Altronic VariSpark CPU-XL User manual

Operating Instructions

CPU-XL VariSpark Digital Ignition System with Enhanced Display

Form CPU-XL VariSpark IOM 07-21

CPU-XL VariSpark IOM 07-21

All rights reserved © ALTRONIC, LLC 2021 2

1.0 OVERVIEW

1.1 The Altronic CPU-XL VariSpark Digital Ignition with enhanced display is a DC-

powered, microprocessor-based, capacitor discharge system applicable to slow

and medium speed, stationary, natural gas-fueled engines. It features crankshaft-

triggered timing accuracy and the capability to vary timing electronically by

several means, including an external 4-20mA control signal. This system is field-

programmable and oers a variety of advanced control, emissions reduction,

primary and spark diagnostic, self-diagnostic, serial communications and engine

protection features.

2.0 COMPONENTS

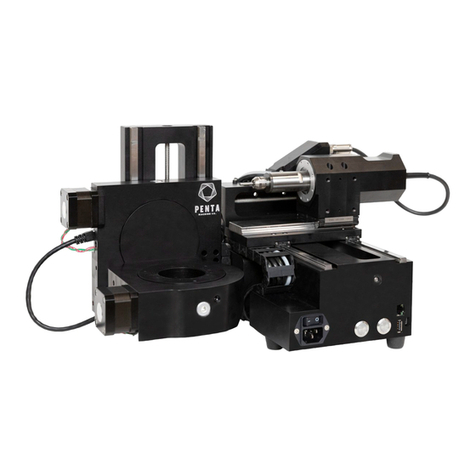

2.1 The system consists of a Logic/Display Module, a Junction/Diagnostic Module,

up to two Output Modules, up to four EZRails, two magnetic pickups and cables,

a Hall-eect pickup and trigger magnet (4-cycle engines only), appropriate

cables and harnesses, and an ignition coil for each spark plug. For a total system

overview, refer to Figure 1.

2.2 Logic/Display Module (291400-1) – Typically mounted in the engine control

panel, the Logic/Display Module has a graphical, color, backlight LCD display

showing the operating status, engine RPM, energy level, spark profile in use,

current loop input value and ignition timing. Additional display screens show

set-up and diagnostic information. Its menu structure is similar to those of the

CPU-2000 and CPU-95 systems.

2.3 Output Module(s) (291410-1)– Connected by harness to the Junction/Diagnostic

Module, an Output Module is installed on each bank of the engine. This device

generates the high voltage DC power and distributes this energy to the ignition

coil rails. Two modules are required to run V-type engines with one module

generating firings for each bank. Each Output Module can drive 10 separate

outputs and each output can be used to drive one coil or two coils for engines

having two spark plugs per cylinder.

2.4 Junction/Diagnostic Module (291405-2) – The Junction/Diagnostic Module

replaces the traditional on-engine junction box and serves several purposes. The

Junction/Diagnostic Module wiring is used to determine which cylinder is fired for

each output event of the Logic/Display Module. The CPU-XL ignition fires in the

same order as all other Altronic digital ignition systems. The first firing event is the

one following the reset. The firing events are brought out in order of occurrence

(1, 2, 3, 4…) on the 20-position terminal strip inside the Junction/Diagnostic

Module.

2.5 Ignition Coil/EZRail Module(s) – The CPU-XL VariSpark ignition coils and primary

wiring are integrated into a series of engine-specific EZRail modules. These

coil/rail modules are connected by harness to the Output Module and deliver a

factory-certified and tested mounting and on-engine wiring solution. Primary

cables and associated connectors are eliminated in the high current portion of the

system, thereby enhancing reliability.

2.6 Harnesses (all connectors sealed with epoxy potting)

Logic/Display Module to Junction/Diagnostic Module – 293030-L, one straight

17-pin connector.

Junction/Diagnostic Module to Output Module – 793101-L, one straight and one

right-angle 19-pin connector or 793102-L, two right-angle 19-pin connectors.

Output Module to EZRail Assembly – 793102-L, two right-angle 19-pin connectors (max. 48").

2.7 To allow for a simple and economical upgrade of existing Altronic CPU-2000

installations, the CPU-XL utilizes existing CPU-2000 magnetic pickups, Hall-eect

pickup and trigger magnet, pickup cables, and inter-module wiring harnesses.

2.8 Power requirement is 24Vdc, 30 amperes.

NOTE: All new installations must use

the 291405-2 Junction/Diagnostic

Module and the 791401-2 Coil.

The -1 versions of these parts are for

replacement application only.

WARNING: Deviation from these

instructions may lead to improper

engine operation which could cause

personal injury to operators or other

nearby personnel.

The ignition system must be

configured prior to use on an

engine. Refer to section 19.9 To

view the current configuration.

Reference form CPU-XL VariSpark

PI for instructions describing how

to configure the ignition system.

Verify eeprom programming prior to

starting engine.

CPU-XL VariSpark IOM 07-21

All rights reserved © ALTRONIC, LLC 2021 3

3.0 MOUNTING THE LOGIC/DISPLAY MODULE

3.1 The CPU-XL Logic/Display Module is preferably panel-mounted o the engine in such

a manner as to minimize exposure to vibration. Refer to Figure 2 for dimensions.

3.2 The Logic/Display Module should be mounted within 50 feet (15m) of the

Junction/Diagnostic Module.

3.3 Operating temperature range is -40°F to 158°F (-40°C to 70°C). Humidity

specification is 0-95%, non-condensing. Housed in a NEMA 4 enclosure, the

CPU-XL Logic/Display Module is splash resistant; however, the mounting site

should provide as much protection from inclement weather as is practical. Avoid

mounting the LCD display and keypad in direct sunlight.

4.0 MOUNTING THE OUTPUT MODULES

4.1 Refer to Figure 3 for physical dimension details. Select a mounting location meeting

the following requirements:

n On the engine, within 50 ft. (15m) of the Logic/Display Module.

n Within 15 ft. (4.5m) of the Junction/Diagnostic Module.

n Within 6 ft. (1.8m) of the ignition rails.

n The maximum ambient temperature must not exceed °F (°C).

4.2 The Output Module enclosure should be fastened securely to a rigid engine

bracket using the shock mounts provided.

5.0 MOUNTING THE JUNCTION/DIAGNOSTIC

MODULE

5.1 Refer to Figure 4 for physical dimension details. Select a mounting location

meeting the following requirements:

n Within 20 ft. (6m) of the Output Modules.

n The front panel door of the Junction/Diagnostic Module should be easily

accessible and free to swing open.

n The maximum ambient temperature must not exceed °F (°C).

5.2 The Junction/Diagnostic Module enclosure should be fastened securely to a rigid

engine bracket using the shock mounts provided.

6.0 MOUNTING FLYWHEEL GEAR/DRILLING FLYWHEEL

HOLES

6.1 The Altronic CPU-XL system requires a source of angular position pulses from the

engine crankshaft. This can be a flywheel ring gear, a separately provided gear or

specially drilled holes in the flywheel. The source of position pulses must meet the

following requirements:

n Must be ferrous material, diameter of 18" or greater.

n No. of teeth or holes must be 180 or greater.

n Maximum run-out referenced to the pickup of .007". Refer to Figures 5

and 6 for further details.

7.0 MOUNTING THE MAGNETIC PICKUPS

7.1 The system requires two magnetic pickup signals: the angular position pulses from

the gear or drilled holes and a reset pulse near the most advanced firing position

desired for no. 1 cylinder. The pickups must be mounted to rigid brackets to

maintain an air gap of .015" ± .005" with respect to the rotating gear or flywheel. It

is also important for maximum signal eciency that the centerline of the rotating

part pass through the center of the pickup. See Figure 5.

CPU-XL VariSpark IOM 07-21

All rights reserved © ALTRONIC, LLC 2021 4

8.0 MOUNTING THE FLYWHEEL RESET PIN

8.1 Set the engine with no. 1 cylinder six (6) degrees ahead of the most advanced

firing point. Mark a point on the flywheel directly opposite the pole piece of the

reset magnetic pickup; then rotate the engine to a position convenient for drilling

and tapping the flywheel at the point marked above. The reset pin should be

made from a steel (magnetic) 1/4"-20 bolt or stud. See Figure 5.

8.2 Rotate the engine to the original set point and adjust the air gap between the end

of the reset pin and the magnetic pickup at .010" using a feeler gauge.

9.0 MOUNTING THE CYCLE TRIGGER (4-cycle engine only)

9.1 The trigger magnet (260604, 260605 or 720002) must be mounted on the engine

camshaft or other accessory drive operating at camshaft speed. An M8 (8mm)

tapped hole, 0.5 inches (13mm) deep is required. See Figures 7, 8 or 9 for details.

The magnet MUST rotate on a diameter NOT EXCEEDING:

n 6 inches (152mm) for magnet 720002, or

n 15 inches (381mm) for magnet 260604 or 260605.

n Maximum run-out referenced to the pickup of .007”

9.2 Set the engine on the COMPRESSION stroke of no. 1 cylinder with the reset pin

DIRECTLY OPPOSITE the reset pickup. The Hall-eect pickup (591014-x) must

be mounted DIRECTLY OPPOSITE the trigger magnet coincident with the reset

pickup and pin being lined-up.

10.0

LOGIC/DISPLAY MODULE ELECTRICAL HOOK-UP

10.1

The power connections to the CPU-XL must be in accordance with the National

Electrical Code or other applicable country code. The CPU-XL is suitable for

installation in Class I, Division 2, Group D locations.

10.2

The Logic/Display Module must have its own 24Vdc power connection. Although

the device has internal protective fuses (3 amp), an external fuse near the power

source is recommended.

10.3

Power wiring and signal wiring must be in separate conduits and conduit entries into the

Logic/Display Module to avoid undesired electrical interaction. All conduit entries are

sized for a 1/2"-14 NPT male conduit fittin g. Separate as follows (refer to Figure 11):

n RIGHT CONDUIT ENTRY Power wiring and cable −xx to

Diagnostic Module

n CENTER CONDUIT ENTRY Magnetic pickups and Hall-eect pickup

n LEFT CONDUIT ENTRY Control inputs, serial communications, and

alarm outputs

10.4

RIGHT ENTRY: Input power supply wires (16 AWG minimum) should enter the

right conduit entry and connect to the 24Vdc supply terminals of the terminal

block. The interface cable 293030-xx, connecting the Logic/Display Module with

the Junction/Diagnostic Module, also enters through the right conduit entry. Refer

to Figures 11 and 12 for connection details.

10.5

CENTER ENTRY: Run a separate conduit for the two (2) magnetic pickup cable

assemblies. These should enter through the center entry in the Logic/Display

Module box and terminate as shown in Figure 11.

4-CYCLE ENGINE ONLY: The cable from the Hall-eect pickup also enters

through the center entry and connects as shown.

10.6

LEFT ENTRY: A separate conduit must be used to the left-hand entry for all

connections to the user interface terminal strips in the Logic/Display Module. Use

24 AWG, UL style 1015 wire or shielded cable for these connections; the 24 AWG

wire is available from Altronic under part no. 603102 (black) or 603103 (white).

A. SHUTDOWN INPUT (terminal 4): Use to stop the ignition for engine shutdown.

This input is open for normal operation of the system and is connected to

engine ground to inhibit ignition firings. NOTE: This is a 5-volt low level signal.

NOTE: The Hall-eect signal and

the reset pickup signal must occur

at the same time for the system to

function.

The Hall-eect pickup dimensions

are shown in Figure 10. The air gap

between the Hall-eect pickup and

trigger magnet must not exceed

.040" (1.0mm).

CPU-XL VariSpark IOM 07-21

All rights reserved © ALTRONIC, LLC 2021 5

B. ALARM OUT (terminal 5), SHUTDOWN OUT (terminal 6), FIRE CONFIRM OUT

(terminal 7): Three output switches are available for monitoring ignition system

status. Each output consists of a solid state switch normally closed to a single

common rail COMMON OUT (terminal 8). The switches are rated

75mA @ 100Vdc. These output switches are electrically isolated from all other

terminals. The recommended hook-up is shown in Figure 11.

C. 4-20mA TIMING CONTROL INPUT: The 4-20mA timing control loop connects

to terminals 9(+) and 10(–). This input is electrically isolated from all other

terminals; refer to Figures 11 and 15.

D. MISC INPUT (terminal 11): Provides for control of various user-selected

features. This input is normally open; connect to engine ground to activate the

selected feature (see Figure 11). NOTE: This is a 5-volt low-level signal.

E: 4-20mA SPARK NUMBER CONTROL INPUT: The 4-20mA spark number

control loop connects to terminals 3(-) and 4(+) of the 2nd (rear) terminal strip.

This input is electrically isolated from all other terminals.

F: SPARK NUMBER OVERRIDE (rear terminal 1): Provides a user-configurable

override of the current selected spark profile number. This input is normally

open; connect to engine ground to activate the selected feature. NOTE: This is

a 5-volt low-level signal.

G: RS-485: The terminals: 5(GND), 6(–), and 7(+) provide an RS-485 port for

external control VIA PC or PLC.

CPU-XL VariSpark IOM 07-21

All rights reserved © ALTRONIC, LLC 2021 6

11.0

OUTPUT MODULE ELECTRICAL HOOK-UP

11.1

All required connections to the CPU-XL Output Module are made through

harnesses using multi-pin, threaded connectors.

11.2

BOTTOM 19-PIN CONNECTOR: The bottom 19-pin of the Output Module

connects to the Junction/Diag Module by means of harness series 793101-L or

793102-L. Insert the connector into the bottom Output Module receptacle and

hand-tighten; then carefully tighten an additional one-sixth turn with a wrench.

11.3

SIDE 19-PIN CONNECTORS: The 19-pin connectors “A on left” and “B on right”

are output connections to the EZRails by means of harness series 793102-L.

11.4

7-PIN CONNECTOR: The 7-pin connector is reserved for future development and is

not presently utilized. A sealed connector cap should be in place over this connector.

12.0

JUNCTION/DIAGNOSTIC MODULE ELECTRICAL

HOOK-UP

12.1

All required external connections to the CPU-XL Junction/Diagnostic Module are made

via harnesses using multi-pin, threaded connectors.

12.2

17-PIN CONNECTOR: Connection to the 17-Pin receptacle of the Junction/

Diagnostic Module is made using harness 293030-L, which has been properly

terminated inside the Logic/Display Module as described in section 10.0

12.3

19-PIN CONNECTORS: The 19-Pin connectors of the Junction/Diagnostic Module

mate to harnesses 793101-L or 793102-L coming from the Output Modules. Take

care that the harnesses route the proper signals to the appropriate bank (Output

Module) according to the application diagram developed for the installation on your

engine. Insert the connector into the receptacle and hand-tighten, then carefully

tighten an additional one-sixth turn with a wrench.

12.4

The firing order of the engine, as well as the cylinder identification (1, 2, 3…or 1L,

1R, 2L…or other), should be recorded on the chart in Figure 1.

12.5

After the correct firing order is identified by cylinder, and the cylinders have

been labeled, the specific ignition rail, which will be used to fire the coils for each

cylinder, can be identified. Each rail connects to one connector of an Output

Module using the harness provided.

12.6

The Junction/Diagnostic Module wiring is is used to determine which cylinder

is fired for each output event of the Logic/Display Module. The CPU-XL ignition

always fires in the same order as all other Altronic digital systems. The first firing

event is the one following the reset. The firing events are brought out in order of

occurrence (1, 2, 3, 4…) on the 20-position terminal strip inside the Junction/

Diagnostic Module. With the Junction/Diagnostic Module mounted with the

20-position terminal strip horizontal, and above the two vertical 10-position

output strips and connectors, the firing events are in order from left to right, going

from the first to the twentieth firing.

12.7

Wiring the Junction/Diagnostic Module internal jumpers to match the specific firing

order of the engine. As with a traditional ignition system such as the CPU-2000, the

igniton outputs must be matched to the proper cylinders according to the firing order

of the engine. This is done inside the Junction/Diagnostic Module using logic level

20AWG, 503128 jumper wires connected between the pluggable terminal blocks.

12.8

Inside the Junction/Diagnostic Module, two vertical, 10-position, terminal strips

are used to connect to the Output Modules via the 79310x-L cables. Each

10-position vertical strip is used to connect to one Output Module, which, in turn,

connects to the two ignition rails on a single bank of the engine. The upper five

terminals go to one rail through one connector of the Output Module and the lower

five terminals go to the other rail mounted on the same bank and connected to the

other connector of the same Output Module. This is more easily understood if the

entire ignition system is viewed as four separate systems, each of which can fire 1

to 5 cylinders with single or dual coils. Each Output Module contains two separate,

five-cylinder ignitions, and each one of these connects to a single rail. Single spark

plug per cylinder engine applications use engine rails having a maximum of five

coils per rail. Dual spark plug applications can have a maximum of ten coils per rail.

All applications service a maximum of five cylinders per rail.

CPU-XL VariSpark IOM 07-21

All rights reserved © ALTRONIC, LLC 2021 7

Point-to-point connections of the system.

Junction Terminal ID

on Label inside

Junction/Diagnostic

Module

Cable to

Output

Module

Output Module

Harness to EZRail

Connector Pin

Cyl. Position, counting

from end away from 19-pin

connector

Rail

Designator

Rail 1 Terminal 1 Out 1 Pin A Connector a Pin A 1 Far end of engine

Rail 1 Terminal 2 Out 1 Pin B Connector a Pin B 2

Rail 1 Terminal 3 Out 1 Pin C Connector a Pin C 3

Rail 1 Terminal 4 Out 1 Pin D Connector a Pin D 4

Rail 1 Terminal 5 Out 1 Pin E Connector a Pin E 5

Junction

Terminal ID

on Label

Cable to

Output

Module Wire

Output Module

Harness to EZRail

Connector Pin

Rail Position, counting

from end away from 19-pin

connector

Rail

Designator

Rail 2 Terminal 6 Out 1 Pin F Connector b Pin E 5

Rail 2 Terminal 7 Out 1 Pin G Connector b Pin D 4

Rail 2 Terminal 8 Out 1 Pin H Connector b Pin C 3

Rail 2 Terminal 9 Out 1 Pin J Connector b Pin B 2

Rail 2 Terminal 10 Out 1 Pin K Connector b Pin A 1 Far end of engine

Junction

Terminal ID

on Label

Cable to

Output

Module Wire

Output Module

Harness to EZRail

Connector Pin

Rail Position, counting

from end away from 19-pin

connector

Rail

Designator

Rail 4 Terminal 1 Out 2 Pin K Connector b Pin A 1 Far end of engine

Rail 4 Terminal 2 Out 2 Pin J Connector b Pin B 2

Rail 4 Terminal 3 Out 2 Pin H Connector b Pin C 3

Rail 4 Terminal 4 Out 2 Pin G Connector b Pin D 4

Rail 4 Terminal 5 Out 2 Pin F Connector b Pin E 5

Junction

Terminal ID

on Label

Cable to

Output

Module Wire

Output Module

Harness to EZRail

Connector Pin

Rail Position, counting

from end away from 19-pin

connector

Rail

Designator

Rail 3 Terminal 6 Out 2 Pin E Connector a Pin E 5

Rail 3 Terminal 7 Out 2 Pin D Connector a Pin D 4

Rail 3 Terminal 8 Out 2 Pin C Connector a Pin C 3

Rail 3 Terminal 9 Out 2 Pin B Connector a Pin B 2

Rail 3 Terminal 10 Out 2 Pin A Connector a Pin A 1 Far end of engine

(1)

(2) (3)

(4)

CPU-XL VariSpark IOM 07-21

All rights reserved © ALTRONIC, LLC 2021 8

13.0

DC POWER HOOKUP: 293030-XX CABLE

13.1

The power connections to the CPU-XL must be in accordance with the National

Electrical Code or other applicable country code. The CPU-XL is suitable for

installation in Class I, Division 2, Group D locations.

13.2

It is necessary to split the control cable and power leads of the 293030 cable in an

engine-mounted Junction/Diagnostic Module or conduit tee. This box should be

separate from the main Junction/Diagnostic Module used to terminate the output

harness(es) to the ignition coils. Refer to Figure 12.

13.3

The CPU-XL system can be powered in one of the following ways:

A. 24 volt battery with charger.

B. DC power supply capable of furnishing 24-28Vdc at currents up to 30

amperes.

IMPORTANT: For proper operation of the CPU-XL system, voltage and current

supplied must be sucient during all selected modes of operation. Figure 14

provides these details regarding the DC power hook-up:

1. CURRENT DRAW PER SYSTEM – formula varies depending on number of

outputs used, engine cycle and RPM, and spark number used.

2. MINIMUM WIRE GAUGE REQUIREMENTS – Chart 1 of Figure 16

gives the requirement vs. the length of run between the power source and

the CPU-XL Junction/Diagnostic Module.

3. MULTIPLE ENGINE INSTALLATIONS – It is recommended that each

engine be supplied by a dedicated power supply capable of up to 30

amperes of 24 volt DC power. If a large, uninterruptible, bussed supply is

available it can be used for multiple engines, but each igniton should be

wired back to the supply main independently of the other ignitions.

14.0

PRIMARY WIRING

14.1

There is no traditional primary wiring required for the use of the CPU-XL ignition

system. All of the necessary primary wiring is supplied pre-configured inside the

flexible conduit harnesses and the ignition rails.

15.0

SECONDARY WIRING

15.1

Mount the ignition rails as close as possible to the engine spark plugs consistent with

a secure mounting and avoidance of temperatures in excess of 185°F (85°C).

15.2

The spark plug leads should be fabricated from silicone insulated 7mm cable with

suitable terminals and silicone spark plug boots. The use of leads with resistor spark

plug boots (Altronic series 59320x-xx) is recommended to minimize interference from

emitted RFI on the operation of other nearby electronic equipment. Another option

is the use of suppression ignition cables. It is also essential to keep spark plug leads

as short as possible and in all cases not longer than 24 inches (600mm). Spark plug

leads should be kept at least 2 inches (50mm) away from any grounded engine part.

In deep spark plug wells, use rigid insulated extenders projecting out of the well.

15.3

The use of a clear, silicone grease (such as Dow Corning DC-4, G.E. G-623 or GC

Electronics ZS) is recommended for all high-tension connections and boots. This

material helps seal out moisture and prevent corrosion from atmospheric sources.

NOTE: The negative (-) of the 24Vdc

supply MUST BE COMMON WITH

ENGINE GROUND. Engines using

positive ground DC accessories

or starter motors will require a

separate dedicated power supply.

WARNING: Although the device has

internal protective fuses (3 AMP

in the Logic/Display Module, and

15 AMP in the Junction/Diagnostic

Module), two external 20 amp

fuses near the power source are

recommended for the protection

of engine and building wiring. This

will reduce the possibility of a fire

occurring in the event of a short

circuit in the wiring. See Figure 16.

CPU-XL VariSpark IOM 07-21

All rights reserved © ALTRONIC, LLC 2021 9

16.0

INPUT/OUTPUT WIRING

16.1

To shut-o the DC-powered CPU-XL system, a special input (SHUTDOWN INPUT

terminal 4) in the Logic/Display Module is provided. This input is open for normal

operation and is connected to engine ground to initiate an ignition shutdown. Use a

switch rated 24Vdc, 0.5 amps. Refer to section 10.6 A, and Figure 11 for details.

16.2

The Logic/Display Module includes two isolated current loop inputs. The first can

be configured to control spark timing. Reference the programming instructions,

form CPU-XL VariSpark PI. See Figure 11 for Terminal Block ID.

16.3

The second current loop input can be configured to control the spark number.

Reference the programming instructions, form CPU-XL VariSpark PI. See Figure

11 for Terminal Block ID.

16.4

Two digital inputs are provided inside the ignition system. These logic-level inputs

are active when shorted to ground. The first, MISC. INPUT, controls one-step

retard, and the second, SPK OVERRIDE, controls the spark override number. See

Figure 11 for Terminal Block ID.

17.0

COMMUNICATIONS

17.1

The Logic/Display Module incorporates a half-duplex RS-485 port which is

Modbus RTU slave compliant. The protocol used follows the Modicon Modbus

RTU standard. A PC (personal computer) or a PLC (programmable logic controller)

can be connected to the RS-485 port to perform remote monitoring or control

functions. This port is also used to configure the ignition system for its application

using a PC and the CPU-XL VariSpark PC terminal software. For a complete list of

the Modbus register addresses, see section 32.0. The CPU-XL VariSpark terminal

program CD contains a PC-based Modbus compatible monitoring program which

can be used to access the ignition data remotely.

17. 2

Logic/Display Module: serves as the user interface for the CPU-XL VariSpark

ignition system. A proprietary CANBUS communications format is used to

connect the Logic/Display Module to the Junction/Diagnostic Module.

17. 3

An internal USB port can also be configured as another Modbus RTU interface.

18.0

DISPLAYS AND INDICATORS

18.1

A graphical, color-changing, back-lit, LCD display provides output to the user. A

sealed-membrane keypad accepts user input. The LCD display and the keypad

function together to provide an interactive user interface that prompts the user as

dierent functions are selected. The screen background color indicates status:

green indicates normal condition, yellow indicates a warning and remains until

a key is pressed, and red indicates a fault and remains until a key is pressed.

Pressing any key results in a white background which remains for 30 seconds.

18.2

All actions and adjustments are immediate and are performed on an incremental

basis using up and down arrow keys. All keypad adjustments, except individual

oset timing adjustments, are performed directly in non-volatile EEPROM

memory. This EEPROM memory retains previous settings even after an engine

shutdown, or an ignition power down.

18.3

Green LED indicators are provided inside the ignition unit for troubleshooting:

POWER LED: on to indicate that the unit has power and the microprocessor is

running. The Power LED is o to indicate that the unit has no power.

TX LED: flashes to indicate that the ignition unit is transmitting on the RS-485

serial link.

RX LED: flashes to indicate that the ignition unit is receiving on the RS-485

serial link.

ALARM LED: turns on to indicate that a warning or fault is present. The ALARM LED

flashes when an acknowledged warning is present.

CPU-XL VariSpark IOM 07-21

All rights reserved © ALTRONIC, LLC 2021 10

19.0

UNDERSTANDING THE HOME SCREEN

19.1

A series of home screens are used to describe the current status of the ignition

system. The LCD display always reverts back to one of the home screens after

a keypad operation is completed or times out. The home screen is designed to

display the most critical operating parameters on one screen.

19.2

The READY message is displayed when the ignition is ready for the engine to

crank for starting.

19.3

Once the engine begins turning, the SYNCING message is displayed while the

ignition system verifies signals from the engine pickups.

After the ignition system has synchronized with the engine, the system displays

TRYING. This message means that the system has begun firing.

19.4

The FIRING message is displayed after one channel of each Output Module has

fired at least once. When this is displayed, the fire-confirm signal is also closed.

Additional data is provided on this screen to describe the selected mode of

operation for the ignition. The spark mode (#1-8) is described beneath the status.

19.5

The STALLED message is displayed when a loss of rotation is detected after the

ignition is firing and neither a SHUTDOWN or FAULT has occurred. This signifies

that the engine has stopped without any detected cause from the ignition system.

CPU-XL VariSpark IOM 07-21

All rights reserved © ALTRONIC, LLC 2021 11

19.6

The WARNING message will supersede all of the above home screens if a

diagnostic warning condition is present. When a diagnostic warning exists, a

** Press DIAG ** message will appear on the display. The Ignition Module will

continue to operate under a warning condition while alerting the operator of a

potential problem in several ways: by turning on the Alarm LED in the Ignition

and by changing the state of the Alarm Out switch (switch opens), and changing

the screen background color to yellow. The Logic/Display Module will display the

WARNING message. The various types of diagnostic warnings are described in

section 25.6.

19.7

The FAULT message will supersede all of the above home screens if a diagnostic

fault condition is present. When a diagnostic fault exists, a ** Press DIAG **

message will appear on the display. The ignition system will stop operating under

a fault condition and will alert the operator to the problem in several ways: by

changing the state of the Fire Confirm Out switch (switch opens), by turning on

the alarm LED on the Logic/Display Module, by changing the state of the Alarm

Out switch (switch opens), and by displaying the Fault message and changing

the screen background color to red. The various types of diagnostic faults are

described in section 25.5.

CPU-XL VariSpark IOM 07-21

All rights reserved © ALTRONIC, LLC 2021 12

19.8

The SHUTDOWN screen will supersede all other home displays if the logic level

shutdown input of the Ignition Module. This screen indicates that the ignition

is not firing because a shutdown input was triggered to shutdown the engine. If

a diagnostic fault or warning exists while the ignition is in shutdown, a ** Press

DIAG ** message will appear on the display. The Fire Confirm Out switch will

change state (switch opens) and the other outputs will function as described

above based on the existence of faults or warnings.

19.9

From the HOME SCREEN, pressing the NEXT key allows you to cycle through the

configuration comments which describe the configuration of the ignition system.

AT

PRESS TO

GO TO

NEXT

NEXT

The configuration screens are shown starting on the next page.

CPU-XL VariSpark IOM 07-21

All rights reserved © ALTRONIC, LLC 2021 13

The following types of screens can be viewed by pressing NEXT to advance.

FIRING PATTERN CODE: (JB.HC)

SPECIAL FEATURE CODE: (#)

( STEP DEFAULT)

IGNITION MODULE TYPE: ( P A R T

NUMBER)

NEXT

LOCATION:

USER SPECIFIED DESCRIPTION

NEXT

DATE CONFIGURED: (−−)

TIME CONFIGURED: (:)

CONFIGURED BY: (HD)

TERMINAL VERSION #: (v.)

NEXT

CURRENT LOOP CURVE DESCRIPTION

AT mA ° RETARD

AT mA ° RETARD

USER SPECIFIED DESCRIPTION

NEXT

RPM RETARD CURVE DESCRIPTION

YES⁄NO Status

RPM RANGE Retard Range

⁄ ⁄ ret

NEXT

CPU-XL VariSpark IOM 07-21

All rights reserved © ALTRONIC, LLC 2021 14

ENGINE NUMBER OR DESCRIPTION

USER SPECIFIED DESCRIPTION

NEXT

SPECIAL USER COMMENTS AREA #

USER SPECIFIED COMMENTS

NEXT

SPECIAL USER COMMENTS AREA #

USER SPECIFIED COMMENTS

NEXT

PRESS NEXT TO RETURN TO HOME

SCREEN

NEXT

PRESS ESC. FROM ANY SCREEN TO

RETURN TO HOME SCREEN

ESC

NOTE: Because EEPROMS can

be reconfigured (using a PC and

Altronic’s configuration software),

these comments should be viewed to

identify and verify the configuration

settings of the ignition prior to

operation. Refer to the programming

instructions, form CPU-XL VariSpark

PI, for further information on

configuration.

CPU-XL VariSpark IOM 07-21

All rights reserved © ALTRONIC, LLC 2021 15

BREAKDOWN OF FIRING PATTERN CODE: JB.LC#

JREPRESENTS THE NUMBER OF OUTPUTS USED, IN THIS CASE

(F =, L = , ETC.)

REPRESENTS THE CYCLE TYPE OF THE ENGINE

= TWO−CYCLE

= FOUR−CYCLE

BREPRESENTS THE ALTRONIC PATTERN CODE (SEE FORM CPU−XL VA−

RISPARK AL)

REPRESENTS THE NUMBER OF GEAR TEETH OR HOLES TO BE SENSED

LREPRESENTS A DESIGNATOR FOR CPU−XL VARISPARK VERSION

CREPRESENTS THE CURRENT LOOP RETARD CURVE TYPE

A = ° AT MA ⁄ ° AT MA

B = ° AT MA ⁄ ° AT MA

C = ° AT MA ⁄ ° AT MA

D = ° AT MA ⁄ ° AT MA

E = ° AT MA ⁄ ° AT MA

N = SPECIAL NON−STANDARD TIMING CURVE VS. CURRENT OR RPM,

NON−FACTORY PROGRAMMED

S =SPECIAL NON−STANDARD TIMING CURVE VS. CURRENT OR RPM,

FACTORY

PROGRAMMED

X =NO CURRENT LOOP CURVE

# REPRESENTS THE SPECIAL FEATURE CODE

(TOTAL SUM OF ALL SELECTED OPTIONS; =DEFAULT)

= USE STEP RETARD WHEN RPM IS LESS THAN

= USE STEP RETARD WHEN MISC INPUT IS GROUNDED

CPU-XL VariSpark IOM 07-21

All rights reserved © ALTRONIC, LLC 2021 16

20.0

ADJUSTING GLOBAL RETARD

20.1

Global retard is an adjustment aecting the timing of all cylinders equally. This

adjustment can be equated to the manual timing switch of the Altronic CPU-XL

VariSpark system. Adjustments made as described below will be in eect until

another adjustment is made.

20.2

To adjust global retard:

FROM PRESS

TIMING

THEN AT PRESS

THEN AT PRESS

THEN AT NOTE: RESULTANT

TIMING SHOWN ON

BOTTOM LINE.

PRESS TO PRESS TO PRESS TO

INCREASE DECREASE EXIT

RETARD RETARD

ESC

⬆

⬇

⬆⬇

CPU-XL VariSpark IOM 07-21

All rights reserved © ALTRONIC, LLC 2021 17

20.3

The increment of timing change is dependent on the number of holes or teeth

being sensed. The minimum timing change is defined as follows.

The timing increment is “⁄N” degrees, where N = no. of holes or teeth.

Example: ⁄ = .° min. timing increment.

20.4

Global spark timing is determined based on the sum of several spark retard

components which include manual retard, current loop retard, RPM retard, and

1 step retard. The range of total retard is limited to 255 X timing increment. When

the sum of all retard components reaches 255 X timing increment, the actual

timing will be at the retard limit.

21.0

SELECTION OF GLOBAL TIMING MODES

21.1

Several options exist with regard to global timing modes. Once the global timing

mode menu is entered as described below, the status of each option can be

viewed and changed.

FROM PRESS

TIMING

THEN AT PRESS

THEN AT PRESS

⬆

⬇

CPU-XL VariSpark IOM 07-21

All rights reserved © ALTRONIC, LLC 2021 18

21.2

The first mode selection can enable or disable the pre-configured retard curve

controlled by the 4-20mA current loop input. The choices are ON or OFF, with

the active selection displayed in capital letters. A PC is required to configure the

4-20mA curve; reference the programming instructions, form CPU-XL VariSpark

PI. When the current loop is on, the current loop value is displayed (xx.x mA) with

the “A” capitalized. When the current loop is o, the value is displayed (xx.x ma)

with the lower case “a”.

AT NOTE: DISPLAY

SHOWS CURRENT

LOOP ON.

TO TO FOR TO

TURN TURN NEXT EXIT

ON OFF OPTION

NEXT

ESC

21.3

The next mode selection can enable or disable the pre-configured retard curve

controlled internally by engine RPM. To configure the RPM retard curve, refer to

the Programming Instructions, Form CPU-XL VariSpark PI.

AT THE NOTE: DISPLAY

NEXT SHOWS RPM

OPTION MAP OFF.

SCREEN

TO TO FOR TO

TURN TURN NEXT EXIT

ON OFF OPTION

NEXT

ESC

⬆⬇

⬆⬇

CPU-XL VariSpark IOM 07-21

All rights reserved © ALTRONIC, LLC 2021 19

21.4

The next mode selection can increase or decrease the 1 step retard value. The

first screen below is displayed when 1 step retard is both configured and is active.

The second screen below is displayed when the 1 step retard is configured but

not active. The default configuration selects 1 step retard to be controlled by the

Misc. Input terminal. The additional retard would be implemented when the input

is grounded. The third screen below is displayed when the 1 step retard feature is

not configured. The actual engine timing is displayed on this screen so the eect

of 1 step retard can be seen during adjustments (if the Misc Input terminal is

grounded).

AT THE

NEXT

OPTION

SCREEN

OR

OR NOTE: 1 STEP

RETARD NOT

CONFIGURED.

TO TO TO GO TO

INCREASE DECREASE BACK TO E X IT

FIRST

⬆⬇NEXT ESC

CPU-XL VariSpark IOM 07-21

All rights reserved © ALTRONIC, LLC 2021 20

22.0

ADJUSTING INDIVIDUAL OFFSETS

22.1

The timing of individual cylinders can be oset by up to 3 degrees of advance or

retard from the global timing of the engine. The values are not saved in EEPROM

memory. See section 23.2.

22.2

Enter the individual timing adjustment menu as described below.

FROM PRESS

TIMING

THEN AT PRESS

THEN AT PRESS

22.3

The individual timing adjustment screen identifies the primary output to be

adjusted, and the degrees of oset in use for the output.

THEN AT NOTE: 0.0 degrees

advance for

output A.

TO ADJUST TO SELECT TO SELECT

INDIVIDUAL CYL NEXT PREVIOUS

TIMING CYLINDER CYLINDER

OFFSET

NEXT

SETUP

TO VIEW TO GO TO TO GO TO TO

CURRENT CYLINDER DIAGNOSTIC RETURN

CYLINDER SELECT OFFSET TO HOME

GRAPH

F1

F4

SCREEN

ESC

IADVANCE TO THE TO RESET THE

NEXT CYLINDER CYLINDER TIMING

IN THE FIRING ORDER TO EEPROM

TIMING

STORED VALUE

RESET

⬇

⬆

NOTE: In applications with narrow

firing angles, the adjustment range

may be limited.

NOTE: Cylinder identification infor-

mation describes:

1L = Cylinder Label

01 = Firing Order

1A = Rail/Coil Position.

⬆⬇

F3

Table of contents

Other Altronic Control System manuals