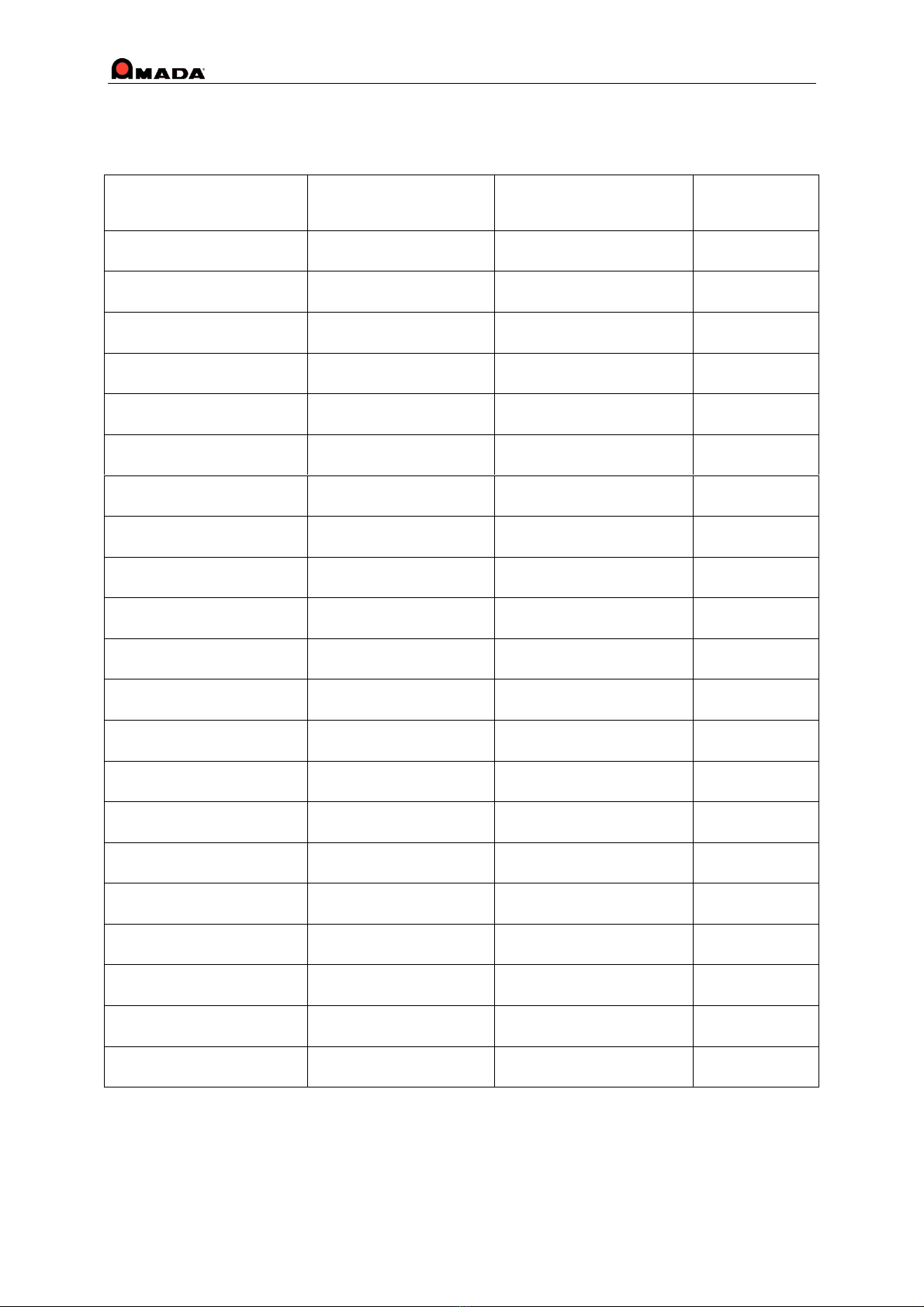

CONTENTS 9/12

OPERATOR’S MANUAL HFE M2 – X41176B Issue 05/2010

6.10.4. DIE HOLDERS EDIT........................................................................................... 69

6.10.5. DIE BLOCK EDIT................................................................................................ 70

6.10.6. FINGER EDIT....................................................................................................... 71

6.11. DELETE MENU.......................................................................................................... 72

6.11.1. DELETE PROGRAMS......................................................................................... 72

6.11.2. DELETE PUNCHES............................................................................................. 74

6.11.3. DELETE PUNCH HOLDERS.............................................................................. 75

6.11.4. DELETE DIES...................................................................................................... 75

6.11.5. DELETE DIE BLOCK.......................................................................................... 75

6.11.6. DELETE DIE HOLDERS.................................................................................... 75

6.11.7. DELETE FINGER................................................................................................. 75

6.12. RENAME MENU........................................................................................................ 76

6.12.1. RENAME PROGRAMS ....................................................................................... 76

6.12.2. RENAME PUNCHES........................................................................................... 77

6.12.3. RENAME PUNCH HOLDERS ............................................................................ 77

6.12.4. RENAME DIES .................................................................................................... 77

6.12.5. RENAME DIE BLOCKS...................................................................................... 77

6.12.6. RENAME DIE-HOLDERS................................................................................... 77

6.12.7. RENAME FINGERS............................................................................................. 77

6.13. COPY MENU.............................................................................................................. 78

6.13.1. COPY PROGRAMS ............................................................................................. 78

6.13.2. COPY PUNCHES ................................................................................................. 79

6.13.3. COPY PUNCH HOLDER..................................................................................... 79

6.13.4. COPY DIES........................................................................................................... 79

6.13.5. COPY DIE HOLDERS ......................................................................................... 79

6.13.6. COPY DIE BLOCK .............................................................................................. 79

6.13.7. COPY FINGER..................................................................................................... 79

6.14. SAVE MENU .............................................................................................................. 80

6.14.1. SAVE PROGRAMS.............................................................................................. 80

6.14.2. SAVE PUNCHES ................................................................................................. 83

6.14.3. SAVE PUNCH HOLDER..................................................................................... 83

6.14.4. SAVE DIE............................................................................................................. 83

6.14.5. SAVE DIE BLOCK .............................................................................................. 83

6.14.6. SAVE DIE HOLDER............................................................................................ 83

6.14.7. SAVE FINGER ..................................................................................................... 83

6.15. RESTORE MENU....................................................................................................... 84

6.15.1. RESTORE PROGRAMS ...................................................................................... 84

6.15.2. RESTORE PUNCHES.......................................................................................... 87

6.15.3. RESTORE PUNCH HOLDER.............................................................................. 87

6.15.4. RESTORE DIES ................................................................................................... 87

6.15.5. RESTORE DIE BLOCK....................................................................................... 87