AMC-1022D Monitor

1

3 PRODUCT DESCRIPTION

The AMC-1022D is a multi-sensor gas monitoring system designed to continuously monitor for

traces of hazardous gases (listed in Product Information Section). It can be calibrated to detect

a wide variety of toxic gases. The monitor comes with the following features.

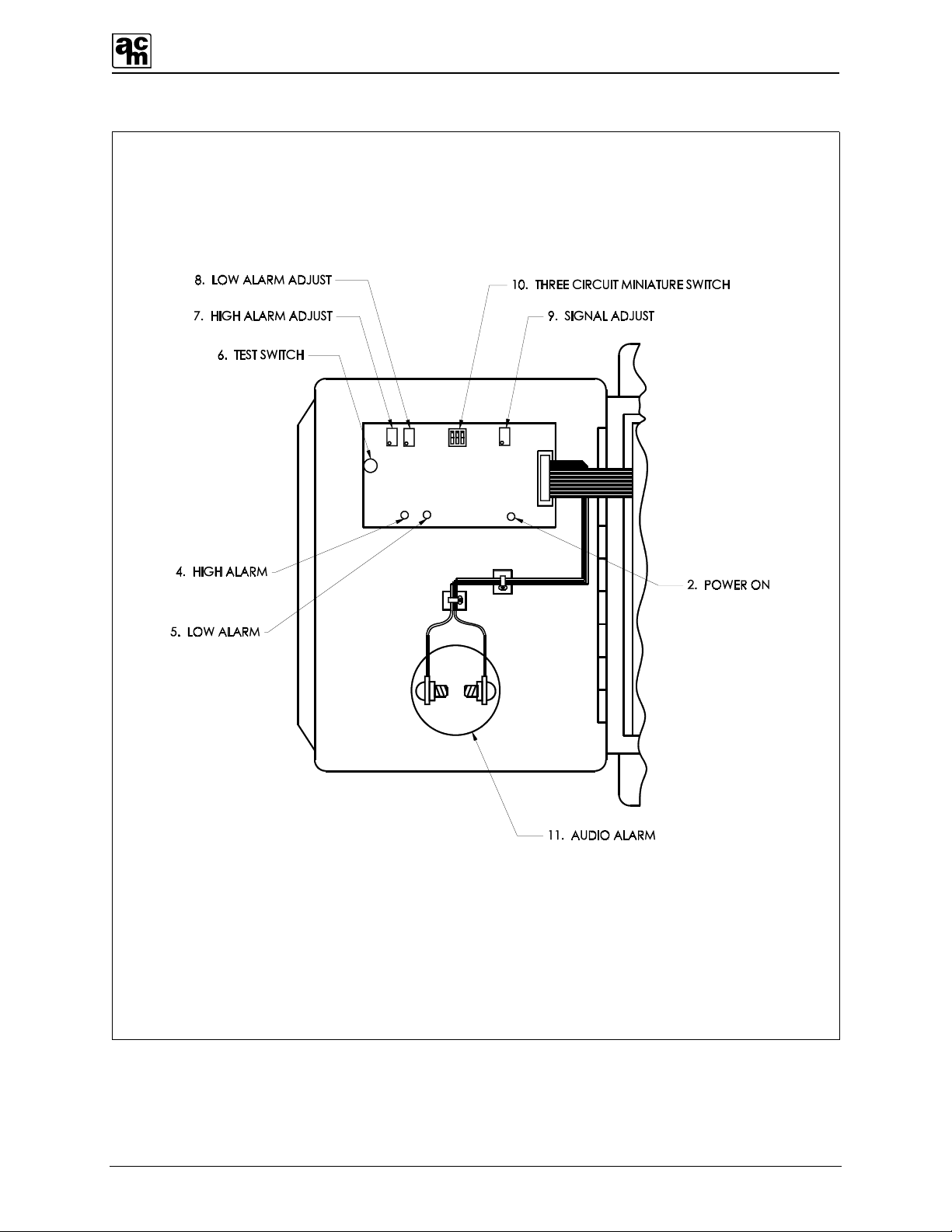

1. POWER SWITCH: Main AC power switch for all channels.

2. FUSE HOLDER: Front panel mounted for easy access to the fuse.

3. AUDIO ALARM INDICATOR: When operational, the buzzer will activate when a high

alarm condition occurs.

4. CLAMPS: To secure the front panel, restricting access to internal

controls.

5. POWER TERMINAL BLOCK: For line voltage connections (120 VAC, 60 Hz.)

6. POWER ON INDICATOR: Power is indicated by a green LED.

7. FAIL INDICATOR: Sensor module signal fail is indicated by an amber LED.

(only when this option is installed).

8. HIGH ALARM INDICATOR: High levels of gas are indicated by a red LED.

9. LOW ALARM INDICATOR: Low levels of gas are indicated by a yellow LED.

10. TEST SWITCH: The test switch is provided to electronically simulate alarms

in order to test the low and high alarm indicators, relays, and

the audio alarm indicator.

11. HIGH ALARM ADJUST: Sets the High alarm trip point.

12. LOW ALARM ADJUST: Sets the Low alarm trip point.

13. THREE CIRCUIT

MINIATURE SWITCH:

Each actuator on the miniature switch controls a different

circuit as shown in Figure 1. If the actuator is set in the UP

position, its corresponding circuit is ON. If the actuator is set

in the DOWN position, the circuit is OFF.

13.a) LEFT ACTUATOR: Provides a TEN minute time delay, when switch is ON, to

eliminate unnecessary alarms caused by momentary

exposure to high levels of gas.

13.b) MIDDLE ACTUATOR: Provides a FIVE minute time delay, when switch is ON, to

eliminate unnecessary alarms caused by momentary

exposure to low levels of gas.