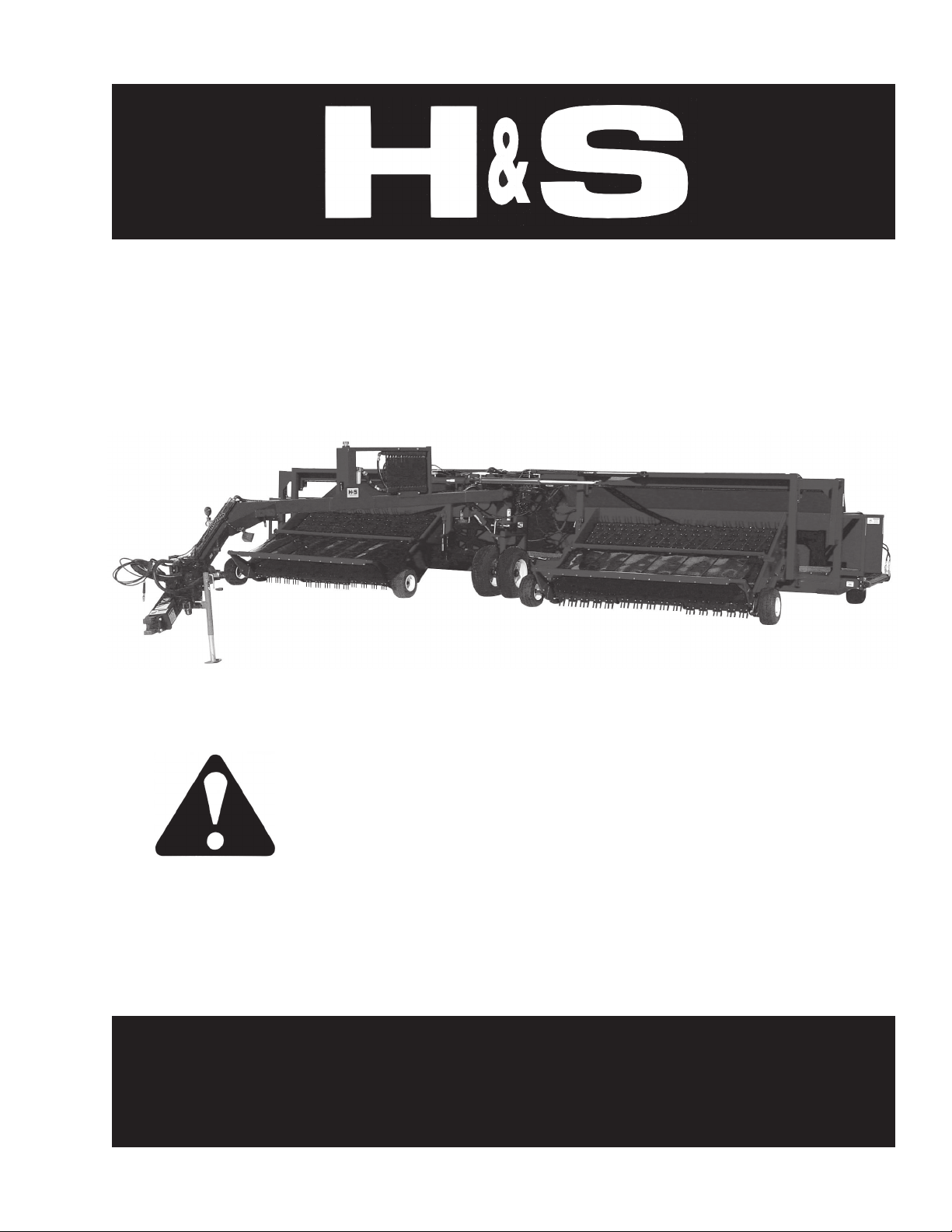

H & S

TWIN MERGER

PARTS AND OPERATOR’S MANUAL

CONTENTS

Warranty & Warranty Registration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

Dealer Pre-Delivery & Delivery Checklist. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

BeAlert Symbol. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Explanation of Safety Signs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Danger - Warning Signs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Warning - Owner Must Read and Understand. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Bolt Torque Chart. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . .9

Tractor Set-up, Pre-Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-12

Hydraulic DriveAttachment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Open/Closed Center Valve Conversion. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-14

Adjustments. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-16

Wiring Diagram - Joystick Plug. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Optional Equipment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Lubrication. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Decal Location & Identification. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18-19

Trouble Shooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Ordering Parts -About Improvements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Figure 1 - 9’& 12’Twin Merger Main Frame. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22-23

Figure 2 - 9’& 12’Twin Merger Main Frame Continued. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24-25

Figure 3 - 9’Twin Merger Left Pick-up Head. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26-27

Figure 4 - 9’Twin Merger Right Pick-up Head. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28-29

Figure 5 - 12’Twin Merger Left Pick-up Head. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30-31

Figure 6 - 12’Twin Merger Right Pick-up Head. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32-33

Figure 7 - 9’& 12’Twin Merger Pole Circuit Hydraulics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34-35

Figure 8 - 9’Twin Merger Electric Head Hydraulics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36-37

Figure 9 - 12’Twin Merger Head Hydraulics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38-39

Figure 10 - 9’& 12’Twin Merger Main Frame Hydraulics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40-41

Figure 11 - 9’& 12’Twin Merger Pick-up Lift Cylinder. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Figure 12 - 9’& 12’Twin Merger Pole Swing Cylinder. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Figure 13 - 9’Twin Merger Head Shuttle Cylinder. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

Figure 14 - 9’& 12’Twin Merger Load Leveler Cylinder. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

Figure 15 - 9’Twin Merger Electric/Hydraulic Valve. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46-47

Figure 16 - 9’& 12’Twin Merger Electric Wiring Harness. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48-49

Figure 17 - 9’& 12’Twin Merger PTOAssembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50

Figure 18 - 9’& 12’Twin Merger HitchAssembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51

Figure 19 - 9’& 12’Twin Merger Valve Mounting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .52

Figure 20 - 9’& 12’Twin Merger Cross Conveyor Control Box. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Figure 21 - 9’& 12’Twin Merger OptionalAccelerator. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54-55

Figure 22 - 9’& 12’Twin Merger Crop Roller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Service & Maintenance Records. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .57

Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Inside Back Cover