Amano American Sanders Epoch HD User manual

Epoch HD

230V Dual Speed Rotary Sander

Operator’s Manual

READ THIS BOOK

This book has important information for the use and safe operation of this machine. Failure to read this book prior to

operating or attempting any service or maintenance procedure to your American Sanders machine could result in injury

to you or to other personnel; damage to the machine or to other property could occur as well. You must have training in

the operation of this machine before using it. If your operator(s) cannot read this manual, have it explained fully before

attempting to operate this machine.

All directions given in this book are as seen from the operator’s position at the rear of the machine.

***This product is intended for commercial use only***

WARNING!

The Products sold with this Manual contain or may contain chemicals that are known to certain governments (such as the State of

California, as identied in its Proposition 65 Regulatory Warning Law) to cause cancer, birth defects or other reproductive harm. In

certain locations (including the State of California) purchasers of these Products that place them in service at an employment job site

or a publicly accessible space are required by regulation to make certain notices, warnings or disclosures regarding the chemicals that

are or may be contained in the Products at or about such work sites. It is the purchaser’s responsibility to know the content of, and

to comply with, any laws and regulations relating to the use of these Products in such environments. The Manufacturer disclaims any

responsibility to advise purchasers of any specic requirements that may be applicable to the use of the Products in such environments.

In this Operation Manual you will find three statements that you must read and observe to ensure safe operation of this

machine.

DANGER means: Severe bodily injury or death can occur to you or other personnel if the DANGER statements

found on this machine or in this Operation Manual are ignored or are not adhered to. Read and observe

all DANGER statements found in this Operation Manual and on your machine.

WARNING means: Injury can occur to you or to other personnel if the WARNING statements found on your

machine or in the Operation Manual are ignored or are not adhered to. Read and observe all WARNING

statements found in this Operation Manual and on your machine.

CAUTION means: Damage can occur to the machine or to other property if the CAUTION statements found

on your machine or in this Operation Manual are ignored or are not adhered to. Read and observe all

CAUTION statements found in this Operation Manual and on your machine.

Operator Safety Instructions

EN

SECTION II - Parts and Service Manual

Notes ................................................................................13

Main Assembly ........................................................... 14-15

Base Assembly........................................................... 16-17

Handle Assembly........................................................ 18-19

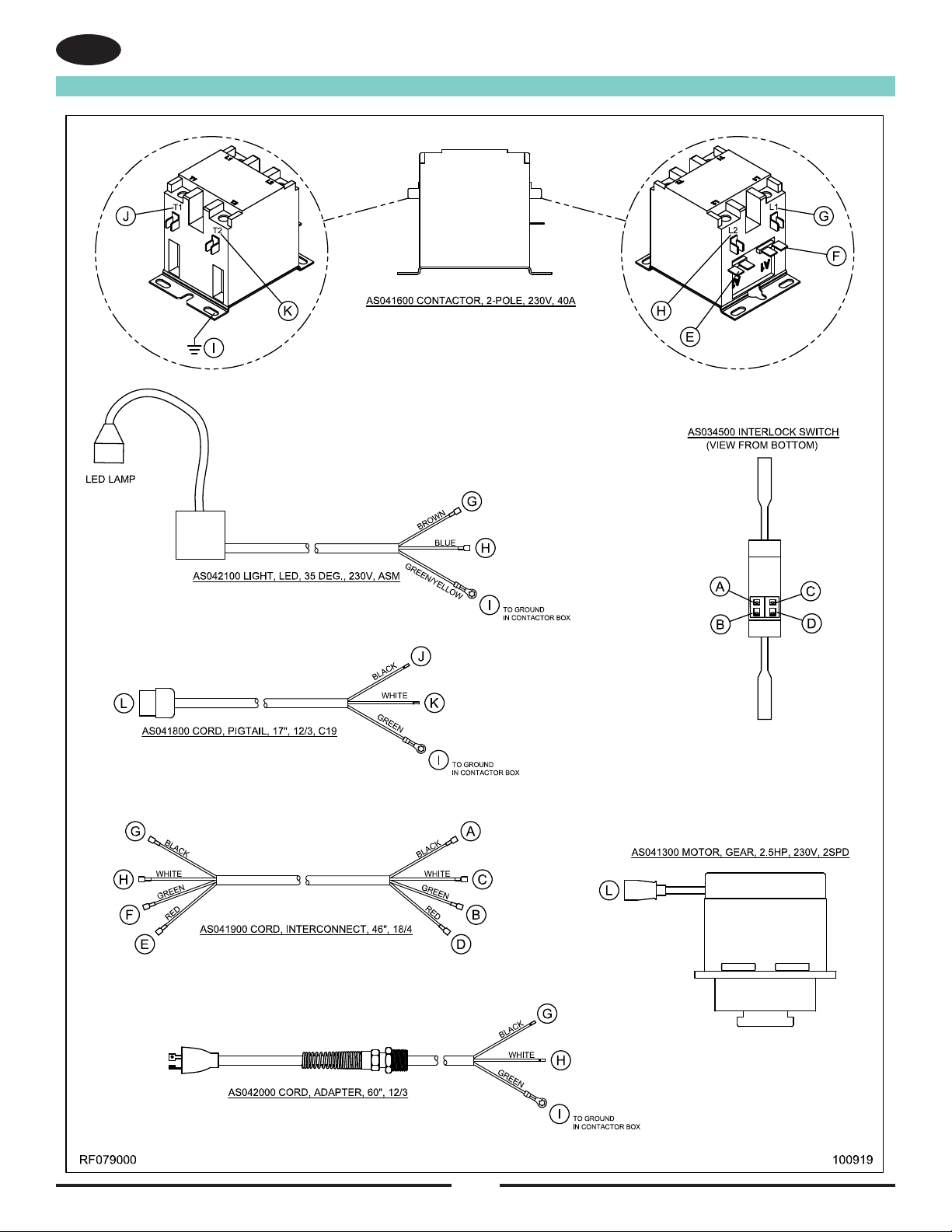

Connection Diagram.........................................................20

Motor & Gearbox Assembly..............................................21

16" HydraSand Assembly.................................................22

20" HydraSand Assembly.................................................23

Wiring Diagrams...............................................................24

Warranty ...........................................................................25

Contents

Operator Safety Instructions...................................................2-5

Machine Introduction ................................................................. 6

230V Electrical Connection Instructions.................................... 6

Machine Set-up ......................................................................7-8

Operating Instructions ............................................................... 9

Maintenance....................................................................... 10-11

3

EN

DANGER: Failure to read the Owner’s Manual prior to operating or servicing your American Sanders machine could result in injury to

you or to other personnel; damage to the machine or to other property could occur as well. You must have training in the

operation of this machine before using it. If you or your operator(s) cannot read English, have this manual explained fully

before attempting to operate this machine.

DANGER: A. Sanding/nishing wood oors can create an explosive or combustible environment. Do not operate this machine around

solvents, thinners, alcohol, fuels, oor nishes, wood dust or any other ammable materials. Cigarette lighters, pilot lights,

electrical sparks and all other sources of ignition should be extinguished or avoided. Keep work area well ventilated.

B. Dust generated from sanding wood oors can spontaneously ignite or explode. Promptly dispose of any sanding dust in

a metal container clear of any combustibles. Do not dispose in a re.

DANGER: A. Electrocution could occur if the machine is being serviced while the machine is connected to a power source. Disconnect

the power supply before servicing.

B. Electrocution or re could occur if the machine is being operated with a damaged power cord. Keep the power cord clear

of the pad. Always lift the cord over the machine. Do not move the machine by the power cord.

C.Shock hazard. Do not use the machine if it has been rained on or sprayed with water.

DANGER: To avoid injury keep hands, feet, and loose clothing away from all moving parts on the machine. Disconnect the power cord

before replacing the pad, changing the abrasive, or when servicing. Do not operate the machine unless all guards are in

place. Never leave the machine unattended while connected to a power source.

WARNING: Injury can occur if protective clothing or equipment is not used while sanding. Always wear safety goggles, protective

clothing, and dust mask while sanding.

WARNING:

This sander is not to be used on pressure treated wood. Some pressure treated woods contain arsenic and sanding

pressure treated wood produces hazardous dust. Inhaling hazardous dust from pressure treated wood can cause serious

injury or death. Sanding pressure treated wood decks or uneven surfaces can damage the sander which is not covered

under warranty or damage waiver.

WARNING: Any alterations or modications of this machine could result in damage to the machine or injury to the operator or other

bystanders. Alterations or modications not authorized by the manufacturer voids any and all warranties and liabilities.

WARNING: Risk of explosion. Floor sanding can result in an explosive mixture of ne dust and air. Use oor sanding machine only in a

well-ventilated area free from any ame or match.

4

EN

5

EN

6

Introduction

EN

The Epoch is a oor sanding machine. It can also be used for polishing, bufng and stripping. The machine can be used on wood, vinyl, terrazzo or cement oors.

CAUTION: Your equipment may be inappropriate on some installations. Always consult with the ooring manufacturer on the proper

installation, preparation, and nishing of their product. Determine suitability of your equipment in preparing the product.

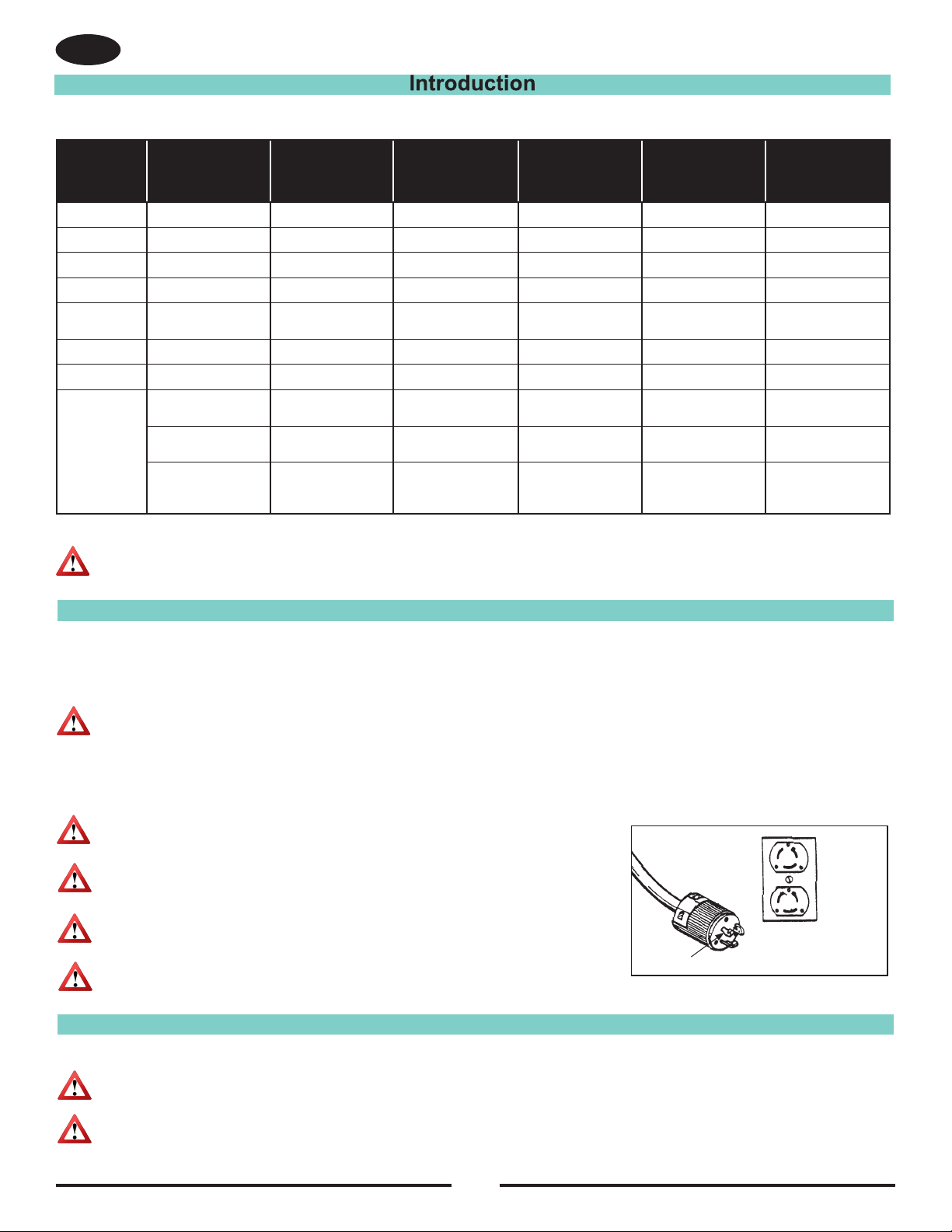

Model

07233A

EPOCH HD 16"

with HydraSand

07237A

EPOCH HD 16"

without HydraSand

07233C

EPOCH HD 16"

with HydraSand

(CSA)

07234A

EPOCH HD 20”

with HydraSand

07238A

EPOCH HD 20”

without HydraSand

07234C

EPOCH HD 20”with

HydraSand (CSA)

Voltage (Volts) 230 230 230 230 230 230

Frequency (Hz) 60 60 60 60 60 60

Current (Amps) 14 14 14 15 15 15

Power (HP) 2.5 (1.86 kw) 2.5 (1.86 kw) 2.5 (1.86 kw) 2.5 (1.86 kw) 2.5 (1.86 kw) 2.5 (1.86 kw)

Pad Driver

Diameter (in) 16 (401mm) 16 (401mm) 16 (401mm) 20 (508 mm) 20 (508 mm) 20 (508 mm)

Pad Speed (rpm) 175 or 300 175 or 300 175 or 300 175 or 300 175 or 300 175 or 300

Cord Length (ft) 50 (15.2m) 50 (15.2m) 50 (15.2m) 50 (15.2 m) 50 (15.2 m) 50 (15.2 m)

Weight (pounds)

Machine only

120 lbs (54 kg)

Machine only

120 lbs (54 kg)

Machine only

120 lbs (54 kg)

Machine only

120 lbs (56 kg)

Machine only

120 lbs (56 kg)

Machine only

120 lbs (56 kg)

Machine with weights

145 lbs (66 kg)

Machine with weights

145 lbs (66 kg)

Machine with weights

145 lbs (66 kg)

Machine with weights

150 lbs (68 kg)

Machine with weights

150 lbs (68 kg)

Machine with weights

150 lbs (68 kg)

Machine with weights

& HydraSand

158 lbs (72 kg)

Machine with weights

& HydraSand

158 lbs (72 kg)

Machine with weights

& HydraSand

158 lbs (72 kg)

Machine with weights

& HydraSand

169 lbs (72 kg)

Machine with weights

& HydraSand

169 lbs (72 kg)

Machine with weights

& HydraSand

169 lbs (72 kg)

Extension Cords (230V)

Use only an approved extension cord with two main conductors and one earthing conductor.

WARNING: If you use an extension cord, use an extension cord with minimum wire size 10 AWG. Do not use an extension cord longer

than 50 ft. Do not join two extension cords.

WARNING: Do not cut, remove, or break the ground terminal. Do not try to fit a three-terminal plug into a receptacle or connector body

that does not fit the plug. If the receptacle or connector body does not fit the plug, see your Authorized person to make

the connection.

Electrical Connection Instructions (230V)

This product must be grounded. If it should malfunction or breakdown, grounding provides a path of least resistance for electric current to reduce the

risk of electrical shock. This product is equipped with a cord having an equipment-grounding conductor and grounding plug. The plug must be inserted

into an appropriate oulet that is properly installed and grounded in accordance with all local codes and ordinances.

WARNING: Improper connection of the equipment-grounding conductor can result in a risk of electric shock. Check with qualied

This product is for use on a nominal 230 volt circuit and has a grounding attachment plug that looks like the plug illustrated in Fig. 12. Make sure that

the product is connected to an outlet having the same conguration as the plug. No adaptor should be used with this product.

WARNING: To prevent possible electric shock, protect the machine from rain.

Keep the machine in a dry building.

WARNING: To prevent possible electric shock, always use a 3-wire electrical

system connected to the electrical ground. Consult your electrical contractor.

WARNING: Do not cut, remove or break the ground pin.

If the outlet does not t the plug, consult your electrical contractor.

WARNING: Have worn, cut or damaged cords replaced by an authorized service person.

Instructions for connection to the power supply and the electrical ground.

Figure 12

Grounded

Outlet

Grounding

Pin

Grounded

Outlet

Box

electrician or service person if you are in doubt as to whether the outlet is properly grounded. Do not modify the plug

provided with the product - if it will not t the outlet, have a proper outlet installed by a qualied electrician.

7

Machine Set-up

EN

WARNING:

Always remove the electrical plug from the electrical outlet before installing or

changing the sandpaper.

How To Install The Sandpaper (HydraSand)

To install the sandpaper, follow this procedure:

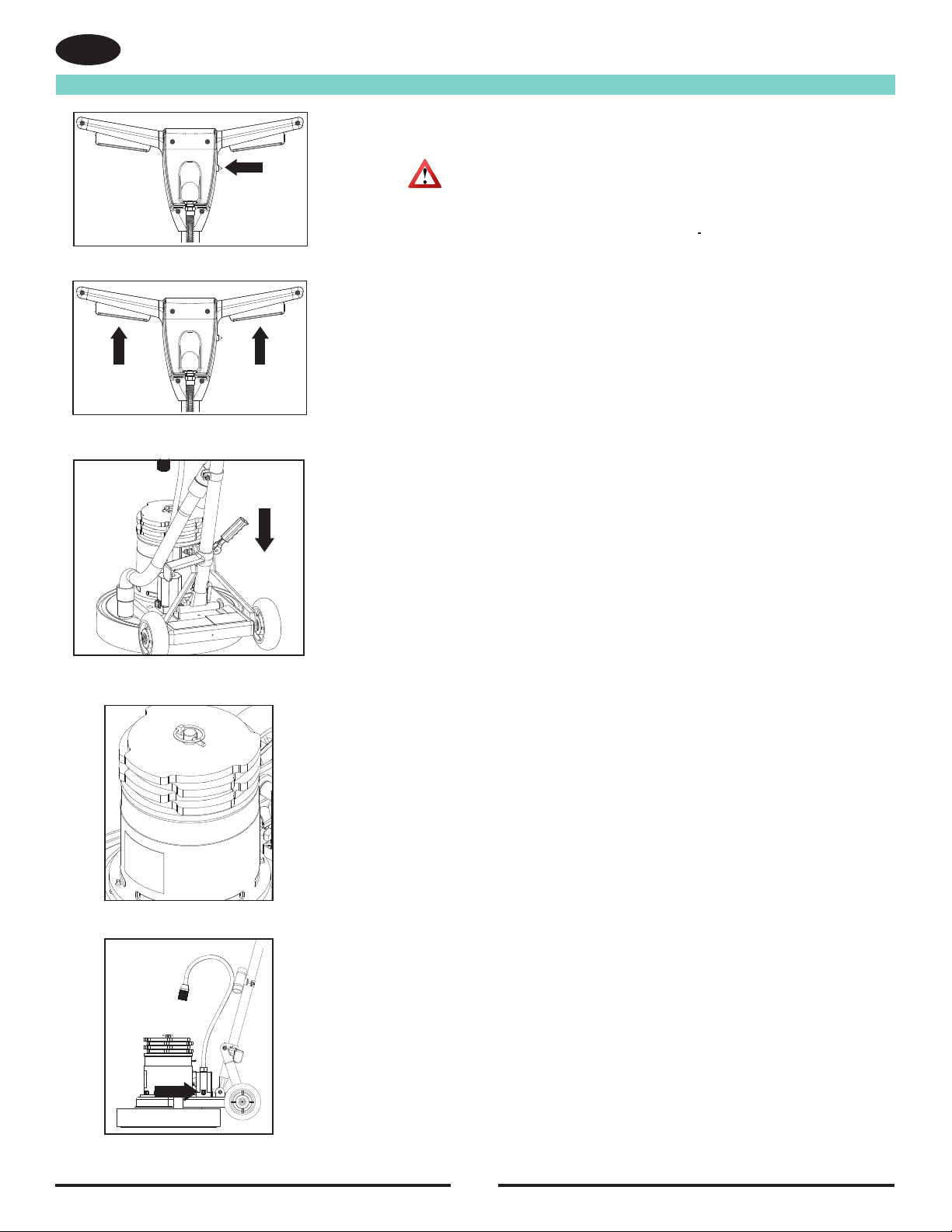

1. Put the handle in the vertical position.

2. Lock the handle. To lock the handle, push the locking lever down. See gure 1.

3. Tilt the machine backward until the handle is on the oor.

4. Put one foot on each side of the machine.

5. The HydraSand sanding head utilizes hook and loop style sanding paper. Pull off the pad hook the spent

abrasive

6. Replace with new sanding abrasive. See gure 1A.

How To Install The Sandpaper (Alternate Hard Plate)

1. Put the handle in the vertical position.

2. Lock the handle. To lock the handle, push the locking lever down. See gure 1.

3. Tilt the machine backward until the handle is on the oor.

4. Put one foot on each side of the machine.

5. Using a 7/8 wrench, remove the nut and the washer that hold the paper holder.

See gure 2.

6. Put the sandpaper on the sanding pad.

7. Put the paper holder in position. See gure 3.

8. Install the washer and the nut that hold the paper holder.

Two Speed Selection

This machine comes equipped with a selector switch for 175 or 300 RPM operation.

See gure 4 for location of speed switch.

175 RPM speed selection is for use with ner grit sanding abrasive (100 grit or greater) to help reduce the effects

of abrasive heat on the wood that can lead to closing wood pours and discoloration from burnishing the woods

surface. This speed is also used for bufng and polishing.

300 RPM operation will yield the greatest wood removal and productivity and can successfully be used with

more course grit abrasives. (80 grit or below)

CAUTION: Wood species differ greatly in their sanding characteristics, always test the speed

selection with any grit abrasive used to understand how the wood will react. The general guidelines

given here may not be appropriate for your conditions.

CAUTION: Do not use the 175 RPM setting for 80 grit or lower. This could result in an over-current

condition.

Sanding Cuts and Sandpaper

Initial Cut

The purpose of the initial cut is to remove old nish and gross imperfections on the oor surface. A coarse

abrasive should be used.

If glazing, loading, or burning takes place immediately into an initial cut, select a coarser abrasive. If this should

occur during an initial cut, the abrasive has dulled and must be replaced.

Final Cuts

The purpose of a nishing cut is to remove the scratches produced during the initial cut. Use a ne (60-80 grit)

grain abrasive.

If the surface remains rough after a nishing cut, it may be necessary to use an even ner grain of abrasive (80-

100 grit). Care should be taken in selecting the grit size of the abrasive. A very ne grain will close the pores on

a wood oor making admission of a stain difcult. Note some ner grain abrasives may begin to heat the woods

surface and burnish the wood grain. use the low motor speed to help avoid this result.

Figure 2

Figure 1

Figure 1A

Figure 4

Figure 3

8

Machine Set-up

EN

WARNING: Always remove the electrical plug from the

electrical outlet before installing or changing

the pad or brush.

How To Install The Brush Or Pad Driver

To install the brush or pad driver, follow this

procedure:

1. Put the handle in the vertical position.

2. To lock the handle, push the locking lever down.See gure 5.

3.

Tilt the machine backward until the handle is on the oor. See gure 6.

4. Put one foot on each side of the machine. See gure 6.

5. Align the lugs (1) on the locking plate into the pad driver adapter

openings (2). See gure 7.

6. To lock the brush or pad into position, turn the brush or pad driver

clockwise.

7. Turn the brush or pad counterclockwise to unlock and remove the

brush.

8. Lift the machine to the vertical position.

NOTE: To prevent damage to the brush or pad driver, remove the

accessory while not in use. Keep the brush in a cool, dry place.

How To Adjust The Handle

To adjust the handle, follow this procedure:

1. The locking lever is on the lower part of the handle tube. Use your

foot to lift the lever. See gure 5.

2. Lower the handle to the best operating position.

NOTE: For the best operating position, keep your back straight, bend

only your arms.

3. Using your foot, push the locking lever down.

4. Hold the handle against your body for the best control.

Figure 5

Figure 6

Figure 7

1. The lugs.

2. The drive adpater openings.

9

WARNING: Never start machine when the handle is in the vertical

position.

The switch to start and stop the machine is activated by the interlock switch (Fig. 8) and

the levers (Fig 8A) under the handle grips.

To start the machine, follow this procedure:

1. Lower the handle

2. Lock the handle in the best position for operation. (Fig. 9)

NOTE: Make sure you hold the handle with both hands.

3. Push the interlock switch (Fig. 8), and apply pressure to the levers

(Fig. 8A).

How To Control The Machine

NOTE: Sanding operations create higher torque conditions than normal oor polishing.

Make sure you rmly grip the handle with both hands.

The side to side movement of the machine is controlled by raising the handle and pressing

down on the handle. To move the machine to the left, press down on the handle slightly.

To move the machine to the right, raise the handle slightly.

Adding And Removing Additional Weight

This Machine comes with four (4) 6.25 pound (2.8 kg) removable weights for a total of

25 pounds (11.3 kg) maximum that can be added to increase the PSI load and abrasive

performance. See gure 10.

Caution should be used if adding weight to the machine as this increases the torque

required to turn the abrasive, thus increasing the amperage required by the motor to

perform the sanding operation.

Floors with nish or residue like sealers increase the resistance on the abrasive; adding

weight in this condition can overload the motor and trip a 20 amp circuit breaker.

Should this occur allow 15 minutes for the machine and breaker to cool. Remove additional

weight and operate the machine in the 300 rpm setting to reduce the load placed on the

motor.

How To Use The Lamp

To Position the Lamp

1. The attached LED lamp will only operate when the machine is plugged in.

2. Bend the exible arm of the lamp to the desired position.

3. Press the “ON” switch at the base of the lamp attached to the frame of the machine.

See gure 11.

Operating Instructions

EN

Figure 8

Figure 8A

Figure 9

Figure 11

Figure 10

10

EN

Maintenance

WARNING: Maintenance must be done by authorized personnel only.

CAUTION:

Keep all adjustments according to specications.

Maintenance Instructions

Return the machine to a American Sanders Authorized Service Location every 12 months for maintenance inspections.

Switches

WARNING: All electrical repairs must be done by authorized personnel only. The machine must be tested after electrical

repairs to make sure it is safe to operate. Disconnect the electrical plug from the electrical outlet before doing

any electrical repairs.

The start and stop switch has an interlock which prevents the contacts from being closed. If any part of the switch is not operating, replace the

part. If any part of the electrical system of the machine is not operating or is damaged, replace the part. Make sure all connections are tight.

Return the machine to the American Sanders Service Branch or a American Sanders Authorized Service Center for electrical repairs or testing.

Maintenance Of The Motor

If repairs to the gear unit or motor are needed, do not disassemble the gears and motor. Return the machine to the nearest American Sanders

Service Branch or American Sanders Authorized Service Center.

For safe operation, and longer life to your American Sanders product, use only American Sanders parts.

NOTE: The grease (503802) for the gear box needs to be changed every year. The Epoch requires 8 oz. of grease.

11

EN

Problem Possible Cause Solution

Machine will not start

No power Check the main power supply (building circuit breaker).

Check the cord connection at the wall outlet

Switch lever safety lock not

depressed

Hold in the switch lever safety lock and then engage

switch levers.

Bad connection Check the motor and cord interlock connections.

Bad motor speed selector

switch

Change the motor speed. If motor runs, change the

speed selector switch.

Defective Switch Check and replace if necessary.

Motor runs sluggish

Low voltage

Using extension cord with wire smaller than 10/3.

Replace with a 10/3 extension cord.

Using more than one extension cord. Only use one 50ft

10/3 extension cord.

Electrically connect to American Sanders Power

Booster.

Motor carbon brushes are worn Check and replace if necessary.

Defective handle switch Check and replace if necessary.

Bad rectier Contact an authorized American Sander Dealer.

Fuse / circuit breaker repeatedly trips

Low voltage

Eliminate extension cord & locate a power source closer

to work site.

Have voltage checked by a qualied electrican.

Electrically connect to American Sanders Power

Booster.

Not on a dedicated circuit Make sure there is no other items using power on the

circuit.

Motor is overloaded

Remove weights.

Switch to high speed, especially if using paper lower

than 100 grit or if removing nish.

Bad connection Contact an authorized American Sander Dealer.

Defective motor Contact an authorized American Sander Dealer.

Machine wobbles during operation

Defective pad One side is more dense than the other. Replace pad.

Machine left setting on pad for

extended time Pad has taken "a set". Replace pad.

Warped block on brush or

padholder Check and replace if necessary.

Block not installed properly Remove and install properly.

HydraSand head damaged. Inspect head and repair or replace

Light does not work Light switch not turned "ON". Turn "ON" light.

Light damaged Check and replace if necessary.

Maintenance

52

FloorCrafter

Belt Sander

Parts Manual

Notes:

________________________________________________

________________________________________________

________________________________________________

________________________________________________

________________________________________________

________________________________________________

________________________________________________

________________________________________________

________________________________________________

________________________________________________

________________________________________________

________________________________________________

________________________________________________

________________________________________________

________________________________________________

________________________________________________

________________________________________________

________________________________________________

________________________________________________

________________________________________________

________________________________________________

________________________________________________

________________________________________________

13

52

FloorCrafter

Belt Sander

Parts Manual

Notes:

________________________________________________

________________________________________________

________________________________________________

________________________________________________

________________________________________________

________________________________________________

________________________________________________

________________________________________________

________________________________________________

________________________________________________

________________________________________________

________________________________________________

________________________________________________

________________________________________________

________________________________________________

________________________________________________

________________________________________________

________________________________________________

________________________________________________

________________________________________________

________________________________________________

________________________________________________

________________________________________________

Epoch HD

Operator’s Manual

14

Main Assembly

EN

RF079200 122019

19

13

14

15

17

16

6

8

7

11

12

10

20

21

23

3

1

9

22

4

18

27

14

26

29

19

25

24

29

28

31

30

32

2

5

15

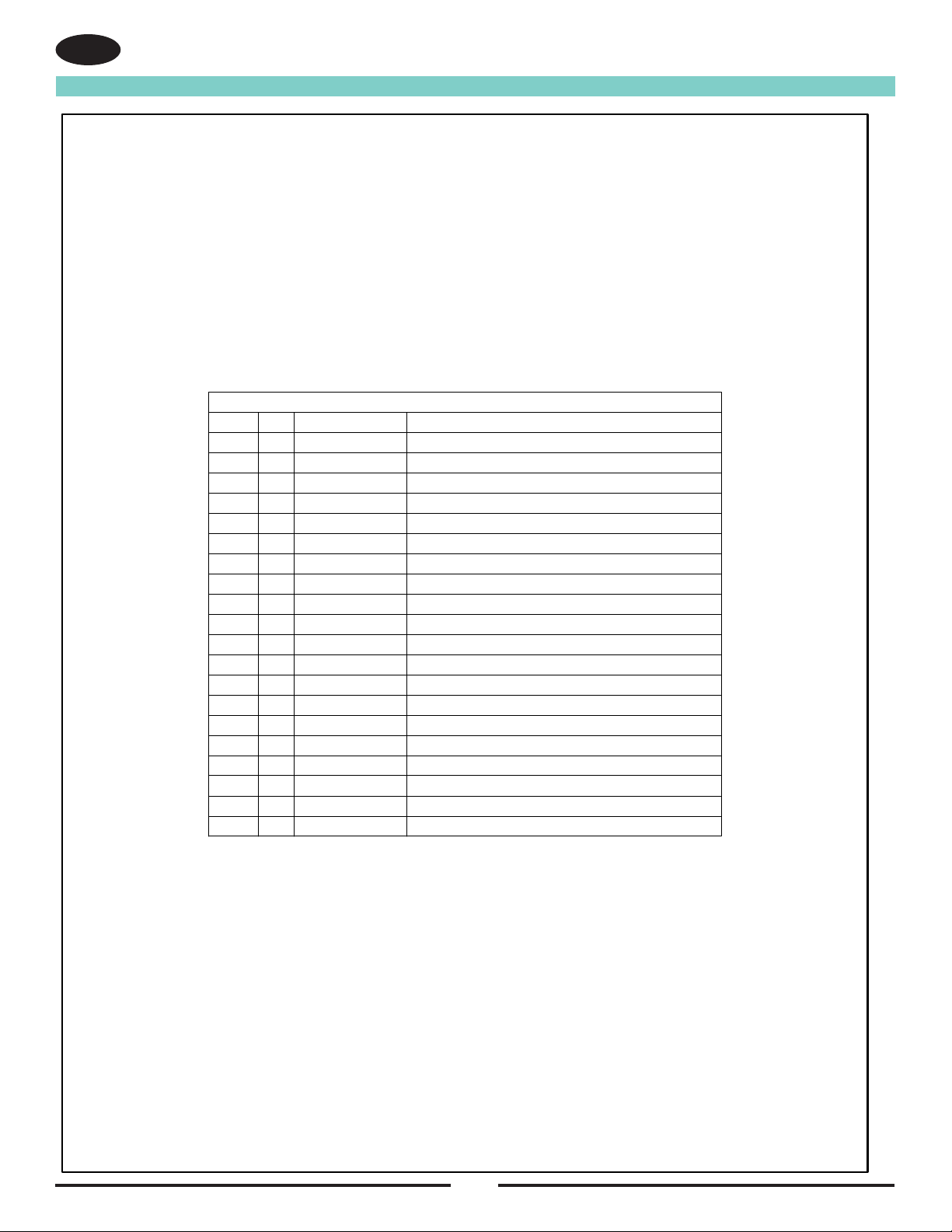

Main Assembly

EN

PARTS LIST

DESCRIPTION

PART

NUMBER

QTY

ITEM

HANDLE ASM., SANDERS, 07233AAS042200

CORD SET-HARD SERVICE (50 FT)

42200A

BUSHING NYLON C2K50794A

MOTOR, GEAR, 2.5HP, 230V, 2SPDAS041300

DECAL, AMERICAN SANDERS, 3"AS013600

SEAL FOAM52368A

WLDMNT DUST SHIELD

10241A

SHIELD, DUST, 20", WELDMENT (20" MODELS ONLY)AS058500B7 1

1 1

2 1

3 2

4 1

5 1

6 1

7 1

8 1

9 1

BUMPER 1730381A

BUMPER, SHROUD, 20"(20" MODELS ONLY)AS058700

B8 1

SHIELD INNER RS 16DC61832A

SHIELD, INNER, 20"(20" MODELS ONLY)AS058600

B9 1

SCREW, 5/16-18 X 2 1/2", SHCS, W/ DOG PTNB07380001 4

WASHER 5/16 SAE FLAT98065111 4

WASHER, LOCK, 5/16

98065221 4

PLATE, WEIGHT, BRACKET, 7.8" DIA.AS02500031 1

SCREW, SOCKET, FLAT, 10-32 X 3/4, CS, SS

NB07350041 7

ROD, WEIGHT, BRACKET, THREADEDAS02510051 1

PIN, LYNCH, 1/4" X 1 3/4"NB04630061 1

WEIGHT, 8" DIA, W/ RUBBER FEETAS027200

4

17

FEET, RUBBER, .81"OD, .12" H, BLACK (NOT SHOWN-

3 REPLACEMENT FEET PER WEIGHT )

AS02520012

-

LIGHT, LED, 35 DEG., 230V, ASMAS04210081 1

BULB, LIGHT, LED (NOT SHOWN)AS027600

1

-

TRANSFORMER, LIGHT, LED, 230V (NOT SHOWN)AS0286001

-

SHADE, LIGHT, LED (NOT SHOWN)AS0278001

-

TRANSFORMER HOUSING, LIGHT, LED (NOT SHOWN)AS027900

1

-

SOCKET WIRE ASM, LIGHT, LED (NOT SHOWN)AS0280001

-

ROCKER SWITCH, LIGHT, LED (NOT SHOWN)AS028100

1

-

SWITCH COVER, LIGHT, LED (NOT SHOWN)AS0282001

-

SCREW, 8-32 X 1", RH, PHILLIPSNB07390091 8

SKIRT, RS-16DC

30725A

SKIRT, 20" DIA X 3.25"H, VINYL (20" MODELS ONLY)

AS059920

02 1

B02 1

SKIRT, 20" DIA X 3"H, FABRIC (20" MODELS ONLY)

AS058800

C02 1

ASSY PAD DRIVER

10242A12 1

DRIVER, PAD, 20", MIGHTY-LOK (20" MODELS ONLY)AS042500B12 1

PLATE, DRIVE, HYDRA SAND, KITSA03160022 1

HYDRASAND 20" KIT (20" MODELS ONLY)SA035400

B22 1

1.5" X 30" CUFFS BE BLACK30408B32 1

GROMMET, 11/16 X 1

NB00990042 1

CONDUIT CONNECTOR 3/8" 2-SCREW17063752 1

BASE, CONTACTOR BOX,W/INSERTSAS04340062 1

COVER, CONTACTOR BOX,W/INSERTSAS043500

72 1

CONTACTOR, 2-POLE, 230V, 40AAS04160082 1

NUT, KEPS, 10-32

NB00660092 8

WASHER, LOCK 1/4"98065703 2

WASHER 1/4 SAE FLAT PLTD98064613 2

SCREW 1/4-20 X 3/4 HX SZ CAP

85806A23 2

RF079200 072420

16

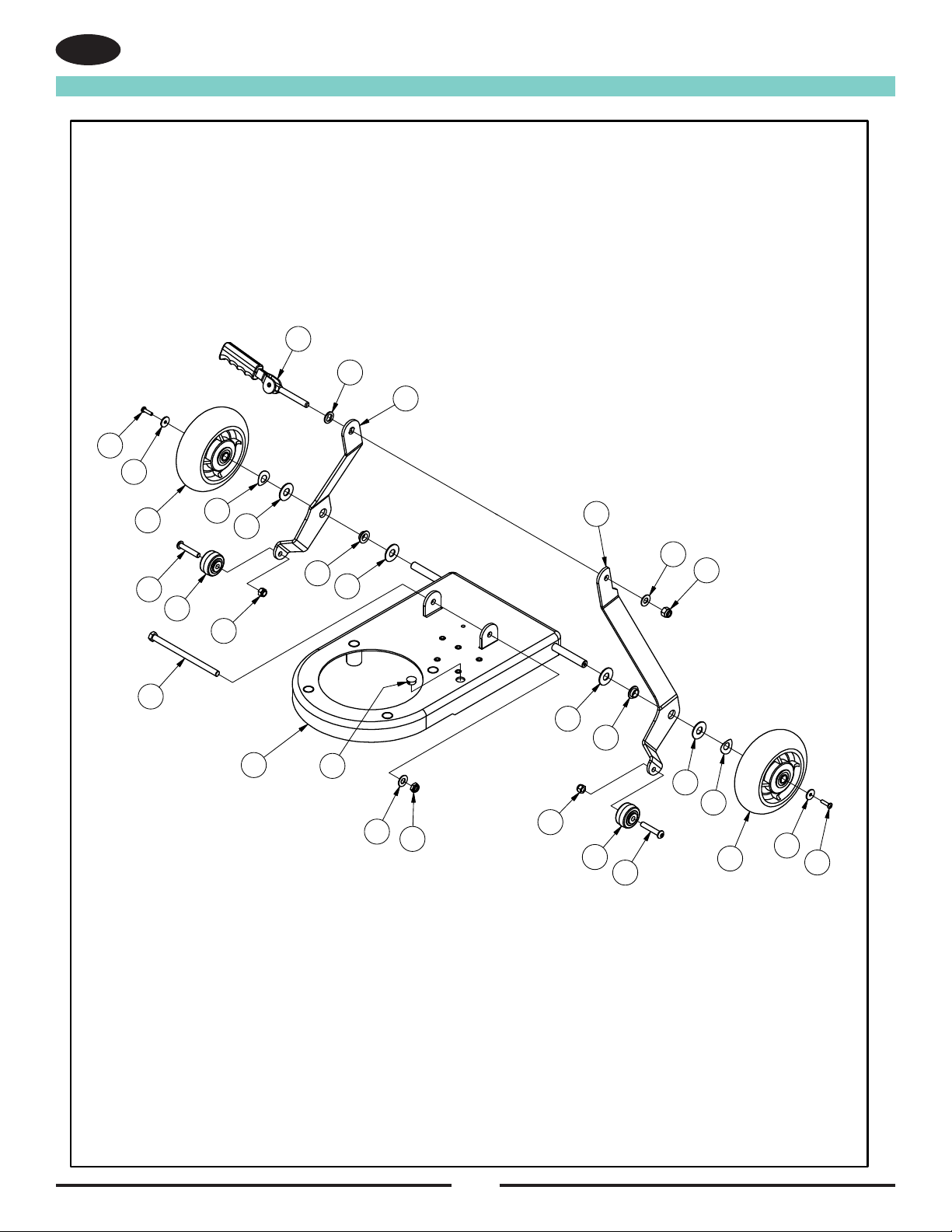

Base Assembly

EN

RF078900 121919

15

16

8

9

14

6

14

6

9

8

2

16

15

2

3

4

12

10

11

13

7

17

15

12

20

18

19

20

18

19

17

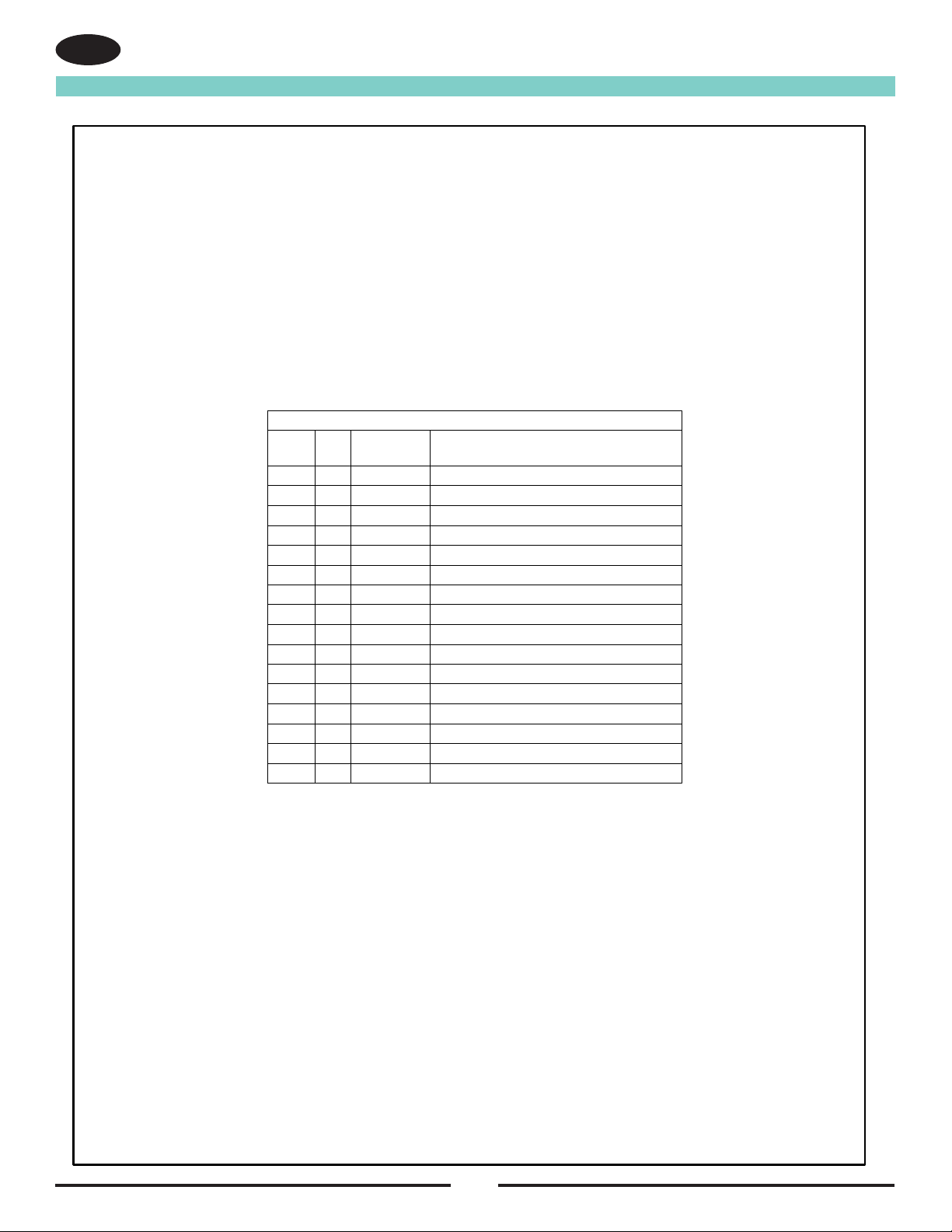

Base Assembly

EN

PARTS LIST

DESCRIPTION

PART NUMBER

QTY

ITEM

FRAME, EPOCH, W/ INSERTSAS02710011

WHEEL, PERFORMA, 6" GREYRV00960022

ARM, LINK, RIGHT, EXTENDED,PLTAS04380213

ARM, LINK, LEFT, EXTENDED,PLT

AS043902

14

PLUG-BUTTON

57120A15

BUSHING, FLANGED, BRONZE, 1/2 ID X 1/4 LMP16540026

SCREW 3/8-16 X 680087A1

7

WASHER BOWED .516ID X 1.06OD80295A28

WASHER, FLAT, 1/2", SSNB03460029

NUT LK 3/8 -16 REG

920342110

WASHER WEAR CAM

980349111

WASHER, 3/8" SAE, FLAT980645212

CAM ASSY WITH GRIP56109699113

WASHER FLT 1.25X .52 X .06 NYLON87607A214

SCREW 10-32 X 3/4 PAN HD85383A215

WASHER FLAT 10 TYPE B WIDE

80291A216

NUT 3/8-16 ESNA LIGHT

920248117

WHEEL, PERFORMA, 1 5/8 X 7/8MP246200218

SCREW, BH, 5/16-18 X 1 3/4NB3003219

NUT, 5/16-18 HEX LOCK920110220

RF078900 121919

18

Handle Assembly

EN

RF078800 100719

4

4

2

10

16

6

5

13

15

14

3

8

9

11

12

1

7

19

Handle Assembly

EN

Parts List

DESCRIPTION

PART

NUMBER

QTY

ITEM

HANDLE FRONT CFP

21074A11

HANDLE BACK CFP21075A12

CLAMP HANDLE C2K50781A13

SCREW 10-32UNF X .75 HRCS80284A64

SCREW 10-32 X 3/8 HRCS

80290A15

WASHER FLAT 10 TYPE B WIDE

80291A16

MODULE INTERLOCK ASM.AS0345001

7

TUBE, HANDLE, 1600AS02950018

BUSHING CORD C2K50796A19

CORD, ADAPTER, 60", 12/3AS042000110

CORD, INTERCONNECT, 46", 18/4AS041900

111

DECAL, HANDLE, EPOCH HDAS042600

112

ADAPTER, HOSE, SANDER, WELD.10304A113

BOLT, CARRIAGE, 5/16-18 X 1 1/288643A114

NUT, 5/16-18 HEX LOCK920110115

LABEL CCA WARNING71347A116

RF078800 100719

20

Connection Diagram

EN

This manual suits for next models

1

Table of contents

Other Amano Sander manuals

Amano

Amano American SANDERS EZ-8 User manual

Amano

Amano Pioneer Eclipse PE225FP User manual

Amano

Amano American Sanders American 12 User manual

Amano

Amano American SANDERS EZ Sand - HDTR User manual

Amano

Amano Pioneer Eclipse 225FP16TR User manual

Amano

Amano American Sanders 3DS User manual

Amano

Amano American Sanders OSB-18 User manual

Amano

Amano American Sanders OBS-18DC User manual

Amano

Amano American SANDERS FloorCrafter User manual

Amano

Amano American SANDERS FloorCrafter User manual