January 1st 14

4

TAC-14, TAC-20 Twel e Months Warranty*

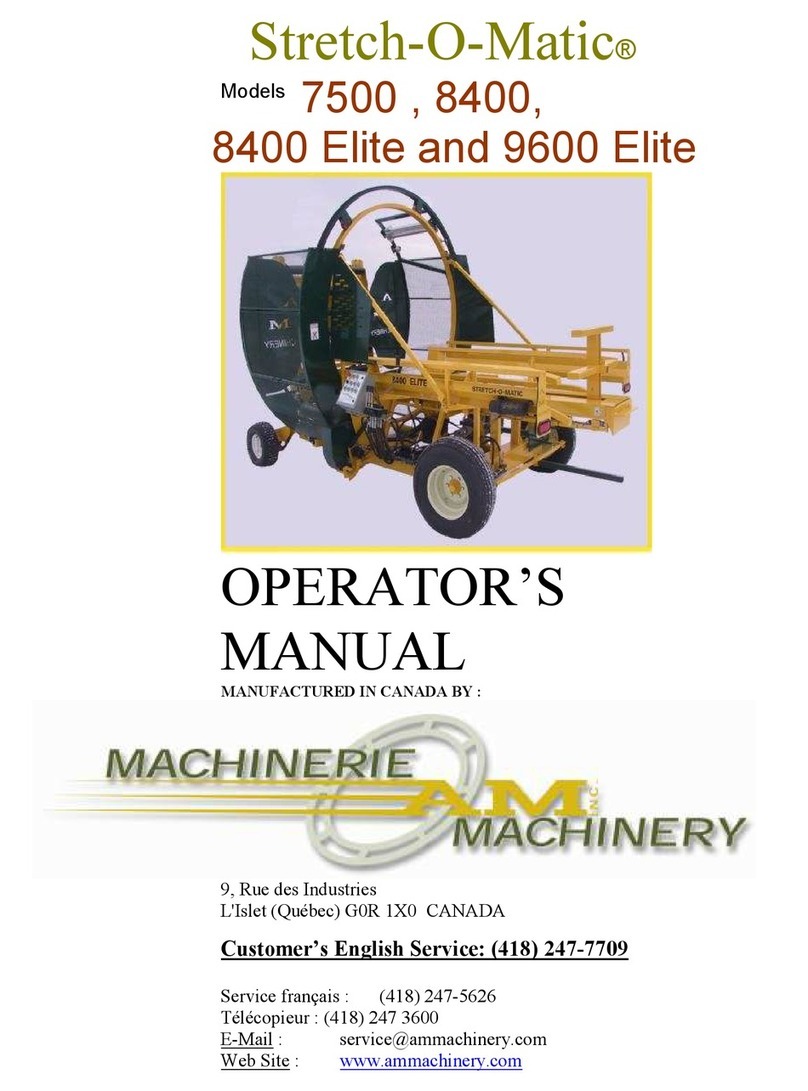

Congratulations ! You are now the proud owner of the best Self Loader on the arket,

the TAC-14 or TAC-20. We are convinced that you will enjoy the trouble free experience of

working with the TAC.

CAUTION !

For your safety and to get the best out of your invest ent, please read the

operator’s anual carefully before operation.

IMPORTANT

Warranty registration for

(page 5)

ust be co pleted and returned

to A.M. Machinery within ten days of ownership to validate warranty.

Warranty coverage

AM Machinery Inc. warranties that the TAC-14, TAC-20 is anufactured under high quality standards

and agrees to replace or repair at seller’s place of business all parts (**except : tires), which are

defective in aterial or work anship without charge for parts and labor if a defect appears within 12

onths fro the date of the purchase by the original purchaser.

The warranty is only valid if the fault is reported to us or our distributors by the dealer sub itting a

co plete warranty clai for within 15 days of the breakdown. The purchaser shall pay any charge

for aking service call and for transporting the achine to the place where the warranty work is to be

perfor ed.

Exclusion

This warranty covers only defective aterial or work anship. It does not cover depreciation or

da age caused under nor al wear, accidents, i proper aintenance, and i proper protection in

storage or i proper use.

The cost of nor al aintenance and nor al replace ent of service ite s such as air filters, oil filters,

etc. shall be paid by the purchaser.

Disclaimer of consequential damage

The warranty exclude any secondary da age, for exa ple consequential losses caused as a result of

achine breakdown or non-availability of spare parts.

As for the final product, high quality forage depends on any factors (exa ple : the quality of forage

being put up, the quality of the plastic used etc.)

A.M. Machinery accepts no liability for forage losses or poor quality forage conservation.

* If used and aintained according to the owner’s anual instructions.

** Tires, battery, fil tensionners and otor are under the warranty of their respective anufacturer.