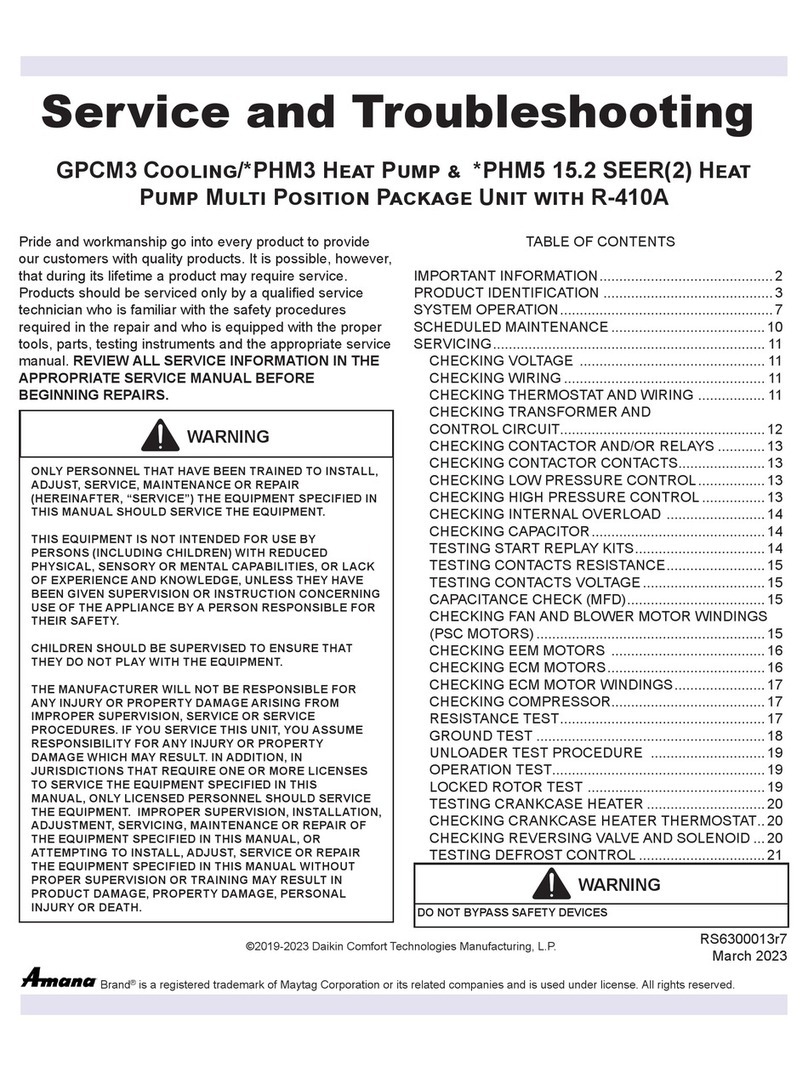

SYSTEM OPERATION

7

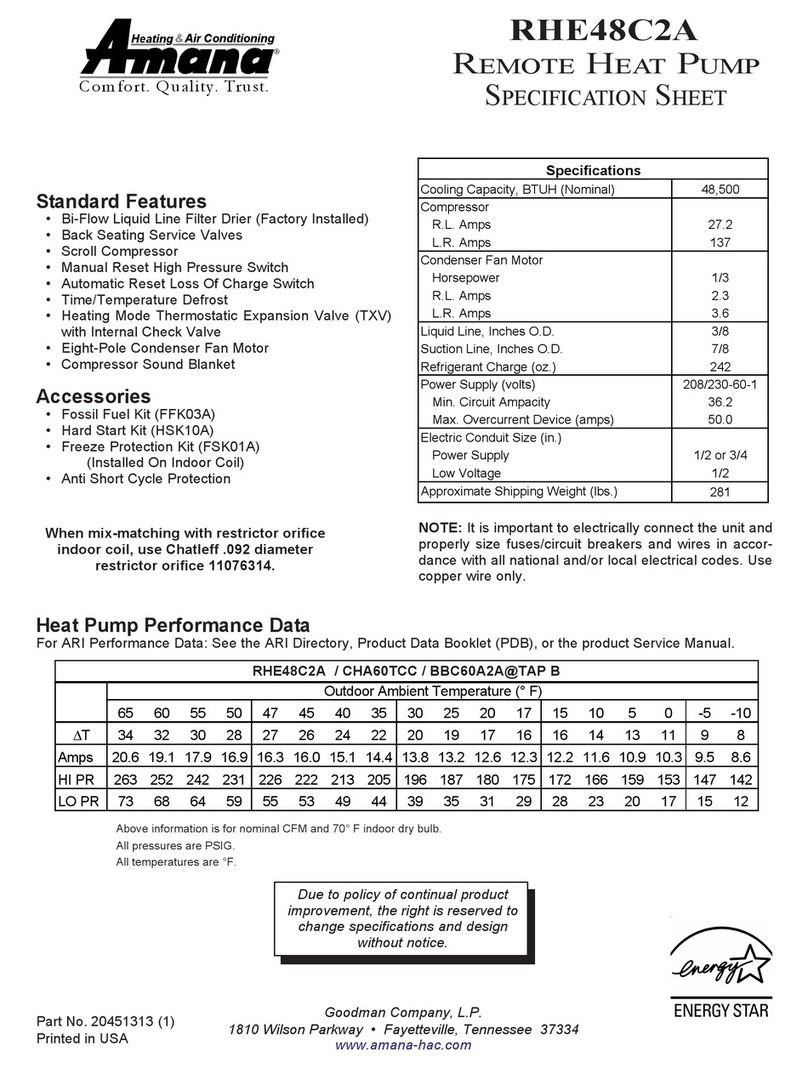

The refrigerant used in the system is R-410A. It is a clear,

colorless, non-toxic and non-irritating liquid. R-410A is a

50:50 blend of R-32 and R-125. The boiling point at atmo-

spheric pressure is -62.9°F.

A few of the important principles that make the refrigeration

cycle possible are: heat always ows from a warmer to a

cooler body. Under lower pressure, a refrigerant will absorb

heat and vaporize at a low temperature. The vapors may

be drawn o and condensed at a higher pressure and

temperature to be used again.

The indoor evaporator coil functions to cool and dehumidify

the air conditioned spaces through the evaporative process

taking place within the coil tubes.

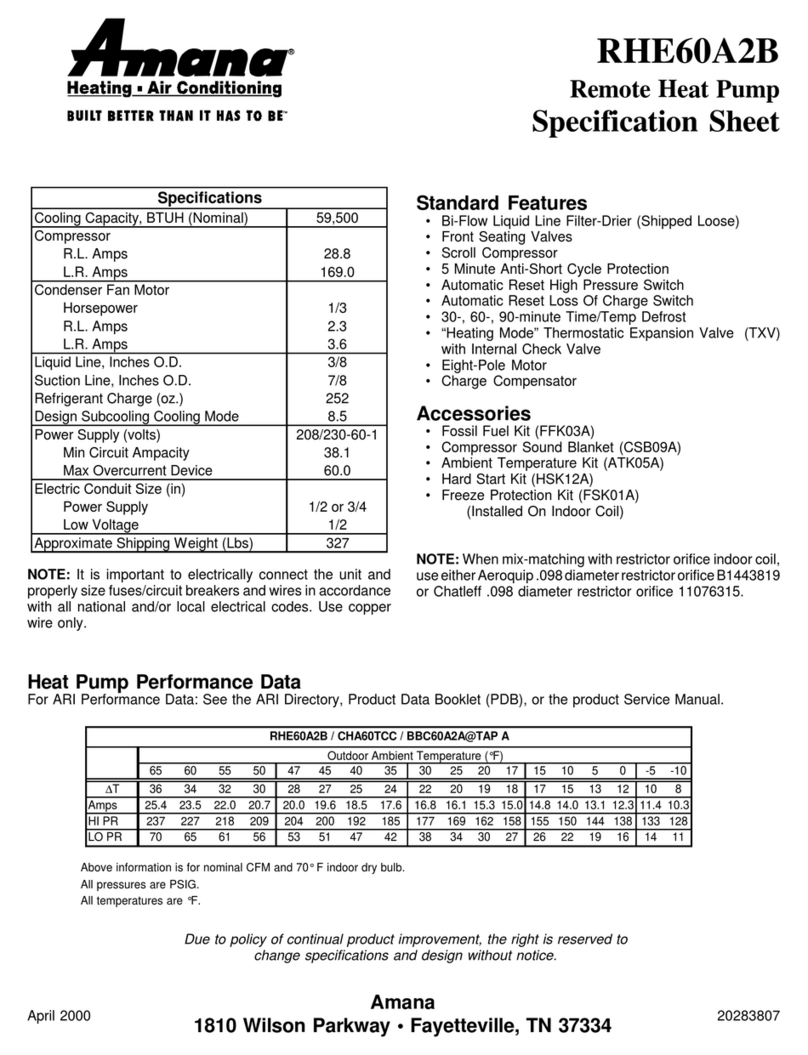

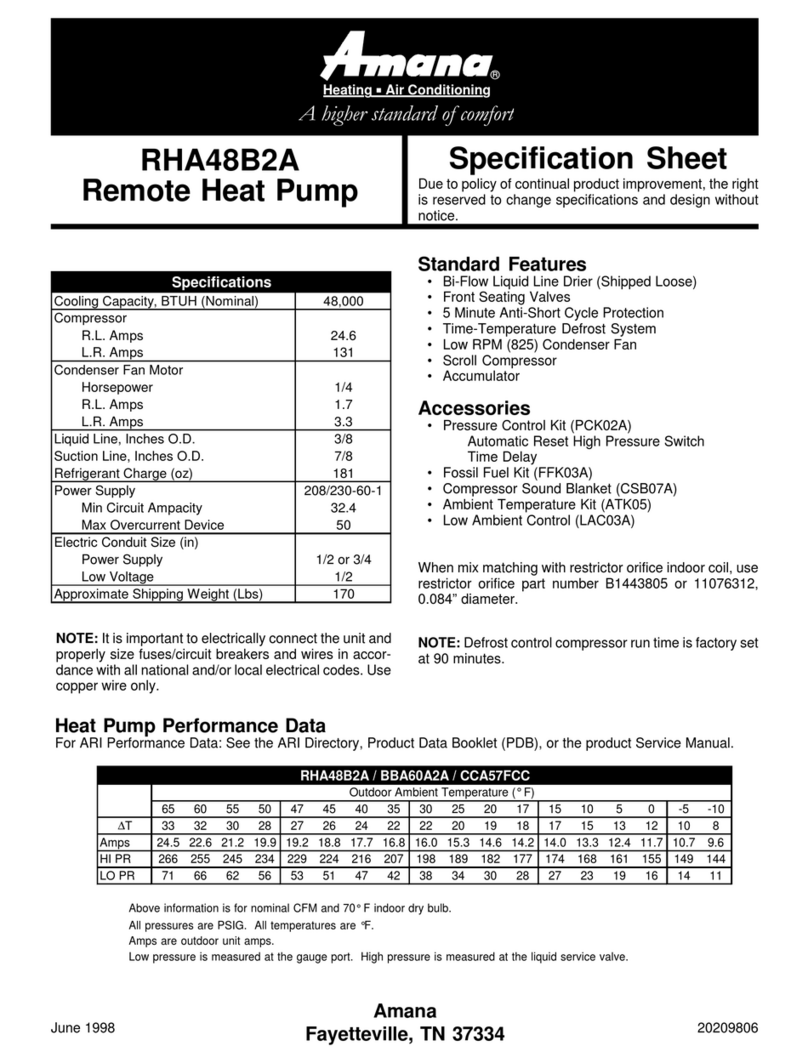

Liquid refrigerant at condensing pressure and

temperatures, (270 psig and 122°F), leaves the outdoor

condensing coil through the drier and is metered into the

indoor coil through the metering device. As the cool, low

pressure, saturated refrigerant enters the tubes of the

indoor coil, a portion of the liquid immediately vaporizes.

It continues to soak up heat and vaporizes as it proceeds

through the coil, cooling the indoor coil down to about 48°F.

Heat is continually being transferred to the cool ns and

tubes of the indoor evaporator coil by the warm system air.

This warming process causes the refrigerant to boil. The

heat removed from the air is carried o by the vapor.

As the vapor passes through the last tubes of the coil, it

becomes superheated. That is, it absorbs more heat than

is necessary to vaporize it. This is assurance that only

dry gas will reach the compressor. Liquid reaching the

compressor can weaken or break compressor valves.

The compressor increases the pressure of the gas, thus

adding more heat, and discharges hot, high pressure

super-heated gas into the outdoor condenser coil.

In the condenser coil, the hot refrigerant gas, being

warmer than the outdoor air, rst loses its superheat by

heat transferred from the gas through the tubes and ns

of the coil. The refrigerant now becomes saturated, part

liquid, part vapor and then continues to give up heat until

it condenses to a liquid alone. Once the vapor is fully

liqueed, it continues to give up heat which subcools the

liquid, and it is ready to repeat the cycle.

When the contacts of the room thermostat close, making

terminals R to Y and R to G, the low voltage circuit to the

contactor is completed starting the compressor and outdoor

fan motor. The EEM indoor blower motor is energized at

the cool speed when the compressor contactor energizes.

When the thermostat is satised, breaking the circuit

between R to Y and R to G, the compressor and outdoor

fan motor will stop. The indoor blower will stop after the fan

o delay.

If the room thermostat fan selector switch should be set

to the “on” position then the indoor blower would run

continuous rather than cycling with the compressor.

Any time the room thermostat is switched to cool, the O

terminal is energized. This energizes the 24 volt coil on the

reversing valve and switches it to the cooling position.

When the contacts of the room thermostat close, this

closes the circuit from R to Y and R to G in the unit.

This energizes the compressor contactor and will energize

the indoor blower on models equipped with the EEM motor.

When the thermostat is satised, it opens its contacts

breaking the low voltage circuit causing the compressor

contactor to open and indoor fan to stop after the

programmed 60 second o delay on units with the EEM

motor.

If the room thermostat fan selector switch should be set

to the “on” position then the indoor blower would run

continuous rather than cycling with the compressor.

With the thermostat set to the heat position and a call

for heat, R to W will be energized. This will energize the

electric heat contactor(s)/sequencer(s) and the EEM indoor

blower motor. When the normally open contacts of the

heat contactor(s)/sequencer(s) close, this will energize the

electric resistance heat.