Amano American SANDERS FloorCrafter User manual

Belt Sander

FloorCrafter

Operator’s Manual

Contents

Operator Safety Instructions......................................................3-6

Introduction...................................................................................7

Machine Specifications................................................................. 7

230V Electrical Schematic............................................................ 7

Machine Transportation.............................................................8-9

Machine Setup ........................................................................9-10

Machine Operation................................................................ 11-12

Chatter-Wave Prevention........................................................... 13

Sanding Cuts & Sandpaper........................................................ 13

Sander Adjustment Procedure ................................................... 14

Routine Maintenance .................................................................16

Troubleshooting.....................................................................17-18

Wiring Diagram...........................................................................53

Handle Assembly...................................................................54-55

Base Assembly......................................................................56-57

Belt Tensioner Assembly.......................................................58-59

Dolly Assembly......................................................................60-61

Dust Control Assembly.........................................................62-63

Motor Assembly.....................................................................64-65

Sanding Drum Assembly.......................................................66-67

READ THIS BOOK

This book has important information for the use and safe operation of this machine. Failure to read this book prior to

operating or attempting any service or maintenance procedure to your American Sanders machine could result in injury

to you or to other personnel; damage to the machine or to other property could occur as well. You must have training in

the operation of this machine before using it. If your operator(s) cannot read this manual, have it explained fully before

attempting to operate this machine.

All directions given in this book are as seen from the operator’s position at the rear of the machine.

***This product is intended for commercial use only***

WARNING!

The Products sold with this Manual contain or may contain chemicals that are known to certain governments (such as the State of

California, as identied in its Proposition 65 Regulatory Warning Law) to cause cancer, birth defects or other reproductive harm. In

certain locations (including the State of California) purchasers of these Products that place them in service at an employment job site

or a publicly accessible space are required by regulation to make certain notices, warnings or disclosures regarding the chemicals that

are or may be contained in the Products at or about such work sites. It is the purchaser’s responsibility to know the content of, and

to comply with, any laws and regulations relating to the use of these Products in such environments. The Manufacturer disclaims any

responsibility to advise purchasers of any specic requirements that may be applicable to the use of the Products in such environments.

In this Operation Manual you will find three statements that you must read and observe to ensure safe operation of this

machine.

DANGER means: Severe bodily injury or death can occur to you or other personnel if the DANGER

statements found on this machine or in this Operation Manual are ignored or are not adhered to. Read

and observe all DANGER statements found in this Operation Manual and on your machine.

WARNING means: Injury can occur to you or to other personnel if the WARNING statements found on

your machine or in the Operation Manual are ignored or are not adhered to. Read and observe all

WARNING statements found in this Operation Manual and on your machine.

CAUTION means: Damage can occur to the machine or to other property if the CAUTION statments found

on your machine or in this Operation Manual are ignored or are not adhered to. Read and observe all

CAUTION statments found in this Operation Manual and on your machine.

Operator Safety Instructions

EN

4

EN

DANGER: Failure to read the Owner’s Manual prior to operating or servicing your American Sanders machine could result in

injury to you or to other personnel; damage to the machine or to other property could occur as well. You must have

training in the operation of this machine before using it. If you or your operator(s) cannot read English, have this

manual explained fully before attempting to operate this machine.

DANGER: A. Sanding/nishing wood oors can create an explosive or combustible environment. Do not operate this machine

around solvents, thinners, alcohol, fuels, oor nishes, wood dust or any other ammable materials. Cigarette

lighters, pilot lights, electrical sparks and all other sources of ignition should be extinguished or avoided. Keep

work area well ventilated.

B. Dust generated from sanding wood oors can spontaneously ignite or explode. Promptly dispose of any sanding

dust in a metal container clear of any combustibles. Do not dispose in a re.

DANGER: A. Electrocution could occur if the machine is being serviced while the machine is connected to a power source.

Disconnect the power supply before servicing.

B. Electrocution or re could occur if the machine is being operated with a damaged power cord. Keep the power

cord clear of the drum. Always lift the cord over the machine. Do not move the machine by the power cord.

C. Shock hazard. Do not use the machine if it has been rained on or sprayed with water.

DANGER: To avoid injury keep hands, feet, and loose clothing away from all moving parts on the machine. Disconnect the

power cord before changing the abrasive or when servicing. Do not operate the machine unless all guards are in

place. Never leave the machine unattended while connected to a power source.

WARNING: Injury can occur if protective clothing or equipment is not used while sanding. Always wear safety goggles,

protective clothing, and dust mask while sanding.

WARNING: Thissanderisnottobeusedonpressure-treatedwood.Somepressure-treatedwoodscontainarsenicandsanding

pressure-treated wood produces hazardous dust. Inhaling hazardous dust from pressure-treated wood can cause

serious injury or death. Sanding pressure-treated wood decks or uneven surfaces can damage the sander which is

not covered under warranty or damage waiver.

WARNING: Any alterations or modications of this machine could result in damage to the machine or injury to the operator or

otherbystanders. Alterations or modications not authorized by the manufacturer voids any and all warranties and

liabilities.

WARNING: Risk of explosion. Floor sanding can result in an explosive mixture of ne dust and air. Use oor sanding machine

only in a well-ventilated area free from any ame or match.

5

EN

WARNING: Read all safety warnings and instructions. Failure to follow warnings and instructions may result in electric shock, re

and or serious injury.

Save all warnings and instructions for future use.

Safety Warnings For Sanding Operations

1. This power tool is intended to function as a sander. Read all safety warnings, instructions and specications provided with this power

tool. Failure to follow all instructions listed below may result in electric shock, re, or personal injury.

2. Operations such as grinding, wire brushing, polishing or cutting-off are not recommended to be performed with this power tool.

Operations for which the tool was not designed may create a hazard and cause personal injury.

3. Do not use accessories which are not specically designed and recommended by the tool manufacturer. Just because the accessory can

be attached to your power tool does not assure safe operation.

4. Wear personal protective equipment. Depending on application, use face shield, safety goggles or safety glasses.As appropriate, wear

dust mask, hearing protectors, gloves and workshop apron capable of stopping ying debris generated by various operations. The eye

protection must be capable of stopping ying debris generated by various operations. The dust mask or respirator must be capable of

ltering particles generated by your operations. Prolonged exposure to high intensity noise may cause hearing loss.

5. Keep bystanders a safe distance away from work area.Anyone entering the work area must wear personal protective equipment.

Fragments of work piece or a broken accessory may y away and cause injury beyond immediate area of operation.

6. Hold power tool by gripping insulated surfaces (handle) only, when performing an operation where the cutting accessory may contact

hidden wiring or its own cord. Cutting accessory contacting a "live" wire may make exposed metal parts of the power tool "live" and shock

the operator.

7. Position the cord clear of the drum. If you lose control, the cord may be cut or snagged, and the operator or others could be shocked

by a live wire.

8. Do not operate the power tool near ammable materials. Sparks could ignite these materials.

9. Risk of explosion. Floor sanding can result in an explosive mixture of ne dust and air. Use oor sanding machine only in a

well-ventilated area free from any ame or match.

General Power Tool Safety Warnings

6

EN

Additional Rules For Safe Operation

1. Empty the dust bag or dust collection receiver frequently. Do not leave residue in dust bag or dust collection receiver unattended.

Always empty into a non-combustible metal container. Sanding wood or varnish produces dust that can self ignite and cause injury or

damage.Always empty dust bags or collection receiver before storing the machine.

2. Set all exposed nails. Sweep loose abrasive away from work area. Do not strike metal pipes etc., with sanding paper. Striking metal

or abrasive particles with sanding paper produces sparks that could ignite the sanding dust which can cause injury or damage.

3. Do not operate a partially assembled power tool. Keep all adjustments within manufacturer's specications. Keep all fasteners tight.

Operating a partially assembled power tool could result in injury to the operator or bystander and could cause damage to the equipment

or surroundings.

4. Do not attempt to change the sanding paper while the power tool is running. The sanding drum can snag clothing and cause injury to

limbs, and moving sanding paper can cause abrasions.

5. The power tool should only be used on an electrical system (mains) that is rated for the electrical requirements of the power tool as

shown on the nameplate. Use only on an earthing (grounded) system. Do not service the power tool if it is energized or connected to

an electrical circuit. Improper use could cause re or electric shock.

General Power Tool Safety Warnings

CAUTION: This machine will operate only on AC frequency and on electrical voltage shown on the motor nameplate. Make

sure you have the correct frequency and voltage before connecting the power cord to an outlet. The machine has

a plug as shown below.

DANGER: Electrocution could occur if the machine is exposed to water or rain. Keep the machine in a dry building.

DANGER:

Electrocution could occur if machine is improperly connected to the electrical system. To prevent possible electric

shock

, always use a 3-wire electrical system connected to an electrical ground. For maximum protection against

electrical shock, use a circuit that is protected by a ground fault circuit interrupter. Consult your electrical

contractor.

DANGER: Electrocution could occur if the ground pin is tampered with in any way. Do not cut, remove, or break the ground

pin. Do not try to t a three-terminal plug into a receptacle or connector body other than a three-plug receptacle

or connector body. If the outlet does not t the plug, consult your electrical contractor.

DANGER: Electrocutioncould occurifthemachineisusedwith adamaged plugor powercord. Ifthecordsorplugsareworn

or damaged in any way, have them replaced by an authorized service person or electrician.

If motor appears to labor or takes a considerably longer time to come up to speed, reduce sanding pressure.

Machine Specifications

Introduction

The FloorCrafter can be used on a variety of surfaces. It is an ideal tool for wood flooring maintenance and restoration work.

7

230V Electrical Connection Instructions

This machine must be connected to an electrically grounded circuit in order to

protect the operator from electric shock. This machine has an approved power

cord with three conductors as well as a plug with three terminals. Connect the

plug into a three holed receptacle. For maximum protection against electric

shock, use a circuit that is protected by a ground fault circuit interrupter.

Extension Cords

Use only an approved three-pronged extension cord with two main conductors

and one earthing conductor. This machine is equipped

with a power cord. When greater range is needed follow the table

to determine cable gauge of additional footage. Refer to the

chart to the right for extension cord information

EN

Part # 07104A 07104B 07202B / 07104C 56380917

Model FloorCrafter 8 FloorCrafter 8, Blk FloorCrafter 8 FloorCrafter 8

Electrical Requirements 230~, 60Hz / 15.7A, 3.7 kW 230~, 60Hz / 15.7A, 3.7 kW 230~, 60Hz / 15.7A, 3.7 kW 230~, 50Hz / 16.0A, 3.0 kW

Sound Emission (Lpm)* 93.0 dB(A) 93.0 dB(A) 93.0 dB(A) 96.2 dB(A)

Vibration <.15 in/s <.15 in/s <.15 in/s 2.88 m/s2rms

Motor 4 Hp Induction 4 Hp Induction 4 Hp Induction 3 kW Induction

Contact Wheel Rate 2450 rpm 2450 rpm 2450 rpm 2042 rpm

Abrasive Rate 4500 ft/min 4500 ft/min 4500 ft/min 3750 ft/min

Abrasive Size 29½” x 7⅞” 29½” x 7⅞” 29½” x 7⅞” 29½” x 7⅞”

Fan Flow Rate 234 CFM 234 CFM 234 CFM 195 CFM

Drum Settings 80 lbs., 70lbs., 60 lbs. 80 lbs., 70lbs., 60 lbs. 80 lbs., 70lbs., 60 lbs. 80 lbs., 70lbs., 60 lbs.

Overload Protection Magnetic Circuit Breaker Magnetic Circuit Breaker Magnetic Circuit Breaker Magnetic Circuit Breaker

Electric Cable 50’, 10-3 SJO LP-20P Plug 50’, 10-3 SJO LP-20P Plug 50’, 10-3 SJO LP-20P Plug 100’, H05VVF3G4.0 AV3-20P Plug

Operating Controls Adjustable Lever/Grip Adjustable Lever/Grip Adjustable Lever/Grip Adjustable Lever/Grip

Leveling Controls Externally Adjustable Externally Adjustable Externally Adjustable Externally Adjustable

Operating Wheels 80 Durometer Clear Urethane 80 Durometer Clear Urethane 80 Durometer Clear Urethane 80 Durometer Clear Urethane

Weight 204 lbs. 204 lbs. 204 lbs. 204 lbs.

Dimensions 35 x 13¾ x 38¾35 x 13¾ x 38¾35 x 13¾ x 38¾35 x 13¾ x 38¾

WARNING: The machine is heavy. Remove the motor from the machine before transporting. Get help loading the machine and

motor. Use proper lifting techniques.

Transporting the Machine - Using the Dolly Cart

CAUTION: When deploying the dolly, the drum will contact the floor or ground over which the machine is resting. Care should

be taken to avoid surfaces which might damage or contaminate the drum.

CAUTION: While transporting using the dolly, abrupt changes in the direction of travel or the surface over which the machine

is being transported could cause the machine to tip over. Also, the machine is more likely to tip over when

transporting across inclined surfaces.

Attach the dolly to the rear of the machine as follows:

1. Open the quick release levers (2A) and unscrew the adjustment nuts (2B) to allow installation of the dolly. (See Figure 2)

2. Insert the quick release skewers into the dolly brackets and immediately tighten the adjustment nuts until the dolly mechanism will just swing

free.

Deploy the dolly under the machine as follows:

1. With the dolly mechanism in place as described above, tip the machine by lifting up on the operator's handle to raise the rear of the machine off

the oor/ground until the dolly swings under the machine. (See Figure 3)

2. Hold the dolly in position using your foot and allow the machine to tip back and rest on the dolly wheels. (See Figure 4)

3. Tip the machine back on all four wheels and close the quick release levers for transport. Some adjustment of the quick release skewers may be

necessary to allow the levers to be tightened securely.

Removing/Storing the dolly:

The dolly can be stored on the machine in the “UP” position or it can be removed and stored separately.

1. Open the quick release levers to loosen the dolly.

2. Lift up on the operator's handle to tip the machine forward.

3. Swing the dolly out from under the machine and lower the machine until it rests on its own wheels.

CAUTION: Be careful when lowering the machine. The dolly will swing back toward the operator as the machine is lowered.

4. To store the dolly in the “UP” position, swing the dolly up against the top of the mainframe as far as it will travel and close the quick release

levers to secure it in place. (See Figure 5)

5. To remove the dolly, loosen the quick release adjustment nuts until the levers and nuts clear the counter-bore on the dolly brackets, and remove

the dolly. Tighten the adjustment nuts until the quick release levers can be closed securely.

Machine Transportation

8

Figure 2

AB BA

Figure 3

Figure 4 Figure 5

A

B

Figure 6

EN

Machine Setup

To set-up your machine, follow this procedure:

1. Familiarize yourself with the machine and read all danger,

warning, and caution statements. Make sure all operators

of this machine have read this Operator's Manual. If they

cannot read this manual, have the manual explained fully

before allowing anyone to operate the sander.

2. Locate the electrical source. The receptacle should

be compatible with the plug. The receptacle must be

grounded and must be fused (see nameplate for electrical

requirements) to avoid an electrical hazard.

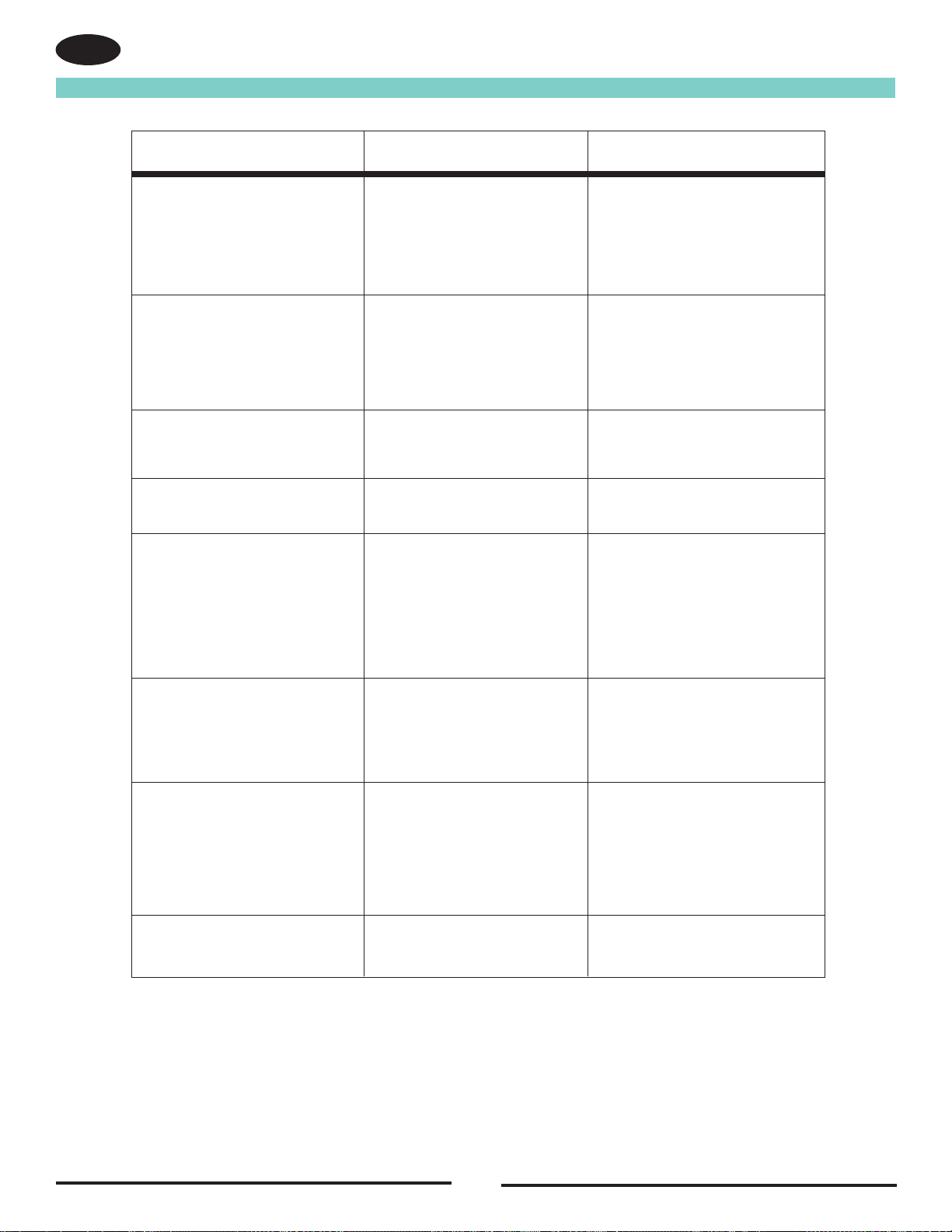

3. Clip the dust bag to the elbow. (See Figure 9) Cross the

strings on the dust bag and draw tight over the flare on the

elbow. Wrap the string around the elbow and secure.

4. Wind the electrical cord through the cable arm.

(See figure 10) Keep the power cord out of path of

equipment. Do not connect the electrical cord at this time.

9

Transporting the Machine by Carrying - Two People

1. Person #1 lifts the machine by the front handle.

2. Person #2 lifts the machine by the operating handle.

Figure 8

Figure 7

EN

Transporting the Machine - One Person

NOTE: This is accomplished by removing the motor from the chassis

and transporting the motor and chassis separately.

To transport the machine, follow this procedure:

1. Make sure the power cable is disconnected from the electrical outlet.

2. Release the tension on the drive belts using the quick release lever.

(See Figure 6A )

3. Open the belt guard by pulling on the handle immediately above the

left truck wheel. (See Figure 6B)

4. Remove the drive belts from the machine

5. Disconnect the motor pigtail from the handle pigtail if so equipped.

(See Figure 7)

6. Unscrew the motor mounting knobs to loosen the motor.

(See Figure 8)

7. Straddle the motor and grasp the motor lift handle. Using your legs,

lift the motor off the chassis and take it to the work site.

8. Lift the chassis by grasping the front and rear handles. Lift the frame

and bring the belt guard against your chest. Take the chassis to the

work site.

To assemble the machine after transporting, follow this procedure:

1. Open the belt guard door. Place the motor assembly on the chassis

and screw the motor mounting knobs sufciently to engage and

secure the motor.

2. Install the drive belts. Tighten the belts using the belt tension quick

release lever.

3. Check the tension on the belts and close the belt guard door.

CAUTION: Premature bearing failure can occur if the fan belt

is set too tight. The fan belt should deect ½” at

the center of the span with 5 lbs. of pressure.

NOTE: It is necessary to adjust the fan belt independently

during this procedure or during replacement. The

idler pulley is factory adjusted.

10

Machine Setup

5. Pull the draw latch forward to release the access door to gain entry to the sanding chamber. (See Figure 12)

6. Rotate the release lever forward. (See Figure 11)

CAUTION: Damage to the sanding drum will occur if the machine is operated without a sanding belt.

Figure 11

Figure 9 Figure 10

7. Install a new abrasive belt by sliding the abrasive over the tension roller and contact wheel. (See Figure 12)

8. Rotate the release lever backward to tighten the abrasive belt.

CAUTION: Do not force the release lever. Doing so can damage the tracking mechanism and cause the abrasive belt to mis-track.

9. Depending on the model, the control switch is found on either the operating handle or on the motor. Verify that the control switch is set to

“OFF”. See the marking on the switch.

10. Connect the electrical cord. On certain models, the connection must be twisted clockwise to lock.

11. Jog (turn on momentarily - test operation) the control switch while observing the belt tracking. Follow the procedures outlined in the “Sander

Adjustment Procedures” on page 16 to correct the belt tracking. There is also a label on the inside of the access door that outlines the

belt adjustment.

12. Close the access door. Place the end of the draw latch over the keeper on the access door and push the draw latch at against the

mainframe to secure.

Figure 12

EN

DANGER: Sanding/finishing wood floors can create an

environment that can be explosive. Cigarette

lighters, pilot lights, and any other source of

ignition can create an explosion when active

during a sanding session. All sources of

ignition should be extinguished or removed

entirely if possible from the work area.

DANGER: Work areas that are poorly ventilated can

create an explosive environment when

certain combustible materials are in the

atmosphere, i.e., solvents, thinners, alcohol,

fuels, certain finishes, wood dust and other

combustible materials. Floor sanding

machines can cause flammable material and

vapors to ignite. Read the manufacturer’s

label on all chemicals used to determine

combustibility. Keep the work area well

ventilated.

DANGER: Sanding dust can self ignite and cause an

injury or damage. Remove the contents

of the dust bag each time you finish using

the machine. Always dispose of the dust

in a metal container located outside of the

building. Never leave a dust bag unattended

with sanding dust in it. Empty the contents

frequently. Do not empty the contents of the

dust bag into a fire.

DANGER: Hitting a nail while sanding can cause sparks

and create an explosion or fire. Always use

a hammer and punch to countersink all nails

before sanding floors.

11

Operating Instructions

EN

To operate the machine follow this procedure:

1. Before sanding, decide on best approach for sanding

desired area. If the floor is uneven, it may be necessary to

sand diagonally to the direction that the floor is laid. This

will help “pull” or stretch low and high spots in the floor

over a greater area, producing a flatter surface.

Preliminary cuts should be performed at angles

approximately 15° to the direction of the wood grain. Cut

direction should change on successive cuts with the final

cut performed in the direction of the wood grain. This will

minimize the tendency of waves to form and provide the

most even floor surface.

When sanding the area, work so that you are moving away

from where the cord set enters the room. This will help

to avoid entanglement with the cord set and eliminate the

need to move the cord set out of the way so frequently.

Work the area in a way that avoids interruption or

termination points (an end of pass.) Make long continuous

passes.

2. Swing cable arm to side of machine opposite the direction

you intend to work. Rotate elbow on dust pipe until

dust bag rests on motor. This will maintain balance and

sanding pressure as the dust bag fills. The machine

should be operated with the dust bag in this position

whenever possible.

3. If the operating belt (American Sanders PN 53560A) is

used, proceed as follows:

a. Position the operating belt around waist.

b. Cross the straps at the waist.

(See Figure 13)

c. Slide the belt loop end over the handle on the control

lever side. Adjust the length as needed.

d. Wrap the remaining strap around the opposite side of

the handle, and hold it in place with your hand.

6. When drum is fully engaged with the surface, gradually adjust your pace for adequate finish removal. Keep sander in motion while the drum is

engaged with the surface or dwell marks will occur.

7. Move the machine in the direction of the grain in the wood whenever it is possible. Sand the surface at a constant pace.

8. Gradually feather-cut out at the termination point by easing the drum up with the control lever. (See Figure 13)

9. Repeat technique described in steps 5, 6, 7, and 8 and sand back down pass just made. When completed, begin a new pass by overlapping

previous pass half the width of the abrasive. Stagger termination points to prevent a distinct ridge and to promote a better blend when edging.

10. Empty contents of the dust bag into a metal container located outside the building. Dust bag should be emptied whenever full, as indicated on

bag.

WARNING: Serious operator injury could occur if the operator

has tied or strapped the loose end of the operator’s

belt strap to the machine. Always wrap the strap

so that you can let go and get away quickly in case

of bag fire or explosion.

4. Activate the control switch.

CAUTION: To prevent damage to the floor, make sure the

machine is in motion when the drum is engaged

with the floor.

5. Feather-cut in by easing the drum down onto the surface with the control

lever while the sander is in motion.

12

Operating Instructions

Figure 13

EN

Sanding Cuts & Sandpaper

Initial Cut

The purpose of the initial cut is to remove old nish and gross imperfections on the oor surface. The sanding equipment should be adjusted to

heavy sanding pressure setting and a coarse abrasive belt should be used. If the surface is severely damaged by deep scratches, preexisting dwell

marks, uneven planks, etc., it may be necessary to sand across or diagonally to the grain to restore evenness to the surface. If these conditions are

not present, the initial cut should be done in the direction of the grain.

If glazing, loading, or burning takes place immediately into an initial cut, select a coarser abrasive. If this should occur during an initial cut, the

abrasive has dulled and must be replaced.

Final Cuts

The purpose of a nishing cut is to remove the scratches produced during the initial cut. Use a ne (60 - 80 grit) grain abrasive and a reduced

sanding pressure setting.

If the surface remains rough after a nishing cut, it may be necessary to use an even ner grain of abrasive (80 - 100 grit). Care should be taken in

selecting the grit size of the abrasive. A very ne grain will close the pores on a wood oor making admission of a stain difcult.

If glazing or burning should occur immediately into a nishing cut, reduce the sanding pressure. If it should occur during a nishing cut, the abrasive

has dulled and must be replaced.

WARNING: Do not overfill dust bag or serious fire may result. Never leave a dust bag containing dust unattended.

Sanding dust can self ignite and cause a fire or explosion. Use only genuine American Sanders replacement bags.

CAUTION: An overfilled dust bag may effect machine balance and performance. Do not handle or disturb dust bag and

elbow while sanding or damage to the floor may occur.

13

Chatter Wave Prevention

American Sanders belt machines are designed and manufactured to the most rigid

tolerances. However, after a nishing cut it is possible to see “chatter” or “waves”.

The best guarantee to remove the chatter is to nish the oor with a rotating

horizontal sander, such as the American Sanders Epoch HD.

To minimize chatter when using a belt or drum sander, the following steps should

be taken:

1. DRUM MARKS...are caused by the operator lowering the drum to the oor

without forward traverse. These marks should be removed by cutting at a 45

degree angle to the mark. Cutting at the mark while maintaining the same

path will only increase the mark depth and width.

(See gure 14)

2. UNEVEN WALKING SPACE...can leave lengthy “waves”. The machine

cuts more material during the slower pace. Pay particular attention to a

steady even pace.

3. EXCESSIVE LIGHT CUTS...may reveal high spots on the paper/contact

wheel and cause chatter. Take a heavier cut and increase the pace.

Figure 14

PROPER CARE OF YOUR MACHINE CAN MINIMIZE CHATTER AND WAVES.

1. V-BELTS...can cause vibration and chatter if they are of low quality. Use only belts specied by American Sanders.

2. TRUCK AND CASTER WHEELS...with at spots, out-of-roundness, or debris adhered to their surface can cause “waves” or a “chatter effect”.

Always clean and inspect all wheels before starting to sand, and before the nish cut. Replace or true the wheels if found to be out-of-round.

Never allow the sander to stand on hard surfaces for lengthy periods of time.

3. DUST PICK-UP SHOES...may need adjusted differently for different materials that are to be sanded. An improperly adjusted shoe will leave

trailing debris that will be run over by the wheels and cause “random waves”.

4. CONTACT WHEELS (DRUMS)...may be out-of-round and cause “chatter”. Contact your American Sanders dealer for assistance to true or

replace the drum.

4. DEBRIS...lodged between the paper and the drum will leave chatter. On a belt sander, debris may be adhered to the drum.

Insure the drum is clean and free of debris before placing the paper on.

5. ABRASIVE QUALITY...may vary. Belt seams can be thicker on low quality paper and cause chatter. Use only American Sanders

specied sandpaper. Store abrasive according to manufacturer’s recommendation.

EN

14

Figure 15

Figure 16

Figure 17

5. BEARINGS...in the motor, drum, or fan system may become worn and induce vibration which could cause “chatter”.

6. PULLEYS..

.that are damaged or severely worn can induce vibration and cause “chatter”. Contact your American Sanders dealer for

assistance.

7. SANDPAPER TENSION...should always be released when the machine is shut off for 10 minutes or longer to avoid compression of the drum.

NOTE: American Sanders is not responsible for rework of oors that are unacceptable to the customer. It is your responsibility to

insure your equipment is in proper operating order and that you use the right machine for the job.

Sander Adjustment Procedures

DANGER: Electrocution could occur if maintenance and repairs are

performed on a unit that is not properly disconnected from

the power source. Disconnect the power supply before

attempting any maintenance or service.

DANGER: Moving parts of this machine can cause serious injury and/or

damage. Keep hands, feet and loose clothing away from all

moving parts of the sander.

The following information provides details on how to adjust different features/

controls of the sander.

Dust Shoe

To adjust the dust shoe follow this procedure:

1. Disconnect machine from power supply.

2. Loosen the three screws fastening the dust shoe to the chassis.

3. Adjust the dust shoe down to reduce clearance.

4. Adjust the dust shoe up to increase clearance.

5. Align the dust shoe to the chassis and tighten screws. (See Figure 15)

Sanding Pressure

There are three pressure settings to select from: heavy, medium and light. The

lower the position the heavier the setting. To change settings, raise the lever and

place in desired position. (See Figure 16)

Leveling the Drum

CAUTION: The belt tracking maybe adversely affected if machine is

operated unleveled.

The machine is leveled at the factory and no adjustments should be necessary.

After any maintenance is performed to the carriage system, the pointer on the

leveling bracket must be returned to original mark (See Figure 17).

If it is necessary to reset level after replacing wheels, follow this procedure:

1. Lower the drum to the floor.

EN

2. Drive the adjusting screw in, to sand heavier on the left (the drive belt

side). Back the adjusting screw out, to sand heavier on the right (the

side opposite the drive belts). Test the setting on an even surface.

Make further adjustments if necessary.

3. Mark new pointer location on main frame.

Belt Tracking

NOTE: The sanding belt should run evenly on the face of the drum. For

this, the outer edge of the sanding belt must be .09 inches (2mm) out from

the end of the drum. This provides optimum transition between “passes”.

WARNING: Injury to the operator could occur if any

machine adjustments are made while the

motor is running. Do not attempt to make any

adjustments while the machine is plugged in or

running.

To adjust the belt tracking follow this procedure:

1. Locate the belt tracking adjuster screw. (See Figure 18A)

2. Hold the belt tracking adjuster screw and loosen the locknut.

(See Figure 18B).

3. Rotate the tracking adjuster screw counterclockwise to move the belt

in.

4. Rotate the tracking adjuster screw clockwise to move the belt out.

5. Test adjustment and tighten the locknut.

Operating Control

To increase the travel or extend the reach on the grip control, follow this

procedure:

1. Loosen the locknut on the control rod. (See Figure 19A)

2. Screw the control rod adjuster (See Figure 19B) “In” until the desired

reach is found.

3. Tighten the locknut.

To decrease the travel or reduce the reach on the grip control, follow this

procedure:

1. Loosen the locknut on the control rod. (See gure 20A)

2. Screw the control rod adjuster “out” until desired reach is found.

3. Tighten the locknut.

15

Figure 19

Figure 18

AA

AB

AA

AB

EN

Figure 20

A

Figure 21

Routine Maintenance

Turn the adjustment screw “OUT” (See Figure 21) one quarter turn. Restore

tension using quick release lever and check adjustment. Repeat this process

if necessary. To lower tension, the adjustment screw is turned “IN”.

Bearings

Periodically check the bearings for wear or damage according to the

following schedule:

Guide rollers after 1st 650 hrs.

Idler pulley after 1st 1500 hrs.

Fan shaft after 1st 2500 hrs.

Tension roller after 1st 2500 hrs.

Arbor shaft after 1st 5000 hrs.

Motor shaft after 1st 5000 hrs.

Rollers

Periodically check the guide rollers and the tension roller for wear.

16

EN

The following items need to be periodically inspected and maintained to keep your sander in good working condition.

Sanding Chamber

Periodically blow out the sanding chamber to prevent large accumulations of debris which could interfere with the performance of the tension roller.

NOTE: The tension lever should be in the run/tight abrasive position to blow out.

Wheels

Periodically remove the debris from the truck and caster wheels. Debris can cause waves on a sanded surface.

Dust Bag

Remove the dust bag from the machine and shake it thoroughly to remove the sanding dust from the dust bag. Turn the dust bag inside out and

machine wash in cold water to prevent pore blockage and loss of dust recovery.

Drive Belt

Drive belt tension is factory set and should not require adjustment. Periodically check the drive belt tension. Proper belt tension is achieved when

5 lbs. of force at the mid-span of the belt produces ½ inch of deection.

To increase belt tension, release tension using quick release lever (See Figure 6).

Troubleshooting

17

EN

Troubleshooting

18

EN

Problem Cause Action

Burning or glazing. Dull abrasive. Replace abrasive.

Excessive sanding pressure. Decrease sanding pressure setting.

(Fig. #16, page 15).

Too fine of an abrasive belt. Use coarser abrasive.

Slow cutting. Dull abrasive. Replace abrasive.

Too fine of an abrasive belt. Use a coarser abrasive belt.

Insufficient sanding pressure. Increase sanding pressure setting.

(Fig. #16, page 15).

Waves on sanded surface. Debris on wheels. Remove and clean wheels.

Flat spot on tire(s). Replace tires.

Chatter marks on sanded surface. See Chatter Wave Prevention, See Chatter Wave Prevention,

(Close evenly spaced ripples) page 14. page 14.

Difficult to actuate tension release Debris interferes with mechanism Blow out sanding chamber.

lever. Remove and disassemble

mechanism. Clean out.

Worn sleeve bearing. Replace.

Galled linkages. Lubricate with spray lubricant.

Abrasive belt hunts (seeks). Worn sleeve bearing. Check for excessive play, replace.

High edges on drum. Contact an authorized dealer

or replace the drum.

Abrasive belt will not track. Extreme difference in side-to-side Replace abrasive belt.

length of belt.

High edge on drum . Check several different abrasive

belts. Contact an authorized

dealer or replace the drum.

Abrasive belt tears along its Debris built-up on (top) tension Clean tension roller.

length. roller.

Contents

Instruccionesde seguridadparael operador...........................20-21

Introducción y especicaciones de la máquina............................22

Instrucciones de conexión eléctrica a 230V................................23

Cómo transportar la máquina...................................................24-25

Instalación de la máquina.......................................................26-27

Operación de la máquina.........................................................28-29

Cortesdelijaypapeldelija............................................................29

Cómo evitar marcas de vibraciones y ondulaciones................30

Procedimientosdeajustedelalijadora.....................................31-32

Mantenimiento de rutina...............................................................33

Resolucióndeproblemas........................................................34-35

LEA ESTE MANUAL

Este manual contiene información importante acerca del uso y la seguridad de la máquina. Si no lee el manual antes de utilizar su

máquina American Sanders o de intentar realizar los procedimientos de reparación o mantenimiento de la misma, usted o el resto

del personal podrían sufrir lesiones; asimismo, podrían producirse daños a la máquina o a otras propiedades. Antes de utilizar la

máquina, es necesario recibir la capacitación adecuada en la operación de la misma. Si el operador de la máquina no sabe leer en

español, explíquele el manual exhaustivamente antes de que intente utilizarla.

Todas las indicaciones incluidas en este manual se ofrecen desde la posición del operador en la parte posterior de la máquina.

ADVERTENCIA!

Los Productos a la venta en este Manual contienen, o pueden contener, productos químicos reconocidos por algunos gobiernos (como el Estado

de California, según lo indica en su Proposición 65, Ley de Advertencia Regulatoria) como causantes de cáncer, defectos de nacimiento u otros

daños reproductivos. En algunas jurisdicciones (incluido el Estado de California), los compradores de estos Productos que los coloquen en servicio

en un emplazamiento laboral o en un espacio de acceso público tienen la obligación regulatoria de realizar determinados avisos, advertencias o

divulgaciones respecto de los productos químicos contenidos o posiblemente contenidos en los Productos utilizados en tal lugar. Eslaresponsabilidad

del comprador conocer y cumplir con todas las leyes y reglamentaciones relacionadas con el uso de estos Productos en tales entornos. ElFabricante

niega toda responsabilidad de informar a los compradores sobre requisitos especícos que pueden regir el uso de los Productos en tales entornos.

19

ES

PELIGRO signica: Usted u otras personas pueden estar expuestos a sufrir lesiones personales, inclusive la

muerte si las indicaciones de PELIGRO que se encuentran en esta máquina o en el manual

de instrucciones se ignoran o no se tienen en cuenta. Lea y respete todas las indicaciones

de PELIGRO que se encuentran en el manual de instrucciones y en la máquina.

ADVERTENCIA signica: Usted u otras personas pueden estar expuestos a sufrir lesiones personales, si las

indicaciones de ADVERTENCIA que se encuentran en esta máquina o en el manual de

instrucciones se ignoran o no se tienen en cuenta. Lea y respete todas las indicaciones de

ADVERTENCIA que se encuentran en el manual de instrucciones y en su máquina.

PRECAUCIÓN signica:

La máquina u otros bienes pueden sufrir daños materiales si las indicaciones de PRECAUCIÓN

que se encuentran en la máquina o en el manual de instrucciones se ignoran o no se

tienen en cuenta. Lea y respete todas las indicaciones de PRECAUCIÓN que se

encuentran en el manual de instrucciones y en la máquina.

Instrucciones De Seguridad Para El Operador

ES

20

Other manuals for American SANDERS FloorCrafter

2

This manual suits for next models

1

Table of contents

Languages:

Other Amano Sander manuals

Amano

Amano American Sanders American 8 User manual

Amano

Amano American SANDERS EZ-8 User manual

Amano

Amano American SANDERS EZ Sand - HDTR User manual

Amano

Amano American Sanders American 12 User manual

Amano

Amano Pioneer Eclipse PE225FP User manual

Amano

Amano American Sanders Epoch HD User manual

Amano

Amano American SANDERS FloorCrafter User manual

Amano

Amano American Sanders 3DS User manual

Amano

Amano American Sanders OSB-18 User manual

Amano

Amano American Sanders OBS-18DC User manual