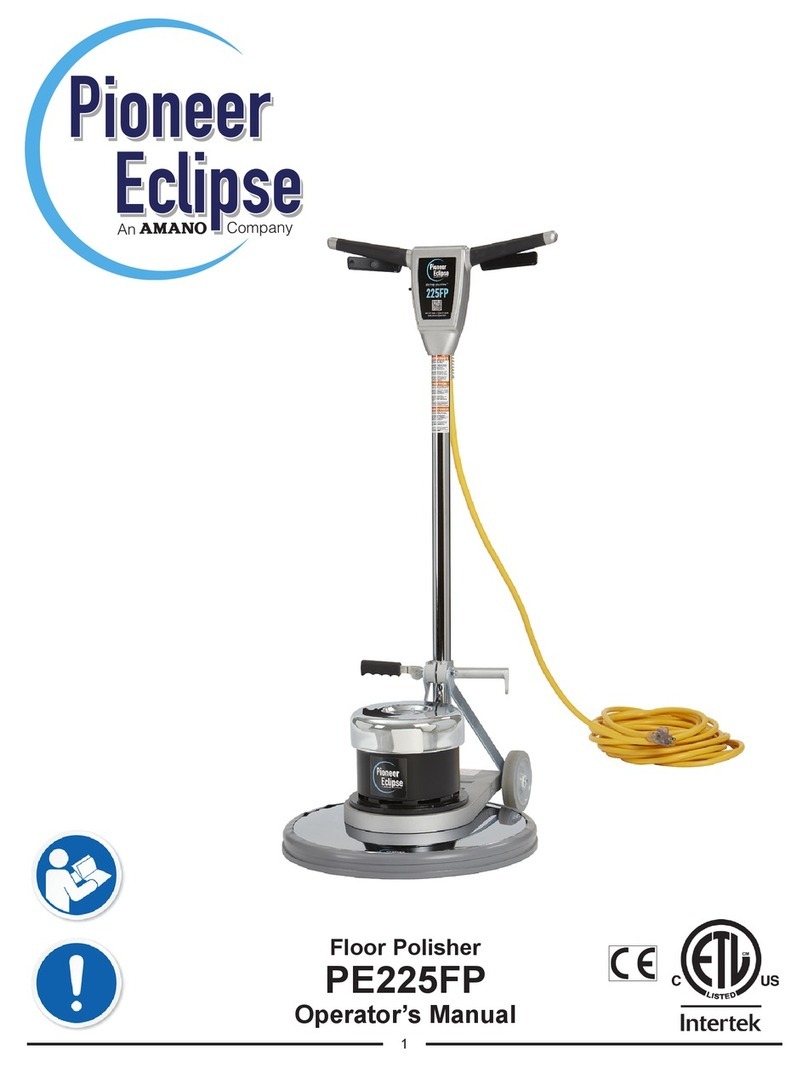

Amano American Sanders American 12 User manual

Drum Sander

American 12

Operator’s Manual

3

EN

2

EN

***This product is intended for commercial use only***

WARNING!

The Products sold with this Manual contain or may contain chemicals that are known to certain governments (such as the State of

California, as identied in its Proposition 65 Regulatory Warning Law) to cause cancer, birth defects or other reproductive harm. In

certain locations (including the State of California) purchasers of these Products that place them in service at an employment job site

or a publicly accessible space are required by regulation to make certain notices, warnings or disclosures regarding the chemicals that

are or may be contained in the Products at or about such work sites. It is the purchaser’s responsibility to know the content of, and

to comply with, any laws and regulations relating to the use of these Products in such environments. The Manufacturer disclaims any

responsibility to advise purchasers of any specic requirements that may be applicable to the use of the Products in such environments.

In this Operation Manual you will find three statements that you must read and observe to ensure safe operation of this

machine.

DANGER means: Severe bodily injury or death can occur to you or other personnel if the DANGER statements

found on this machine or in this Operation Manual are ignored or are not adhered to. Read and observe

all DANGER statements found in this Operation Manual and on your machine.

WARNING means: Injury can occur to you or to other personnel if the WARNING statements found on your

machine or in the Operation Manual are ignored or are not adhered to. Read and observe all WARNING

statements found in this Operation Manual and on your machine.

CAUTION means: Damage can occur to the machine or to other property if the CAUTION statements found

on your machine or in this Operation Manual are ignored or are not adhered to. Read and observe all

CAUTION statements found in this Operation Manual and on your machine.

Operator Safety Instructions

DANGER: Failure to read the Owner’s Manual prior to operating or servicing your American Sanders machine could result in injury to

you or to other personnel; damage to the machine or to other property could occur as well. You must have training in the

operation of this machine before using it. If you or your operator(s) cannot read English, have this manual explained fully

before attempting to operate this machine.

DANGER: A. Sanding/nishing wood oors can create an explosive or combustible environment. Do not operate this machine around

solvents, thinners, alcohol, fuels, oor nishes, wood dust or any other ammable materials. Cigarette lighters, pilot lights,

electrical sparks and all other sources of ignition should be extinguished or avoided. Keep work area well ventilated.

B. Dust generated from sanding wood oors can spontaneously ignite or explode. Promptly dispose of any sanding dust in

a metal container clear of any combustibles. Do not dispose in a re.

DANGER: A. Electrocution could occur if the machine is being serviced while the machine is connected to a power source. Disconnect

the power supply before servicing.

B. Electrocution or re could occur if the machine is being operated with a damaged power cord. Keep the power cord clear

of the pad. Always lift the cord over the machine. Do not move the machine by the power cord.

C.Shock hazard. Do not use the machine if it has been rained on or sprayed with water.

DANGER: To avoid injury keep hands, feet, and loose clothing away from all moving parts on the machine. Disconnect the power cord

before replacing the pad, changing the abrasive, or when servicing. Do not operate the machine unless all guards are in

place. Never leave the machine unattended while connected to a power source.

WARNING: Injury can occur if protective clothing or equipment is not used while sanding. Always wear safety goggles, protective

clothing, and dust mask while sanding.

WARNING: This sander is not to be used on pressure treated wood. Some pressure treated woods contain arsenic and sanding

pressure treated wood produces hazardous dust. Inhaling hazardous dust from pressure treated wood can cause serious

injury or death. Sanding pressure treated wood decks or uneven surfaces can damage the sander which is not covered

under warranty or damage waiver.

WARNING: Any alterations or modications of this machine could result in damage to the machine or injury to the operator or other

bystanders. Alterations or modications not authorized by the manufacturer voids any and all warranties and liabilities.

WARNING: Risk of explosion. Floor sanding can result in an explosive mixture of ne dust and air. Use oor sanding machine only in a

well-ventilated area free from any ame or match.

SECTION II - Parts and Service Manual

Handle Assy (Models 07108A, 07109A, 07204A, 07108C) .................. 36

Handle Assy (Model 07001A, 07108B)................................................. 38

Handle Assy (Model 07120A). .............................................................. 40

Motor Assy (Model 07001A, 07108B). .................................................. 42

Motor Assy (Models 07108A, 07109A, 07204A, 07108C) .................... 43

Motor Assy (Model 07120A) ................................................................. 44

Drum Assy ............................................................................................ 45

Dust Control Assy ................................................................................. 46

Base Assy ............................................................................................. 48

Base Assy (Models 07044C, 07049C).................................................. 50

Belt Guard Assy (Models 07108A, 07109A, 07204A, 07108C) ............ 52

Belt Guard (Model 07001A, 07108B) ................................................... 53

Belt Guard (Model 07120A) .................................................................. 54

Accessories .......................................................................................... 55

Wiring Diagrams ................................................................................... 56

Warranty ............................................................................................... 58

Contents

Operator Safety Instructions ...............................2

Introduction and Machine Specications ............6

230V Electrical Connection Instructions

.............

7

How to Transport the Machine............................8

Machine Set-Up ..................................................9

How to Operate the Machine ............................10

Sanding Cuts and Sandpaper ..........................13

Sander Adjustment Procedures ........................13

Routine Maintenance........................................15

Troubleshooting ................................................16

Chatter-Wave Prevention .................................17

General Power Tool Safety Warnings

WARNING: Read all safety warnings and instructions. Failure to follow warnings and instructions may result in electric

shock, re and or serious injury.

Save all warnings and instructions for future use.

The term "power tool" in the warnings refers to your main-operated (corded) power tool or battery operated (cordless) power tool.

1) Work area safety

a) Keep work area clean and well lit. Clutter or dark areas invite accidents .

b)

Power tools create sparks which may ignite the dust or fumes.

c) Distractions can cause you to lose control.

2) Electrical safety

a) Power tool plugs must match the outlet. Never modify the plug in any way. Do not use any adapter plugs with

earthed (grounded) power tools. Unmodied plugs and matching outlets will reduce risk of electric shock .

b) There is an

increased risk of electric shock if your body is earthed or grounded .

c) Do not expose power tools to rain or wet conditions. Water entering a power tool will increase the risk of electric shock.

d)

heat, oil, sharp edges or moving parts. Damaged or entangled cords increase the risk of electric shock.

e) Use of cord suitable for outdoor

use reduces the risk of electric shock .

READ THIS BOOK

This book has important information for the use and safe operation of this machine. Failure to read this book prior to operating

or attempting any service or maintenance procedure to your American Sanders machine could result in injury to you or to other

personnel; damage to the machine or to other property could occur as well. You must have training in the operation of this machine

before using it. If your operator(s) cannot read this manual, have it explained fully before attempting to operate this machine.

All directions given in this book are as seen from the operator’s position at the rear of the machine.

45

EN EN

f)

interrupter (GFCI ) protected supply. Use of a RCD or GFCI reduces the risk of electric shock .

3) Personal safety

a) Stay alert, watch what you are doing and use common sense when operating a power tool. Do not use a power tool

A moment of inattention while operating

power tools may result in serious personal injury.

b} Protective equipment such as dust mask, non-skid

safety shoes, hard hat, or hearing protection used for appropriate conditions will reduce personal injury.

c)

pack, picking up, or carrying the tool. Carrying power tools with your nger on the switch or energizing power tools that

have the switch on invites accidents .

d) A wrench or key left attached to a rotating part

of the power tool may result in personal injury.

e) This enables better control of the power tool in

unexpected situations .

f) Dress properly. Do not wear loose clothing or jewelry. Keep your hair, clothing and gloves away from moving parts.

Loose clothes, jewelry, or long hair can be caught in moving parts.

g) If devices are provided for the connection of dust extraction and collection facilities, ensure these are connected and

properly used. Use of dust collection can reduce dust related hazards. It is recommendation that the tool always be supplied

via a residual current device with a rated residual current of 30mA or less.

4) Power tool use and care

a) Do not force the power tool. Use the correct power tool for your application. The correct power tool will do the job better

and safer at the rate for which it was designed .

b) Any power tool that cannot be controlled with the

switch is dangerous and must be repaired .

c)

adjustments, changing accessories or storing power tools. Such preventative safety measures reduce the risk of starting

the power tool accidently.

d) Store idle power tools out of the reach of children and do not allow persons unfamiliar with the power tool or these

instructions to operate the power tool. Power tools are dangerous in the hands of untrained users.

e)

Many accidents are

caused by poorly maintained power tools .

f) Keep cutting tools sharp and clean. Properly maintained cutting tools with sharp cutting edges are less likely to bind and

are easier to control.

g)

Use of the power tool for operations dierent from those intended could

result in a hazardous situation.

5) Service

a) This will ensure that

the safety of the power tool is maintained . If the supply cord is damaged, it must be replaced by the manufacturer, its service

agent or similarly qualied persons in order to avoid a hazard.

Safety Warnings For Sanding Operations

1. This power tool is intended to function as a sander. Read all safety warnings, instructions and specications provided with

this power tool. Failure to follow all instructions listed below may result in electric shock, re, or personal injury.

2. Operations such as grinding, wire brushing, polishing or cutting-o, are not recommended to be performed with this power tool.

Operations for which the tool was not designed may create a hazard and cause personal injury.

3. Do not use accessories which are not specically designed and recommended by the tool manufacturer. Just because the

accessory can be attached to your power tool, it does not assure safe operation .

4. The rated speed of the accessory must be at least equal to the maximum speed marked on the power tool. Accessories

running faster than their rated speed can break and y apart .

5. The outside diameter and thickness of your accessory must be within the capacity rating of your power tool. Incorrectly sized

accessories cannot be adequately guard or controlled.

6. The arbor size of wheels, anges, backing pads or any other accessory must t the spindle of the power tool. Accessories

with arbor holes that do not match the mounting hardware of the power tool will run out of balance, vibrate excessively and

may cause loss of control.

7. Do not use damaged accessory. Before each use inspect the accessory such as abrasive wheel for chips or cracks, backing

pad for cracks, tear or excess wear, wire brush for loose or cracked wires . If power tool or accessory is dropped, inspect

for damage or install an undamaged accessory. After inspecting or installing an accessory, position yourself or bystanders

away from the plane of the rotating accessory and run the power tool at maximum no-load speed for one minute . Damaged

accessories will normally break apart during this time .

8. Wear personal protective equipment. Depending on application, use face shield, safety goggles or safety glasses. As

appropriate, wear dust mask, hearing protectors, gloves and workshop apron capable of stopping ying debris generated by

various operations. The eye protection must be capable of stopping ying debris generated by various operations . The dust

mask or respirator must be capable of ltering particles generated by your operations. Prolonged exposure to high intensity

noise may cause hearing loss.

9. Keep bystanders a safe distance away from work area. Anyone entering the work area must wear personal protective

equipment. Fragments of work piece or a broken accessory mayy away and cause injury beyond immediate area of

operation .

10. Hold power tool by gripping insulated surfaces (handle) only, when performing an operation where the cutting accessory may

contact hidden wiring or its own cord. Cutting accessory contacting a "live" wire may make exposed metal parts of the power

tool "live" and shock the operator.

11. Position the cord clear of the spinning accessory. If you loose control, the cord may be cut or snagged and your arm or hand

may be pulled into the spinning accessory.

12. Never lay the power tool down until the accessory has come to a complete stop. The spinning accessory may grab the

surface and pull the power tool out of your control.

13. Do not run the power tool while carrying it at your side. Accidental contact with the spinning accessory could snag your

clothing, pulling the accessory into your body.

14. Regularly clean the power tools air vents. The motor's fan will draw the dust inside the housing and excessive accumulation

may cause electrical hazards.

15. Do not operate the power tool near ammable materials. Sparks could ignite these materials.

16. Do not use excessively oversized sanding disc paper. Follow manufacturer's recommendations when selecting sanding paper.

Larger sanding paper extending beyond the sanding pad presents a laceration hazard and may cause snagging, tearing of the

disc or kickback.

17. Risk of explosion. Floor sanding can result in an explosive mixture of ne dust and air. Use oor sanding machine only in a

well-ventilated area free from any ame or match.

Kickback is a sudden reaction to a pinched or snagged rotating wheel, backing pad, brush or any other accessory. Pinching or

snagging causes rapid stalling of the rotating backing pad which in turn causes uncontrolled power tool to be forced in the opposite

direction of the backing pad's rotation at the point of the binding.

For example, if an abrasive wheel is snagged or pinched by the work piece, the edge of the wheel that is entering into the pinch

point can dig into the surface of the material causing the wheel to climb out or kick out. The wheel may either jump toward or away

from the operator, depending on direction of the wheel's movement at the point of pinching. Abrasive wheels may also break under

these conditions.

Kickback is the result of power tool misuse and incorrect operating procedures or conditions and can be avoided by taking proper

precautions as given below.

1. Maintain a rm grip on the power tool and position your body and arms to allow you to resist kickback forces . Always use

auxiliary handles, if provided for maximum control over kickback or torque reactions during start up. The operator can control

torque reactions or kickback forces, if proper precautions are taken.

2. Never place your hand near the rotating accessory. Accessory may kickback over your hand.

3. Do not position your body in the area where power tool will move if kickback occurs. Kickback will propel the tool in the

direction opposite to the wheel's movement at the point of the snagging.

4. Use special care when working corners, sharp edges etc. Avoid bouncing and snagging the accessory. Corners, sharp edges

or bouncing have a tendency to snag the rotating accessory and cause loss of control or kickback.

Additional Rules For Safe Operation

1. Empty the dust bag or dust collection receiver frequently. Do not leave residue in dust bag or dust collection receiver

unattended . Always empty in a non-combustible metal container. Sanding wood or varnish produces dust that can self ignite

and cause injury or damage. Follow this precaution for storage.

2. Set all exposed nails. Sweep loose abrasive away from work area. Do not strike metal pipes, ect., with sanding paper.

Striking metal or abrasive particles with sanding paper produces sparks that could ignite the sanding dust which can cause

injury or damage.

3. Do not operate a partially assemble power tool. Keep all adjustments within manufacturer's specications . Keep all fasteners

tight. Operating a partially assembled power tool could result in injury to the operator or bystander and could cause damage to

the equipment or surroundings .

4. Do not attempt to change the sanding paper while the power tool is running. The sanding pad can snag clothing and cause

injury to limbs and moving sanding paper can cause abrasions.

5. The power tool should only be used on an electrical system (mains) that is rated for the electrical requirements of the power

tool as shown on the nameplate. Use only on an earthing (grounded) system. Do not service the power tool if it is energized

or connected to an electrical circuit. Improper use could cause re or electric shock.

67

EN EN

Introduction Electrical Connection Instructions

CAUTION: Your equipment may be inappropriate on some installations. Some softer woods used in ooring cannot support the

pressure created by hard wheels. Always consult with the ooring manufacturer on the proper installation, preparation,

and nishing of their product. Determine suitability of your equipment in preparing the product.

Tool Storage Tray Leveling Adjustment

Sanding Pres. Adjust

Motor Starter / Protector

Operating Controls

CAUTION: This machine will operate only on AC fre-

quency and on electrical voltage shown on

the equipment nameplate. Make sure you

havethe correctfrequencyand voltagebefore

connecting the power cord to an outlet. See

the example in gure 1.

This machine must be connected to an electrical source with an

earthing conductor in order to protect the operator from electric

shock. This machine has an approved power cord with three

conductors as well as a plug with three terminals. Connect the

plug to a matching receptacle.

DANGER: Electrocution could occur if the machine is

exposed to water or rain. Keep the machine

in a dry building.

DANGER: Electrocution could occur if machine is not

connected to an electrical source with an

earthing conductor. To prevent possible

electric shock, use an electrical cord with an

earthing conductor and connect it to a match-

ingelectrical source. Formaximum protection

against electrical shock, use a circuit that is

protected by a ground fault circuit interrupter.

Consult your electrical contractor.

DANGER: Electrocution could occur if the machine is

used with a damaged plug or power cord. If

the cords or plugs are worn or damaged in

any way, have them replaced by an authorized

service person or electrician.

Extension Cords

Use only an approved three-pronged extension cord with two main

conductors and one earthing conductor. This machine is equipped

with a power cord. When greater range is needed follow the table

below to determine cable gauge of additional footage. Refer to

the chart to the right for extension cord information.

If motor appears to labor or takes a considerable longer time to

come up to speed reduce sanding pressure.

Feet/Wire Guage (Stranded Copper)

208 6

230 10 8

Use Voltage

Booster

Figure 1

07108A / 07204A / 07108C 07109A 07120A

MODEL

Electrical Requirements ~208-240V 60 Hz ~220-240V 50 Hz ~220-240V 50 Hz -230V6 0 Hz 3Ø

Amperage 15.7 11.8 11.8 24

Sound Emisson{Lpm) 83.0 dB(A) 79.4 dB(A) 79.4d B(A) 83.0 dB(A)

Contact Wheel Rate(rpm) 2000/240 1670/200 1670/2000 2000/240

Abrasive Rate 3800/4560 ft/ min 970/1160 m/min 970/1160 m/min 3800/4560 ft/ min

Abrasive Sheet Size 280 CFM 970/1160 m/min 970/1160 m/min 3800/4560 ft/ min

Fan Flow Rate 12" x261/8" 305mm x 664mm 305mm x 664mm 12" X 26 1/8"

Motor 4 Hp Continuous 2.2 kW Continuous 2.2 kW Continuous 10 Hp

Overload Protection Magnetic Circuit Breaker Magnetic Circuit Breaker 13 A Fuse Magnetic Circuit Breaker

Operating Controls Adjustable Lever/Grip Adjustable Lever/Grip Adjustable Lever/Grip Adjustable Lever/Grip

Leveling Controls Externally Adjustable Externally Adjustable Externally Adjustable Externally Adjustable

Electrical Cable 100' 10-3 SJO with H05VVF3G4.0 H07RNF3G1.5 mm N/A

L6-20P Plug AU3-20P Plug with UK1-13P Plug

Operating Wheels 80 Durometer 80 Durometer 80 Durometer 80 Durometer

Clear Urethane Clear Urethane Clear Urethane Clear Urethane

Weight 240 lbs. 204 lbs. 92.7 kg 256 lbs

Dimensions 40½X 15X 36 3/4 40½X 15X 36 3/4 103cmx 38cmx 93cm 40½X 15X 36 3/4

8 9

EN EN

Machine Transportation

WARNING: The machine is heavy. Remove the motor

from the machine before transporting. Get

help loading the machine and motor.

To transport the machine, follow this procedure:

1. Make sure the power cable is disconnected from the electrical

outlet.

2. Disconnect the handle plug connection. See gure 1.

3. Remove the belt cover.

4. Remove the fan belt.

5. Loosen the motor bolt. Using the ¾" wrench, turn the motor bolt

counterclockwise. See gure 2.

6. Slide the motor forward.

7. Remove the drive belt.

8. Remove the motor from the chassis.

To re-assemble the machine after transporting, follow this

procedure:

1. Reposition motor on chassis.

2. Install the drum belt. Slide the motor back until adequate tension

is achieved in belt.

CAUTION: To prevent damage to the oor surface,

make sure the drive belt is tight.

3. Resecure the motor to the chassis.

4. Install the fan belt.

5.

Install the belt cover.

6. Reconnect the handle plug.

Figure 1

Figure 2

To set-up your machine follow this procedure:

1. Familiarize yourself with the machine and read all danger,

warning and caution statements. Make sure all operators of

this machine have read this Owner's Manual. If they cannot

read English, have the manual explained fully before allowing

anyone to operate the sander.

2. Locate the power supply. The receptacle should be

compatible with the plug. The receptacle must be grounded

and must be fused (30 amp) to avoid an electrical hazard.

3. Clip the dust bag to the elbow. Cross the strings on the dust

bag and draw tight over the are on the elbow. Wrap the

string around the elbow and secure.

4. Wind the power cord through the cable arm. Keep the power

cord out of path of equipment.

How To Install The Abrasive

To install the abrasive, follow this procedure:

1. Prepare abrasive with template supplied.

2. Place backing of abrasive on the template. The template is

marked "This Side Up." Make sure the marked side of the

template is facing up.

3. Cut the abrasive to the exact lenght of the template.

4. Align one edge of the abrasive with a notch in the template.

5. Fold the other end of the abrasive over the end of the template

and crease.

6. Repeat steps 4 and 5 for remaining notch.

7. Lift the drum cover.

8. Put the smooth side of the abrasive against the sanding drum.

9. Put one end of the abrasive against the sanding drum slot (1).

See gure 3.

10. Turn the drum one revolution. Put the other end of the

abrasive in the drum slot (2).

See gure 3.

WARNING: Disconnect power before

changing abrasive.

11. Tighten the abrasive.

To tighten the abrasive, follow this procedure:

1. The end wrenches are given with the machine.

Put a wrench around the nut at each end of the

durm (1).

See gure 4.

2. Make sure the at sides of the nuts

are parallel with the drum slot.

3. Turn the wrenches the opposite rotation

until the abrasive is tight against the drum (2).

See gure 4.

12. Remove the end wrenches.

13. Close the cover.

NOTE: When using #4 or 4½ grit abrasive,

remove the large grains from the folded

ends. To remove the grains, rub the

folded ends together.

Figure 3

Figure 4

This manual suits for next models

7

Table of contents

Languages:

Other Amano Sander manuals

Amano

Amano American Sanders OSB-18 User manual

Amano

Amano American Sanders American 8 User manual

Amano

Amano American Sanders 3DS User manual

Amano

Amano American Sanders OBS-18DC User manual

Amano

Amano American SANDERS EZ-8 User manual

Amano

Amano Pioneer Eclipse 225FP16TR User manual

Amano

Amano Pioneer Eclipse PE225FP User manual

Amano

Amano American SANDERS FloorCrafter User manual

Amano

Amano American SANDERS EZ Sand - HDTR User manual

Amano

Amano American SANDERS FloorCrafter User manual