2

IMPORTANTNOTETOTHEOWNER

This equipment is to be serviced by professionally trained

personnel only. If this equipment is improperly installed,

adjusted or altered by an unqualified person, a safety

hazard may result.

IMPORTANT NOTE TO THE SERVICER

Read this manual and familiarize yourself with the specific

items which must be adhered to before attempting to

service this unit. The precautions listed in this manual

should not supersede existing practices but should be

considered as supplemental information.

TransportationDamage

All units are securely packed in shipping containers ap-

provedbytheNationalSafeTransitAssociation. Thecarton

should be checked upon arrival for external damage. If

damage is found, immediately make a written request for

inspection by the carrier’s agent.

In the event of damage:

1. Note on the delivery receipt any visible damage to

shipment or container.

2. Notifycarrier promptly and requestan inspection.

3. Filethe claimwiththefollowing supporting documents

within the six month statute of limitations.

a. Original Bill of Lading, certified copy, or indemnity

bond.

b. Original paid freight bill or indemnity.

c. Original invoice or certified copy, showing trade and

otherdiscounts orreductions.

d. Copy of the inspection report issued by carrier’s

representative at the time damage is reported to the

carrier.

The carrier is responsible for making prompt inspection of

damageandforathoroughinvestigationofeachclaim. The

distributor or manufacturer will not accept claims from

dealers for transportation damage.

Unpacking The Unit

1. Cut the carton banding and open the carton.

2. Removetheliterature,hardwarepack,upperstyrofoam

shipping blocks, and styrofoam corner posts.

3. Removethefrontassembly.

4. Lift the unit from the remaining carton.

5. Disposeofthecardboardandstyrofoamatanapproved

Recycle Center. Check all contents for damaged or

missingparts. Incaseofconcealeddamage,notifythe

carrier as soon as possible—preferably within 5 days.

Refertostep3oftheTransportationDamagesectionif

damageor missing parts are noted.

PartsSupplied

Size Description Quantity

#8 x 3/8” Blunt Point Sheet Metal Screw 1

(Thisscrewisusedforgroundwireconnectiontothesleeve)

UnitAccessories

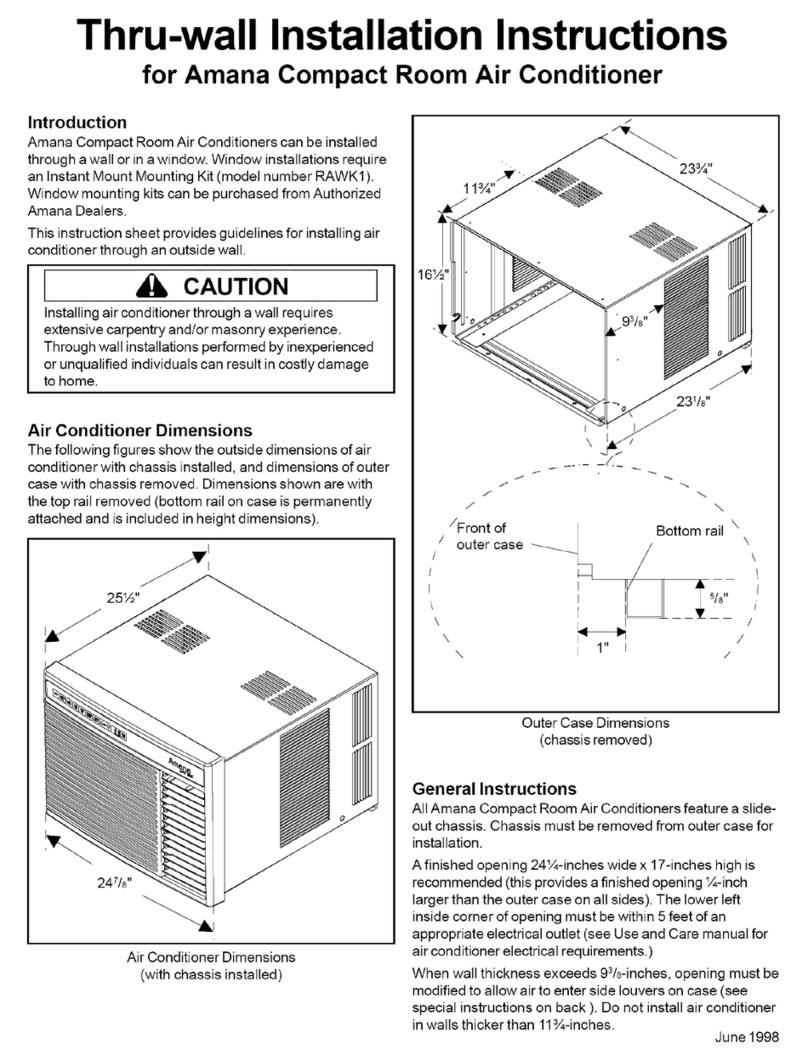

Thisunitisdesignedforthrough-the-wallinstallationinnew

or existing buildings. To complete the installation in an

existing wall sleeve, a TWKGSLV rear louver panel kit, a

TWEAK2 or TWFAK2 adapter kit is required.

If the sleeve is an Amana®brand wall sleeve, use the

TWKGSLVrearlouverpanelkit. IfthesleeveisanEmerson

wall sleeve, use the TWEAK2 adapter kit, If the sleeve is

a Fedders or Freidrich wall sleeve, use the TWFAK2

adapter kit.

OperatingInstructions

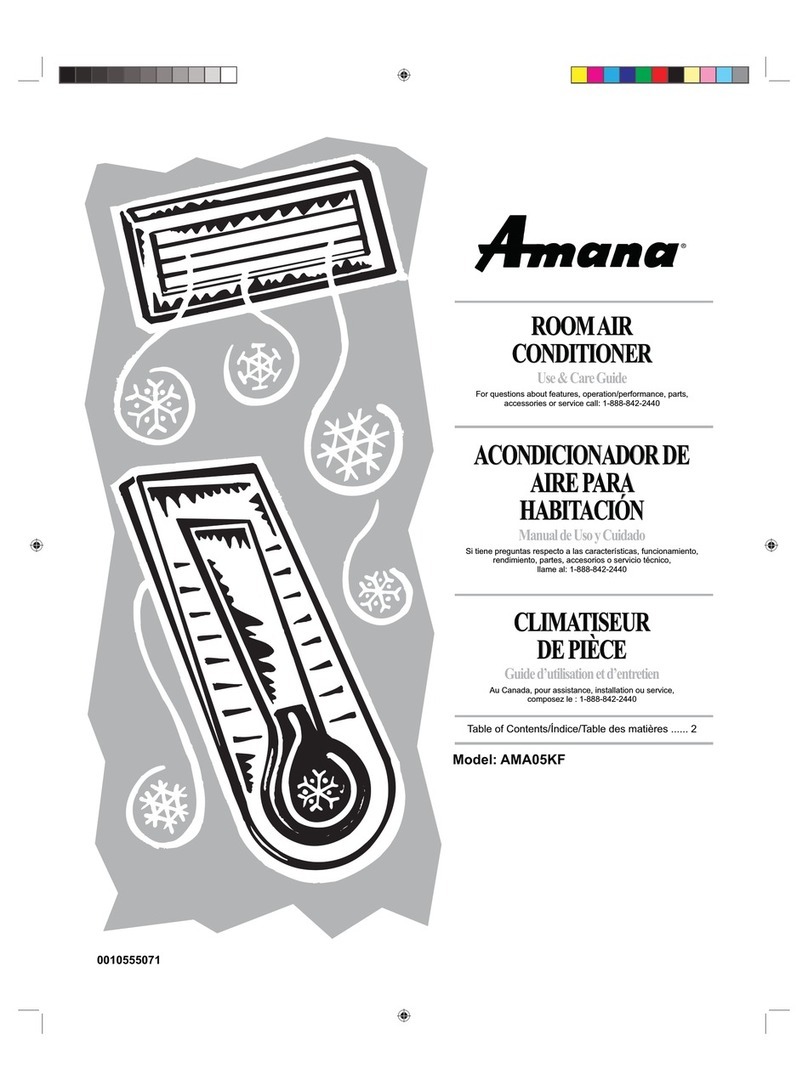

Check the data specification plate and ensure the proper

voltageandcurrentratingforthetypeofpowerplugonthe

unit is available. DO NOT REMOVE THE GROUNDING

PRONGFROMTHEPOWERCORD. SeeFigure1forthe

types of acceptable plugs. Do not use an extension cord

for the installation of this product. Refer to the data

specificationplateforelectricalrequirements.

110V 230V 230V

15 amp 15 amp 20 amp

Figure 1

•LCDI or AFCI Power Cords - Underwrites Laboratories

and the National Electric Code (NEC) now require

power cords that sense current leakage and can open

the electrical circuit to the unit on units rated at 250

volts or less. In the event that unit does not operate,

check the reset button located on or near the head of

the power cord as part of the normal troubleshooting

procedure.

LCDI power Cord