOR

Terminal Module inputs may optionally be used for a lube/no-flow proximity

cycle switch. Wire the sensor according to section 7.5.1. The sensor may be

wired as either N/O or N/C with a jumper. The DIP switches on the Terminal

Module must be set as an analog configuration. The lube/no-flow channels

generate a fault when the time between pulses exceeds the programmed run

pulse time.

7.7 TERMINAL MODULE OUTPUT SWITCH WIRING

Each Terminal Module provides eight discrete outputs, DO1 through DO8.

These switches are fault protected, ground isolated, solid-state switches that

turn on from DOx+ to DOx-. Each discrete output is rated at 60V, 2A max.

These outputs can be wired as high-side or low-side switches. For wiring ex-

amples, refer to Figure 10.

7.8 RPM/SPEED WIRING

Typical speed signals can come from magnetic pickups or Hall effect pickups

monitoring the engine flywheel or other rotating gears. Each speed input is

protected from mis-wires of up to 200 volts max.

The RPMx- terminals are common to DC-. Connect the speed input to the

terminals marked RPMx+ and RPMx-. Altronic magnetic pickups or Hall effect

pickups are typical sources for RPM measurement.

#MAGNETIC PICKUP – Connect the two wires from the 691118 series or

similar magnetic pickup to the module at terminals RPMx+ and RPMx- us-

ing cable assembly 693104 series.

#HALL EFFECT PICKUP – Connect the three wires from the 791050 series

Hall effect pickup to the module at terminals RPMx+, RPMx-, and a +5 volt

source using cable assembly 593050 series. Connect pickup cable wire B

to a +5V supply, wire A to terminal RPMx+ (plus), and wire C to terminal

RPMx- (minus). In addition, a 10,000-ohm pull-up resistor must be placed

across the +5V supply to GT of the monitor. Refer to the wiring diagrams for

hookup details.

7.9 CONTROLLER MODULE DISCRETE INPUTS:

The three discrete inputs—STOP, RESET, START—can be connected to

terminals 7–10 on the back of the HMI Display Module 691766-1. This allows

for a hardware connection from the STOP, RESET, and START keys on the HMI

keypad to the Controller Module. Wire each connection from the Controller

Module to the Display Module as follows:

#STOP (+) to STOP (terminal 7)

#RESET (+) to RESET (terminal 8)

#START (+) to START (terminal 9)

#STOP (-) to MINUS(-) (terminal 10)

The STOP, RESET, and START inputs on the Controller Module can also be

connected to normally-open, momentary panel-mounted dry contact switches.

Please note that these inputs are internally pulled high to 3.3VDC and are

activated when switched to (-).

NOTE: One minus (-) connection

only is required from the Controller

Module to the Display Module; all

(-) connections on the Controller

Module are common.

DE-4000 II

All rights reserved © ALTRONIC, LLC 2019 16

7.10 CONTROLLER MODULE OUTPUT SWITCH WIRING

The Controller Module has four discrete outputs rated 52VDC, 1.2 amp max.

The discrete outputs are typically used for on/off control of on-engine pro-

cesses. Typical applications are: Fuel Valve, Ignition Shutdown, Purge, and

Crank Disconnect. The discrete outputs can be configured for either shelf

state (normally-open) or failsafe (normally-closed) operation and have an LED

indicator associated with them. If a discrete output is configured for failsafe

(energized for run), the LED will be ON in the normal run condition and OFF

for a fault condition. For outputs that are configured for shelf state the LED

will be OFF for normal run condition and turn ON for a fault condition. The

four discrete outputs are optically isolated, bipolar solid-state switches which

are isolated from power supply minus and engine ground. These outputs can

be wired as high-side or low-side configurations. The output switches will be in

the open (de-energized) condition when the unit is not powered.

DSO1 – FUEL SHUTOFF: Typical use of Output 1 on the Controller Module

is for fuel shutoff. Output 1 can be used to control a 12-24 volt fuel

valve either as energized to run or pulsed to shut off.

DO NOT attempt to control a C.D.-powered fuel valve directly with any

of the DSOx output switches. The C.D. ignition system exceeds the

max operating voltage of the output switch. An interposing relay and

a Murphy Panel Board Adapter must be used when the Fuel Valve is a

C.D. ignition-type Murphy Fuel Valve.

DS02 – IGNITION SHUTDOWN: Typical use of Output 2 on the Controller

Module is for Ignition Shutdown. Output 2 can be used in conjunction

with the low voltage shutdown on most Altronic ignition systems. In

addition DSO2 can be used to control the source power to the ignition

system using a Power Management Module.

DO NOT attempt to directly ground-out (stop) a C.D. ignition system

with output DSO2. The C.D. ignition system shutdown lead exceeds

the max operating voltage of output switch DSO2. An interposing relay

with high current contacts must be used when grounding the shut-

down lead on a C.D. ignition system.

DO NOT connect directly to the ignition system common coil ground.

DSO3 – CRANK DISCONNECT: Typical use of Output 3 on the Control-

ler Module is for crank disconnect. When auto start is configured,

digital output 3 is used for crank disconnect. If the voltage or current

requirement of the crank disconnect solenoid is greater than 52VDC or

1.2 amp, wire DS03 to a pilot duty relay.

DSO4 – PRELUBE/POST LUBE: Typical use of Output 4 on the Controller

Module is for prelube/post lube. If the voltage or current requirement

of the prelube/post lube solenoid is greater than 52VDC or 1.2 amp,

wire DS04 to a pilot duty relay.

7.11 RS-485 COMMUNICATIONS WIRING

There are two RS-485 communication ports available on the Controller Module:

RS485 1 port is used for Modbus slave data

RS485 2 is used for Modbus master data.

The DE-4000 System can communicate to other instruments, PC’s or PLC’s

via the two serial RS-485 communication wires. Use a two-conductor

shielded cable of fine gauge stranded wire and connect the wires

to the terminals marked RS-485A, RS-485B, and shield. Make the following

connections to the other communication device A to A(-) and B to

B(+). If required, connect the shield wire to the master device only.

7.12 CAN COMMUNICATIONS WIRING

The CAN port on the Terminal Module is marked CANH, and CANL.

DE-4000 II

All rights reserved © ALTRONIC, LLC 2019 17

8.0 HAZARDOUS AREA OPERATION

8.1 The DE-4000 Series Configurable Safety Shutdown and Control System is CSA

(C/US) – certified for Class I, Division 2, Groups C and D areas or non-hazardous

locations.

#The HMI Display Module is CSA certified (C/US) with an ambient tempera-

ture range of -30°C to 80°C (-22°F to 176°F) temperature code T4

#The Controller Module is CSA certified (C/US) with an ambient temperature

range of -40°C to 85°C (-40°F to 185°F) temperature code T4

#The Terminal Module is CSA certified (C/US) with an ambient temperature

range of -40°C to 85°C (-40°F to 185°F) temperature code T3C

The DE-4000 System must be installed in a suitable enclosure.

The following requirements must also be met (refer to NFPA standard no. 493):

#The low voltage sensor switch wires within the panel enclosure must be kept

at least two (2) inches away from other wiring. Run the sensor switch wires

leaving the panel in a separate conduit from all other wiring and keep them

separate throughout the installation.

#Wiring to the sensors must have a grade of insulation capable of withstanding

an AC voltage of 500 volts RMS.

#Sensor wires must be run in separate conduits and junction boxes from high

voltage wires such as ignition, fuel valve, and other high voltage wiring.

8.2 The power for the DE-4000 System must be from a Class 2 power source with

transient protection or from a 24-volt battery system.

The DE-4000 System must be installed in accordance with the requirements of

the National Electrical Code (US) and the Canadian Electrical Code (Canada)

8.3 WARNINGS

#WARNING – EXPLOSION HAZARD – Substitution of components may impair

intrinsic safety and/or suitability for Class 1, Div. 2, Groups C and D.

#AVERTISSEMENT – RISQUE D’EXPLOSION – La substitution de composants eu-

trendre ce materiel inacceptable pour les emplacements de Classe I, Division 2.

#WARNING – EXPLOSION HAZARD – Do not disconnect equipment in Div.

2 environment unless power is switched off or the area is known to be non-

hazardous.

#AVERTISSEMENT – RISQUE D’EXPLOSION – Avant de deconnecter l’equipement,

couper le courant ou s’assurer que l’emplacement est designe non.

#Warning – EXPLOSION HAZARD - Do not use USB connectors in hazardous area.

#AVERTISSEMENT – RISQUE D’EXPLOSION – Ne pas utiliser les connecteurs

USB en zone dangereuse.

8.4 When the DE-4000 System is installed in hazardous area, it shall be installed

in a suitable enclosure which provides an ingress protection minimum level of

IP54 (splash protected).

8.5 The inputs are rated non-incendive:

#Terminal Module – when the inputs are configured as:

• “Discrete” or “Digital” inputs must be connected to passive switches only.

• When configured as thermocouple, inputs must be connected to thermo-

couples only.

• When connected as an analog input, inputs must not exceed 5VDC.

• When connected as 4-20mA, inputs must not exceed 24mA.

#RPM inputs – when connected to Altronic 691118-x magnetic pickup or

Altronic 791050-x Hall Effect pickup. Both pickups are CSA approved as

non-incendive outputs.

#Controller Module Discrete Inputs –when connected to dry contacts.

WARNING: Substitution of

components may impair intrinsic

safety and/or suitability for Class

I, Div. 2, Groups C and D. Do

not disconnect equipment in Div.

2 environment unless power is

switched off or the area is known to

be non-hazardous.

DE-4000 II

All rights reserved © ALTRONIC, LLC 2019 18

8.6 WiFi Antenna – Coaxial cable leaving the system enclosure shall be routed in

conduit or be protected by another approved Division 2 wiring method. The an-

tenna itself shall be located in a non-hazardous area, or shall not have exposed

bare metal elements.

9.0 CONNECTING VIA ETHERNET TO CONFIGURE THE DE-4000

9.1 Each DE-4000 System requires configuration prior to use. The DE-4000 is a

web-enabled smart device. Configuration of the DE-4000 is through the web

interface. Unlike previous DE products, there is no stand-alone "Terminal Pro-

gram". A standard laptop computer with a hard-wired ethernet connection and

a web browser is required for configuration. A CAT5 or CAT6 cable, terminated

with a standard RJ45 connector on both ends, is required. Ethernet Cable,

CAT5 1.0m (39") (693221-2) is a suitable cable available from Altronic.

A network connection is required to connect the laptop PC to the DE-4000.

This can be accomplished in one of two ways, a temporary change to the TCP/

IP configuration of the existing network adapter on your laptop PC, or to create

a separate private network using a second network adapter to build a private

network. The necessary steps to accomplish this vary with your operating

system. Temporarily changing the TCP/IP configuration of the existing network

adapter is outlined below for Microsoft®Windows-based computers. The laptop

PC must have at least one Network Interface Card (NIC) installed.

#IP Address 98.102.65.174 is the default IP address for the DE-4000 System.

#The IP address of your laptop PC network interface must be set to an ad-

dress of 98.102.65.x, where x is any integer from 1 to 254, excluding the

range of 160-174.

#The IP address on your laptop PC must be set to static. The PC is typically

configured to obtain an IP address dynamically; if so, you will usually have

no control over its address and will have to set it to static.

Follow the procedure below for Microsoft®Windows 7 operating system:

1. From the Microsoft®Windows 7 desktop, click on the Windows Button in

the lower left-hand corner and then click on Control Panel.

2. Click on Network and Sharing Center.

3. Click on Local Area Connection.

4. Click on the Properties button.

5. Click on the Internet Protocol Version 4 (TCP/IPv4) item and click on the

Properties button.

6. Click on the Use the following IP address: option.

7. Change the IP address to 98.102.65.xxx (for example 98.102.65.115).

8. Change the Subnet Mask to 255.255.255.0.

9. Click OK.

10. Click OK on the Local Area Connection Properties screen.

11. Click Close on the Local Area Connection Status screen.

For further information, please refer to the document How to Establish an Ether-

net Connection to a PLC+ Module on the Altronic website www.altronic-llc.com.

#A web browser on the laptop PC is used to communicate to the DE-4000

System. Preferred browsers are Google®Chrome and Firefox.

#Open the web browser and type in the IP address (98.102.65.174). The DE-

4000 configuration page will be loaded.

DE-4000 II

All rights reserved © ALTRONIC, LLC 2019 19

10.0 LIST OF FIGURES

FIG 1 SYSTEM DIAGRAM AND GENERAL HOOKUP

FIG 2 POWER DISTRIBUTION AND HARDWARE SAFETY DIAGRAM

FIG 3 SYSTEM CONFIGURATION CONNECTION, CONTROLLER MODULE

FIG 4 HMI DISPLAY MODULE, DIMENSIONS AND SPECIFICATIONS

FIG 5A CONTROLLER MODULE, DIMENSIONS

FIG 5B CONTROLLER MODULE, SPECIFICATIONS

FIG 6A TERMINAL MODULE, DIMENSIONS

FIG 6B TERMINAL MODULE, SPECIFICATIONS

FIG 7 WIRING DIAGRAM – CONTROLLER, POWER AND OUTPUTS

FIG 8 WIRING DIAGRAM – CONTROLLER, INPUTS AND COMMUNICATIONS

FIG 9 WIRING DIAGRAM – TERMINAL, SENSOR AND TRANSDUCERS INPUTS

FIG 10 WIRING DIAGRAM – TERMINAL, DIGITAL OUTPUTS

FIG 11 WIRING DIAGRAM – TERMINAL, CURRENT LOOP OUTPUTS

FIG 12 WIRING DIAGRAM – TERMINAL, RPM INPUT

DE-4000 II

All rights reserved © ALTRONIC, LLC 2019 20

FIG 1 SYSTEM DIAGRAM AND GENERAL HOOKUP

DISPLAY

MODULE

CONTROLLER

MODULE

PLC+

MODULE

WIFI

ANTENNA

TERMINAL I/O

MODULE

(LOCAL)

SK2205

11-14-17

WTP

TERMINAL I/O

MODULE

(LOCAL)

TERMINAL I/O

MODULE

(REMOTE)

FIG. 1 - SYSTEM DIAGRAM AND GENERAL HOOKUP

PC, SCADA

INTRANET,

INTERNET

TABLET OR

SMART PHONE

NOTES:

SYSTEM MODULES ARE INTERCONNECTED

1.

WITH CAT5e ETHERNET CABLE ASSEMBLIES.

Other manuals for DE-4000

2

Table of contents

Other Altronic Control System manuals

Popular Control System manuals by other brands

Riftek

Riftek RF096-35/55-100 Series user manual

Gecko

Gecko Aeware Swim spa solution Tech book

Inovance

Inovance NICE9000-V Series user guide

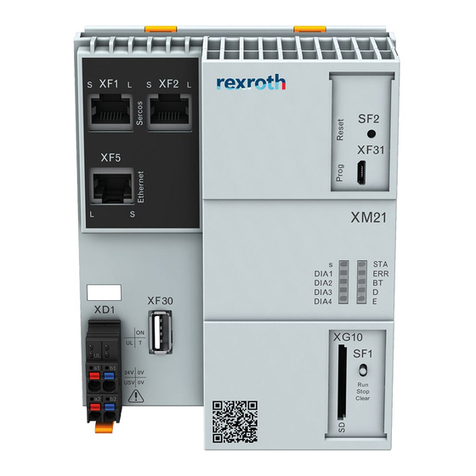

Bosch

Bosch Rexroth IndraControl XM21 operating instructions

Minitech

Minitech Mini-Mill Series user guide

Mitsubishi Electric

Mitsubishi Electric MELDAS 60 Series Programming manual