Ambic Equipment Ltd –EasiDoser™ Operating Notes

-3- ADE7500 v1.3 (16/03/18)

Introduction

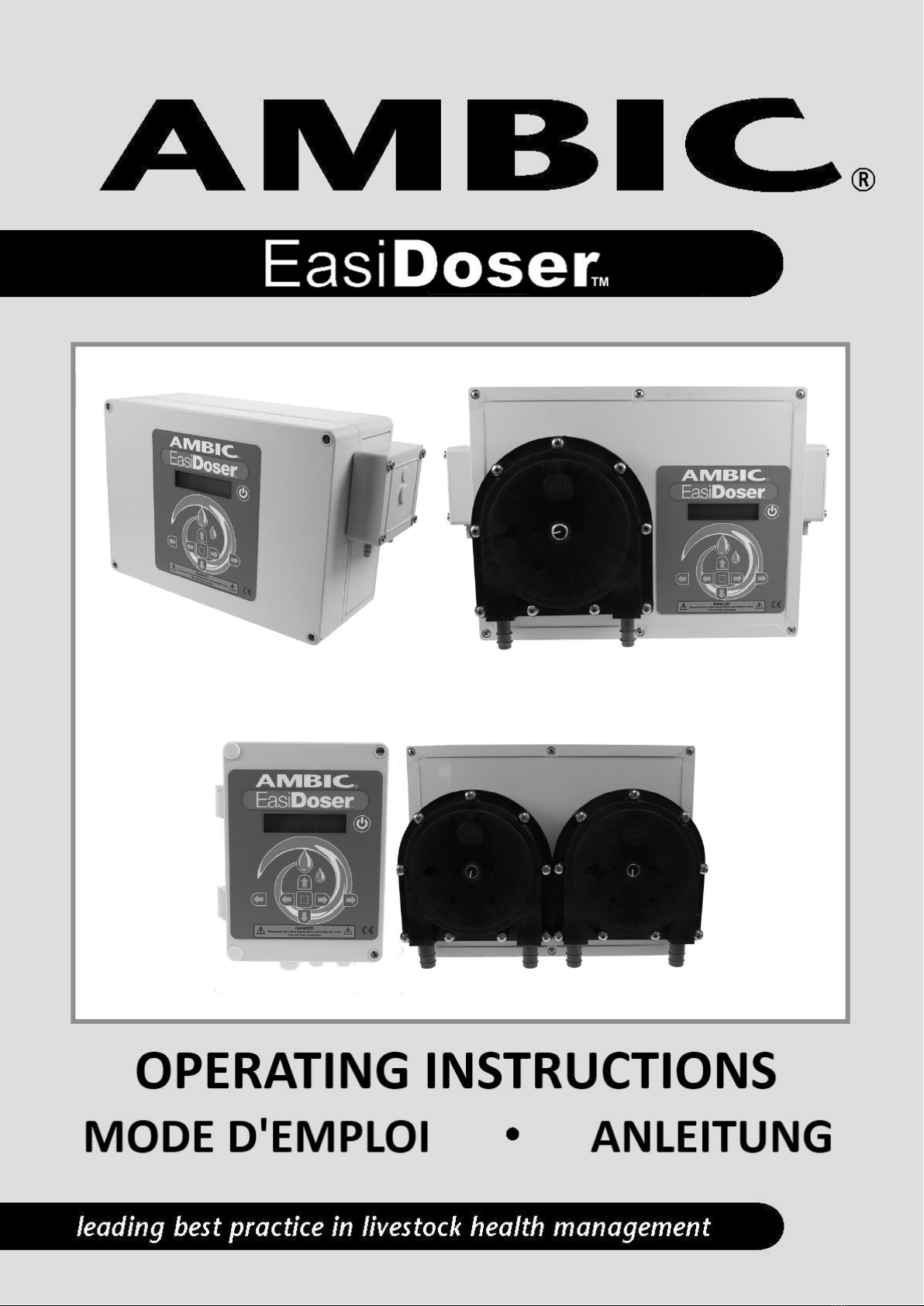

The EasiDoser™is an advanced microprocessor-controlled dosing system for dispensing a precise

amount of chemical. The dispenser features an electronic circuit board with an LCD display. Programming

is set using the keypad on the front of the unit and has a special pump ‘Lock-out’ that will prevent

consecutive dispensing. The EasiDoser™also has a “delay pump start”feature and a direct mode (Relay

Mode) which allows for a timed signal from a microprocessor to control the pump run timing.

The EasiDoser™is offered in various configurations: one, two or three low volume pumps, or an industrial

pump version.

Depending how the unit is programmed, the EasiDoser™ will activate when the circuit receives a 12-230V

AC or 12-24V DC machine signal through the Opto Isolator, or closed contact to one of the trigger inputs.

Also, it can be used for manual dosing and this is activated by pressing a button on the keypad.

Safety

The EasiDoser™Chemical Dosing System is designed exclusively for dosing chemicals by function of

Time, Time and Speed or Direct (Relay) mode in unrestricted pressure tanks. Any application outside the

use described in this operating manual will be taken to be not in accordance with the intended purpose.

The manufacturer/supplier will not be held responsible for any losses arising as a result of such use. The

user will take full responsibility for use.

USE IN ACCORDANCE WITH THE INTENDED PURPOSE ALSO INCLUDES COMPLYING WITH THE

OPERATING MANUAL AND THE CONDITIONS FOR INSPECTION AND MAINTENANCE.

Specifications

Power Source 230V –Pumping unit • 220-240V AC 50Hz

–Fuses • T1.0A

115V –Pumping unit • 110-120V AC 60Hz

–Fuses • T2.0A

Machine Signal - • 12 –230V AC

• 12 –24V DC

• Contact switch

Maximum Length of Distribution Tubing • 10 Metres

Operating Temperature • 5 –40 °C

Float Switch • Normally Open type