Amano American Sanders American 8 User manual

Drum Sander

American 8

Operator’s Manual

1

Contents

Operator Safety Instructions................................................... 1-4

Machine Specifications...............................................................5

230V Electrical Schematic..........................................................6

Machine Transportation..............................................................6

Machine Setup ....................................................................... 7-8

Chatter-Wave Prevention ...........................................................8

Machine Operation ............................................................... 9-10

Sander Adjustments ............................................................11-12

Routine Maintenance ...............................................................13

Troubleshooting........................................................................14

Wiring Diagram.........................................................................17

Handle Assy ....................................................................... 18-19

Base Assy - 1 ..................................................................... 20-21

Base Assy - 2 ..................................................................... 22-23

Accessories ..............................................................................23

Warranty ...................................................................................24

READ THIS BOOK

This book has important information for the use and safe operation of this machine. Failure to read this book prior to

operating or attempting any service or maintenance procedure to your American Sanders machine could result in injury

to you or to other personnel; damage to the machine or to other property could occur as well. You must have training in

the operation of this machine before using it. If your operator(s) cannot read this manual, have it explained fully before

attempting to operate this machine.

All directions given in this book are as seen from the operator’s position at the rear of the machine.

***This product is intended for commercial use only***

In this Operation Manual you will find three statements that you must read and observe to ensure safe operation of this

machine.

DANGER means: Severe bodily injury or death can occur to you or other personnel if the DANGER

statements found on this machine or in this Operation Manual are ignored or are not adhered to. Read

and observe all DANGER statements found in this Operation Manual and on your machine.

WARNING means: Injury can occur to you or to other personnel if the WARNING statements found on

your machine or in the Operation Manual are ignored or are not adhered to. Read and observe all

WARNING statements found in this Operation Manual and on your machine.

CAUTION means: Damage can occur to the machine or to other property if the CAUTION statments found

on your machine or in this Operation Manual are ignored or are not adhered to. Read and observe all

CAUTION statments found in this Operation Manual and on your machine.

Operator Safety Instructions

WARNING!

The Products sold with this Manual contain or may contain chemicals that are known to certain governments (such as the State of

certain locations (including the State of California) purchasers of these Products that place them in service at an employment job site

or a publicly accessible space are required by regulation to make certain notices, warnings or disclosures regarding the chemicals that

are or may be contained in the Products at or about such work sites. It is the purchaser’s responsibility to know the content of, and

to comply with, any laws and regulations relating to the use of these Products in such environments. The Manufacturer disclaims any

2

Failure to read the Owner’s Manual prior to operating or servicing your American Sanders machine could result in injury to

you or to other personnel; damage to the machine or to other property could occur as well. You must have training in the

operation of this machine before using it. If you or your operator(s) cannot read English, have this manual explained fully

before attempting to operate this machine.

A. Sanding/nishing wood oors can create an explosive or combustible environment. Do not operate this machine around

solvents, thinners, alcohol, fuels, oor nishes, wood dust or any other ammable materials. Cigarette lighters, pilot lights,

electrical sparks and all other sources of ignition should be extinguished or avoided. Keep work area well ventilated.

B. Dust generated from sanding wood oors can spontaneously ignite or explode. Promptly dispose of any sanding dust in

a metal container clear of any combustibles. Do not dispose in a re.

A. Electrocution could occur if the machine is being serviced while the machine is connected to a power source. Disconnect

the power supply before servicing.

B. Electrocution or re could occur if the machine is being operated with a damaged power cord. Keep the power cord clear

of the pad. Always lift the cord over the machine. Do not move the machine by the power cord.

C.Shock hazard. Do not use the machine if it has been rained on or sprayed with water.

To avoid injury keep hands, feet, and loose clothing away from all moving parts on the machine. Disconnect the power cord

before replacing the pad, changing the abrasive, or when servicing. Do not operate the machine unless all guards are in

place. Never leave the machine unattended while connected to a power source.

Injury can occur if protective clothing or equipment is not used while sanding. Always wear safety goggles, protective

clothing, and dust mask while sanding.

This sander is not to be used on pressure treated wood. Some pressure treated woods contain arsenic and sanding

pressure treated wood produces hazardous dust. Inhaling hazardous dust from pressure treated wood can cause serious

injury or death. Sanding pressure treated wood decks or uneven surfaces can damage the sander which is not covered

under warranty or damage waiver.

Any alterations or modications of this machine could result in damage to the machine or injury to the operator or other

bystanders. Alterations or modications not authorized by the manufacturer voids any and all warranties and liabilities.

Risk of explosion. Floor sanding can result in an explosive mixture of ne dust and air. Use oor sanding machine only in a

well-ventilated area free from any ame or match.

DANGER:

DANGER:

DANGER:

DANGER:

WARNING:

WARNING:

WARNING:

WARNING:

WARNING: Read all safety warnings and instructions. Failure to follow warnings and instructions may result in electric

shock, re and or serious injury.

Save all warnings and instructions for future use.

The term “power tool” in the warnings refers to your main-operated (corded) power tool or battery operated (cordless) power tool.

1) Work area safety

a) Keep work area clean and well lit. Clutter or dark areas invite accidents.

b) Do not operate power tools in explosive atmospheres, such as in the presence of ammable liquids, gasses, or dust.

Power tools create sparks which may ignite the dust or fumes.

c) Keep children and bystanders away while operating a power tool. Distractions can cause you to lose control.

2) Electrical safety

a) Power tool plugs must match the outlet. Never modify the plug in any way. Do not use any adapter plugs with

earthed (grounded) power tools. Unmodied plugs and matching outlets will reduce risk of electric shock.

b) Avoid body contact with earthed or grounded surfaces such as pipes, radiators, ranges, and refrigerators. There is an

increased risk of electric shock if your body is earthed or grounded.

c) Do not expose power tools to rain or wet conditions. Water entering a power tool will increase the risk of electric shock.

d) Do not abuse the cord. Never use the cord for carrying, pulling or unplugging the power tool. Keep cord away from

heat, oil, sharp edges or moving parts. Damaged or entangled cords increase the risk of electric shock.

e) When operating a power tool outdoors, use an extension cord suitable for outdoor use. Use of cord suitable for outdoor

use reduces the risk of electric shock.

General Power Tool Safety Warnings

3

Failure to read the Owner’s Manual prior to operating or servicing your American Sanders machine could result in injury to

you or to other personnel; damage to the machine or to other property could occur as well. You must have training in the

operation of this machine before using it. If you or your operator(s) cannot read English, have this manual explained fully

before attempting to operate this machine.

A. Sanding/nishing wood oors can create an explosive or combustible environment. Do not operate this machine around

solvents, thinners, alcohol, fuels, oor nishes, wood dust or any other ammable materials. Cigarette lighters, pilot lights,

electrical sparks and all other sources of ignition should be extinguished or avoided. Keep work area well ventilated.

B. Dust generated from sanding wood oors can spontaneously ignite or explode. Promptly dispose of any sanding dust in

a metal container clear of any combustibles. Do not dispose in a re.

A. Electrocution could occur if the machine is being serviced while the machine is connected to a power source. Disconnect

the power supply before servicing.

B. Electrocution or re could occur if the machine is being operated with a damaged power cord. Keep the power cord clear

of the pad. Always lift the cord over the machine. Do not move the machine by the power cord.

C.Shock hazard. Do not use the machine if it has been rained on or sprayed with water.

To avoid injury keep hands, feet, and loose clothing away from all moving parts on the machine. Disconnect the power cord

before replacing the pad, changing the abrasive, or when servicing. Do not operate the machine unless all guards are in

place. Never leave the machine unattended while connected to a power source.

Injury can occur if protective clothing or equipment is not used while sanding. Always wear safety goggles, protective

clothing, and dust mask while sanding.

This sander is not to be used on pressure treated wood. Some pressure treated woods contain arsenic and sanding

pressure treated wood produces hazardous dust. Inhaling hazardous dust from pressure treated wood can cause serious

injury or death. Sanding pressure treated wood decks or uneven surfaces can damage the sander which is not covered

under warranty or damage waiver.

Any alterations or modications of this machine could result in damage to the machine or injury to the operator or other

bystanders. Alterations or modications not authorized by the manufacturer voids any and all warranties and liabilities.

Risk of explosion. Floor sanding can result in an explosive mixture of ne dust and air. Use oor sanding machine only in a

well-ventilated area free from any ame or match.

f) If operating a power tool in a damp location is unavoidable, use a residual current device (RCD) or ground fault circuit

interrupter (GFCI) protected supply. Use of a RCD or GFCI reduces the risk of electric shock.

3) Personal safety

a) Stay alert, watch what you are doing and use common sense when operating a power tool. Do not use a power tool

while you are tired or under the inuence of drugs, alcohol, or medication. A moment of inattention while operating

power tools may result in serious personal injury.

b) Use personal protective equipment. Always wear eye protection. Protective equipment such as dust mask, non-skid

safety shoes, hard hat, or hearing protection used for appropriate conditions will reduce personal injury.

c) Prevent unintentional starting. Ensure switch is in o-position before connecting to power source and/or battery

pack, picking up, or carrying the tool.

have the switch on invites accidents .

d) Remove any adjustment wrench or key before turning the power tool on. A wrench or key left attached to a rotating part

of the power tool may result in personal injury.

e) Do not overreach. Keep proper footing and balance at all times. This enables better control of the power tool in

unexpected situations .

f) Dress properly. Do not wear loose clothing or jewelry. Keep your hair, clothing and gloves away from moving parts.

g) If devices are provided for the connection of dust extraction and collection facilities, ensure these are connected and

properly used.

via a residual current device with a rated residual current of 30mA or less.

4) Power tool use and care

a) Do not force the power tool. Use the correct power tool for your application. The correct power tool will do the job better

and safer at the rate for which it was designed .

b) Do not use the power tool if the switch does not turn it on and o. Any power tool that cannot be controlled with the

switch is dangerous and must be repaired .

c) Disconnect the plug from the power source and/or the battery pack from the power tool before making any

adjustments, changing accessories or storing power tools. Such preventative safety measures reduce the risk of starting

the power tool accidently.

d) Store idle power tools out of the reach of children and do not allow persons unfamiliar with the power tool or these

instructions to operate the power tool. Power tools are dangerous in the hands of untrained users.

e) Maintain power tools. Check for misalignment or binding of moving parts, breakage of parts and any other condition

that may aect the power tool's operation. If damaged, have the power tool repaired before use. Many accidents are

caused by poorly maintained power tools .

f) Keep cutting tools sharp and clean. Properly maintained cutting tools with sharp cutting edges are less likely to bind and

are easier to control.

g) Use the power tool, accessories and tool bits ect. in accordance with these instructions , taking into account the

working conditions and the work to be performed.

5) Service

a) Have the power tool serviced by a qualied repair person using only identical replacement parts. This will ensure that

the safety of the power tool is maintained . If the supply cord is damaged, it must be replaced by the manufacturer , its service

Safety Warnings For Sanding Operations

accessory can be attached to your power tool, it does not assure safe operation .

4. The rated speed of the accessory must be at least equal to the maximum speed marked on the power tool. Accessories

accessories cannot be adequately guard or controlled.

with arbor holes that do not match the mounting hardware of the power tool will run out of balance, vibrate excessively and

may cause loss of control.

7. Do not use damaged accessory. Before each use inspect the accessory such as abrasive wheel for chips or cracks, backing

pad for cracks , tear or excess wear, wire brush for loose or cracked wires . If power tool or accessory is dropped , inspect

for damage or install an undamaged accessory. After inspecting or installing an accessory, position yourself or bystanders

away from the plane of the rotating accessory and run the power tool at maximum no-load speed for one minute . Damaged

accessories will normally break apart during this time .

4

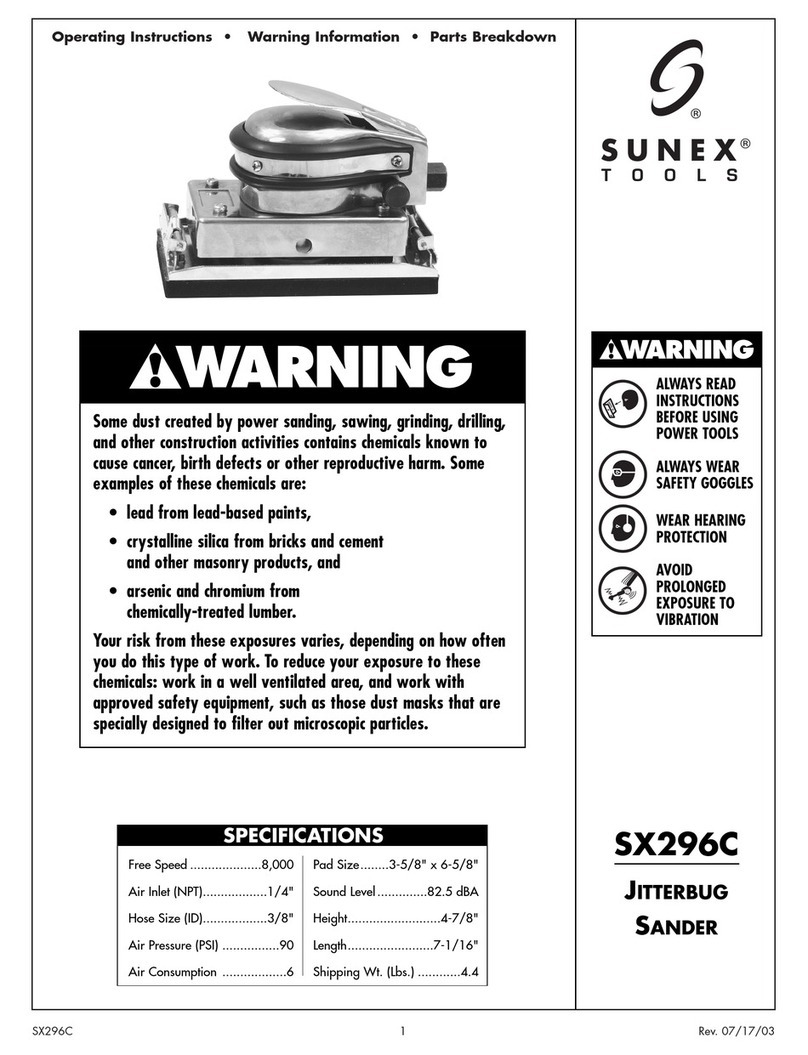

8. Wear personal protective equipment. Depending on application, use face shield, safety goggles or safety glasses. As

noise may cause hearing loss.

9. Keep bystanders a safe distance away from work area. Anyone entering the work area must wear personal protective

operation .

10. Hold power tool by gripping insulated surfaces (handle) only, when performing an operation where the cutting accessory may

contact hidden wiring or its own cord. Cutting accessory contacting a "live" wire may make exposed metal parts of the power

tool "live" and shock the operator.

11. Position the cord clear of the spinning accessory. If you loose control, the cord may be cut or snagged and your arm or hand

may be pulled into the spinning accessory.

12. Never lay the power tool down until the accessory has come to a complete stop. The spinning accessory may grab the

surface and pull the power tool out of your control.

13. Do not run the power tool while carrying it at your side. Accidental contact with the spinning accessory could snag your

clothing, pulling the accessory into your body.

14. Regularly clean the power tools air vents. The motor's fan will draw the dust inside the housing and excessive accumulation

disc or kickback.

Kickback and Related Warnings

Kickback is a sudden reaction to a pinched or snagged rotating wheel, backing pad, brush or any other accessory. Pinching or

snagging causes rapid stalling of the rotating backing pad which in turn causes uncontrolled power tool to be forced in the opposite

direction of the backing pad's rotation at the point of the binding.

For example, if an abrasive wheel is snagged or pinched by the work piece, the edge of the wheel that is entering into the pinch

point can dig into the surface of the material causing the wheel to climb out or kick out. The wheel may either jump toward or away

from the operator, depending on direction of the wheel's movement at the point of pinching. Abrasive wheels may also break under

these conditions.

Kickback is the result of power tool misuse and incorrect operating procedures or conditions and can be avoided by taking proper

precautions as given below.

auxiliary handles, if provided for maximum control over kickback or torque reactions during start up. The operator can control

torque reactions or kickback forces, if proper precautions are taken.

2. Never place your hand near the rotating accessory. Accessory may kickback over your hand.

3. Do not position your body in the area where power tool will move if kickback occurs. Kickback will propel the tool in the

direction opposite to the wheel's movement at the point of the snagging.

4. Use special care when working corners, sharp edges etc. Avoid bouncing and snagging the accessory. Corners, sharp edges

or bouncing have a tendency to snag the rotating accessory and cause loss of control or kickback.

Additional Rules For Safe Operation

1. Empty the dust bag or dust collection receiver frequently. Do not leave residue in dust bag or dust collection receiver

unattended . Always empty in a non-combustible metal container. Sanding wood or varnish produces dust that can self ignite

and cause injury or damage. Follow this precaution for storage.

2. Set all exposed nails. Sweep loose abrasive away from work area. Do not strike metal pipes, ect., with sanding paper.

Striking metal or abrasive particles with sanding paper produces sparks that could ignite the sanding dust which can cause

injury or damage.

tight. Operating a partially assembled power tool could result in injury to the operator or bystander and could cause damage to

the equipment or surroundings .

4. Do not attempt to change the sanding paper while the power tool is running. The sanding pad can snag clothing and cause

injury to limbs and moving sanding paper can cause abrasions.

5. The power tool should only be used on an electrical system (mains) that is rated for the electrical requirements of the power

5

Machine Specifications

Operating Controls

Motor Starter / Protector

Sanding Pressure

Adjustment

Leveling Controls

Tool Storage Tray

* revolutions per min. *surface feet per min. *meters per min * cubic feet per min.

**Steel (Standard) Urethane or canvas (optional) ***Urethane (Standard) Steel or Canvas (optional)

CAUTION Your equipment may be inappropriate

cannot support the pressure created by hard wheels. A felt

or rubber wheel should be used when these woods are

encountered. See parts list for optional wheels.

product. Determine suitability of your equipment in

preparing the product.

Model American 8

PART NUMBER 07032C 07105A 07048C 07106A

Abrasive Size 8 x 26½” paperback 20.3 x 67.3 cm

Contact Wheel Speed (rpm)* 2400/2800 2000/2333

Abrasive Speed (sfm)* (m/min)* 4398/5131 sfm 1117/1303 m/min.

Dust Fan Speed (rpm)* 6000 5000

Dust Fan Flow (cfm)* 210 cfm 83 liters/second

Motor 60 Hz 230V 4hp (3 kW) 50 Hz 240V 3hp (2.2 kW)

Leveling Control Externally Adjustable

Operating Control Adjustable Lever

Motor Starter/Protector Magnetic Circuit Breaker

Sanding Pressure Adjustment Innitely Circuit Breaker

Wheels (Truck Assembly) Steel ** Urethane*** Steel** Urethane***

Wheel (Rear) Steel Canvas Steel Canvas

Drive V-Belt

Dimensions 40½ x 15 x 36 103 cm x 38 cm x 93 cm

Weight 216 lbs. 98kg

6

230V Electrical Connection Instructions

Machine Transportation

CAUTION: This machine will operate only on AC frequency and on electrical voltage shown on the motor nameplate. Make

sure you have the correct frequency and voltage before connecting the power cord to an outlet. The machine has

a plug as shown below.

DANGER: Electrocution could occur if the machine is exposed to water or rain. Keep the machine in a dry building.

DANGER:

Electrocution could occur if machine is improperly connected to the electrical system. To prevent possible electric

shock

, always use a 3wire electrical system connected to an electrical ground. For maximum protection against

electrical shock, use a circuit that is protected by a ground fault circuit interrupter. Consult your electrical

contractor.

DANGER: Electrocution could occur if the ground pin is tampered with in any way. Do not cut, remove, or break the ground

pin. Do not try to t a three-terminal plug into a receptacle or connector body other than a three plug receptacle

or connector body. If the outlet does not t the plug, consult your electrical contractor.

DANGER: Electrocution could occur if the machine is used with a damaged plug or power cord. If the cords or plugs are worn

or damaged in any way, have them replaced by an authorized service person or electrician.

If motor appears to labor or takes a considerable longer time to come up to speed reduce sanding pressure.

This machine must be connected to an electrically ground circuit in order to pro-

tect the operator from electric shock. This machine has an approved power cord

with three conductors as well as a plug with three terminals. Connect the plug into

a three holed receptacle. For maximum protection against electric shock, use a

circuit that is protected by a ground fault circuit interrupter.

Extension Cords

Use only an approved three-pronged extension cord with two main conductors

and one earthing conductor. This machine is equipped

with a power cord. When greater range is needed follow the table

below to determine cable gauge of additional footage. Refer to the

chart to the right for extension cord information

To transport the machine, follow this procedure:

1. Make sure the power cable is disconnected from the electrical outlet.

2. Disconnect the handle plug connection. See gure 1.

3. Remove the belt cover.

4. Remove the fan belt.

5. Loosen the motor bolt. Using the ¾” wrench, turn the motor bolt counterclockwise.

6. Using the 9/16” wrench, remove the two hex nuts (1).

7. Lower the motor locating screws (2). To lower the motor locating screws, turn the screws

clockwise. Make sure the screws are aligned with the openings at the front of the motor

platform. See gure 2.

8. Slide the motor forward.

9. Remove the drive belt.

10. Remove the motor from the chassis.

To re-assemble the machine after transporting, follow this procedure:

1. Reposition motor on chassis.

2. Install the drum belt. Slide the motor back until adequate tension is achieved in belt.

3. Resecure the motor to the chassis.

4. Install the fan belt.

5. Install the belt cover.

6. Reconnect the handle plug.

Clarke®American Sanders American 8 Floor Sander Operator's Manual Page 7

How to Transport the Machine

WARNING: The machine is heavy. Remove the

motor from the machine before trans-

porting. Get help loading the machine

and motor.

To transport the machine, follow this procedure:

1. Make sure the power cable is disconnected from the

electrical outlet.

2. Disconnect the handle plug connection. See gure 1.

3. Remove the belt cover.

4. Remove the fan belt.

5. Loosen the motor bolt. Using the ¾” wrench, turn the motor

bolt counterclockwise.

6. Using the 9/16” wrench, remove the two hex

nuts (1).

7. Lower the motor locating screws (2). To lower the motor

locating screws, turn the screws clockwise. Make sure the

screws are aligned with the openings at the front of the

motor platform. See

gure 2.

8. Slide the motor forward.

9. Remove the drive belt.

10. Remove the motor from the chassis.

To re-assemble the machine after transporting, follow this

procedure:

1. Reposition motor on chassis.

2. Install the drum belt. Slide the motor back until adequate

tension is achieved in belt.

CAUTION: To prevent damage to the oor

surface, make sure the drive belt is

tight.

3. Resecure the motor to the chassis.

4. Install the fan belt.

5. Install the belt cover.

6. Reconnect the handle plug.

Figure 1

Figure 2

Clarke®American Sanders American 8 Floor Sander Operator's Manual Page 7

How to Transport the Machine

WARNING: The machine is heavy. Remove the

motor from the machine before trans-

porting. Get help loading the machine

and motor.

To transport the machine, follow this procedure:

1. Make sure the power cable is disconnected from the

electrical outlet.

2. Disconnect the handle plug connection. See gure 1.

3. Remove the belt cover.

4. Remove the fan belt.

5. Loosen the motor bolt. Using the ¾” wrench, turn the motor

bolt counterclockwise.

6. Using the 9/16” wrench, remove the two hex

nuts (1).

7. Lower the motor locating screws (2). To lower the motor

locating screws, turn the screws clockwise. Make sure the

screws are aligned with the openings at the front of the

motor platform. See

gure 2.

8. Slide the motor forward.

9. Remove the drive belt.

10. Remove the motor from the chassis.

To re-assemble the machine after transporting, follow this

procedure:

1. Reposition motor on chassis.

2. Install the drum belt. Slide the motor back until adequate

tension is achieved in belt.

CAUTION: To prevent damage to the oor

surface, make sure the drive belt is

tight.

3. Resecure the motor to the chassis.

4. Install the fan belt.

5. Install the belt cover.

6. Reconnect the handle plug.

Figure 1

Figure 2

Figure 1

Figure 2

WARNING:

The machine is heavy. Remove the motor from the machine before transporting. Get help loading the machine and motor. Use proper lifting techniques.

7

Machine Set-Up

To set-up your machine follow this procedure:

1.

Familiarize yourself with the machine and read all danger, warning and caution statements. Make sure all operators of this machine have read this

Owner’s Manual. If they cannot read English, have the manual explained fully before allowing anyone to operate the sander.

2. Locate the power supply. The receptacle should be compatible with the plug. The receptacle must be grounded and must be fused (30

amp)

to avoid an electrical hazard.

3. Clip the dust bag to the elbow. Cross the strings on the dust bag and draw tight over the are on the elbow. Wrap the string around the

elbow and secure.

4. Wind the power cord through the cable arm. Keep the power cord out of path of equipment.

How To Install The Abrasive

WARNING: Disconnect power before changing abrasive.

To install the abrasive, follow this procedure:

1. Prepare abrasive with template supplied.

2. Place backing of abrasive on the template. The template is marked “This Side Up.” Make sure the marked side of the template is facing up.

3. Cut the abrasive to the exact lenght of the template.

4. Align one edge of the abrasive with a notch in the template.

5. Fold the other end of the abrasive over the end of the template and crease.

6. Repeat steps 4 and 5 for remaining notch.

7. Lift the drum cover.

8. Put the smooth side of the abrasive against the sanding drum.

9. Put one end of the abrasive against the sanding drum slot (1). See gure 3.

10. Turn the drum one revolution. Put the other end of the abrasive in the drum slot (2). See gure 3.

11. Tighten the abrasive.

To tighten the abrasive, follow this procedure:

a. The end wrenches are given with the machine. Put a wrench around the nut at each end of the drum (1). See gure 4.

b. Make sure the at sides of the nuts are parallel with the drum slot.

c. Turn the wrenches the opposite rotation until the abrasive is tight against the drum (2). See gure 4.

12. Remove the end wrenches.

13. Close the cover.

NOTE: When using #4 or 4½ grit abrasive, remove the large grains from the folded ends. To remove the grains, rub the folded ends together.

Clarke®American Sanders American 8 Floor Sander Operator's Manual Page 9

8. Put the smooth side of the abrasive against the sanding

drum.

9. Put one end of the abrasive against the sanding drum slot

(1). See gure 3.

10. Turn the drum one revolution. Put the other end of the

abrasive in the drum slot (2).

See gure 3.

11. Tighten the abrasive.

To tighten the abrasive, follow this procedure:

1. The end wrenches are given with the machine.

Put a wrench around the nut at each end of the

durm (1).

See gure 4.

2. Make sure the at sides of the nuts

are parallel with the drum slot.

3. Turn the wrenches the opposite rotation

until the abrasive is tight against the drum (2).

See gure 4.

12. Remove the end wrenches.

13. Close the cover.

NOTE: When using #4 or 4½ grit abrasive,

remove the large grains from the folded

ends. To remove the grains, rub the

folded ends together.

Figure 3

Figure 4

Clarke®American Sanders American 8 Floor Sander Operator's Manual Page 9

8. Put the smooth side of the abrasive against the sanding

drum.

9. Put one end of the abrasive against the sanding drum slot

(1). See gure 3.

10. Turn the drum one revolution. Put the other end of the

abrasive in the drum slot (2).

See gure 3.

11. Tighten the abrasive.

To tighten the abrasive, follow this procedure:

1. The end wrenches are given with the machine.

Put a wrench around the nut at each end of the

durm (1).

See gure 4.

2. Make sure the at sides of the nuts

are parallel with the drum slot.

3. Turn the wrenches the opposite rotation

until the abrasive is tight against the drum (2).

See gure 4.

12. Remove the end wrenches.

13. Close the cover.

NOTE: When using #4 or 4½ grit abrasive,

remove the large grains from the folded

ends. To remove the grains, rub the

folded ends together.

Figure 3

Figure 4

8

Machine Set-Up

Chatter - Wave Prevention

American Sanders are designed and manufactured to the most rigid tolerances. However, after a nishing cut it is possible to see “chatter” or “waves”.

The

best guarantee to remove the chatter is to nish the oor with a rotating horizontal sander, such as American Sanders’s Sander 16.

To minimize chatter when using a belt or drum sander the following steps should be taken:

1) DRUM PAPER... insure the paper is secured in the slot, but not too tight. Paper that

is too tight will force the drum slot wider, leaving a “slot mark chatter” on the oor.

2) DRUM MARKS... are caused by the operator lowering the drum to the oor without forward traverse. These marks should be

removed by cutting at a 45 degree angle to the mark. Cutting at the mark while maintaining the same

path will only increase the mark depth and width.

3) UNEVEN WALKING PACE... can leave lengthy “waves”. The machine cuts more material during the slower pace. Pay

particular attention to a steady, even pace.

4) EXCESSIVE LIGHT CUTS... may reveal high spots on the paper/contact wheel and cause chatter. Take a heavier cut and

increase the pace.

5) DEBRIS... lodged between the paper and the drum will leave chatter. On a belt sander, debris may be adhered to the drum.

Insure the drum is clean and free of debris before placing the paper on.

6) SANDER PAPER QUALITY... may vary. Belt seams can be thicker on low quality paper and cause chatter. Use only

American Sanders specied sandpaper.

PROPER CARE OF YOUR MACHINE CAN MINIMIZE CHATTER AND WAVES

1) V-BELTS... can cause vibration and chatter if they are of low quality. Use only belts specied by American Sanders.

2) TRUCK AND CASTER WHEELS... with at spots, out-of-roundness, or debris adhered to their surface can cause “waves” or a

“chatter effect”. Always clean and inspect all wheels before starting to sand, and before the

nish cut. Replace or true the wheels if found to be out-of-round.

3) DUST PICK-UP SHOES.......may need adjusted differently for different materials that are to be sanded. An improperly adjusted

shoe will leave trailing debris that will be run over by the wheels and cause “random waves”.

4) CONTACT WHEELS (DRUMS)... may be out-of-round and cause “chatter”. Contact your American Sanders dealer for

assistance to true or replace the drum.

5) BEARINGS... in the motor, drum, or fan system may become worn and induce vibration which could cause “chatter”.

6) PULLEYS... that are damaged or severly worn can induce vibration and cause “chatter”. Contact your American Sanders

dealer for assistance.

American Sanders is not responsibile for rework of oors that are unacceptable to the customer. It is your

responsibility to insure your equipment is in proper operating order, and that you use the right machine for the job.

Clarke®American Sanders American 8 Floor Sander Operator's Manual Page 27

Chatter - Wave Prevention

Clarke American Sanders are designed and manufactured to the most rigid tolerances. However, after a nishing cut it is possible to

see “chatter” or “waves”.

The best guarantee to remove the chatter is to nish the oor with a

rotating horizontal sander, such as Clarke American Sanders’s Sander 16.

To minimize chatter when using a belt or drum sander the following steps should be taken:

1) DRUM PAPER...insure the paper is secured in the slot, but not too tight. Paper that

is too tight will force the drum slot wider, leaving a “slot mark chatter” on the oor.

2) DRUM MARKS........are caused by the operator lowering the drum to the oor without forward traverse. These marks

should be removed by cutting at a 45 degree angle to the mark. Cutting

at the mark while maintaining the same path will only increase the mark depth and width.

Clarke®American Sanders American 8 Floor Sander Operator's Manual Page 27

Chatter - Wave Prevention

Clarke American Sanders are designed and manufactured to the most rigid tolerances. However, after a nishing cut it is possible to

see “chatter” or “waves”.

The best guarantee to remove the chatter is to nish the oor with a

rotating horizontal sander, such as Clarke American Sanders’s Sander 16.

To minimize chatter when using a belt or drum sander the following steps should be taken:

1) DRUM PAPER...insure the paper is secured in the slot, but not too tight. Paper that

is too tight will force the drum slot wider, leaving a “slot mark chatter” on the oor.

2) DRUM MARKS........are caused by the operator lowering the drum to the oor without forward traverse. These marks

should be removed by cutting at a 45 degree angle to the mark. Cutting

at the mark while maintaining the same path will only increase the mark depth and width.

Clarke®American Sanders American 8 Floor Sander Operator's Manual Page 27

Chatter - Wave Prevention

Clarke American Sanders are designed and manufactured to the most rigid tolerances. However, after a nishing cut it is possible to

see “chatter” or “waves”.

The best guarantee to remove the chatter is to nish the oor with a

rotating horizontal sander, such as Clarke American Sanders’s Sander 16.

To minimize chatter when using a belt or drum sander the following steps should be taken:

1) DRUM PAPER...insure the paper is secured in the slot, but not too tight. Paper that

is too tight will force the drum slot wider, leaving a “slot mark chatter” on the oor.

2) DRUM MARKS........are caused by the operator lowering the drum to the oor without forward traverse. These marks

should be removed by cutting at a 45 degree angle to the mark. Cutting

at the mark while maintaining the same path will only increase the mark depth and width.

Initial Cut:

The purpose of the initial cut is to remove old nish and gross imperfections on the oor surface. The sanding equipment should be adjusted to heavy sanding

pressure setting and a coarse abrasive should be used. If the surface is severely damaged by deep scratches, pre-existing dwell marks, uneven planks, etc., it may

be necessary to sand across or diagonally to the grain to restore evenness to the surface. If these conditions are not present, the initial cut should be done in the

direction of the grain. If glazing, loading, or burning takes place immediately into an initial cut, select a coarser abrasive. If this should occur during an initial cut, the

abrasive has dulled and must be replaced.

Final Cuts:

The purpose of a nishing cut is to remove the scratches produced during the initial cut. Use a ne (60 - 80 grit) grain abrasive and a reduced sanding pressure setting.

If the surface remains rough after a nishing cut, it may be necessary to use an even ner grain of abrasive (80 - 100 grit). Care should be taken in selecting the grit

size of the abrasive. A very ne grain will close the pores on a wood oor making admission of a stain difcult. If glazing or burning should occur immediately into a

nishing cut, reduce the sanding pressure. If it should occur during a nishing cut, the abrasive has dulled and must be replaced.

9

Operating Instructions

Clarke®American Sanders American 8 Floor Sander Operator's Manual Page 11

To operate the machine follow this procedure:

1. Install the operator’s belt as follows:

a. Position the operator’s belt around waist.

b. Cross the straps at the waist. See gure 5.

c. Slide the belt loop end over the handle on the control

lever side. Adjust the length as needed.

d. Wrap the remaining strap around the opposite side of

the handle and hold it in place with your hand.

WARNING: Should quick release of the machine

be necessary, serious operator injury

could occur if the operator has tied the

loose end of the operator’s belt strap to

the machine. Always position the strap

so that you can let go and get away

quick in case of bag re or explosion.

2. Put the On/Off switch into the “ON” position.

DANGER: Serious damage can occur to the oor

surface if the machine is not in motion

while the contact wheel is running on

the oor surface. To prevent damage to

the surface, make sure the machine is

always moving when the contact wheel

is in contact with the oor.

3. Work right to left. For each forward pass, move the

machine 4” over the pass you have just nished. Retrace

your reverse path without overlapping. See gure 6.

4. Feather-cut in by easing the contact wheel down onto the

surface with the control lever while the sander is in motion.

5. When contact wheel is fully engaged with the surface,

gradually adjust your pace for adequate nish removal.

Keep sander in motion while the contact wheel is engaged

with the surface or dwell marks will occur.

6. Move the machine in the direction of the grain in the wood

whenever it is possible. Sand the surface at a constant

pace.

7. Gradually feather-cut out at the termination point (the end of

your pass) by easing the contact wheel up with the control

lever. Stagger the termination points for a better blend

when edging.

Figure 5

8. Empty dust bag whenever it is 1/3 full. Never leave a dust

bag unattended with sanding dust in it. Sanding dust

can spontaneously ignite and cause a re or explosion.

Empty dust into a metal container located outside of the

building.

DANGER: Sanding/nishing wood oors can create

an environment that can be explosive.

Cigarette lighters, pilot lights and any

other source of ignition can create an

explosion when active during a sanding

session. All sources of ignition should

be extinguished or removed entirely if

possible from the work area.

DANGER: Work areas that are poorly ventilated,

can create an explosive environment

when certain combustible materials are in

the atmosphere, i.e., solvents, thinners,

alcohol, fuels, certain nishes, wood dust

and other combustible materials. Floor

sanding machines can cause ammable

material and vapors to ignite. Read the

manufacturer’s label on all chemicals

used to determine combustibility. Keep

the work area well ventilated.

DANGER: Sanding dust can self ignite and cause

an injury or damage. Remove the

contents of the dust bag each time you

nish using the machine. Always dispose

of the dust in a metal container located

outside of the building. Never leave a

dust bag unattended with sanding dust in

it. Empty the contents frequently. Do not

empty the contents of the dust bag into a

re.

DANGER: Hitting a nail while sanding can cause

sparks and create an explosion or re.

Always use a hammer and punch to

countersink all nails before sanding

oors.

To operate the machine follow this procedure:

1. Install the operator’s belt as follows:

a. Position the operator’s belt around waist.

b. Cross the straps at the waist. See gure 5.

c. Slide the belt loop end over the handle on the control

lever side. Adjust the length as needed.

d. Wrap the remaining strap around the opposite side of

the handle and hold it in place with your hand.

WARNING: Should quick release of the machine

be necessary, serious operator injury could occur if the

operator has tied theloose end of the operator’s belt

strap to the machine. Always position the strap so that

you can let go and get away quick in case of bag

re or explosion.

2. Put the On/Off switch into the “ON” position.

DANGER: Serious damage can occur to the oor

surface if the machine is not in motion while the contact

wheel is running on the oor surface. To prevent damage

to the surface, make sure the machine is always moving

when the contact wheel is in contact with the oor.

3. Work right to left. For each forward pass, move the machine over

the pass you have just nished. Retrace your reverse path

without overlapping. See gure 6.

4. Feather-cut in by easing the contact wheel down onto the

surface with the control lever while the sander is in motion.

5. When contact wheel is fully engaged with the surface, gradually

adjust your pace for adequate nish removal. Keep sander in

motion while the contact wheel is engaged with the surface or

dwell marks will occur.

6. Move the machine in the direction of the grain in the wood

whenever it is possible. Sand the surface at a constant pace.

7. Gradually feather-cut out at the termination point (the end of your

pass) by easing the contact wheel up with the control lever.

Stagger the termination points for a better blend when edging.

Figure 5

8. Empty dust bag whenever it is 1/3 full. Never leave a dust

bag unattended with sanding dust in it. Sanding dust can

spontaneously ignite and cause a re or explosion. Empty dust

into a metal container located outside of the building.

To operate the machine follow this procedure.

Figure 5

10

Page 12 Clarke®American Sanders American 8 Floor Sander Operator's Manual

A. First pass forward, right to left. B. First pass reverse, retrace same path.

C. Second pass forward, overlap ½ the

drum width.

E. Work the remaining unsanded oor

in the same fashion, right to left.

Figure 6

D. Second pass reverse, retrace

second path forward, etc...for the

entire room.

Operating Instructions

A. First pass forward, right to left. B. First pass reverse, retrace same path.

C. Second pass forward, overlap ½ the

drum width.

D. Second pass reverse, retrace

second path forward, etc...for the

entire room.

E. Work the remaining unsanded oor

in the same fashion, right to left.

11

Sander Adjustment Procedures

DANGER:

Electrocution could occur if maintenance and repairs are performed

on a unit that is not properly disconnected from the power source.

Disconnect the power supply before attempting any

maintenance

or service.

DANGER: Moving parts of this machine can cause serious injury and/or

damage. Keep hands, feet and loose clothing away from all

moving parts of the sander.

Sanding Pressure

To adjust the sanding pressure follow this procedure:

1. Screw the sanding pressure knob down to increase the sanding pressure

when making the roughing in cut.

2. Screw the sanding pressure knob up to decrease the sanding pressure when

making the nishing cut.

Drum Rates

The machine can be operated at two rates. To change the speed of the drum,

follow this procedure:

1. Remove the belt cover.

2. Remove the fan belt.

3. Loosen the motor bolt.

4. Remove the hex nuts at the front of the motor.

5. Using the 5/32” Allen wrench, lower the motor locating screws.

6. Slide the motor forward.

7. For high drum rates, install drive belt in larger diameter of the grooves

available on the motor pulley and in the smaller diameter of the two grooves

available on the drum pulley. For lower rates, install drive belt in smaller

diameter of the grooves available on the motor pulley and in the larger

diameter of the two grooves available on the drum pulley.

8. Tighten belt and secure motor to chassis.

9. Install the fan belt.

10. Install the belt guard.

12

Sander Adjustment

Leveling

If the sanding drum is out of adjustment, follow this

procedure:

1. Remove the belt cover.

4. Tighten the eccentric lock screw. To tighten the eccentric lock

screw, turn the screw clockwise.

5. Install the belt cover.

How to Lubricate the Wheel Pivots

NOTE: The wheel pivots must be lubricated after every 25 hours of

use.

To lubricate the wheel pivots, follow this procedure:

1. Put the machine on its side.

2.

Lubricate the pivots. The pivots are behind the truck wheels. See gure 8

.

3. Put the machine on its wheels.

Operating Control

To increase the travel or extend the reach on the grip control follow this

procedure:

1. Loosen the locknut on the control rod. See gure 9.

2. Screw the control rod adjuster in until the desired reach is found.

3. Tighten the locknut.

To decrease the travel or reduce the reach on the grip control follow this

procedure:

1. Loosen the locknut on the control rod. See gure 9.

2. Screw the control rod adjuster out until desired reach is found.

3. Tighten the locknut.

Clarke®American Sanders American 8 Floor Sander Operator's Manual Page 15

Leveling

If the sanding drum is out of adjustment, follow this

procedure:

1. Remove the belt cover.

2. Loosen the eccentric lock screw. Using the 7/16” wrench,

turn the eccentric lock screw (1) counterclockwise. See

gure 7.

3. To raise or lower the drum, turn the eccentric (2). See gure 7.

4. Tighten the eccentric lock screw. To tighten the eccentric lock

screw, turn the screw clockwise.

5. Install the belt cover.

How to Lubricate the Wheel Pivots

NOTE: The wheel pivots must be lubricated after every 25

hours of use.

To lubricate the wheel pivots, follow this procedure:

1. Put the machine on its side.

2. Lubricate the pivots. The pivots are behind the truck wheels.

See gure 8.

3. Put the machine on its wheels.

Operating Control

To increase the travel or extend the reach on the grip control

follow this procedure:

1. Loosen the locknut on the control rod.

See gure 9.

2. Screw the control rod adjuster in until the desired reach is

found.

3. Tighten the locknut.

To decrease the travel or reduce the reach on the grip control

follow this procedure:

1. Loosen the locknut on the control rod.

See gure 9.

2. Screw the control rod adjuster out until desired reach is

found.

3. Tighten the locknut.

Figure 7

Figure 8

Figure 9

13

Routine Maintenance

The following items need to be periodically inspected and maintained to keep your sander in good working condition.

Wheels

Periodically remove the debris from the truck and caster wheels. Debris can cause waves on a sanded surface. Lubricate truck

mechanism every 25 hours of use. The machine is equipped with lubrication ttings and are located on shaft supporting mechanism.

Dust Bag

Remove the dust bag from the machine and shake it thoroughly to remove the sanding dust from the dust bag. Turn the dust bag

inside out and machine wash in cold water to prevent pore blockage and loss of dust recovery.

Drive Belt

Periodically check the drive belt tension.

Bearings

Periodically check the bearings for wear or damage according to the following schedule:

Idler pulley after 1st 1500 hrs.

Fan shaft after 1st 2500 hrs.

Arbor shaft after 1st 5000 hrs.

Motor shaft after 1st 5000 hrs.

14

Troubleshooting

Problem Cause Action

Drive belts slip. Insufcient tension. Tension drive belts

(Squeaking or squealing sound)

Worn belts. Replace belts.

Squealing, growling or grinding Damaged and/or worn bearing. Remove drive belts, rotate arbor

noise coming from machine. motor, fan, shafts and idler pulley to

located ragging or rough bearing

Contact an authorized dealer.

Dust p ck-up is poor. Dust bag is over 1/3 full. Empty contents of bag.

Dust bag is dirty. Shake debris from bag and wash.

Dust chute is obstructed Remove fan cover and clear throat.

Motor will not start. Defective motor starter. Contact an authorized dealer.

Defective start capacitor. Contact an authorized dealer.

Defective electronic starts switch. Contact an authorized dealer.

Defective motor Contact an authorized dealer.

No power Check power supply and connection. s

Motor runs sluggishly. Low voltage from excessive footage, Locate power source nearer to work site.

under sized extension cord, or poor Decrease sanding pressure.

connection

Defective run capacitor Contact an authorized dealer

Defective motor Contact an authorized dealer

Motor starter trips/repeatedly Excessive load. Contact an authorized dealer.

trips. Defective electronic start switch. Contact an authorized dealer

Defective motor starter Contact an authorized dealer.

Low voltage from poor connection. Contact an authorized dealer.

Defective motor Contact an authorized dealer.

Defective capacitor. Contact an authorized dealer.

Uneven cut. Leveling out of adjustment. Readjust leveling.

Burning or glazing. Dull abrasive Replace abrasive

Excessive sanding pressure Decrease sanding pressure setting.

Too ne of an abrasive. Use coarser abrasive

Slow cutting. Dull abrasive Replace abrasive

Too ne of an abrasive Use a coarser abrasive

Insufcient sanding pressure. Increase sanding pressure setting.

Waves on sanded surface. Debris on wheel. Remove and clean wheels.

Flat spot on tire(s). Replace tires.

Chatter marks on sanded Drum out of round. Contact an authorized dealer.

surface (close evenly spaced) or replace the drum.

Drum vibration. Change shim combination. Remove debris

from surface or ends of drum.

15

Notes

17

Wiring Diagram

Clarke®American Sanders American 8 Floor Sander Operator's Manual Page 19

WIRING DIAGRAM

18

Handle Assembly

1

45

2

345

6 7

8

9

10

11

12

15

13

21

22

833 23

13

11

10

26

3

34

32

31

35

36

41

38

43

37

39

31 42

41

40

36

32

24

25

27

28

26

29

30

17

16

18

19

20

44

22

8

33

Table of contents

Other Amano Sander manuals

Amano

Amano American Sanders OSB-18 User manual

Amano

Amano American SANDERS EZ-8 User manual

Amano

Amano American Sanders OBS-18DC User manual

Amano

Amano Pioneer Eclipse 225FP16TR User manual

Amano

Amano American SANDERS EZ Sand - HDTR User manual

Amano

Amano American SANDERS FloorCrafter User manual

Amano

Amano Pioneer Eclipse PE225FP User manual

Amano

Amano American Sanders American 12 User manual

Amano

Amano American Sanders 3DS User manual

Amano

Amano American SANDERS FloorCrafter User manual