-3-

FN7501 V2 (27.09.16)

SAFETY

The “Foam’n’Dip” Teat Dipping System is designed exclusively for use in milking installations. Any

application outside the use described in this operating manual will be taken to be not in accordance

with the intended purpose. The manufacturer/supplier will not be held responsible for any losses

arising as a result of such use. The user will take full responsibility for use. USE IN ACCORDANCE

WITH THE INTENDED PURPOSE ALSO INCLUDES COMPLYING WITH THE OPERATING

MANUAL AND THE CONDITIONS FOR INSPECTION AND MAINTENANCE.

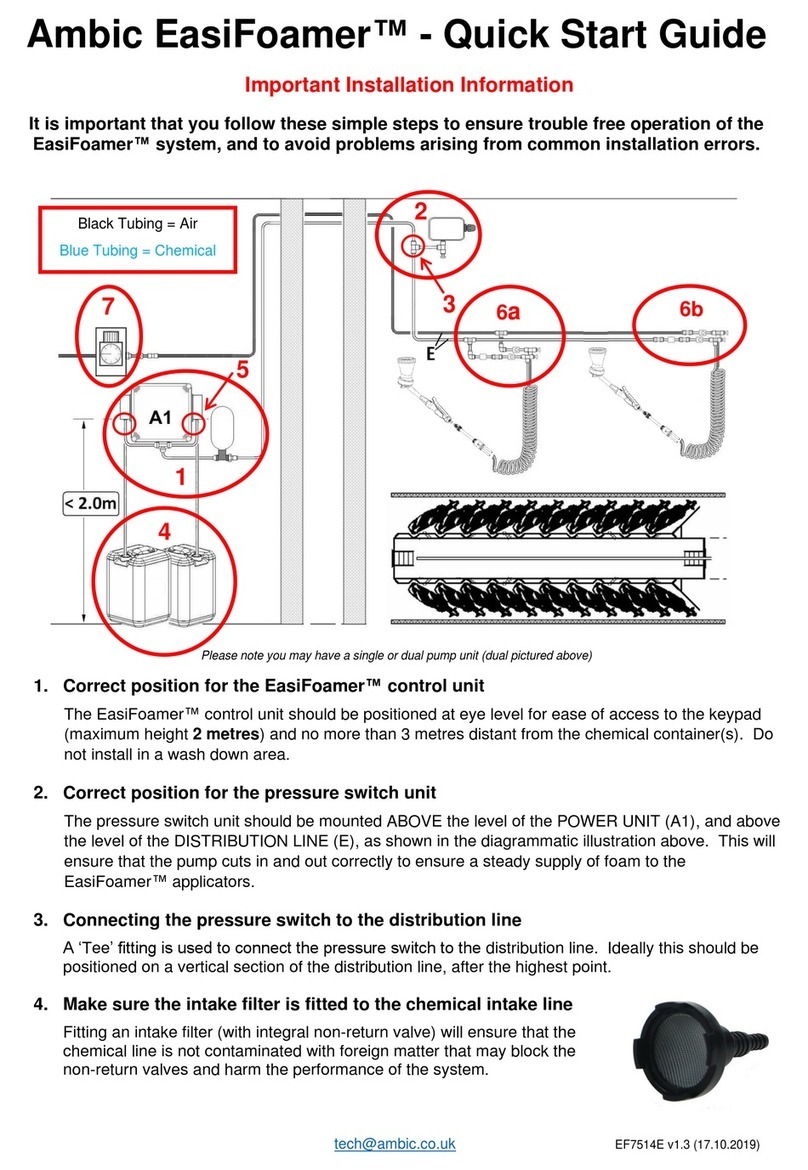

INSTALLATION (see Fig. 1 opposite)

The “Foam’n’Dip” unit is based on the well-proven PowerFoamer and requires a supply of

compressed air to operate. The Regulator (A) supplies LOW PRESSURE air (3 - 4 psi; 0.2 Bar) for

dipping cows’ teats using an appropriate chemical. It is designed to be installed as a ring main

system.

WARNING: BEFORE connecting the Regulator to the existing compressed air system ENSURE

THAT THE AIR SUPPLY IS ISOLATED FROM THE DISTRIBUTION LINE AND THAT THE LINE IS

NOT UNDER PRESSURE.

Fit the Regulator (with adjustment knob vertically upwards) to a suitable solid wall (for drilling template

see page 8).

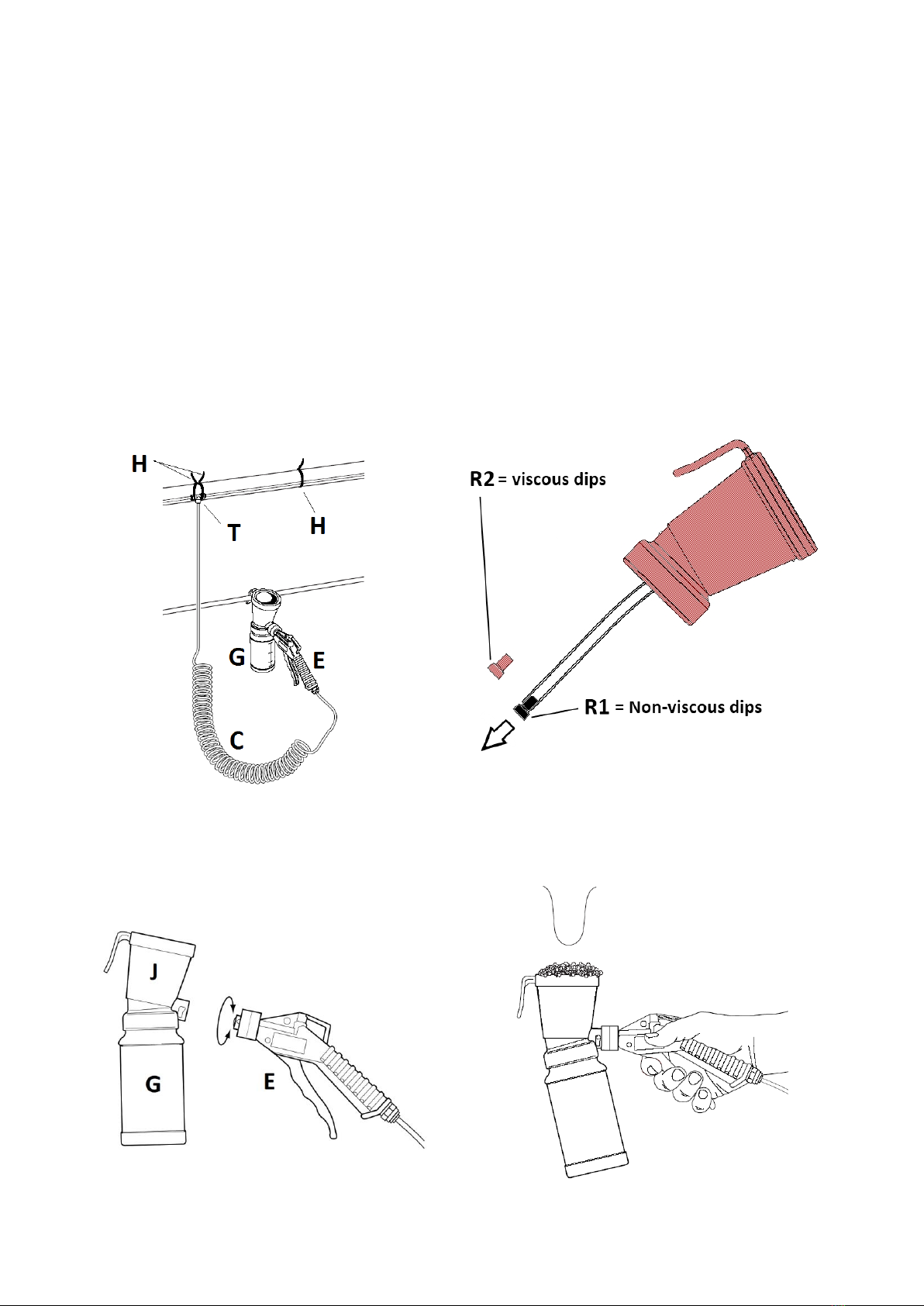

Routing the ring main tube (B) will depend on the parlour design and will be either at high level or low

level. If high level, it will ideally be positioned above the rump rail on each side with the coil (C)

connected via a 'T' fitting (T) fixed with cable ties (H). Alternatively it can be routed along the centre of

the parlour. Cable ties (H) will also be used to secure the ring main. (see Fig. 2 overleaf)

CAUTION: Do not over tighten cable ties as air flow may be restricted.

IT IS IMPORTANT that tubes are pushed fully into fittings to prevent leakage of air which may hamper

the operation of the system.

Foam (F) and Dip (D) Applicators should be positioned such that all milking points can be reached

comfortably without over-stretching the coils. In order to avoid the tubes becoming intertwined, install

the Red tubes so that the coiled section is closest to the spray gun and the Black tubes with the long

straight section adjacent to the spray gun. Extension kits are available to enable as many

Applicators as required to be installed.

If no suitable horizontal bar is available on which to hang the unit, the Plastic Hanging Hook supplied

may be either fitted to a suitable horizontal tube using 2 cable ties (crossed for stability), or can be

drilled with 2 holes and fitted (using 2 screws) to a flat surface.

OPERATION

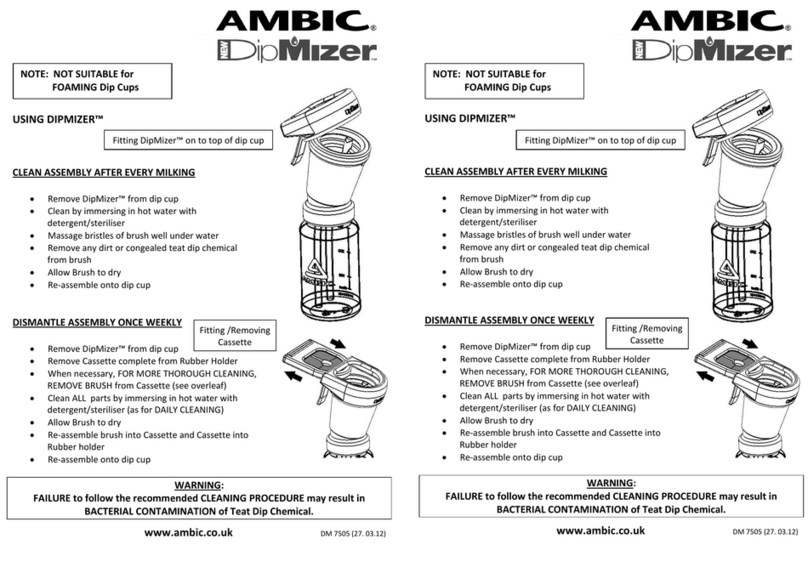

Dipping Cups are provided with 2 restrictors (R1, R2);-

Black (R1) for non-viscous dip chemicals;

Red (R2) for viscous barrier/film-forming dips.

Unscrew bottle to fit appropriate restrictor (Fig. 3).

Switch on compressor. Remove enclosure lid of Regulator (A), open the tap and observe Pressure

Gauge. Gauge should read 3-4 psi (0.2 Bar). Turn tap to OFF and check that the air pressure remains

near constant. If air pressure falls rapidly, then check system for leaks and remedy.

Adjust the pressure by lifting the Regulator knob and turn clockwise to increase Pressure. Verify

pressure correct with a gun operational and, when correct, press down knob to lock.

Fill bottles (G) with suitable Foaming (or Dipping) teat product to the 250 ml mark –do not overfill.

Bottle can either be unscrewed from Applicator (J) with gun (E) attached, or after releasing from the

gun bayonet (Fig 4).